N80ESN/N80ESL(Series A): Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

2

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance, or

use can cause explosion, fire, electrical shock, or other conditions which

may cause death, personal injury, or property damage. Consult a

qualified installer, service agency, or your distributor or branch for

information or assistance. The qualified installer or agency must use

factory-authorized kits or accessories when modifying this product.

Refer to the individual instructions packaged with the kits or accessories

when installing.

Follow all safety codes. Wear safety glasses, protective clothing, and

work gloves. Have a fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions include in literature and

attached to the unit. Consult local building codes, the current editions of

the current edition of National Fuel Gas Code (NFGC) NFPA 54/ANSI

Z223.1 and the current edition of National Electrical Code (NEC) NFPA

70.

Recognize safety information. This is the safety-alert symbol . When

you see this symbol on the unit and in instructions or manuals, be alert to

the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION.

These words are used with the safety-alert symbol. DANGER identifies

the most serious hazards which will result in severe personal injury or

death. WARNING signifies hazards which could result in personal

injury or death. CAUTION is used to identify unsafe practices which

may result in minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in enhanced

installation, reliability, or operation.

The following additional safety considerations should be followed for

gas furnaces:

1. Use only with type of gas approved for this furnace. Refer to the

furnace rating plate.

2. Install this furnace only in a location and position as specified in the

“Location” section of these instructions.

3. Provide adequate combustion and ventilation air to the furnace

space as specified in “Air for Combustion and Ventilation” section.

4. Combustion products must be discharged outdoors. Connect this

furnace to an approved vent system only, as specified in the

“Venting” section of these instructions.

5. Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of leaks

to check all connections, as specified in the “Gas Piping” section.

6. Always install furnace to operate within the furnace’s intended

temperature-rise range with a duct system which has an external

static pressure within the allowable range, as specified in the

“Start-Up, Adjustments, and Safety Check” section. See furnace

rating plate.

7. When a furnace is installed so that supply ducts carry air circulated

by the furnace to areas outside the space containing the furnace, the

return air shall also be handled by duct(s) sealed to the furnace

casing and terminating outside the space containing the furnace.

See “Air Ducts” section.

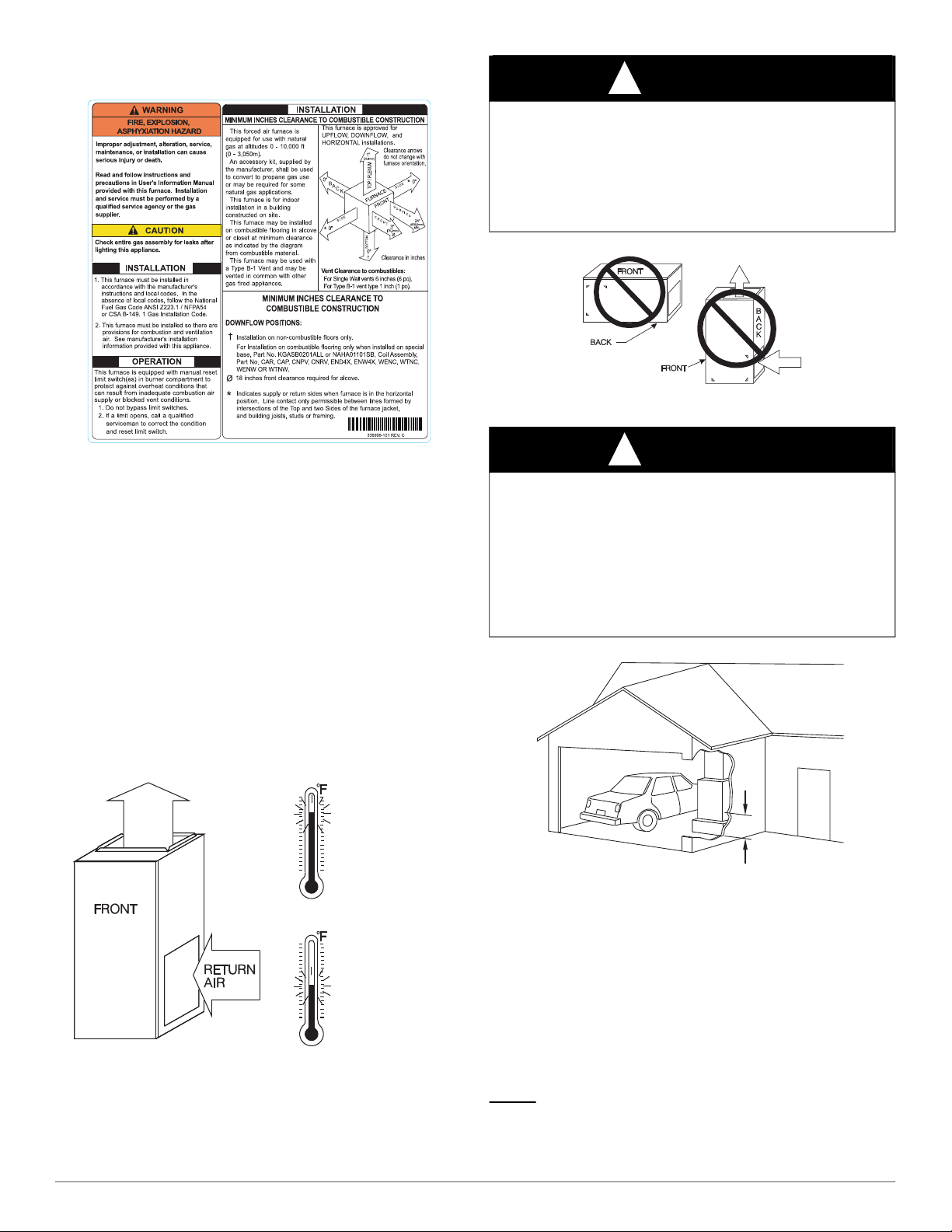

8. A gas-fired furnace for installation in a residential garage must be

installed as specified in the warning box in the “Location” section.

9. The furnace may be used for construction heat provided that the

furnace installation and operation complies with the first

CAUTION in the LOCATION section of these instructions.

10. These Multipoise Gas-Fired Furnaces are CSA (formerly A.G.A.

and C.G.A). design-certified for use with natural and propane gases

(see furnace rating plate) and for installation in alcoves, attics,

basements, closets, utility rooms, crawlspaces, and garages. The

furnace is factory-shipped for use with natural gas. A CSA listed

accessory gas conversion kit is required to convert furnace for use

with propane gas.

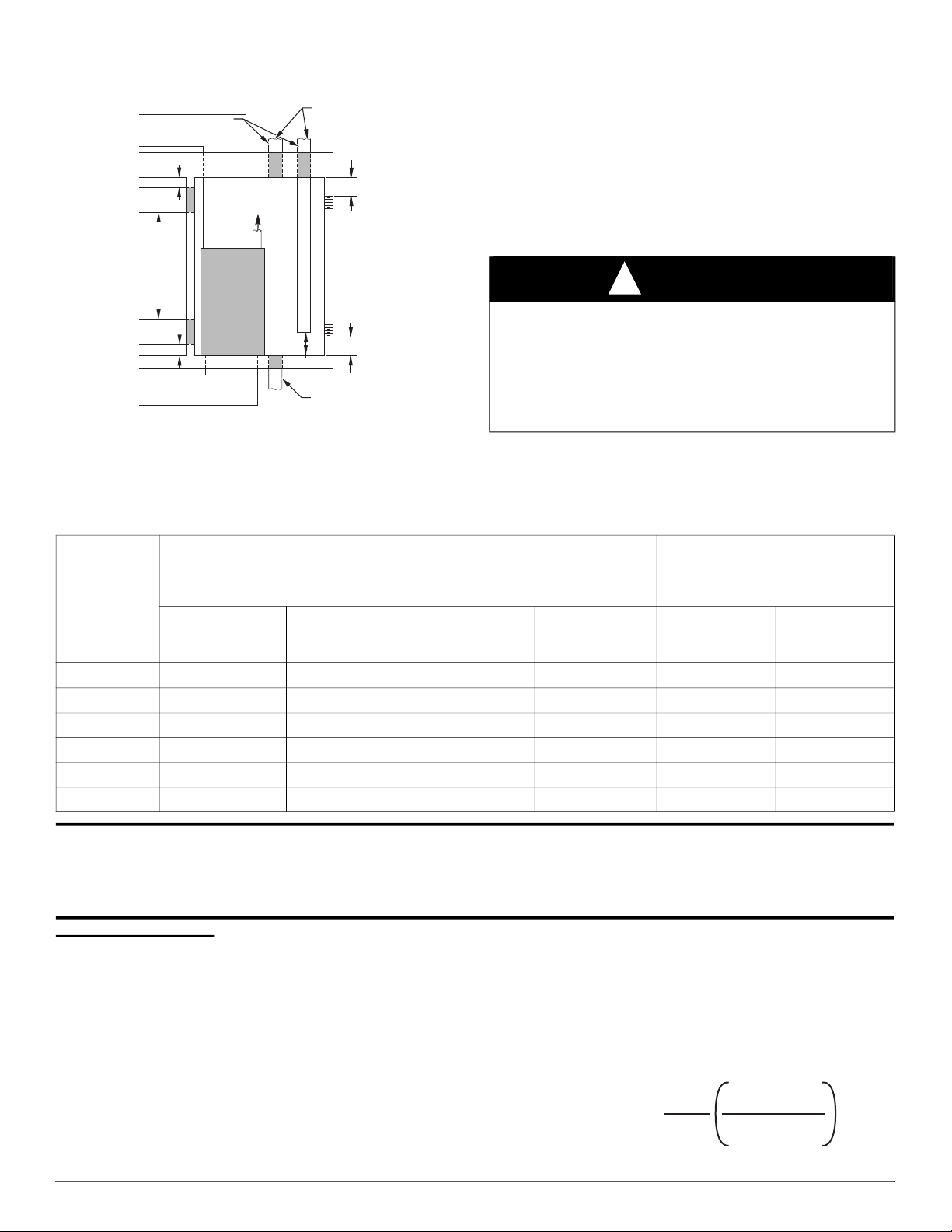

11. See Fig. 1 for required clearances to combustible construction.

12. Maintain a 1-in. (25 mm) clearance from combustible materials to

supply air ductwork for a distance of 36 inches (914 mm)

horizontally from the furnace. See current edition of NFPA 90B or

local code for further requirements.

13. These furnaces SHALL NOT be installed directly on carpeting, tile,

or any other combustible material other than wood flooring. In

downflow installations, factory accessory floor base MUST be used

when installed on combustible materials and wood flooring. Special

base is not required when this furnace is installed on manufacturer’s

coil model numbers END4X, ENW4X or coil casing model number

NAEA is used. See Fig. 1 for clearance to combustible construction

information.

WARNING

!

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous operation,

serious injury, death, or property damage.

Improper installation, adjustment, alteration, service, maintenance, or

use could cause carbon monoxide poisoning, explosion, fire, electrical

shock, or other conditions which may cause personal injury or property

damage. Consult a qualified service agency, local gas supplier, or your

distributor or branch for information or assistance. The qualified

service agency must use only factory-authorized and listed kits or

accessories when modifying this product.

WARNING

!

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POINSING HAZARD

Failure to follow this warning could result in dangerous operation,

personal injury, death, or property damage.

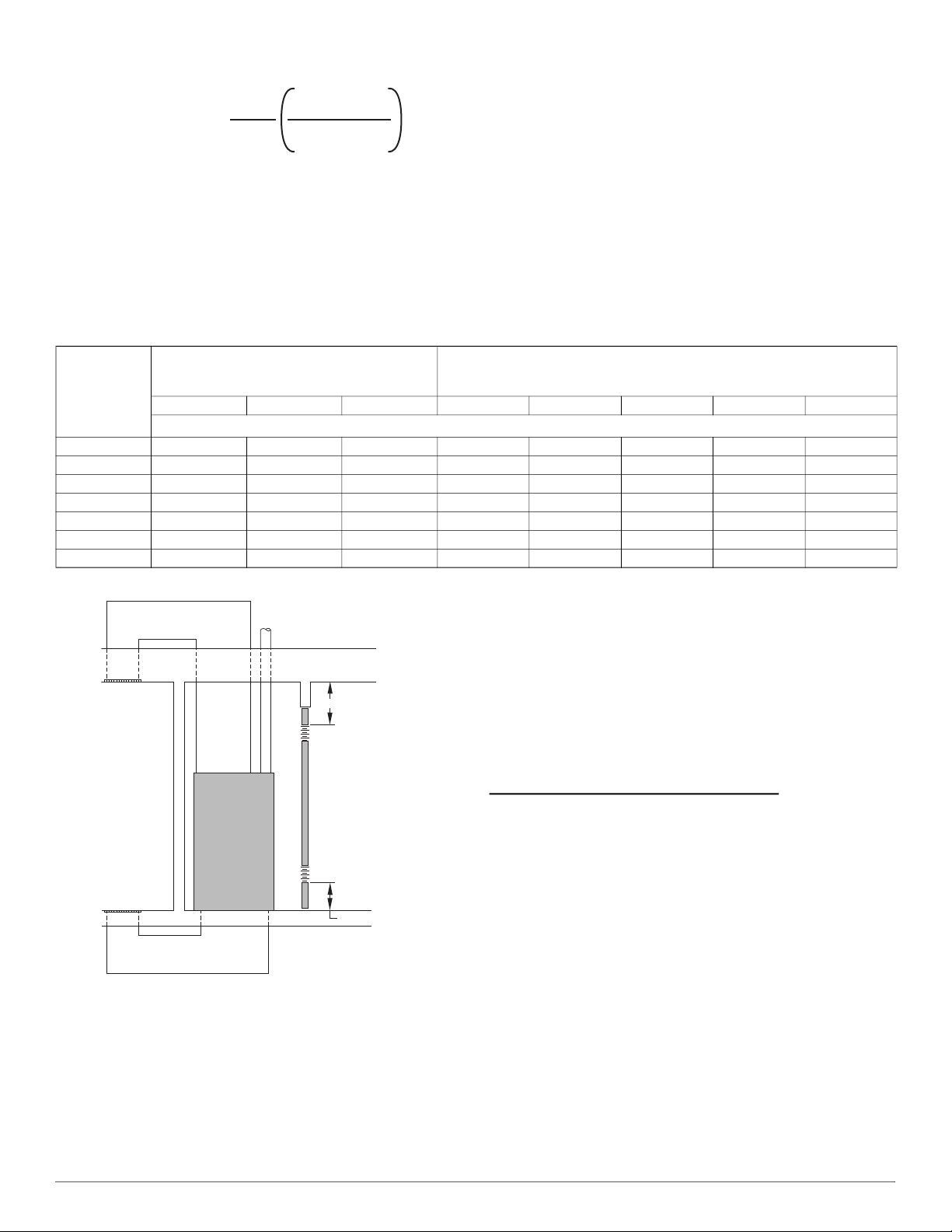

Furnaces shall NOT be twinned (i.e. tandem or staged operation) unless

approved in factory technical specifications literature for the furnace. A

factory authorized, field-supplied Twinning Kit MUST be used.

Consult furnace pre-sale literature for specific models approved for

twinning and the correct twinning kit. Twinned furnaces must be

installed on both a common supply AND a common return duct system

as shown in the Twinning Kit Installation Instructions. Only two

furnaces can be twinned on a common supply and return duct system

using a factory authorized twinning kit.

CAUTION

!

FURNACE RELIABILITY HAZARD

Improper installation or misapplication of furnace may require

excessive servicing or cause premature component failure.

Application of this furnace should be indoors with special attention

given to vent sizing and material, gas input rate, air temperature rise,

unit leveling, and unit sizing.

CAUTION

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear

appropriate protective clothing, safety glasses and gloves when

handling parts and servicing furnaces.