Blata MIDIQuadard User manual

Noise emitted by machinery and equipment (Minibike BLATA QUADARD) - Measurement of emission sound pressure levels at a work

station and at other specified positions. Levels measured by authorized person ( TUV CZ s.r.o.). Test record (no. : 815/90/06/BT/IZ/H) is

deposited with producer.

RPM Average level of the acoustic pressure A at

a work station (ČSN EN ISO 11202)

Total average level of the acoustic power

(ČSN EN ISO 3744)

2600 rpm (idling speed) LAeq = 79,6 dB LWA [dB (A)] = 86,6 dB

11 000 rpm LAeq = 96,3 dB LWA [dB (A)] = 104,1 dB

1

QUADARD

INSTRUCTION MANUAL

TABLE OF CONTENTS

Page

INTRODUCTION................................................................................................................................ 2

PURPOSE OF USE ........................................................................................................................... 2

SAFETY WARNING .......................................................................................................................... 2

TECHNICAL SPECIFICATIONS ....................................................................................................... 3

UNPACKING AND SETTING UP BEFORE RIDING - Fig. 1 ........................................................... 4

BEFORE STARTING THE ENGINE.................................................................................................. 4

ENGINE STARTING - Fig. 2 ............................................................................................................. 5

CARBURETOR - Fig. 3..................................................................................................................... 5

RIDING............................................................................................................................................... 6

INSPECTION AND MAINTENANCE................................................................................................. 6

DRIVE CHAIN ADJUSTMENT ..........................................................................................................7

CENTRIFUGAL CLUTCH SHOES REPLACEMENT ....................................................................... 7

REAR BRAKE ADJUSTMENT - Fig. 4............................................................................................ 7

REAR BRAKE PADS REPLACEMENT ........................................................................................... 8

WHEEL REMOVAL – Fig. 14............................................................................................................ 8

TYRE CHANGE – Fig. 14 ................................................................................................................. 8

AIR FILTER CLEANING .................................................................................................................. 9

PINION REPLACEMENT - Fig. 5...................................................................................................... 9

FRONT AXLE ALIGNMENT.............................................................................................................. 9

STORAGE PROCEDURE ................................................................................................................. 9

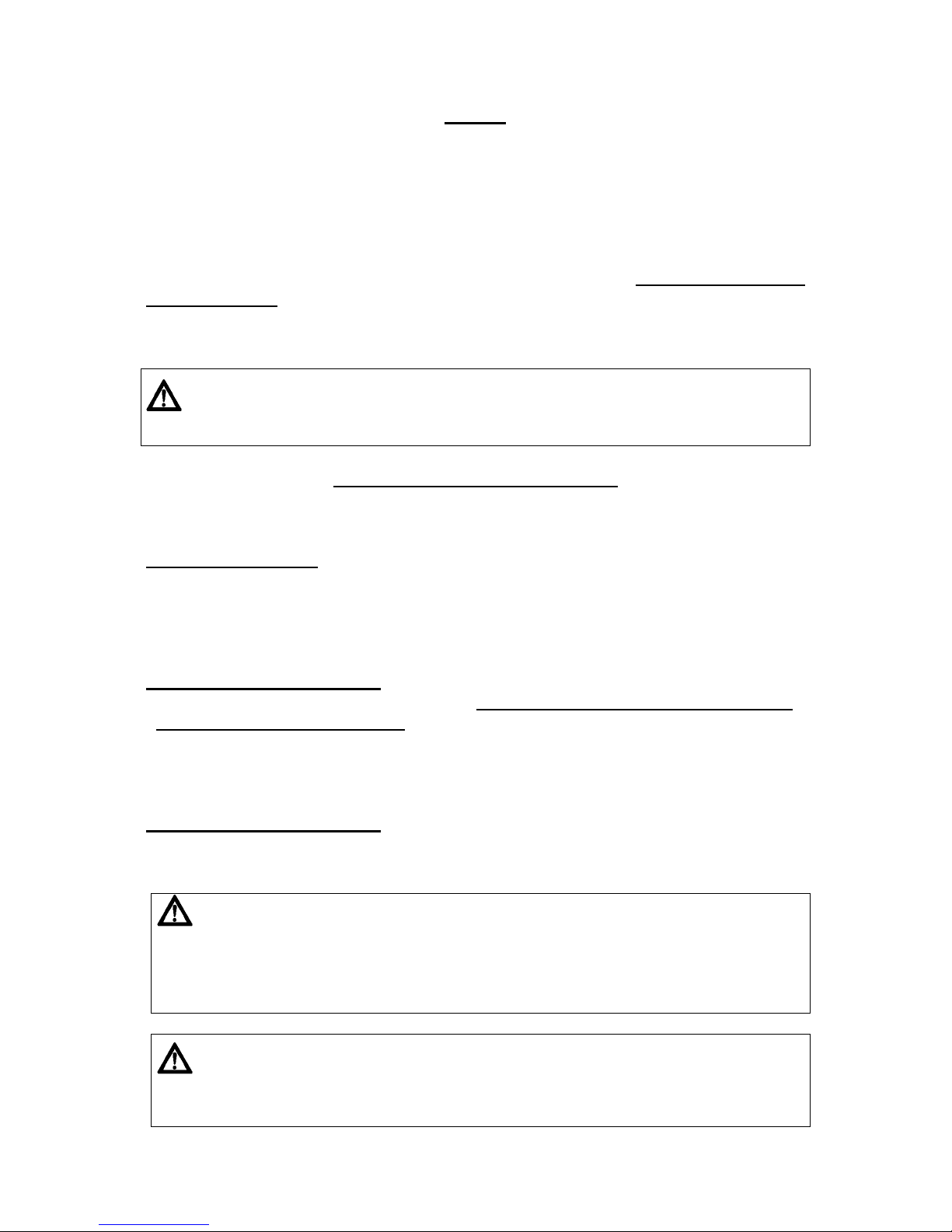

QUADARD – assembly – Fig. 6............................................................................................... 10, 11

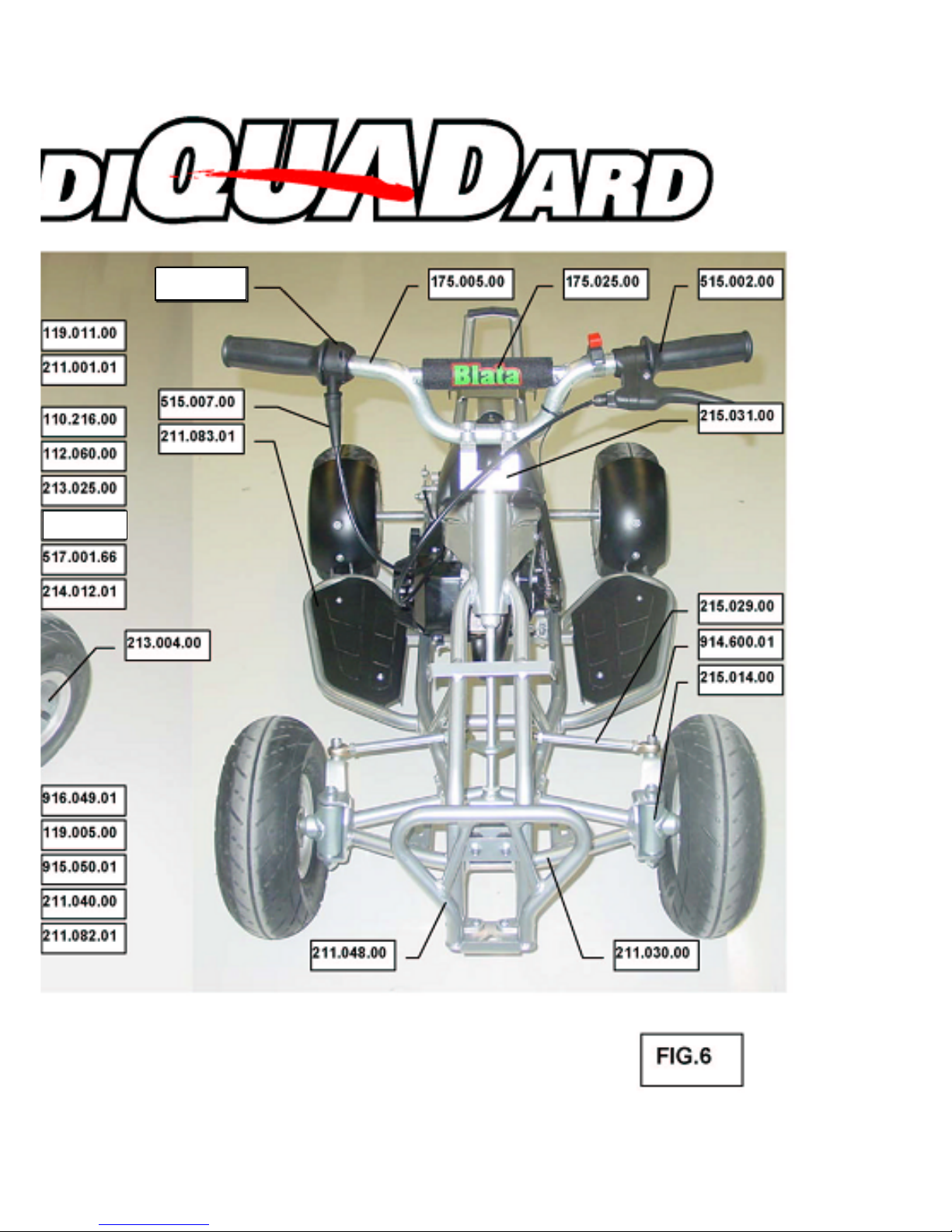

REAR BRAKE – assembly – Fig. 7 ............................................................................................... 12

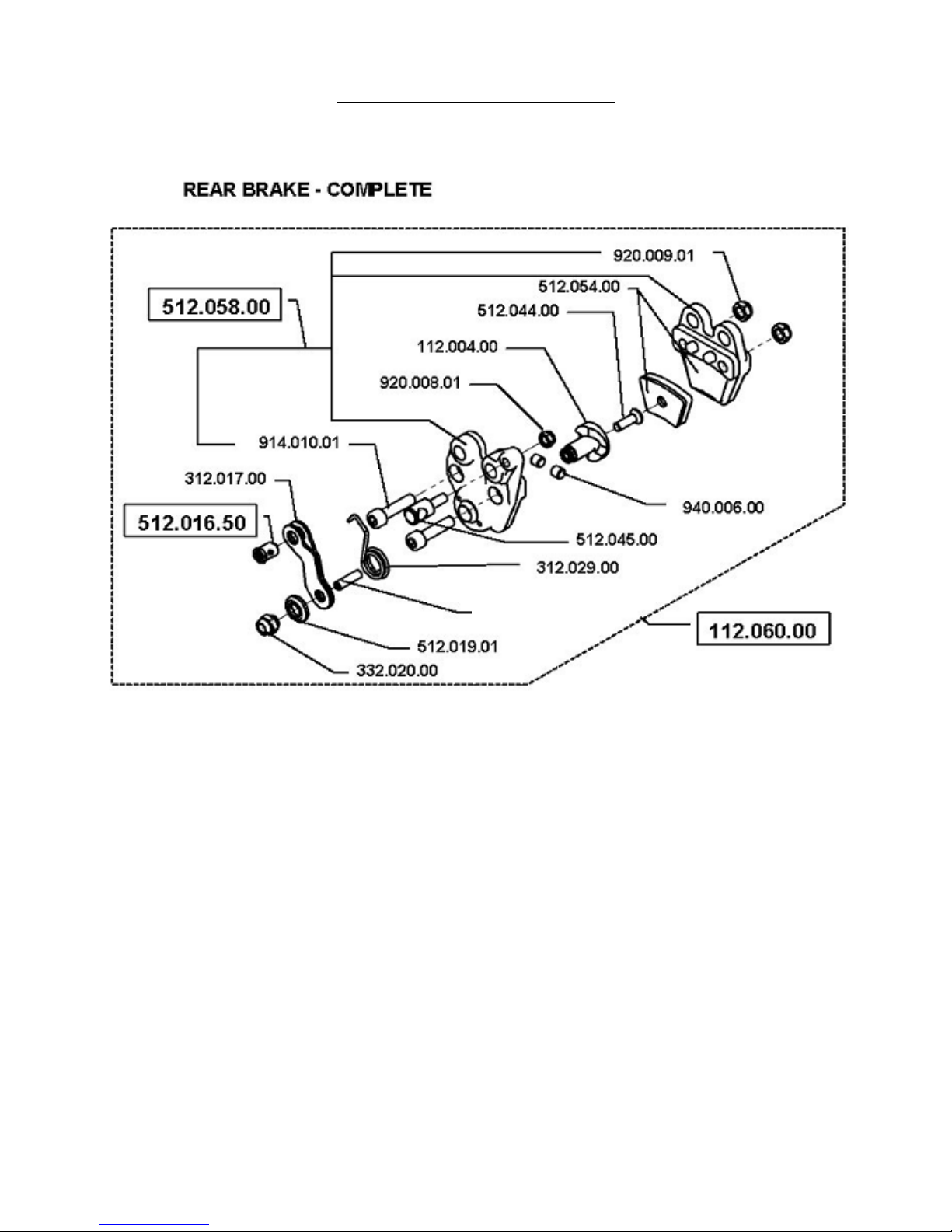

ENGINE COMPLETE – Fig. 8......................................................................................................... 13

FRONT AXLE – Fig. 9, REAR AXLE SHAFT – Fig. 10 ................................................................. 14

BUMPER – Fig. 11, FRONT STEERING ROD – Fig. 12................................................................ 15

BODY KIT, GAS TANK – Fig. 13, FRONT AND REAR WHEEL – Fig. 14 ................................... 16

QUADARD – SPARE PARTS LIST ........................................................................................... 17,18

TORQUE SETTINGS....................................................................................................................... 19

CERTIFICATE OF WARRANTY ..................................................................................................... 20

2

INTRODUCTION

Dear customer,

Thank you for purchasing this product manufactured by Blata. The proper care and

maintenance that your Quadard requires is outlined in this manual. Following these

instructions will ensure a long trouble-free operating life of the vehicle and your

satisfaction with it.

PURPOSE OF USE

Quadard is designed to be driven on closed tracks with an even, smooth, and dust-

free surface. This product is not designed to be used on public highways. Both adults

and children can ride the vehicle (children only under the supervision of an adult /

responsible person. This Product is not designed for rough terrain. Minibike Blata

should not be used during winter season and under bad weather conditions. Usage

under these conditions leads to abnormal mechanical wear and corrosion of most

minibike parts - especially those directly exposed to climatic influences.

Beside that, riding under these conditions increase the risk of injury or health

damage.

Quadard is equipped with a single-cylinder, two-stroke, petrol combustion engine

with an air filter and exhaust silencer. The gear ratio can be modified by altering the

sprocket sizes. The Quadard rear axle is equipped with a disk brake, controlled by

the brake lever on the left hand side of handlebars.

SAFETY WARNING

This manual contains important safety information and instructions which

should be read carefully before operating the vehicle. For your own safety and

the safety of others follow these rules.

Neither manufacturer nor distributor is responsible for injuries caused by

unsafe and improper use of the vehicle.

This vehicle is not allowed to be used on public roads!

Unsafe and careless use of the vehicle can result in serious injuries. The

driver can minimize the potential risks by wearing safety equipment.

The driver must wear a safety helmet, goggles, gloves, elbow pads,

kneepads, and firm footwear. Avoid rough surfaces and obstacles.

Always drive with both hands on the handlebars.

3

TECHNICAL SPECIFICATIONS

ENGINE one cylinder; two-stroke; air-cooled

DISPLACEMENT 39,9 ccm

POWER OUTPUT 2,5 kW at 8 700 rpm

TORQUE 3,5 Nm at 6 000 rpm

CARBURETOR Dell’Orto 14

IGNITION Contact-less

STARTING Manual – hand pull type

CLUTCH Centrifugal automatic

FRAME welded high-strength steel tubes

BRAKE rear disk – disk diameter 119 mm ( 4,7“ )

front light alloy 4“ - 51

WHEEL RIMS

rear light alloy 4“ - 95

front 3,00 – 4“

TYRES

rear 3,00 – 4“

FUEL mixture of petrol (91 octane or higher) and synthetic oil

2T (mixing ratio 50 : 1) 100 millilitres of oil to 5 litres of

petrol.

{After running in period of 5 tanks of fuel at 30 : 1}

FUEL TANK CAPACITY 1 litre ( 0,26 US gal. )

WEIGHT 29 kg ( 63,8 lb. )

WEIGHT (incl. packing) 33 kg ( 72,6 lb. )

CARRYING CAPACITY 95 kg (209 lb. )

length 1 010 mm ( 39,7“ )

width 590 mm ( 23,2“ )

DIMENSIONS

height 630 mm ( 24,8“ )

length 106,0 cm ( 41,3“ )

width 62,0 cm ( 24,4“ )

BOX PACKING

DIMENSIONS

height 56,0 cm ( 22, 04“ )

4

UNPACKING AND SETTING UP BEFORE RIDING

Your Quadard is packed with folded handlebars and brake lever. After unpacking,

set up the handlebars to a comfortable position. After setting-up the handlebars,

tighten the handlebar bolts (M6), the brake lever bolt, and the throttle grip bolt

according to Fig.1. While tightening the bolts, do not use an excessive force.

Overtightening the bolts may cause damage of the threads or other parts. Verify the

smooth and free movement of both control cables (throttle and brake).

Fig. 1

Controls :

1. Handlebar bolts

2. Brake lever bolt

3. Throttle grip screw

4. Engine stop switch

5. Rear brake lever

BEFORE STARTING THE ENGINE

Engine and performance : It is important for the vehicle to be properly run in. The

engine is considered properly run in after consuming five fuel tanks full of mixed

petrol. During the running in period use a 30 : 1 pre mix 2-stroke synthetic oil.

(166 millilitres of oil to 5 litres of petrol )

Once the engine is run in ( Five fuel tanks full ) you can then change the mixture to

50:1 ratio.

(100 millilitres of oil to 5 litres of petrol )

Always mix your oil and petrol in a seperate container making sure it is mixed

properly before filling the fuel tank.

During the running in period, do not use full throttle and do not allow the engine to

overheat, otherwise you will damage your engine.

Check the tyre pressure which should not exceed 2,5 bar

Always inspect the bike before each ride (refer to the article ‘INSPECTION

AND MAINTENANCE’). Failure to inspect and maintain your Quadard

properly increases the risk of an accident or damage to the vehicle.

1

1

3

2 4

5

5

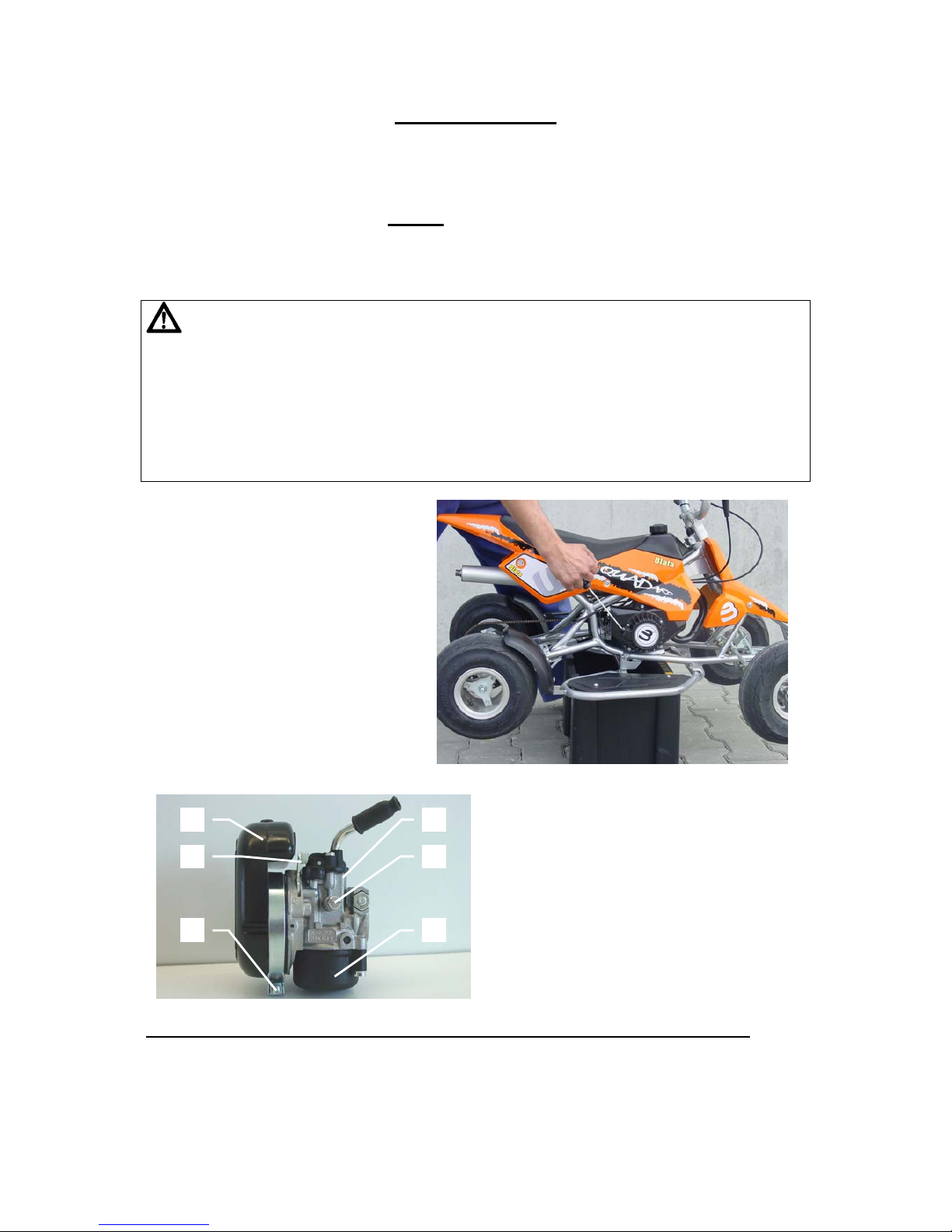

ENGINE STARTING

Fill the fuel tank with pre mix fuel and refit the fuel cap. Open the fuel cock , turning it

to the position “ON”, Fig. 3. Set the choke to open (position “B“, Fig. 3). Without

turning the throttle grip, gently pull the starter rope twice and then on the third pull,

the engine should start, Fig. 2. Do not pull the starter rope out completely! After a

short period , close the choke (position “A”). Let the engine run to normal operating

temperature. and then If needed, adjust idle speed to tick over (use the adjusting

screw on the carburetor, Fig. 3).

Fuel and fuel vapour are highly toxic and flamable. Always be careful

when handling fuel – it can burn or poison you.

- stop the engine and turn off the fuel tap, keep naked flames and

sparks away from your bike.

- do not smoke near your bike.

- refuel only outdoors in a well ventilated space

- clean up any excess fuel immediately

- keep children and pets away

Fig. 2: Starting

Fig. 3: Carburetor

1. Suction chamber

2. Sleeve screw

3. Carburetor body

4. Adjusting screw of no - load run

5. Float chamber

6. Fuel cock

A – choke lever for ride

B – choke lever for cold - starting

It is necessary to adhere to the following instructions for flange reassembling:

always use a new plastic ring 110.078.00 which is inserted into the flange! Tighten

up the screw with torque 5 Nm.

Use of bigger torque can cause carburetor damage which is not covered by

warranty!! Use of smaller torque can cause slackeing of the carburetor.

Check up the screw tightness after every 5 hours of riding!

1

A

2

3

4

5

6

RIDING

Sit on the vehicle and slowly twist the throttle to start moving forward. When riding

the Quadard, keep in mind the rules applicable to riding four-wheel vehicles (sit on

the front part of the seat; do not lean back; try to keep the load of your body as

forward as possible)! Reduce speed accordingly when going around corners.

When braking, always reduce the throttle to the idle position whilst pressing the rear

brake lever with the necessary force to stop the machine. Turn the engine off with

the red button (‘engine kill stop switch‘) on the handlebars. Close the fuel cock

after every ride!

It is necessary to check the tightness of bolts and nuts, including the engine,

and the brake settings, before and after every use.

Always ride within the limits of vehicle/ rider and weather conditions to

avoid unnecessary accidents and injuries.

INSPECTION AND MAINTENANCE

Periodic maintenance check-ups are the best way to ensure premium condition of

the vehicle, providing safety and economical running costs. Perform these services

as listed below:

A - Before each ride:

- Check the rear brake cable and brake efficiency.

- Check the lubrication and tension of the chain. Any slack of the chain should be

adjusted to 5 mm (0,2 in).

- After every ride clean your Quadard carefully and keep it clean. Do not use

aggressive cleaning detergents.

B - Every 10 hours of riding:

- Check the tightness of all bolts and nuts. Tighten them with a torque wrench only!

For torque figures see the table.

- Wash the air filter in petrol and lubricate it with air filter oil.

- Clean the carburetor float chamber carefully.

- Check the brake pads - the thickness of the brake lining must not be less than 1

mm (0.039 in). Review the basic brake adjustment.

C - Every 50 hours of riding:

- Check the state of the clutch pads - the thickness must not be less than 1 mm

(0.039in).

Check-ups

Shut the engine off when performing maintenance check-ups

otherwise You could be severely injured if your hands or clothing get

caught by moving parts.

Make sure the engine and exhaust are cold before performing any

inspection of this machine

7

DRIVE CHAIN ADJUSTMENT

Loosen the bolts (M5) on the rear axle carrier also loosen (M6) bolt on the rear

brake to allow for tensioning the chain, then adjust by moving the excentric disc on

the axle, the drive chain slack should be 5 mm (0,2 in). making sure not to over

tighten the chain. fasten the (M5) bolts on the axle carrier remembering to tighten the

M6 bolt on the brake.

It is important to lubricate the chain regularly, to avoid excess wear. This will prolong

the lifetime of the chain. it is important to lubricate the chain after every ride and

especially in wet conditions. It is recommended to use a quality chain lubricant. If the

chain needs replacement, then please also check the front and rear sprockets for

wear, replace accordingly.

Riding with a chain in poor condition or improperly adjusted can lead to

serious injury. Always, Inspect, Adjust and Maintain the drive chain

properly before each ride.

CENTRIFUGAL CLUTCH SHOES REPLACEMENT

Remove the chain guard by loosening two bolts (M6). Release the chain and

dismantle it. Loosen the four bolts (M6) holding the cover of the clutch. Release the

engine brace on the frame, and move to one side, remove the whole cover together

with the clutch drum. Use a pair of pliers to draw off the clutch springs and loosen

the pins holding the clutch shoes. Install new clutch shoes and springs (if required).

To re-install the clutch assembly, reverse the sequence as described, and then re

adjust the tension of the drive chain.

REAR BRAKE ADJUSTMENT (Fig. 4)

General adjustment:

The general brake adjustment can be made

by turning the adjusting screw on the brake

lever on the handlebars.

Basic brake adjustment:

Screw in the adjusting screw at the brake

lever. Loosen the nut (no. 3), and tighten the

adjusting bolt (no. 4), so the wheel cannot

turn. Back off the bolt (no. 4) about ¼ to ½ of

a turn and fix it with the lock nut (no.3).

Do not adjust the cable retainer (no. 5) for

adjusting the brakes!

Failure to inspect and properly maintain the brake increases the risk of

having an accident. Before each ride check the rear brake cable and the

brake efficiency.

3

4

5

8

REAR BRAKE PADS REPLACEMENT (Fig. 7 )

First, screw in the adjusting screw on the left brake lever on the handlebars. Loosen

the nuts (M5 - 914.003.01) holding the brake body to the brake holder, and pull the

brake body, rearward. Do not loosen the cable retainer! Remove the two distance

bushes and the two threaded bushes from the brake body. Detach both halves of the

brake caliper by screwing out the nuts (M6 – 914.010.01). Remove the worn brake

pads 512.054.00.

Place the new brake pad with the pivot hole into the brake half with the control

mechanism and fully screw out the adjusting bolt. Affix the other brake pad carefully

into it’s matching half. To re-install the brake assembly, reverse the sequence as

described. Perform the brake adjustment.

Riding with worn brake pads can reduce the braking performance and

cause an accident. Check and replace brake pads according to the

instructions in this manual.

WHEEL REMOVAL (Fig. 14)

Screw off the front / rear axle nut (M10) and pull off the wheel. To re-install the

wheel, reverse the sequence – install the wheel and tighten the axle nut (M10)

securely.

TYRE CHANGE (Fig. 14)

Remove the wheel (see above). deflate the inner tube. Detach both halves of the

wheel rim by removing the 3 x M6 fixing bolts (M6-914.011.01). Then replace the

tyre and / or inner tube. To re-assemble, reverse the above making sure not to trap

the inner tube and locate the valve correctly also note the tyre direction. Inflate the

tyre to a maximum of 2.5 bar.

Using worn, improperly inflated, or incorrect tyres will reduce stability

and can cause an accident.

9

AIR FILTER CLEANING

Loosen the sleeve screw, no.2 (see Fig. 3) so you can remove the air filter cover,

no.1. Now you have free acces to the filter. Remove the filter, clean it in petrol and

lubricate it with engine oil. To re-install the filter, reverse the procedure above.

PINION REPLACEMENT (Fig. 5)

First, dismantle the chain guard. Then

loosen the rear axle eccentric bolts and

the rear brake reaction catcher. Remove

the drive chain. Insert, carefully, a large

screwdriver or steel rod into the clutch

drum hole, to avoid the clutch drum

turning when releasing the pinion (Fig. 5).

Use a special pinion wrench (319.050.00)

to replace the pinion.

FRONT AXLE ALIGNMENT

Front axle alignment is performed by adjusting the steering tie rod length. Loosen the

nuts (M8) and dismantle the steering joint at both front wheels. Loosen the steering

tie rod safety nut (M8) and by screwing the tie rod end in or out, adjust the

length accordingly. The toe-in angle of the front wheels should be between 0°

and 1°.

STORAGE PROCEDURE

If the vehicle is to be left unused for a period of time, it is recommended to drain out

all the fuel from the fuel tank and carburetor. Inflate the tyres to the normal working

pressure. Remove the spark plug, clean it, put a few drops of motor oil into the

cylinder, pull the starter rope 2-3 times, so an oil film evenly coats the cylinder walls

and piston. Re-install the spark plug.

10

110.001.00

215.045.01

11

217.010.74

215.006.00

12

Fig. 7 – REAR BRAKE - assembly

916.072.02

13

14

217.010.74

15

16

17

MIDI - QUADARD

210.000.00 MIDI - QUADARD 510.002.00 STARTER COMPLETE

510.003.00 STARTER ROPE

ENGINE 510.004.00 HOLDER

110.001.00 ENGINE COMPLETE 510.005.00 HOLDER

110.001.01 ENGINE PROPER 510.006.00 GUIDE BUSH

110.002.00 CARBURETTER SHA 1412L 510.007.00 STARTER CASE

110.004.00 PISTON COMPLETE - A 510.008.00 STARTER SPRING

110.004.01 PISTON COMPLETE - B 510.009.00 RATCHET WHEEL

110.004.02 PISTON COMPLETE - C 510.011.00 WASHER 4,5 x 16 x 1,5

110.004.03 PISTON COMPLETE - D 510.015.00 WASHER 8,1 x 16 x 1

110.005.00 PISTON RING 510.017.00 WASHER 6,1 x 16 x 1,5

110.006.00 PISTON - A 510.020.00 PINION 6

110.006.01 PISTON - B

110.006.02 PISTON - C FRAME

110.006.03 PISTON - D 211.001.01 FRAME, VARNISHED

110.008.00 WRIST - PIN 211.005.00 DISTANCE SLEEVE, 111 mm

110.011.00 CRANK BALANCED 211.030.00 FRONT AXLE

110.015.00 CLUTCH DISC 211.040.00 PROTECTIVE BEND

110.017.00 CLUTCH LEVER - 2 PCS 211.048.00 BUMPER

110.019.00 CLUTCH SCREW COMPLETE 211.058.00 ECCENTRIC HOLDER - REAR

110.020.00 CLUTCH SCREW 211.066.00 ECCENTRIC , LEFT

110.022.00 CLUTCH SPRING - RACING 1,4 - 2PCS 211.067.00 ECCENTRIC , RIGHT

110.024.00 CLUTCH DRUM 211.082.01 FOOTBOARD PLASTIC, LEFT

110.028.00 CLUTCH CASE 211.083.01 FOOTBOARD PLASTIC, RIGHT

110.031.00 CLUTCH CASE COMPLETE

110.032.00 CLUTCH COMPLETE BRAKES

110.053.00 ENGINE COVERING 112.004.00 LIFTER, RIGHT

110.055.00 ENGINE SEALING SET 112.026.20 REAR BRAKE DISC 3,0 x 119

110.056.00 FLANGE 112.060.00 BRAKE COMPLETE

110.057.00 DIAPHRAGM SEALING - 2PCS 212.001.00 REAR BRAKE HOLDER

110.059.00 DIAPHRAGM 212.002.00 SUPPORTING SLEEVE

110.060.00 DIAPHRAGM WASHER 212.007.00 BOWDEN CABLE - REAR BRAKE

110.063.00 SEALING ENGINE BLOCK 312.017.00 LIFTER LEVER

110.065.00 ENGINE BLOCK 312.029.00 SPRING, LEFT

110.067.00 DIAPHRAGM COMPLETE 312.035.00 WASHER 6,1 x 14 x 3

110.068.00 SEALING 332.020.00 NUT

110.069.00 CYLINDER - A 512.005.00 HANDLE BAR LEVER, LEFT

110.069.01 CYLINDER - B 512.016.50 TERM. CLAMP BOWDEN

110.069.02 CYLINDER - C 512.019.01 WASHER

110.069.03 CYLINDER - D 512.042.00 DISTANCE SLEEVE

110.070.00 CYLINDER + PISTON COMPLETE 512.043.00 BRAKE PIN

110.072.00 EXHAUST SEALING 512.044.00 LIFTER PIN

110.073.00 PLASTIC CONECT, FUEL COCK 512.045.00 BOWDEN HOLDER

110.074.00 FUEL COCK 512.054.00 DISC BRAKE PADS - 2PCS

110.076.00 EXHAUST SILENCER COMPLETE 512.058.00 REAR BRAKE CASE - 1 PAIR

110.077.00 SILENCER MASS

110.078.00 RING WHEELS

110.080.52 JET 52 113.005.00 TIRE WITH PATTERN 3,00 - 4"

110.097.00 FLOAT CHAMBER SEALING 113.007.00 TUBE 3,00 - 4"

110.098.00 CARBURETOR SEALING 1 213.001.00 DISC 2,0 - 4"

110.099.00 ADJUSTING SCREW 213.003.00 WHEEL COMP. 2,0 - 4" WITHOUT TIRE

110.100.00 THROTTLE VALVE 213.004.00 WHEEL COMP. 3,8 - 4" WITHOUT TIRE

110.101.00 CARBURETOR FILTER 213.005.00 DISC 3,8 - 4"

110.102.00 NEEDLE VALVE 213.005.10 DISC 3,8 - 4"

110.103.00 FLOAT 213.021.02 DISTANCE SLEEVE

110.104.00 CARBURETOR SEALING 2 213.022.00 REAR AXLE SHAFT

110.105.00 THROTTLE VALVE SEALING 213.025.00 SHAFT HUB

110.185.00 JET SET 513.011.11 DISTANCE SLEEVE 40,3 mm

110.216.00 EXHAUST COMPLETE 513.011.12 DISTANCE SLEEVE 46,3 mm

18

LINING JOINING ELEMENTS

174.004.00 SEAT - TAIL ASSY, UNPAINTED 912.006.02 SCREW M 5 x 16

174.007.00 SEAT - TAIL ASSY, PAINTED 914.001.01 SCREW M 5 x 16

174.022.00 SADDLE 914.003.01 SCREW M 5 x 20

214.001.00 BODY KIT COMPLETE, UNPAINTED 914.003.02 SCREW M 5 x 20

214.002.00 BODY KIT COMPLETE, PAINTED 914.004.01 SCREW M 5 x 25

214.003.00 FRONT FAIRING, UNPAINTED 914.005.01 SCREW M 5 x 30

214.006.00 FRONT FAIRING, PAINTED 914.007.01 SCREW M 6 x 16

214.012.01 REAR FENDER 914.008.01 SCREW M 6 x 20

214.015.01 CHAIN COVER 914.010.01 SCREW M 6 x 25

514.008.01 RUBBER WASHER 4 x 6,5 x 23,5 914.011.01 SCREW M 6 x 30

914.012.01 SCREW M 6 x 40

CONTROL 914.021.01 SCREW M 6 x 12

175.005.00 HANDLE BAR TUBE 914.035.01 SCREW M 6 x 35

175.025.00 HANDLEBAR BRACKET COVERING 914.049.01 SCREW M 10 x 90

175.026.00 PAD OF COVERING 914.050.01 SCREW M 10 x 50

215.013.00 WHEEL SUSPENSION - R 914.600.01 SCREW M 8 x 30

215.014.00 WHEEL SUSPENSION - L 915.001.01 SCREW M 4 x 8

215.016.00 FRONT STEERING ROD 915.004.01 SCREW M 4 x 10

215.029.00 STEERING TIE ROD 915.050.01 SCREW 4,8 x 9,5

215.030.00 TIE BAR 916.004.02 SCREW M 5 x 6

215.031.00 HANDLEBAR HOLDER 916.005.01 SCREW M 6 x 16

215.032.00 HANDLEBAR WASHER 916.007.02 SCREW M 5 x 12

215.033.00 TIE BAR WASHER 916.012.01 SCREW M 6 x 12

215.035.00 STEERING SEAT ANGLE 916.020.01 SCREW M 6 x 40

215.038.00 TIE BAR BUSH 916.049.01 SCREW M 5 x 6

215.040.00 STEERING SEAT ANGLE COMPLETE 916.055.01 SCREW M 5 x 16

215.045.01 GAS BOWDEN CABLE 916.072.02 SCREW M 5 x 20

515.002.00 HAND GRIPS - 2 PCS 920.007.01 NUT M 8

215.006.00 THROTTLE GAS 920.008.01 NUT M 5 SELFLOCKING

515.007.00 BOWDEN DUST GUARD 920.009.01 NUT M 6 SELFLOCKING

515.008.00 ADJUSTING SCREW 920.010.01 NUT M 8 SELFLOCKING

920.011.01 NUT M 10 SELFLOCKING

TRANSMISSION 920.012.01 NUT M 8 LEFT

217.010.74 SPROCKET NO. TEETH 74 920.015.01 NUT M 6

517.001.66 CHAIN 166 920.110.01 NUT M 6 - NO 3201 A

930.001.01 WASHER 5,4

EL. INSTALLATION 930.002.01 WASHER 6,4

118.001.00 SPARK COIL 930.003.01 WASHER 10,5

118.002.00 ROTOR COMPLETE 930.008.00 WASHER 5,4

118.003.00 SPARK PLUG 930.009.00 WASHER 6,4

118.005.00 SPARK PLUG CONNECTOR 930.010.00 WASHER 8,4

118.010.00 ZIP TIES 3,6 x 140 940.006.00 ROLLER 6 x 6

518.001.00 KILL SWITCH 950.003.00 WOODRUFF KEY 3e7 x 3,7

950.005.00 WOODRUFF KEY 2e7 x 3,7

OTHER PARTS 950.007.00 LOCK 15

119.003.00 DISTANCE SLEEVE 25,8 950.008.00 LOCK 35

119.005.00 CHAIN ROLLER 950.010.00 PISTON PIN LOCK RING

119.006.00 HOLDER ENGINE 950.016.00 SPLIT PIN 3,2 x 32

119.010.00 SCREW CAP 960.003.00 BEARING 6000 ZR

119.011.00 RUBBER FOR FRAME 960.006.00 BEARING 6202 C3

119.035.00 WASHER 6,4 x 18 x 1 960.007.00 BEARING 6202 2ZR

129.008.00 HOSE CLAMP 960.009.00 BEARING 6003 Z

129.017.00 WASHER 6,4 x 16 x 1 960.108.00 CONNECTING ROD BEARING

179.008.00 TANK WITH CAP 970.001.00 PACKUNG RING 12 x 22 x 7

179.009.00 TANK 970.002.00 PACKUNG RING 15 x 26 x 7

179.012.00 DELIVERY HOSE

219.002.00 LABEL COMPLETE, ONE MODEL 971.055.00 O - RING 9 x 1,8

219.020.00 NUT COVER 973.050.00 CIRCULAR MOUNT

319.050.00 PINION KEY 974.050.00 PILLOBALL ROD END M8

Table of contents

Popular Offroad Vehicle manuals by other brands

Polaris

Polaris 2000 Sportsman 6X6 Owner's safety and maintenance manual

Suzuki

Suzuki LT-Z400 2003 Service manual

Yamaha

Yamaha Ultramatic GRIZZLY 660 owner's manual

Polaris

Polaris RZR RS1 2021 Owner's manual for maintenance and safety

Polaris

Polaris 600 HO IQ owner's manual

Polaris

Polaris RANGER XP 1000 2021 owner's manual

High Lifter

High Lifter Arctic Cat Wild Cat Lower Radius Bars quick start guide

LIYA

LIYA E-ZR50 owner's manual

Arctic Cat

Arctic Cat M 9000 King Cat Operator's manual

Yamaha

Yamaha Phazer PZ50Y owner's manual

Polaris

Polaris Sportsman Touring 550 EPS 2012 owner's manual

SMC Networks

SMC Networks CF5 Service manual