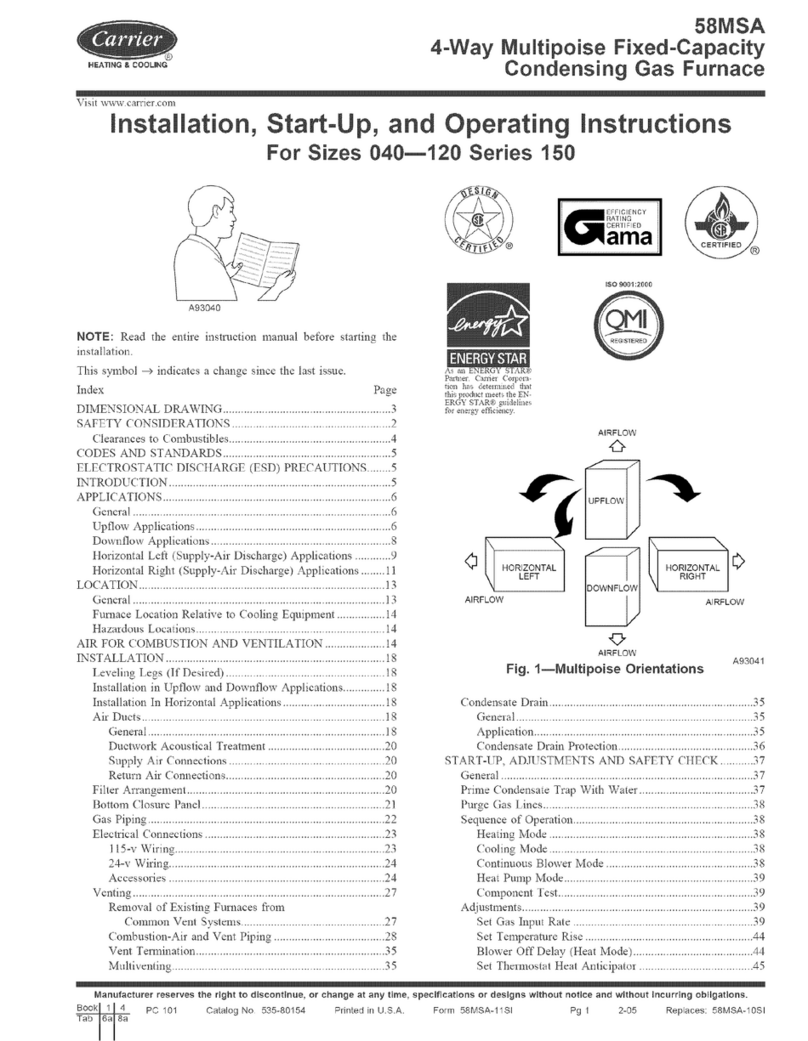

Table 3---Minimum Space Volumes for 100 % Combustion, Ventilation, and Dilution from Indoors

OTHER THAN FAN-ASSISTED TOTAL FAN-ASSISTED TOTAL

(1,000's BTUH INPUT RATE (1,000's BTUH INPUT RATE)

ACH 30 40 50 44 66 88 110 132 154

Space Volume (ft.3)

0.60 1,050 1,400 1,750 1,I00 1,650 2,200 2,750 3,300 3,850

0.50 1,260 1,680 2,100 1,320 1,980 2,640 3,300 3,960 4,620

0.40 1,575 2,100 2,625 1,650 2,475 3,300 4,125 4,950 5,775

0.30 2,100 2,800 3,500 2,200 3,300 4,400 5,500 6,600 7,700

0.20 3,150 4,200 5,250 3,300 4,950 6,600 8,250 9,900 11,550

0.10 6,000 8,400 10,500 6,600 9,900 13,200 16,500 19,800 23,100

0.00 NP NP NP NP NP NP NP NP NP

1. For other than fan-assisted appliances, such as a draft 2. For fan-assisted appliances, such as this furnace:

hood-equipped water heater:

Volume- 21_3( f- tother -) -15ft3 f 'fa_n L"'_j

Other Fan ACH 000 Btu/hrt

ACH L1000 Btu/hr Volume

A04002 A04003

Table 3-Minimum Space Volumes were determined by using the following equations from the National Fuel Gas Code ANSI

Z223.I-2002/NFPA 54-2002,8.3.2.2.

If:

Iother = combined input of all other than fan-assisted appliances in Btu/hr

If_n = combined input of all fan-assisted appliances in Btu/hr

ACH = air changes per hour (ACH shall not exceed 0.60.)

The opening shall commence within 12" (300 mm) of the ceiling.

Appliances in the space shall have clearances of at least 1" (25

mm) from the sides and back and 6"' (150 mm) from the front.

The opening shall directly communicate with the outdoors or

shall communicate through a vertical or horizontal duct to the

outdoors or spaces (crawl or attic) that freely communicate with

the outdoors.

Indoor Combustion-Air?) NFPA & AGA

STEP 3 --Standard- and Known-Air-Infiltration Rate

Methods

Indoor air is permitted for combustion, ventilation, and dilution

if the Standard- or Known-Air-Infiltration Method is used.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury

or death.

Many homes require air to be supplied from outdoors for

furnace combustion, ventilation, and dilution of flue gases.

The furnace combustion air supply must be provided in

accordance with this instruction manual.

The Standard Method:

1. The space has no less volume than 50 cubic feet per 1,000

Btuh of the maximum input ratings for all gas appliances

installed in the space and

2. The air infiltration rate is not known to be less than 0.40

air changes per hour (ACH).

The Known-Air-Infiltration Rate Method shall be used if the

infiltration rate is known to be:

1. Less than 0.40 ACH; and

2. Equal to or greater than 0.10 ACH.

Infiltration rates greater than 0.60 ACH shall not be used. The

minimum required volume of the space varies with the number of

ACH and shall be determined per Table 3 or equations 1 and 2.

Determine the minimum required volume for each appliance in

the space and add the volumes together to get the total minimum

required volume for the space.

The following requirements apply to the Standard Method and

to the Known-Air-Infiltration Rate Method.

1. Adjoining rooms can be considered part of aspace if:

a. There are no closable doors between rooms.

b. Combining spaces on same floor level. Each opening

shall have free area of at least 1 in.2/1.000 Btuh (2,000

mm-/kW) of the total input rating of all gas appliances in

the space, but not less than 100 in. 2 (0.06 m2). One

opening shall commence within 12" (300 mm) of the

ceiling and the second opening shall commence within

12" (300 mm) of the floor. The minimum dimension of

air openings shall be at least 3 in. (80 mm). (See Fig. 5.)

c. Combining space on different floor levels. The volumes

of spaces on different floor levels shall be considered as

communicating spaces if connected by one or more

permanent openings in doors or floors having free area of

at least 2 in.2/1,000 Btuh (4,400 mm2_W) of total input

rating of all appliances.

2. An attic or crawl space may be considered a space that

freely communicates with the outdoors provided there are

adequate permanent ventilation openings directly to

outdoors having free area of at least 1-in.2/4,000 Btuh of

total input rating for all appliances in the space.

3. In spaces that use the Indoor Combustion-Air Method.

infiltration should be adequate to provide air for combus-

tion, permanent ventilation and dilution of flue gases.

However. in buildings with unusually tight construction.

additional air MUST be provided using the methods de-

scribed in the Outdoor Combustion-Air Method section.

Unusually tight construction is defined as construction

with:

a. Walls and ceilings exposed to the outdoors having a con-

tinuous, sealed vapor barrier. Openings are gasketed or

sealed; and