Table of Contents

Section 1: Introduction............................................................................................................ 1

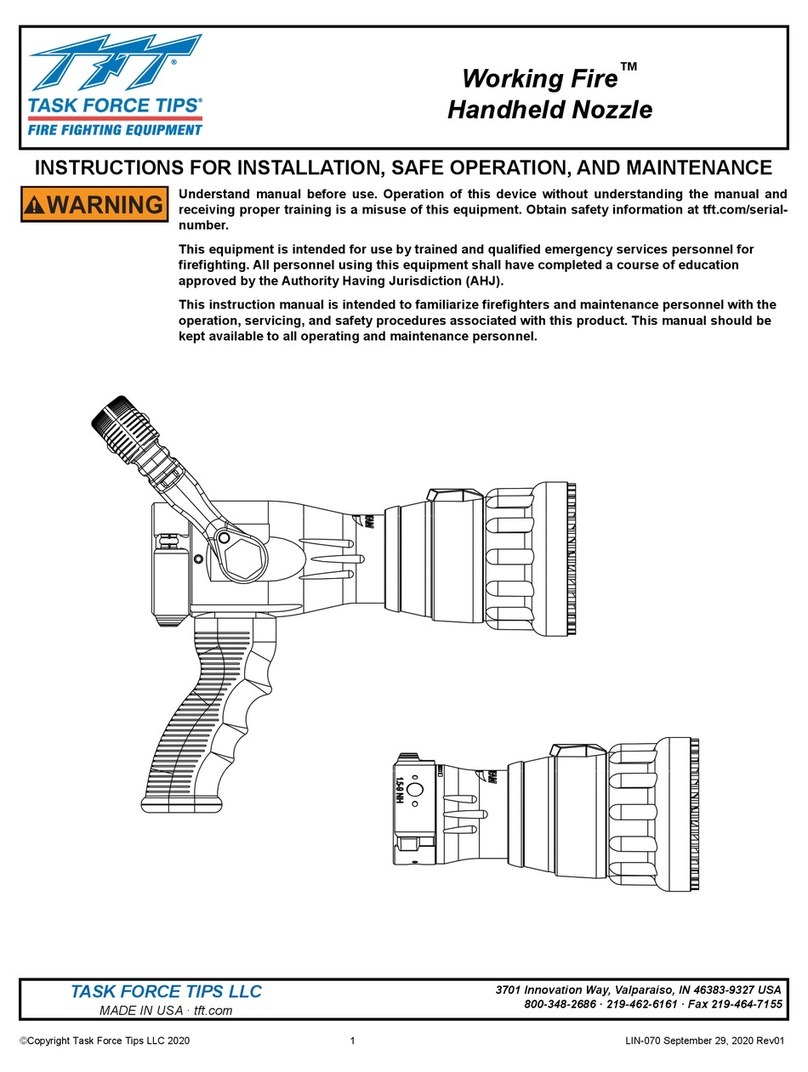

Valve System............................................................................................................................................2

Section 2: Deploying the Bucket............................................................................................. 5

Attaching to the Cargo Hook....................................................................................................................5

Connecting Power.....................................................................................................................................6

Longlines ..................................................................................................................................................7

Checking Tail Rotor Clearance.................................................................................................................8

Instant Deployment System (IDS)............................................................................................................9

Section 3: Accessories...........................................................................................................11

Foam Injection Systems..........................................................................................................................11

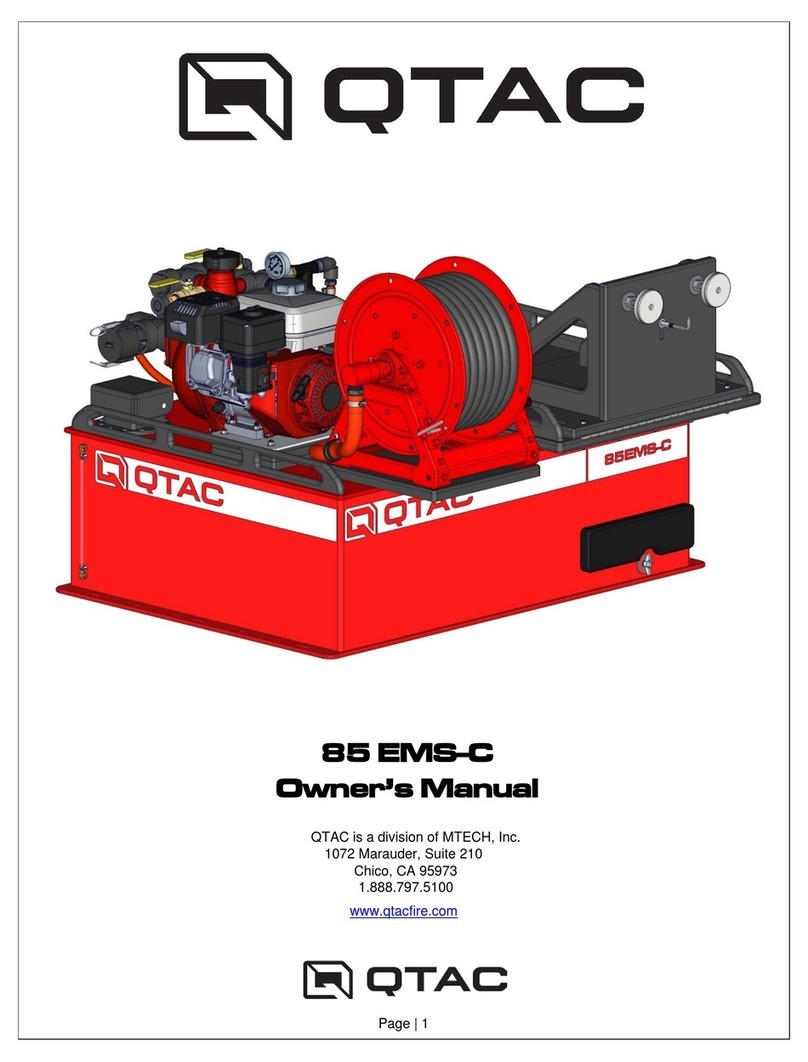

Power Pack..............................................................................................................................................13

Section 4: Making Adjustments.............................................................................................15

Adjusting Components............................................................................................................................15

Section 5: Packing and Storage.............................................................................................17

Packing....................................................................................................................................................17

Storage....................................................................................................................................................20

Section 6: Troubleshooting and Maintenance......................................................................21

Troubleshooting......................................................................................................................................21

Maintenance Procedures.........................................................................................................................25

Section 7: Repair Assessment Guide....................................................................................27

Overview of Repair Categories...............................................................................................................27

Head Repair Criteria...............................................................................................................................28

Cables Repair Criteria.............................................................................................................................29

M-Straps/Top Chains Repair Criteria.....................................................................................................30

IDS Hub Repair Criteria .........................................................................................................................31

Bucket Shell Repair Criteria...................................................................................................................32

Section 8: Repairs...................................................................................................................33

Rigging Repairs ......................................................................................................................................33

Valve Repair and Replacement...............................................................................................................39

Shell Repairs...........................................................................................................................................51