BLEC PBR150H Parts list manual

1

POWER BOX RAKE

MODELS:

PBR150H - PBR180H

INSTRUCTION & PARTS

MANUAL

IMPORTANT - PLEASE READ

BEFORE USE

2

SEE CONTENTS

3

BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

C O N T E N T S

SECTION 1. - DECLARATION OF CONFORMITY

SECTION 2. - INTRODUCTION

SECTION 3. - PRODUCT RECORD SHEET

SECTION 4. - SAFETY NOTES

SECTION 5. - DESCRIPTION

SECTION 6. - CONTROLS

SECTION 7. - PREPARING FOR USE

SECTION 8. - OPERATING

SECTION 9. - MAINTENANCE

SECTION 10. - NOTES

SECTION 11. - PARTS LIST

SECTION 12. - CONDITIONS OF WARRANTY

To be completed and returned to BLEC.

Thank you.

4

SECTION 1 - DECLARATION OF CONFORMITY

BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

EC MACHINERY DIRECTIVE - DECLARATION OF CONFORMITY

We hereby certify that the following machinery complies with all the relevant essential Health and Safety Requirements

of EC Machinery Directive 89/392/EEC as amended and the National Laws and Regulations adopting this directive.

Machine description: POWER BOX RAKE Make: BLEC

Serial Number: Model Number: PBR150H - PBR180H

Made by: BLEC Global Ltd

Address: Crowland Business Centre, Unit 5 Crease Drove Industrial Estate, Crowland

Peterborough PE6 0FB. ENGLAND

A technical construction file for this machinery is retained at the following address (if different from above address).

Signed:

Date: January 2015

NAME: G MUMBY

Position: DIRECTOR .

Being the responsible person appointed by the manufacturer or nominated representative of the manufacturer

established in the EC employed by

BLEC Global Ltd Unit 5 Crowland Business Centre Crease Drove Crowland Peterborough PE6 0FB ENGLAND

,

5

SECTION 2 – INTRODUCTION BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

We thank you for choosing a BLEC product. The reliability, efficiency and safe working of this

product depends on your care, so it is important to read this instruction book before use.

All BLEC equipment has been designed with careful attention directed to operator’s safety

therefore it is vital that all safety precautions are carried out when working and maintaining the

machinery. There are warning details placed on specific machines which should at all times be

complied with, and listed overleaf, are general safety notes which should always be followed.

Additional operator training can be supplied by BLEC Global Ltd on all BLEC machines, please

contact the office for further details.

Please find enclosed registration and guarantee card for your attention. Please complete the

necessary details required and post the “tear off” section back to BLEC within 14 days of

purchase for our records. Thank you.

6

SECTION 3 - PRODUCT RECORD SHEET

BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

MACHINE TYPE: BLEC POWER BOX RAKE

MODEL NUMBER: PBR150H - PBR180H

SERIAL NUMBER:

DELIVERY DATE:

DEALERS NAME & ADDRESS:

TEL NO:

OWNERS NAME & ADDRESS:

TEL NO:

7

SECTION 4 - SAFETY NOTES BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

S A F E T Y N O T E S

DO NOT USE THIS MACHINE BEFORE READING THIS MANUAL.

DO NOT ALLOW PERSONS UNDER THE AGE OF 16 TO OPERATE THIS EQUIPMENT.

DO NOT OPERATE WITHOUT SAFETY CLOTHING/FOOTWEAR.

DO NOT ALLOW ANY PERSON OTHER THAN THE OPERATOR TO STAND NEAR THE

MACHINE WHEN WORKING.

DO NOT ALLOW PEOPLE IN AND AROUND THE WORKING AREA.

DO NOT STAND ON ANY GUARDS.

DO NOT MAKE ANY ADJUSTMENTS WITH THE ENGINE RUNNING.

DO NOT GO UNDERNEATH THE MACHINE WITHOUT SAFETY PROPS.

DO MAKE SURE ALL GUARDS ARE IN PLACE.

DO OBEY SAFETY DETAILS.

DO MAKE SURE MACHINE IS SWITCHED OFF BEFORE MAKING ANY

ADJUSTMENTS.

DO MAKE SURE EQUIPMENT IS IN A SAFE CONDITION.

DO MAKE SURE EQUIPMENT IS REGULARLY SERVICED.

8

SECTION 5 - DESCRIPTION BLEC POWER BOX RAKE

Models:PBR150H - PBR180H

DESCRIPTION

The BLEC Power Box Rakes models PBR150H - PBR180H are designed to attach onto hydraulic

power loaders I,e, Avant or similar with a minimum power requirement of 30hp and minimum oil flow

of 55 litres per minute.

The Power Box Rakes have been designed to carry out many tasks including cultivating, earth

moving, levelling, raking and laser grading.

At the heart of the Power Box Rake is a carbide pointed tooth rotor driven via a powerful hydraulic

motor mounted directly on the rotor shaft. the rotor can be rotated in either direction for working in

forward or reverse. The rotor teeth can penetrate hard packed soil to produce a loose tilth and by

raising up the front and rear barrier blades soil can be thrown backwards to produce a cultivated

depth of soil (see photo 2)

The Power Box Rake will effectively earth move and level soil with the barrier blades down and the

side plates on - large areas can be easily worked quickly. If required soil and debris can be

windrowed to the side by setting the rotor to an angle leaving a graded area (see photo 3) and

accurate raking can be achieved by using the depth control wheels.

The Power Box Rake is a complete Landscape Tool

Photo 2

Photo 3

9

SECTION 6 - CONTROLS BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

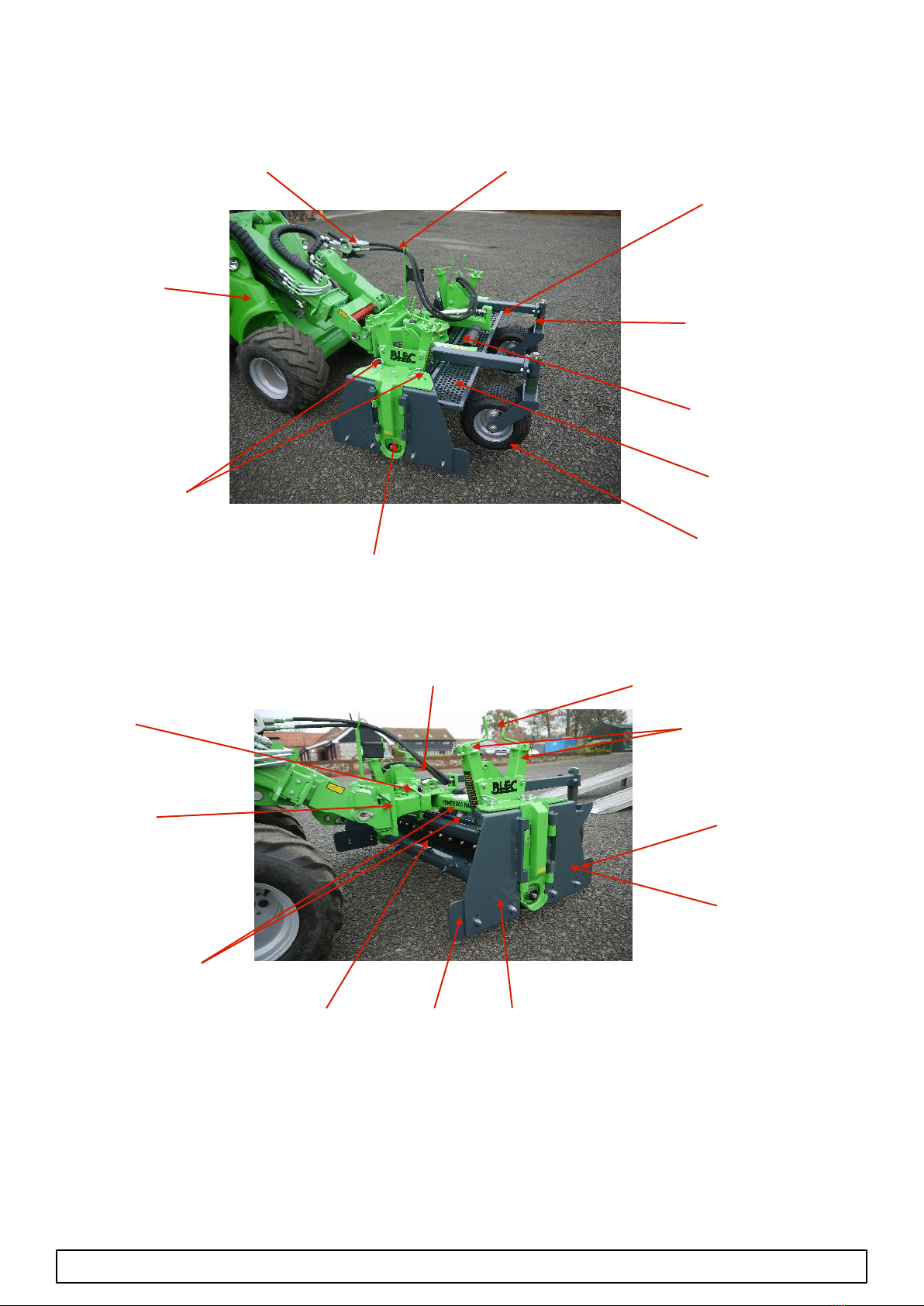

Avant

model 635

Depth control pivot

wheel shaft with

height spacers

Instruction

manual holder

Safety guards

Pivot pins for

side plates

Depth wheels &

Triple seal bearings tyres

Flow and return

hydraulic hoses Screw jack handles c/w

locking pins

Front & rear barrier

blade height control

Quick hitch screw jack adjuster

mounting

bracket Adjustable front

wear plate

Front side plate

Front & rear

barrier blades

Carbide Adjustable Rear side plate

tooth rear wear plate

rotor

Quick hose coupler system Hose support bracket

Lift up wheel arms

Pivot pin & bushes

10

SECTION 7 - PREPARING FOR USE BLEC POWER BOX RAKE

Models:PBR150H - PBR180H

ASSEMBLY

Your BLEC Power Box Rake will be delivered assembled and ready for use. Please check

mounting bracket is suitable for your machine, contact BLEC for advice.

11

SECTION 7 - PREPARING FOR USE

BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

MOUNTING TO LOADER - (see Photos 4 & 5)

1. Select a level hard surface - with the POWER BOX RAKE rotor and castor wheels

resting on the ground. Drive loader forward and position top mounting bars under

hook lift up until bars are fully under hook bracket. Then lift up and tilt until lower side

pins can be lined up with mounting bracket holes, lock in position.

Photo 4 Photo 5

Mounting bracket

Connect Power Box Rake twin hose adaptor quick coupler into loader adaptor coupler

and secure with handle raise up Power Box Rake rotor clear of ground and test

hydraulic circuit in both directions.

Your Power Box Rake is now ready for use.

To dismount carry out previous instructions in reverse order.

Mounting bracket

12

SECTION 8 - OPERATING BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

It is important to plan your work and to decide on your soil levels that need to be achieved and where

any surplus soil and debris are to be positioned. The Power Box Rake will effectively

loosen the soil, grade and rake all in one pass, however if you wish to cultivate the ground first

proceed as follows.

CULTIVATING

The carbide tooth rotor can be rotated in both directions depending on your direction of travel

simply move the loader valve lever in either direction. HOWEVER it is important not to change

direction simultaneously from forward to reverse without a pause to stop the rotor first.

Changing direction too fast can overload the hydraulic motor seals and shafts. BLEC CAN

NOT be held responsible for operator error and damage to the hydraulic motor.

The pointed rotor carbide teeth will penetrate the hardest of ground conditions, but is is important

to travel at a low speed of 1 - 2 kmph.

FIRST

Raise up both barrier blades as high as possible by winding the screw jack handles clockwise

until barrier blades are fully up (lock handles with pins and clips (see photo 6)

Photo 6

SECOND

Position rotor above ground with Power Box Rake frame in a horizontal position, engage rotor in the

opposite rotation to your travelling direction (ie contra rotating, then lower rotor into soil

normally 5cm) Set the depth control with the front castor wheels and the angle on the arms of the

loader. Engage auxiliary oil lever and then raise engine speed to 2000 rpm minimum to produce

sufficient rotor speed. The rotor teeth will be loosening and throwing soil back over the rotor

leaving loose soil to a depth of between 5 - 10cm. Carry on working in a pattern covering all the

required area.

Barrier blade

13

SECTION 8 - OPERATING BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

EARTH MOVING AND GRADING

The BLEC Power Box Rake will effectively move soil, stones and debris. This can be achieved as

follows

FIRST

Adjust down the barrier blades until the rubber edges are clear of the pointed teeth by approx

3 - 5cm (see photo 7)

SECOND

Make sure side plates are on and in the level position (see photo 8)

Photo 7 Photo 8

THIRD

Set the front wheel height so teeth can penetrate the soil only 10-20mm. To adjust wheel height,

re position the nylon spacers, to raise or lower the frame (see photo 9) always run the Power

Box Rake in a horizontal position.

FOURTH

Earth moving and grading can be carried out either in forward or reverse direction, IMPORTANT

Maintain a minimum engine speed of 1500 rpm with a travelling speed of 3-5km phr

FIFTHLY

The Power Box Rake is mounted on a frame with a central pivot (see photo 10). The Power Box

Rake frame can be locked in a fixed position with no float as in (photo 10) for working on level

ground. If required the frame can be set to float when working on uneven ground by simply

removing the black bushes and locking pins.

Photo 9 Photo 10

For working on uneven

ground the frame can

be allowed to pivot by

removing the black

painted spacer bushes

with locking pins

Barrier

blade

Side

Plates

14

SECTION 8 - OPERATING BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

RAKING

Accurate raking and clearing stones and debris can easily be carried out with the Power Box Rake

all as follows:-

Raking the soil is a skilled job, the operator must familiarise and gain experience. The rotor speed

and the travelling speed will depend on the conditions . The faster the rotor and the slower the

travelling speed the more smaller stones and debris and soil are raked up.

The slower the rotor speed and faster the travelling speed the less stones and soil are raked up and

so it is important a balance is achieved with rotor speed and travelling speed.

Setting the depth control with the wheels and the height control of the loader arms is important so

as to maintain a level clear finish, make sure the barrier blades rubber edges are set so they are

within 5mm of the pointed tips on the carbide teeth, which is easily achieved by adjusting the screw

jacks with the handles. The closer the rubber edges are to the teeth the more stones and debris

are raked to the side in a row, in your next pass make sure the row of stones and debris are in

between your loader wheels to keep the loader stable and level and by working in a sequence large

areas can be easily undertaken.

It is advisable to carry out the raking procedure in reverse to avoid running the loader wheels on the

finished area. It is important the operator checks frequently behind for any obstacles or

people in the work area

15

SECTION 8 - OPERATING cont.. BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

RAKING

Raking can be carried out in the following 2 ways:-

WINDROWING

The rake frame can be angled to the right or left by turning the screw link bar in or out

(see photo 11)

Photo 11 Photo 12

BLEC recommend angling the rotor approx 15º with the rotor drive side near to the loader wheels

as in photo 12. Then remove the side plate from the non drive side as in photo 13

Photo 13

Next position the side plate on the drive side to an angle using hole no 3 (see photo 14). When

working with this set up the surplus stones and debris will be raked to the side producing a

windrow.

Photo 14

Remove this side plate

Screw link bar

Rotor

drive side

Drive side plate

16

SECTION 8 - OPERATING cont. BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

Parallel Raking Set the Power Box Rake head parallel with the loader (see photo 15)

by adjusting the screw link bar (photo 11) make sure all 4 side plates are fitted . With the Power Box

Rake in this position the operator can travel forward or reverse raking the stones and debris in front

or to the rear the side plates keep the material inside stopping side spillage for finish raking BLEC

recommend travelling in reverse. It is important the operator checks frequently behind for any

obstacles or people in the work area.

photo 15

17

SECTION 8 - OPERATING cont. BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

TRANSPORTING

Always keep the Power Box Rake clear of the ground by a minimum of 30cm and make sure the

pivot bushes are back in position to (photo 10) stop the frame from swaying.

TRANSPORTING THROUGH A NARROW OPENING The Power Box Rake has been designed to

rotate through 90º to a vertical position keeping the width down within the loader dimensions (see

photo 16)

Photo 16 Photo 17

To adjust first remove both pins (photo 10) then raise up loader arms 1 metre off ground, then rotate

Power Box Rake frame until top bush lines up with bracket hose (see photo 17). Secure with pin

and clip.

TRANSPORTING ON A TRAILER / TRUCK To reduce the overall length of the Power Box Rake

the 2 wheel frame arms can be lifted up vertical (see photo 18/19). First remove pin from hole A lift

up arm and place in hole B and secure with clip

Photo 18 Photo 19

Hole B

Hole A

18

SECTION 9 - MAINTENANCE BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

To keep your Power Box Rake in a good working condition it is important to carry out regular

maintenance as follows:-

GREASING

ROTOR BEARING NON DRIVE END (see photo 20)

Photo 20

HYDRAULIC MOTOR ON DRIVE END (see photo 21)

Photo 21

PIVOT PINS ON FRAME (see photo 22)

Photo 22

Grease pins every 40 hours

or weekly.

Grease bearing only every 40 hours

or weekly.

DO NOT OVER GREASE

1 pump on hand gun is adequate.

No maintenance necessary

sealed bearings in motor

19

SECTION 9 - MAINTENANCE cont BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

CASTOR WHEEL - PIVOT SHAFTS (see photo 23)

Photo 23

SCREW JACK ADJUSTERS (see photo 24)

Photo 24

The box members are drilled with a

lubrication oil hole. Every 40 hours

apply oil through hole to lubricate threads

REGULAR MAINTENANCE INCLUDES checking the rotor for damaged teeth and end shafts for

wire/string etc. entering into bearings. Also regularly wash off and clean.

Make sure instruction manual is inside plate holder at all times.

SIDE WEARING PLATES (see photo 25)

Fitted to the side plates are adjustable and replaceable wear plates, the plates are normally set

with the bottom edge level with the rotor shaft tube, The wearing plates can be repositioned in

different holes when wear has taken place.

Photo 25

Grease every 40 hours or

Weekly.

Wheel bearings are sealed and

do not require greasing

Instruction manual holder

20

SECTION - 9 MAINTENANCE BLEC POWER BOX RAKE

Models: PBR150H - PBR180H

STORAGE

Please store, if possible, inside a building or cover with a sheet.

Make sure the machine is clean

Grease and lubricate regularly

Check all nuts and bolts

Check all oils

This manual suits for next models

1

Table of contents