# 45465K005

Page 4

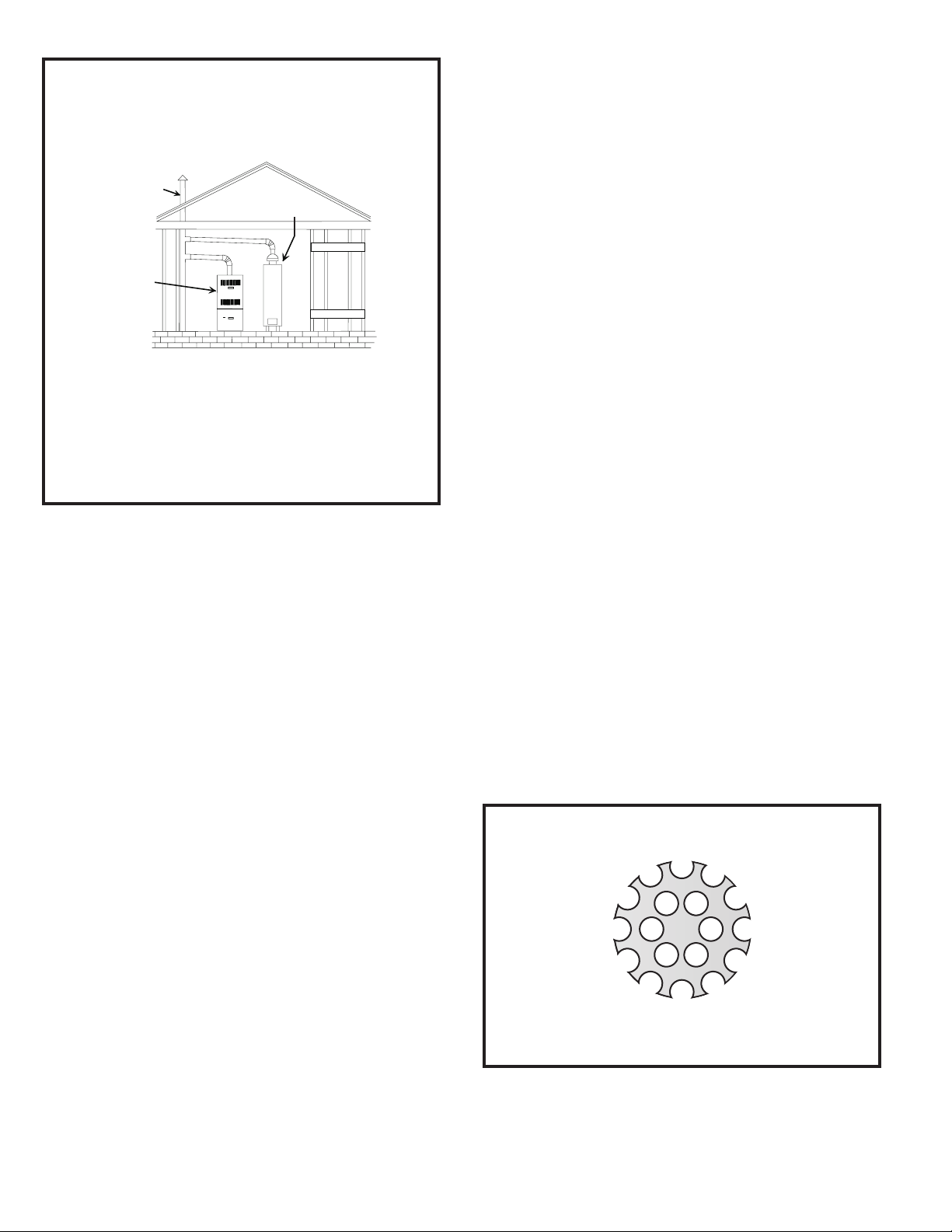

Air openings in the front of the furnace must

be kept free of obstructions. Any obstruction

may cause improper operation that can result

in a fire hazard or carbon monoxide injury.

WARNING

Where servicing clearances are greater than clearances

to combustibles, servicing clearances take precedence.

G1D80BT, G2D80CT, and horizontally installed G1D80BR

and G2D80CR models may be installed on wood flooring,

but shall not be installed directly on carpeting, tile, or other

combustible material other than wood flooring.

G1D80BR and G2D80CR models installed as counterflow

(downflow) units may be installed on combustible flooring

provided a special combustible floor base is used. See

Counterflow (Downflow) Installations on page 14 for

more information. Refer to unit rating plate for combustible

floor base part number.

Location

All models are suitable for closet or utility room installation.

The furnace must be installed so that electrical compo-

nents are protected from water.

The furnace is suitable for installation in buildings con-

structed on-site. The furnace should be centralized in

respect to the heat distribution system as much as

practicable. When installed in a utility room, the door

should be wide enough to allow the largest part of the

furnace to enter, or to permit the replacement of another

appliance, such as a water heater.

A gas-fired furnace for installation in a residential garage

must be installed so the burner(s) and the ignition source are

located not less than 18" above the floor. The furnace is to be

located or protected to avoid physical damage by vehicles.

This furnace is not recommended to be used as a construc-

tion heater during any phase of construction. Very low return

air temperatures, harmful vapors, and operation of the unit

with clogged or misplaced filters will damage the unit.

The furnace may be used for heating of buildings or struc-

tures under construction, if the following conditions are met:

• The vent system must be permanently installed per

these installation instructions.

• A room thermostat must control the furnace. The use

of fixed jumpers that will provide continuous heating is

not allowed.

• The return air duct must be provided and sealed to

the furnace.

• Return air temperature range between 60°F and 80°F

must be maintained.

• Air filters must be installed in the system and must be

maintained during construction.

• Air filters must be replaced upon construction completion.

• The input rate and temperature rise must be set per

the furnace rating plate.

• One hundred percent (100%) outdoor air must be

provided for combustion air requirements during construc-

tion.Temporary ducting may supply outdoor air to the

furnace. Do not connect duct directly to the furnace. Size

the temporary duct following the instructions given on the

next page in the Combustion and Ventilation Air

section regarding confined space with air from outside.

• The furnace heat exchanger, components, duct

system, air filters, and evaporator coils must be thor-

oughly cleaned following final construction cleanup.

• All furnace operating conditions (including ignition,

input rate, temperature rise, and venting) must be

verified according to these installation instructions.

G1D80BR, G1D80BT, G2D80CR, and G2D80CT models

installed in the horizontal position are approved for attic

installations. If the furnace is to be installed in an attic or

other insulated space, it must be kept free and clear of

insulating materials. When a furnace is installed in

conjunction with an evaporator coil in an attic or above a

finished ceiling where condensate overflow could result

in property damage, a drain pan should be provided

under the units as specified by most local building codes.

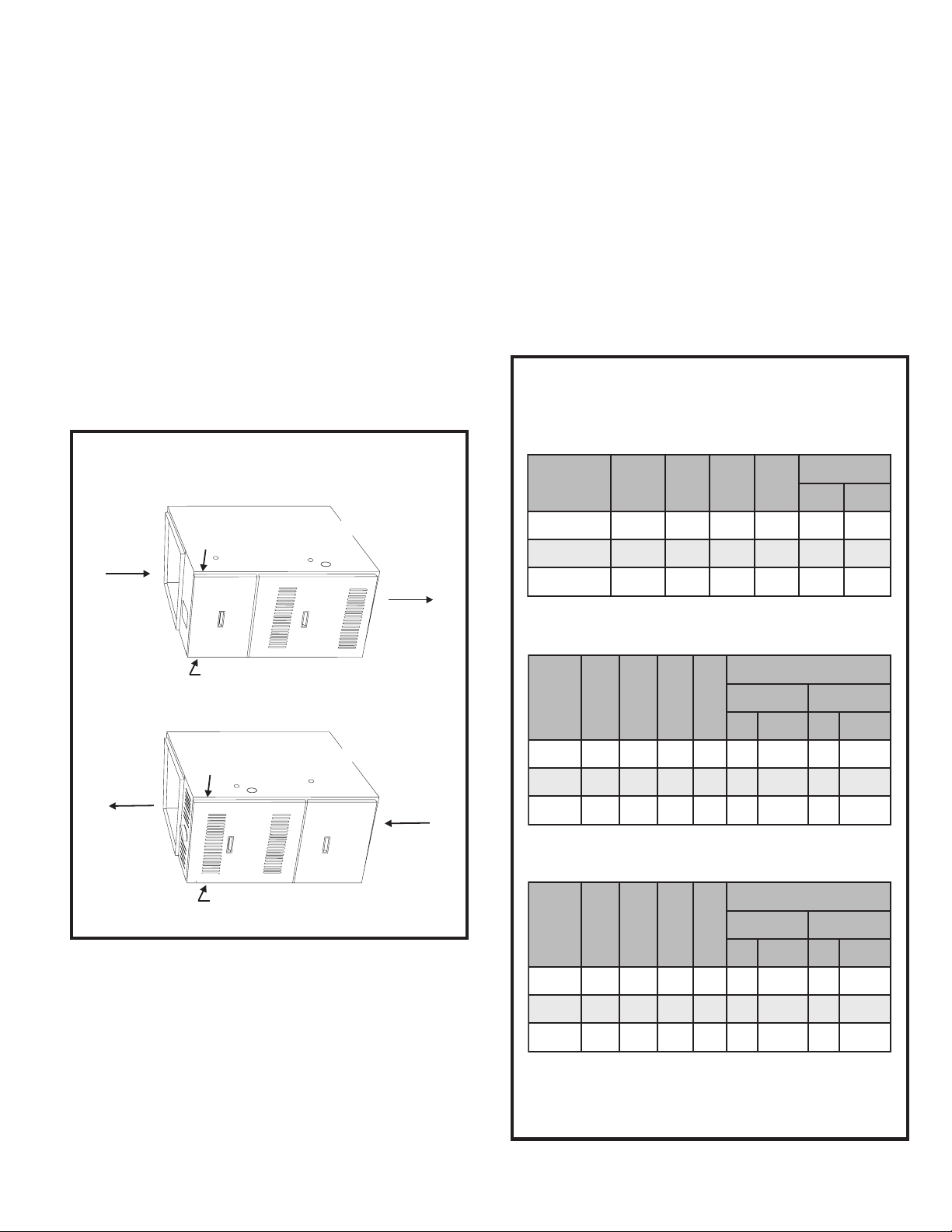

These furnaces may be installed as suspended units in the

horizontal position.These furnaces are not designed for

direct attachment of suspension rods to the furnace casing.

The suspending means must be field fabricated, and

should consist of two “cradles” made by attaching two

rods to a length of angle iron or suitable gauge steel.

Locate the cradles as close as possible to the ends of the

furnace (this will provide access for removal of major

components such as the blower assembly). Provide

enough clearance between the suspension rods and the

furnace to allow removal of access panels.

Combustion and Ventilation Air

Adequate provisions for combustion air and ventilation of

furnace must be made. Refer to Section 5.3, “Air for

Combustion and Ventilation,” of the National Fuel Gas

Code, ANSI Z223.1/NFPA54 (latest edition), Sections 7.2,

7.3, or 7.4 of CSA B149.1 Natural Gas and Propane

Installation Codes (latest editions), or applicable provi-

sions of the local building codes.