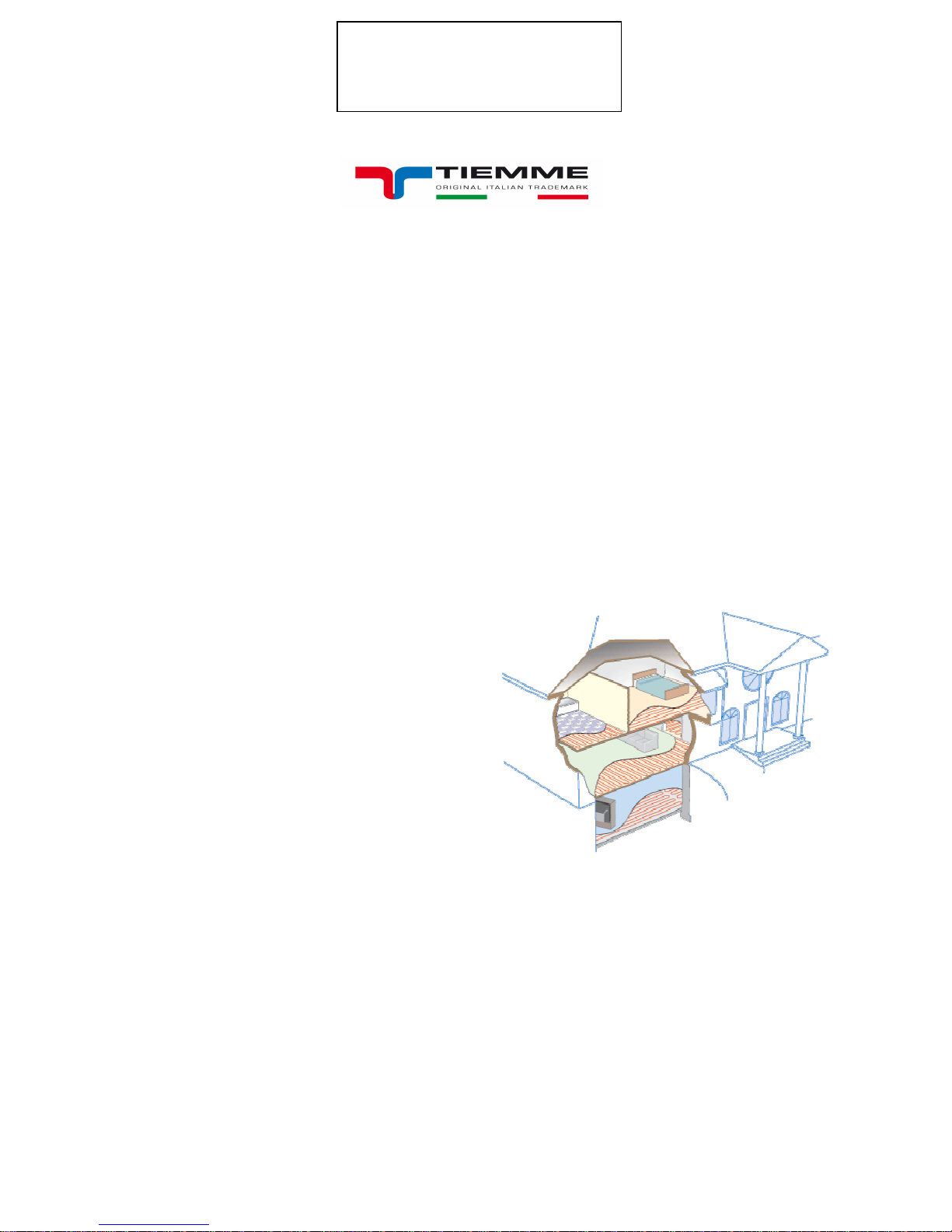

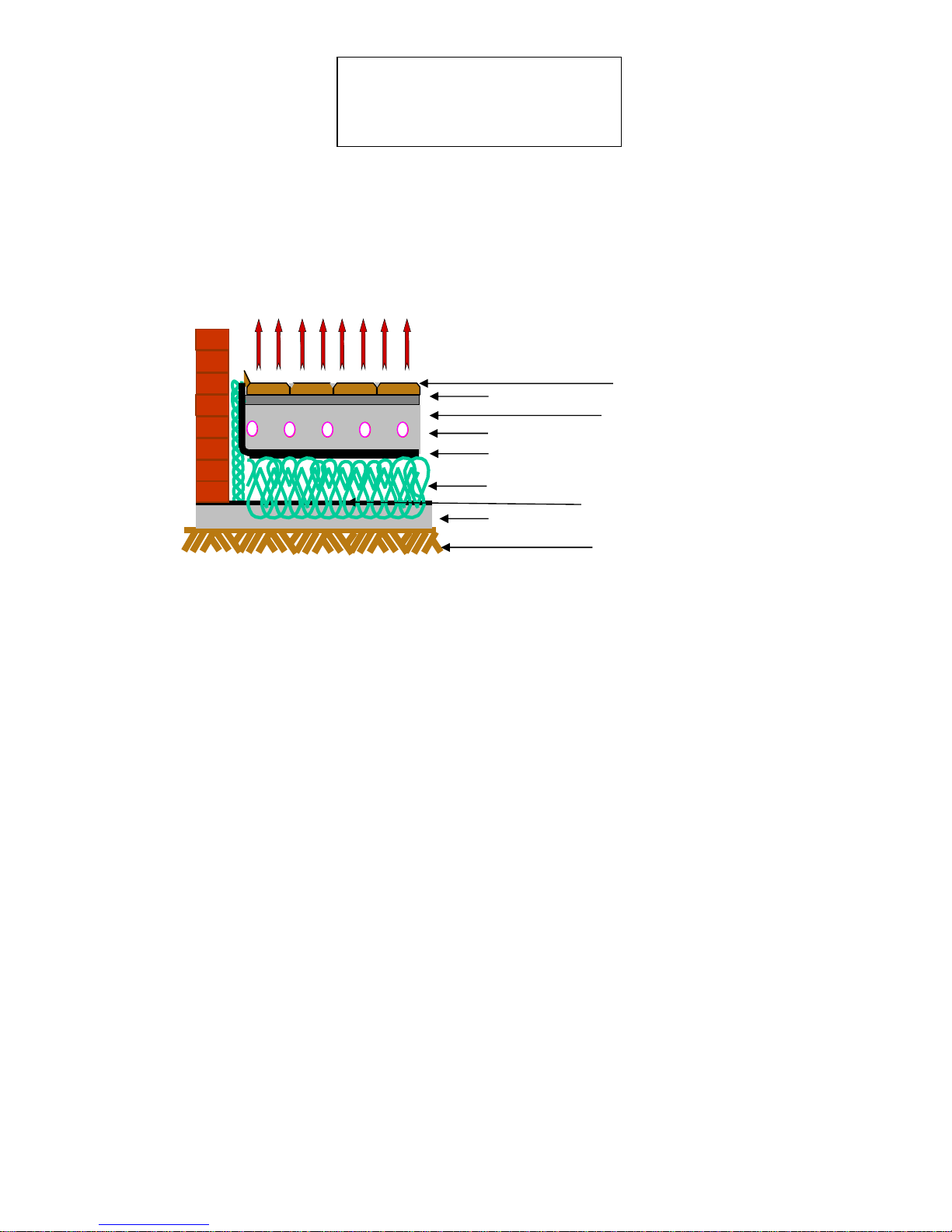

HYDRONIC RADIANT HEATING SYSTEM

Hydronic radiant heating & cooling systems can be installed in many ways to create a wonderfully

warm room environment.

These include:

1. Pipes embedded in the concrete floor.

. Pipes in a floating floor system.

3. Pipes fixed to the underside of a wooden floor.

4. Pipes embedded in the walls of a room.

5. Pipes embedded in the ceiling of a room.

6. All these methods offer many practical benefits to suit the needs of all.

7. Hydronic radiant heating has been used for centuries. In the last few years, significant improvements in

the technology together with the realisation of the benefits of this form of heating and cooling have created

a rapid rise in installations. Tiemme has been one of the companies leading the way.

Benefits - Tiemme radiant floor, wall or ceiling

heating, provides energy saving with comfort, quiet

and clean operation, with room versatility and choice

of energy usage.

Energy Saving - Room temperatures can be set as

much as degrees lower and still maintain the

required comfort level. In houses with high ceilings the

savings can be significant.

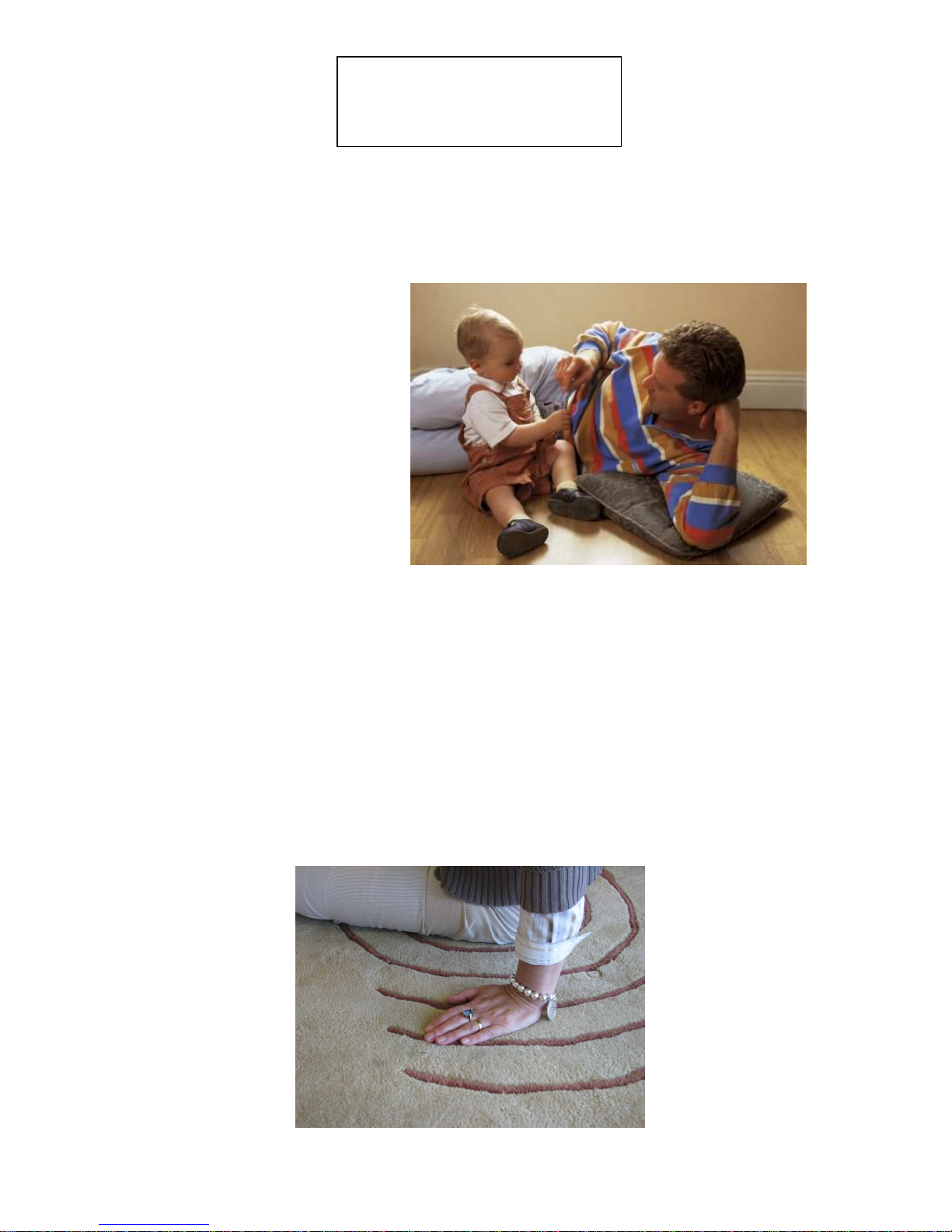

Ultimate Comfort - Rooms can be heated to different

temperatures according to their usage. Zones can be

set to heat rooms at different times to eliminate cold

rooms often during a relative short period of usage.

The floors are always comfortably warm no matter

what the floor coverings are.

Quiet Operation - Tiemme radiant floor heating

systems operate without noise and draughts. Air movement is kept to a minimum so dust and germs are not spread

around the house.

Choice of Surfaces - Tiemme radiant heating systems can be installed in a concrete floor on the ground or

suspended below with wooden floors and even in the walls or ceiling. The choices are unlimited.

Freedom to decorate - As the heat gently radiates from the whole of the floor there are no obstructions or

limitations for the placement of furniture.

Choice of energy – Tiemme radiant systems can be powered by a gas-fired boiler, a combination of heat pump

and solar collectors, solid fuel boiler or any new energy system yet to be discovered. This means your heating

system is always ready for the future.

Healthy Choice - Over the years people who have switched from forced air to floor radiant heating have greatly

improved their allergy problems. This is attributed to less dust blowing around.

Zero maintenance - Once installed Tiemme radiant floor heating does not require routine maintenance or

cleaning.