Page 5

DAir filters must be installed in the system and must be

maintained during construction.

DAir filters must be replaced upon construction comple-

tion.

DThe input rate and temperature rise must be set per the

furnace rating plate.

DOne hundred percent (100%) outdoor air must be pro-

vided for combustion air requirements during construc-

tion. Temporary ducting may supply outdoor air to the

furnace. Do not connect duct directly to the furnace.

Size the temporary duct following these instructions in

section for Combustion, Dilution and Ventilation Air in a

confined space with air from outside.

DThe furnace heat exchanger, components, duct system,

air filters and evaporator coils must be thoroughly

cleaned following final construction clean−up.

DAll furnace operating conditions (including ignition, in-

put rate, temperature rise and venting) must be verified

according to these installation instructions.

General

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

In addition to the requirements outlined previously, the fol-

lowing general recommendations must be considered

when installing this furnace:

•Place the furnace as close to the center of the air dis-

tribution system as possible. The furnace should also be

located close to the vent termination point.

•When the furnace is installed in non−direct vent applica-

tions, do not install the furnace where drafts might blow

directly into it. This could cause improper combustion

and unsafe operation.

•When the furnace is installed in non−direct vent applica-

tions, do not block the furnace combustion air opening

with clothing, boxes, doors, etc. Air is needed for proper

combustion and safe unit operation.

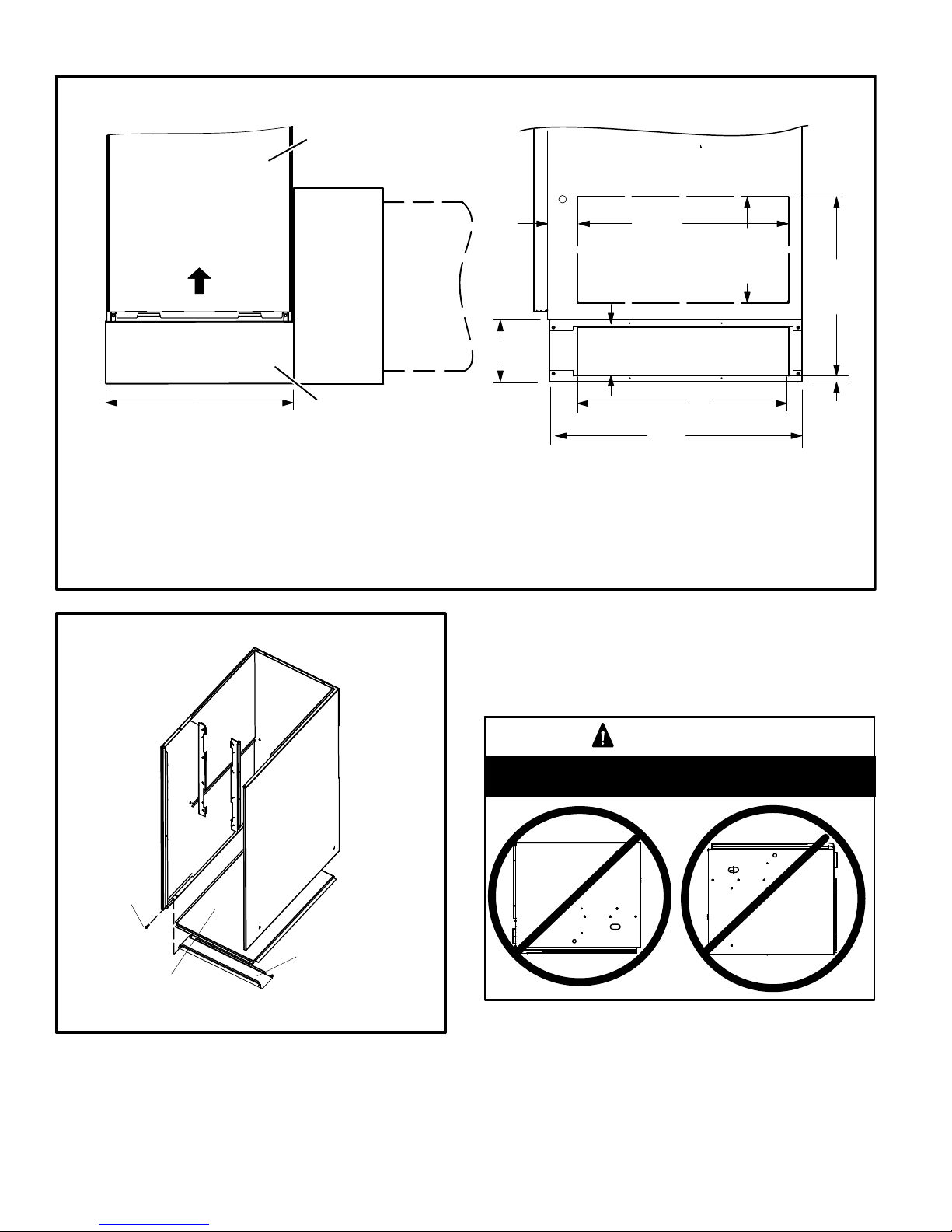

•When the furnace is installed in an attic or other insu-

lated space, keep insulation away from the furnace.

•When the furnace is installed in an unconditioned

space, consider provisions required to prevent freezing

of condensate drain system.

CAUTION

This furnace should not be installed in areas nor-

mally subject to freezing temperatures.

WARNING

The State of California has determined that this prod-

uct may contain or produce a chemical or chemicals,

in very low doses, which may cause serious illness

or death. It may also cause cancer, birth defects or re-

productive harm.

WARNING

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. It will also cause

excess water in the heat exchanger resulting in rust-

ing and premature heat exchanger failure. Excessive

exposure to contaminated combustion air will result

in safety and performance related problems. Avoid

exposure to the following substances in the com-

bustion air supply:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine base swimming pool chemicals

Water softening chemicals

De−icing salts or chemicals

Carbon tetrachloride

Halogen type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Hydrochloric acid

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

Combustion, Dillution & Ventilation Air

If the furnace is installed as a Non−Direct Vent Fur-

nace, follow the guidelines in this section.

NOTE − In Non−Direct Vent installations, combustion air

is taken from indoors and flue gases are discharged out−

doors.

In the past, there was no problem in bringing in sufficient

outdoor air for combustion. Infiltration provided all the air

that was needed. In today’s homes, tight construction

practices make it necessary to bring in air from outside

for combustion. Take into account that exhaust fans, ap-

pliance vents, chimneys, and fireplaces force additional

air that could be used for combustion out of the house.

Unless outside air is brought into the house for combus-

tion, negative pressure (outside pressure is greater than

inside pressure) will build to the point that a downdraft

can occur in the furnace vent pipe or chimney. As a result,

combustion gases enter the living space creating a po-

tentially dangerous situation.