4

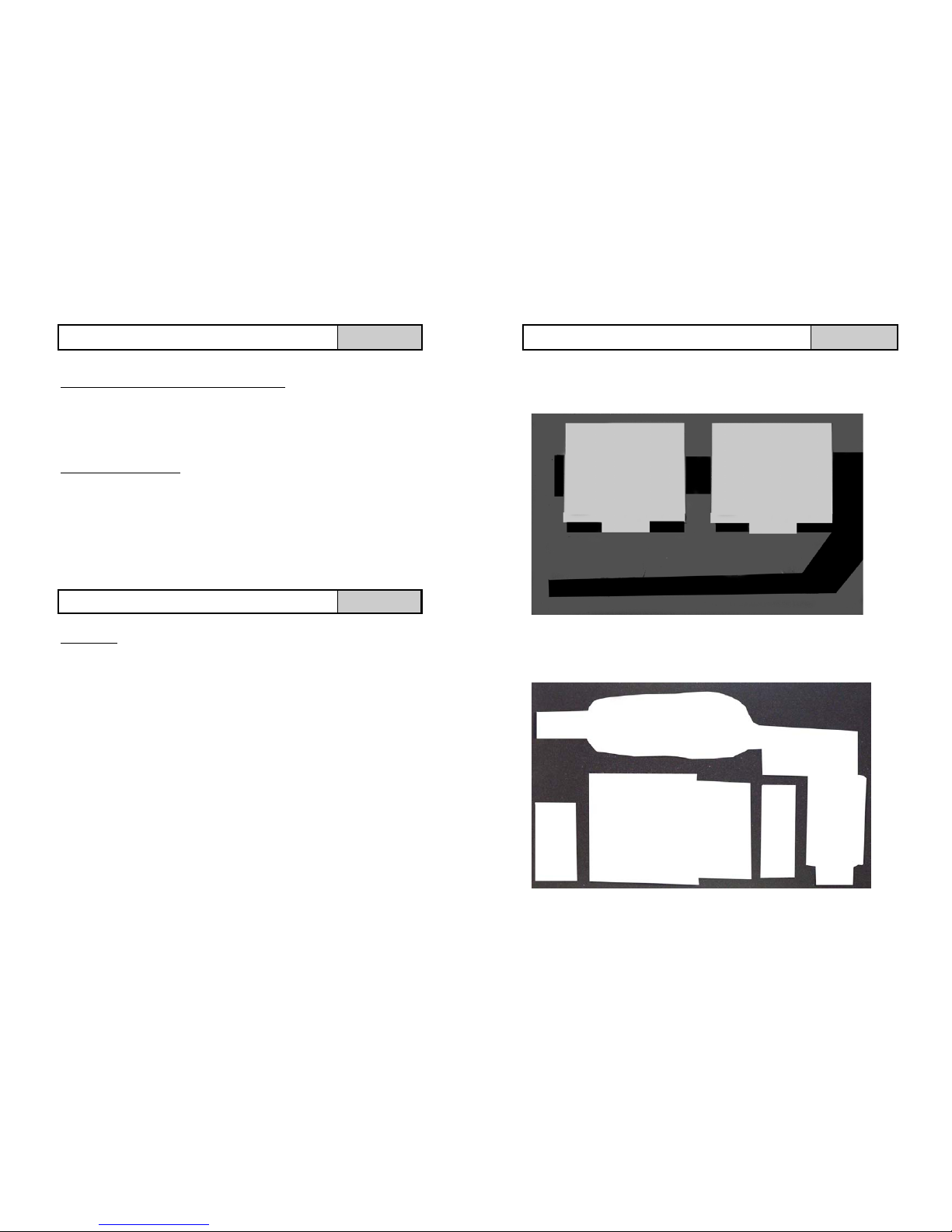

Control Box

The control box sits inside the case and houses the electronics. The control box

should not be opened by anyone other than an approved Castle service engineer.

The isolation switch should be ON (indicating BLUE) when the case is in use and

switched off when the case is not in use,

for safe storage and to prevent battery

discharge.

The LED on the control box will illuminate

RED when the Charger is plugged in.

The LED will illuminate GREEN when an

external Battery Pack or external Power

Supply is plugged into the case.

If the LED illuminates AMBER then both the

Charger and External Power are being

used.

CAUTION:

Never use the ISOLATION switch to Turn OFF the instruments, always

shut down as outlined in the instruments operating manual. Doing so may result

in data loss or corruption.

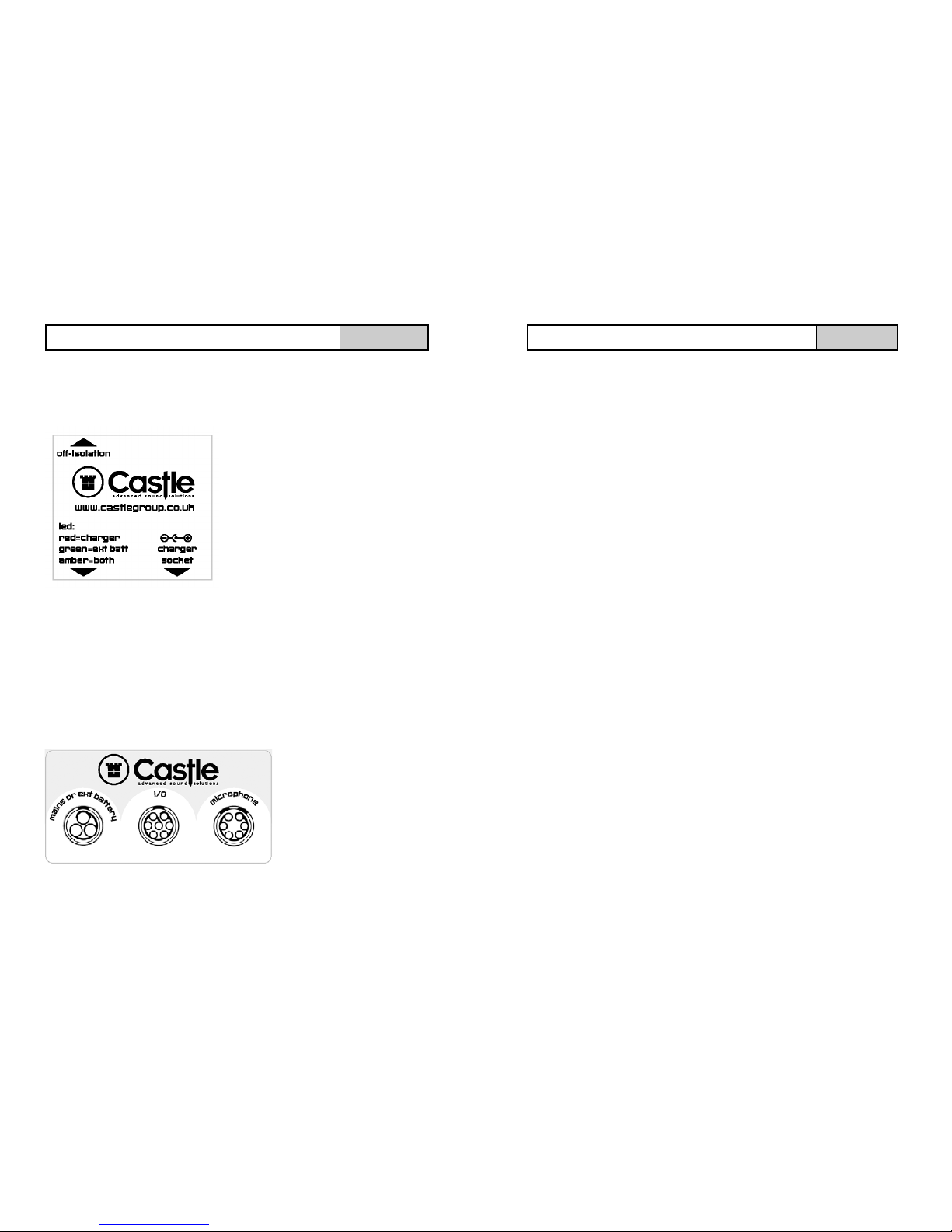

Case Sockets

DO NOT TWIST PLUGS TO CONNECT OR DISCONNECT FROM THE KA018

No turning is required to fit or remove a plug, simply push to fit or pull to

remove.

Please note that each socket is keyed, to fit a plug line up the RED identification

mark on both the socket and

plug.

Plugs will only fit into the

correct sockets. Plugs should

not be forced or damage to the

connector pins may occur.

CASE CONNECTORS AND CONTROL BOX ALL

This section is a guide highlighting the procedure required to make

recordings. It is required that you read this manual fully and refer to

other manuals as required.

Ensure that the 12V batteries are connected or alternatively if you wish to

power the KA018 kit from the mains plug the power lead into the socket

labelled ‘mains or ext battery’.

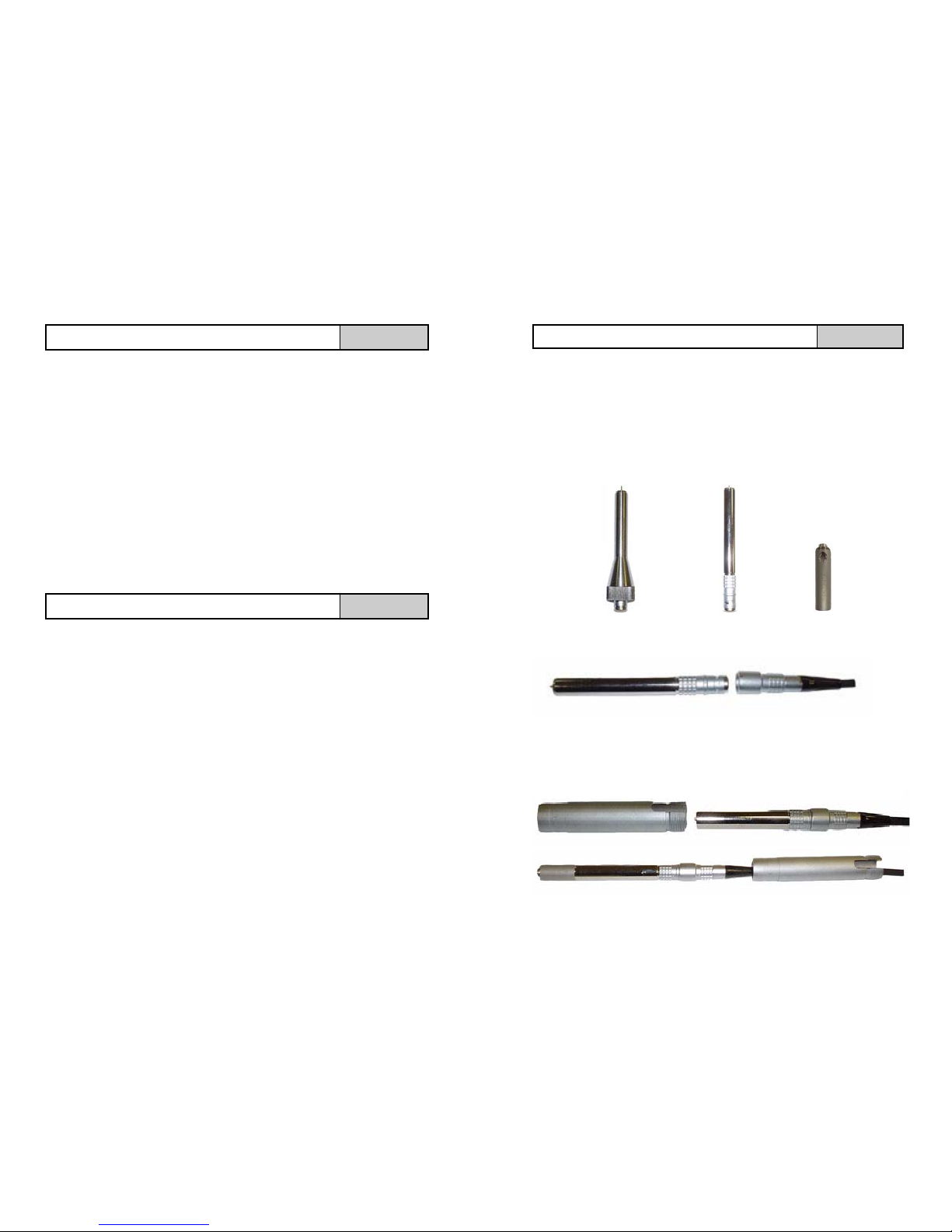

Plug your microphone into the microphone extension lead and attach the

microphone to the MW400 as described on page 14. Now attach the

microphone extension lead into the socket labelled ‘microphone’ on the

KA018 case.

Plug the DAT Remote Switch into the socket labelled ‘I/O’ on the KA018

case.

Switch the control box Battery Isolation Switch to ON (indicating Blue) if you

are powering your kit via the mains this switch position is overridden.

Power on the Pro DX Sound Level Meter and proceed to calibrate the

instrument as described on page 7.

Set the Clock as described on page 8 and then record a Reference Tone on

the tape as described on page 9.

Set the range on your Pro DX Sound Level Meter to the initial recommended

range of 15 – 90dB as described on page 10.

Set the weightings on your Pro DX Sound Level Meter to the recommended

settings as described on page 11.

Activate the DAT option on the Pro DX Meter and select the sound level to

automatically start recording on the DAT machine. This procedure is

described on page 12. An initial recommended level for automatic recording

is 85dB.

Close your KA018 case lid and ensure that the air valve near the case handle

is not fully tightened.

Finally position the KA018 kit / cables and microphone in a safe and secure

manner such as to minimise any possible hazard and leave to record.

PROCEDURE FOR NOISY NEIGHBOUR RECORDING DAT

17