4

CONVERSION INSTRUCTIONS

REQUIRED ABILITY

CONVERSION OF ANY WATER HEATER LISTED IN THIS MANUAL REQUIRES ABILITY EQUIVALENT

TO THAT OF A LICENSED ELECTRICAL TRADESMAN

I. INTRODUCTION

Satisfying a customer order for a commercial electric heater from inventory may require modication to the KW input,

the voltage, or the phase. Conversions may involve revision to 1, 2, or all 3 of these electrical characteristics.

II. HEATER PREPARATION

The heater should be placed in a well lit area. Complete removal of the shipping crate is not required. The front of the

heater with the control box will be visible through the clear plastic. Cut a 3-sided ap into the plastic, cut should be on

top, bottom and right side approximately 4” from the wooden edge.

Release the two control panel screws and unlatch with knob on the water heater door.

To expose elements, remove the foam door covering directly in back of the control panel door.

Remove the T & P valve (separate package).

III. KW CONVERSION (ELEMENT REPLACEMENT)

A. Remove wires from one element at a time. It is not necessary to tag loose wires as the wiring schematic is

inside the control panel door.

B. Remove element from heater using part no. 9000429015 or 1-1/2” deep well socket and ratchet. Return the

elements to appropriate storage bin.

C. Open the appropriate conversion kit and remove the elements. Check each element to ensure correct voltage

and wattage.

D. Install the new element, starting it by hand. A new “O” ring gasket should be installed on each element. Element

threads should be lubricated with Dow Corning® silicon sealant (or equal). Screw element into tting until it

seats. Tighten 1/2 to 3/4 turn with wrench.

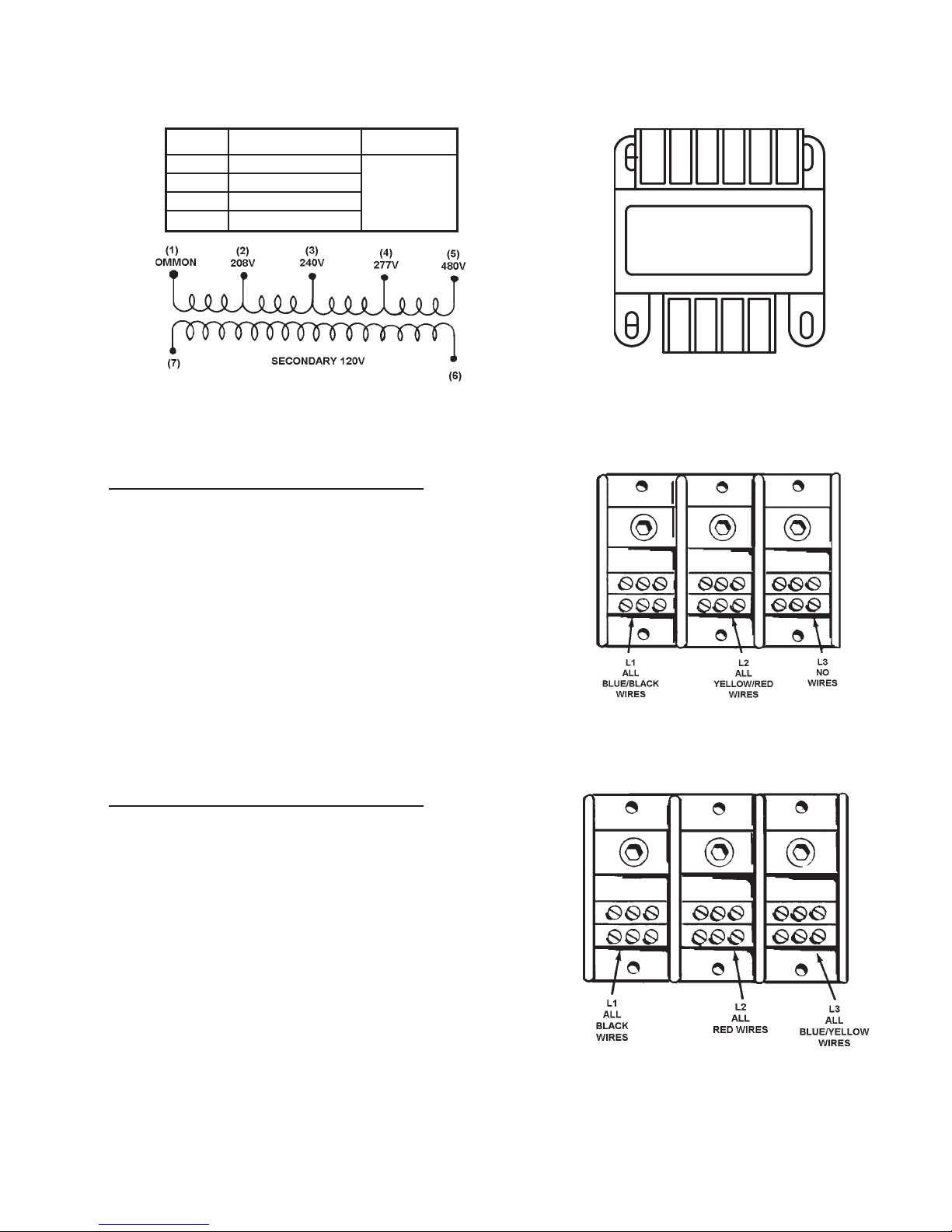

E. Rewire the element as directed on wiring schematic, located inside control panel door. Screw terminals must be

snug, however, caution must be exercised. Overtightening may break the terminal block, requiring replacement

of the element.

F. Repeat steps A thru E for all other elements being replaced.

IV. VOLTAGE CONVERSION

A. Surface thermostat models merely require installation of the appropriate elements to accomplish a change in

voltage. See KW conversion step III.

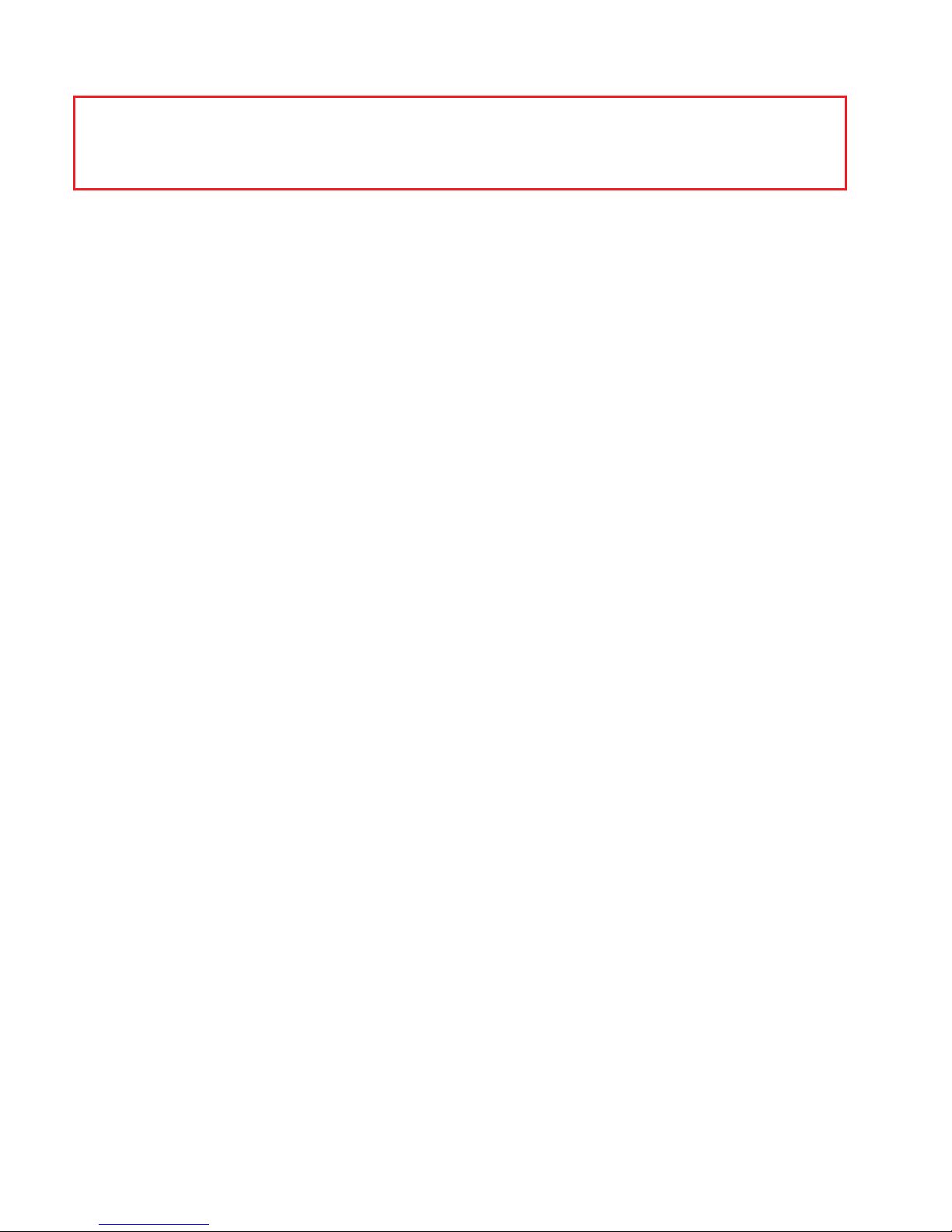

B. Immersion thermostat models require installation of the appropriate elements AND may also require a

transformer tap change. Immersion thermostat models are equipped with a transformer having 5 connections:

common, 208, 240, 277 and 408 and 2 secondary connections. See the following diagrams.

Only one wire need be changed on the transformer to change voltage. Remove the wire from the terminal

marked 208, 240, 277 or 480 and attach it to the appropriate terminal marked 208, 240, 277 or 480.

C. Do not change the common connections or the secondary wire connections.