Ignition6 V -29/5W.

Validfor:20

mph.

enginestonr.772302

25mph.enginestonr.

779301

30mph.enginestonr.780501

Theignitionissupplied

with:

1Coil29W.fortheheadlight

1Coil5 W.foradditionalchargingofthe

battery

1H.T.coil

Allthesecoilsaremountedonthebaseplate,placedin

theflywheel.

Whendismountingtheflywheelitmustbesecuredby

tool

nr.48.50.10.

Afterremovingthenut,theflywheelcanbepulledoff

withtoolnr.48.50.02securedagainwithtoolnr.

48.50.10.

Alwaysputtheflywheelwiththeopensideupwardson

theworkbenchtopreventironparts,likesmallwashers,

tobeattractedbythemagnetos.

Loosenthe3 screwsofthebaseplateandremovethe

baseplateoutofitspositioninthecrankcase.

Inordertomovethewiresfreelythroughtherubber

grommets,oilthema littlebefore.

Neverpullthebaseplatetomovethewiresoutofthe

grommetsbutalwayspullthewiresthemselves.

Mountingtheignitionthewireshavetobeputintothe

grommetsfirst.Someoilonthewiresmakesiteasier.

Fitthebaseplateintothecrankcaselocation,between

thecams.Takecarethatthisisdonecorrectlyandthat

nowireispinchedbetweenbaseplateandcasting.

Fitthe3 screwsbutdoenotyettightenthem.

Nextmounttheflywheelandmakesurethatthekeyfits

inthekeygrooveoftheflywheel.Fitplainwasher,

toothedwasherandnutonthecrankshaft.

Securetheflywheelagainwithtoolnr.48.50.10and

tightenthenut.

Nowturntheflywheelclockwiseuntilthebreakergapis

maximum,visiblethroughtheholesintheflywheel.

Checkthebreakergap.

Thegapmustbebetween.35and.45mm.(.014and

.018").

Ifthegapisnotcorrectitcanbeadjustedbyloosening

thescrewofthebreakerpointset,andmovingthefixed

contactintothedesireddirectionbymeansofa screw

driver.

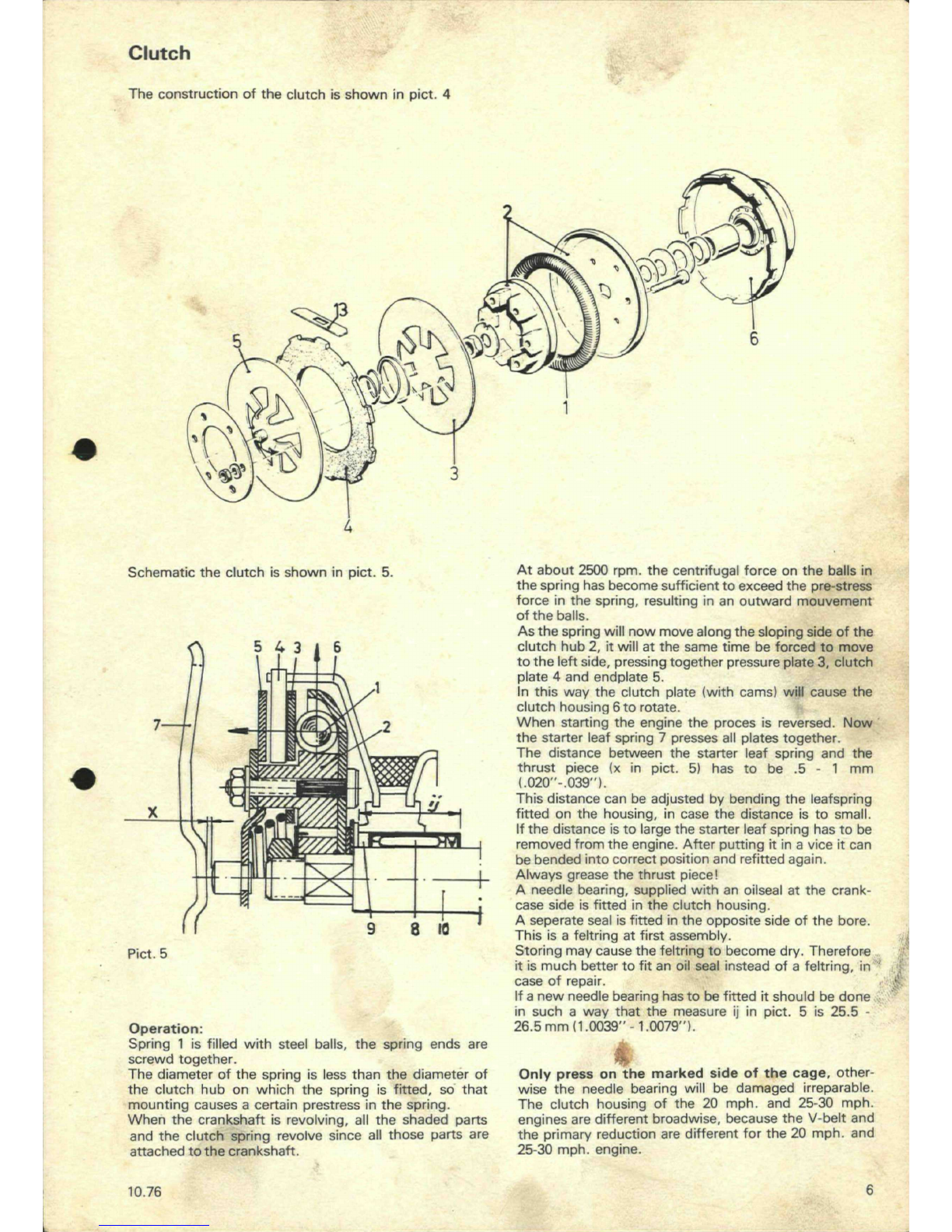

Forthecapacityofthesparktherupturedistance(see

pict.8 distanceA)isveryimportant.

/

:

\

Pict.8

Thisdistance

has

to

be

7-11

mm.

(.28.39").

Thisisanindicationforsuchpositionoftheflywheel

wherethemagneticfieldchangesitsdirection:a position

inwhichtheelectriccurrentismaximum.

Therupturedistancecanonlybechangedbychanging

thebreakergap.

Alargerbreakergapwillgivea smallerrupturedistance,

ashorterbreakergapmeansa largerrupturedistance.

Allpartsaremachinedinsuchanaccuratewaythatthis

rupturedistanceisautomaticallyiscorrectwhenthe

breakerpointgapiscorrectlyadjusted.

Theproceedingsmentionedbeforeguaranteemaximum

spark.

Nowtakecaretohavethismaximumsparkattheright

positionofthepistoninthecylinder,whichis1.8-

2.2.

mm.

(.071"

- .087")before

T.D.C.

Toadjustthis,screwa dialgaugeintothesparkplughole

ofthecylinderhead.

TurntheflywheelclockwiseuntilpistonisatT.D.C,

whichisthepointwherethedialpointerchangesits

direction.

Nowconnectanignitionadjustingapparatus,onewire

grounded(forinstanceoncylinderhead)theotheroneto

thecut-offwire

ofrthe

ignition(blackwire).

Aslongasthebreakerpointsareclosedthelampofthe

adjusterwillburn.

Turntheflywheelanti-clockwise.Themomentthe

breaker

pointsopenthelampwillextinguishbecauseof

theinteruptionoftheelectriccircuit.

Watchthedialgaugetoseehowfarthepistonhas

descended.

Whenthelatterislessthan1.8mm.

(.071")

thespark

betweenthesparkplugelectrodesistoolateorinother

wordstheignitionisretarded.

Inthatcasethebaseplatehastobeturnedanticlock-

wise.

Whenthedescendingofthepistoninthecylinderatthe

momentofignition,ismorethan2.2mm.

(.087")

the

sparkistooearly,orinotherwordstheignitionis

advanced.

Inthatcaseturnthebaseplateclockwise.

Thushavingadjustedthemomentofignition,thethree

baseplatescrewscanbetightened.

Insteadofusinga dialgaugea slidinggauge(vernier

calipers)canbeusedasfollows:

TurnthepistoninT.D.C.andmeasurethedistance

betweenpistonbottomanduppersideofthesparkplug

hole.

Turnbacktheflywheeltillthelampextinguishand

measurethedistanceagain.

Thedifferencebetweenbothsizesistheignition

advance.Ifoneonthecoilshastobereplacedusea

feelergaugetochecktheairgapbetweeninnerrim

(magnetos)andcoreshoes.

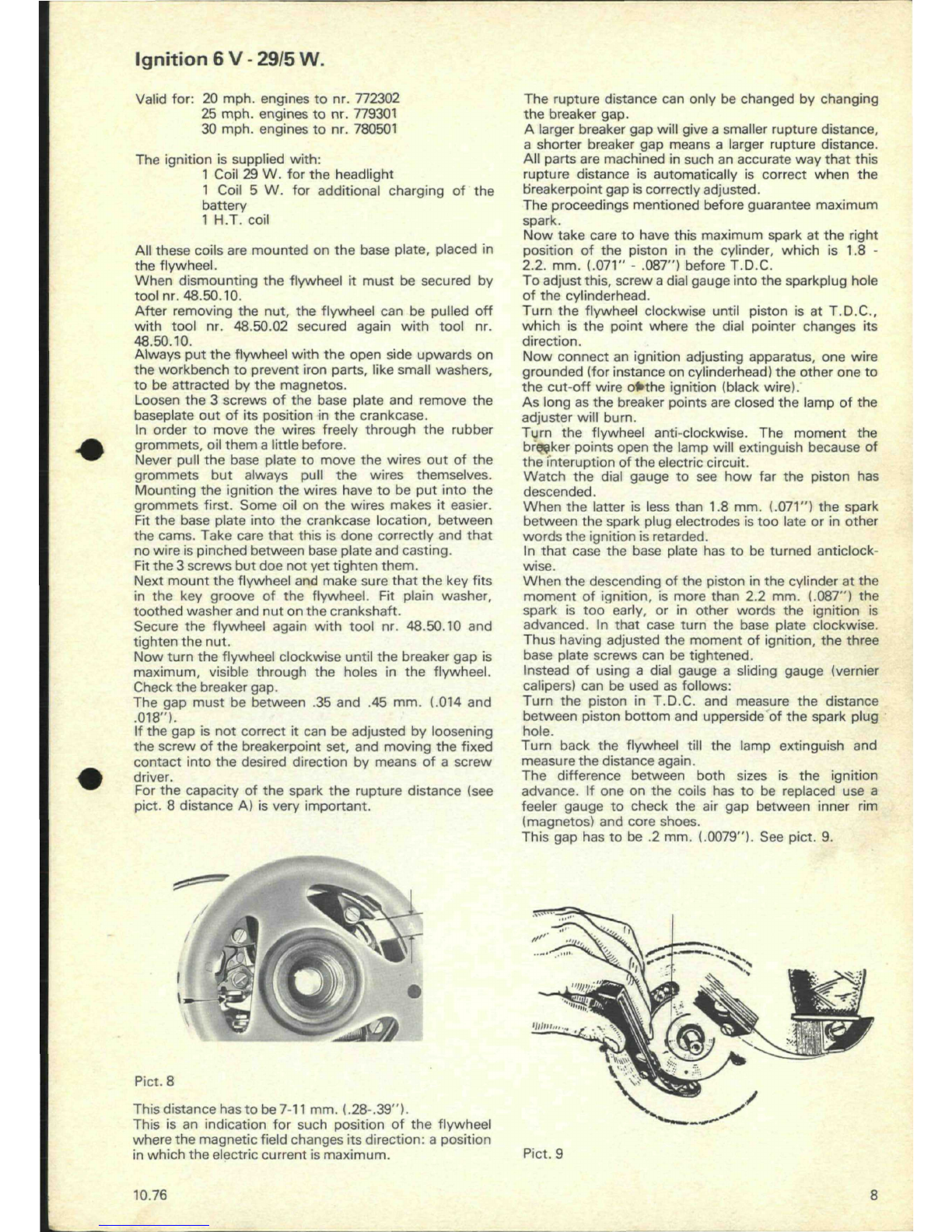

Thisgaphastobe.2mm.(.0079").Seepict.9.

'

!> V>

•m

i

limn i

-v

s

s

Pict.9

10.76 8