4. Function of relay trigger adapter, analog

4 Function of relay trigger adapter, analog

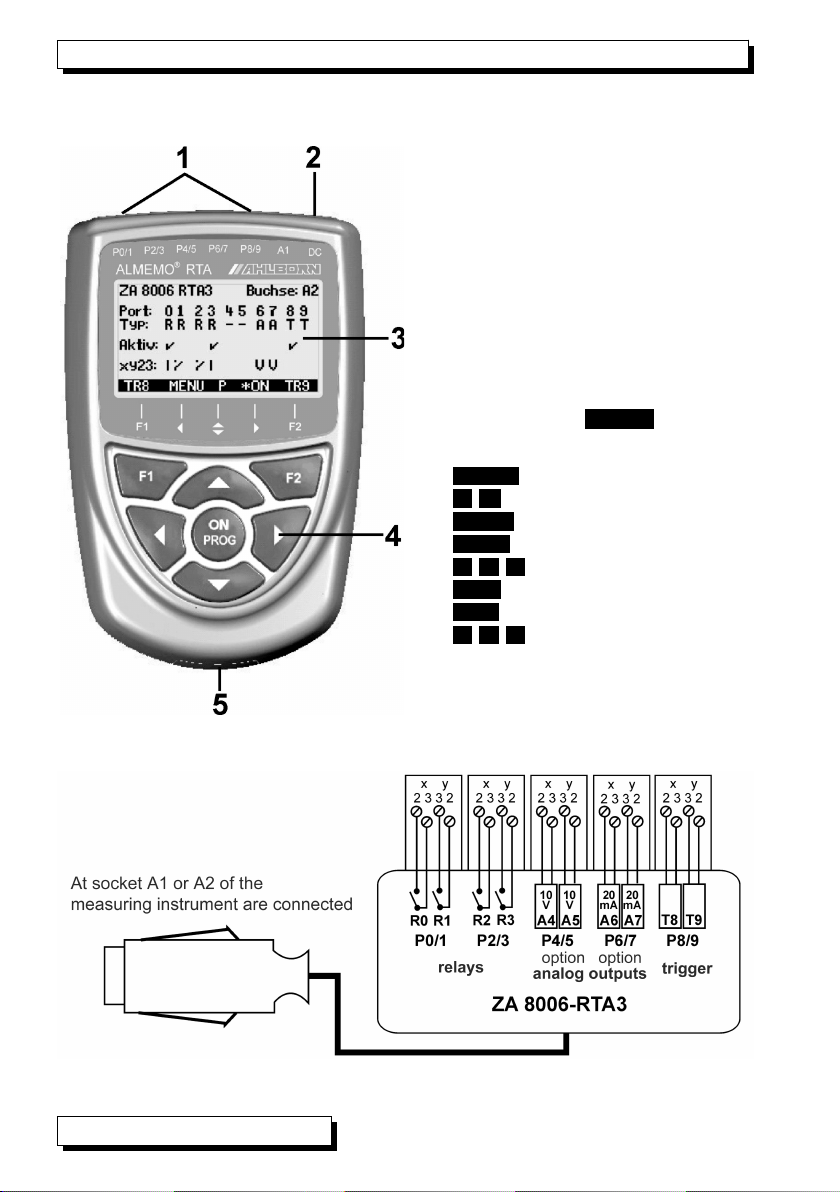

The relay trigger adapter, analog, ZA 8006-RTA3, provides ALM MO® V6 de-

vices (as of 2008 and except 2390) with a universal trigger output interface

with up to 10 interface elements (i.e. maximum 10 semiconductor relays, or 2

trigger inputs, or up to 4 electrically isolated analog outputs).

The adapter is connected via the ALM MO® cable to output socket A1 to A5 (if

available) on the ALM MO® devices. All 10 interface elements of each module

can be individually selected and configured as ports P0 to P9. Programming is

via the ALM MO® device (for a description please refer to the operating in-

structions for the device) or via its interface (for a description please refer to

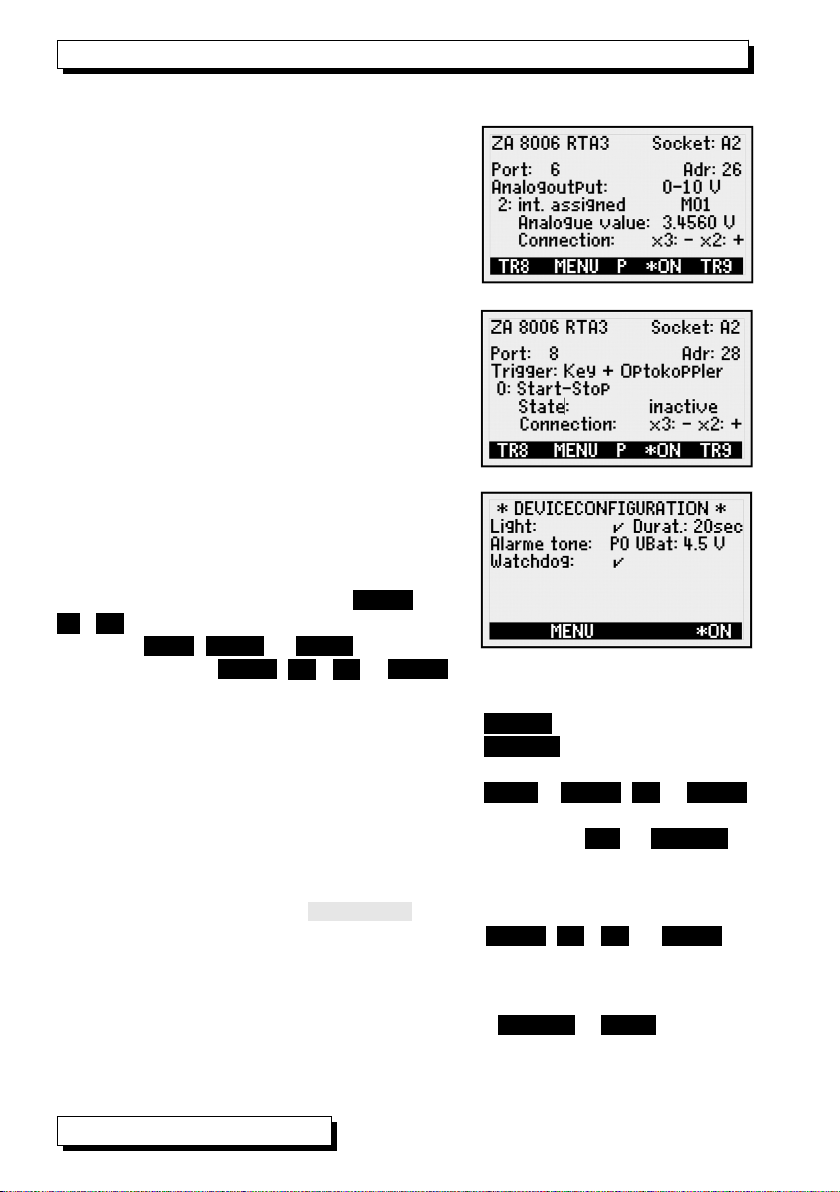

the Manual, 6.10.9.2). Addressing of the modules and ports is determined on

the basis of the socket into which the module is plugged (see Man. 6.10.9.2) :

Modules in socket A1 : Address 10 to 19

Modules in socket A2 : Address 20 to 29, etc.

5 Power supply

The adapter is supplied with a voltage of 9 to 12 VDC via the measuring instru-

ment. In the standard version the maximum requirement is 35 mA - even with il-

lumination. It is only with optional analog outputs. in particular with electric cur-

rent outputs, that the maximum supply current on the measuring instrument must

take the sensors into consideration. If the maximum supply current is exceeded,

a mains adapter (e.g. ZA1312-NA1) should be connected at the DC socket.

6 Interface elements

Sockets P0/1 and P2/3 are fitted as standard with four semiconductor relays,

normally open type (or changeover type as option); socket P8/9 is fitted as

standard with two trigger inputs.

Sockets P4/5 and P6/7 can (as options) be fitted with analog outputs.

6 1 Relays

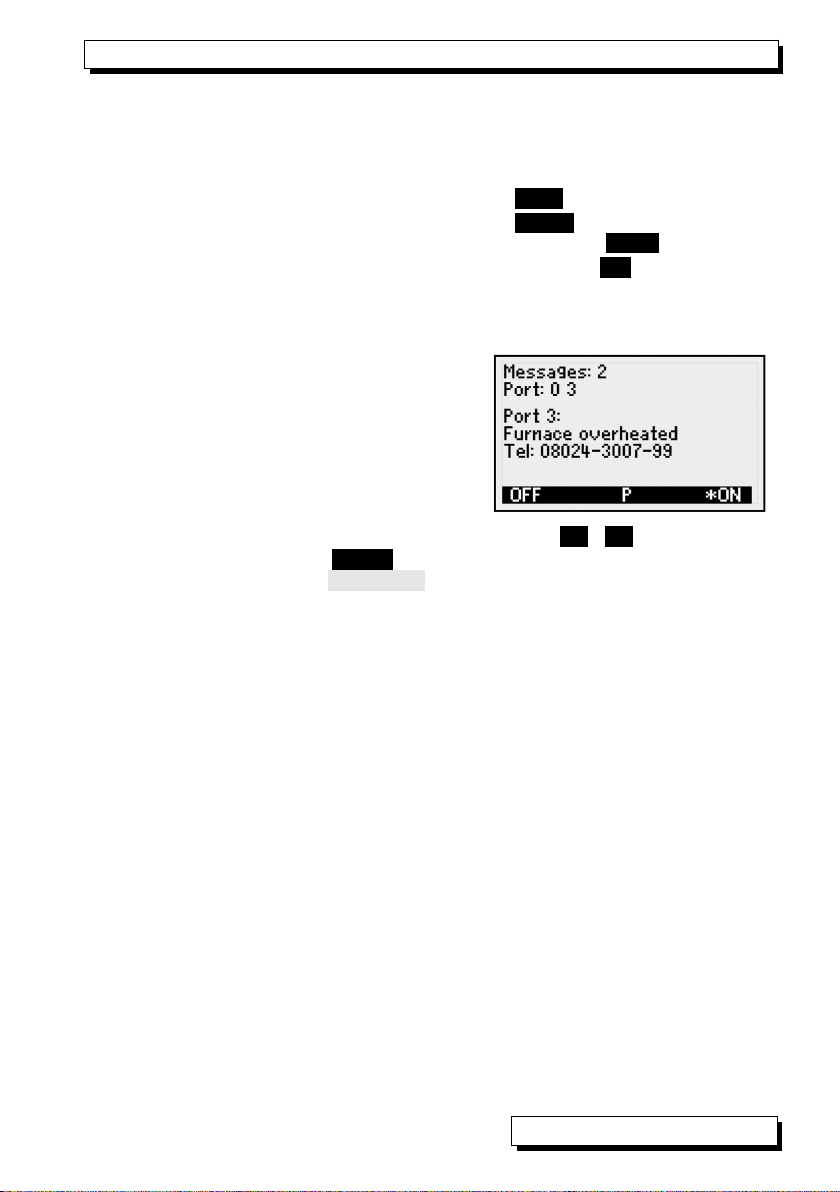

The output relays are driven by the measuring instruments automatically in

the event of alarm or by means of interface commands (see Manual 6.10.10). The

function of each relay can be freely set by configuration (see Manual 6.10.9.2).

The assignment of limit value to relay can be programmed in the sensor by the

device (see Manual 6.10.8). Whenever a relay is activated a programmable mes-

sage appears and whenever there is a change in status a short acoustic alarm

is sounded. The way in which these relays are driven can be configured by

means of inversion so that they pick up in normal conditions and drop out in

the event of alarm or power failure (see below).

In the following cases it is advisable to connect a mains voltage changeover re-

lay downstream (e.g. Phoenix PLC-RSC-24DC/21, 250V 6A) :

► Current or voltage capacity greater than 50 V, 0.5 A

► For separating the mains voltage side

► For implementing an alarm in the event of failure on the control side

4 ALM MO 8006-RTA3