CHEMCHAMP A18 User manual

MODEL A18

SOLVENT RECOVERY SYSTEMS

(EXPLOSION PROOF UNITS)

FOR PROPER AND SAFE USE OF THIS CHEMCHAMP

EQUIPMENT, PLEASE FOLLOW THIS DOCUMENT AND LOCAL

AUTHORITY.

KEEP THIS DOCUMENT FOR FUTURE REFERENCE.

Revision: 122203

TE

CHNICAL DATA:

MODEL:

CHEMCHAMP A18

CLASSIFICATION:

CLASS 1, DIVISION 1,

GROUPS C, D, E, F, G

ELECTRICAL PROTECTION:

INTRINSIC PROTECTION &

EXPLOSION PROOF ENCLOSURES

FUSE PROTECTION:

30 AMP DELAYED ACTION

VOLTAGE:

240 VAC, SINGLE PHASE,

50 or 60 Hz

AMPERAGE:

20 AMP

POWER:

4.2 kW

CAPACITY:

18 US GALLONS (68.14 litres)

OPERATING TEMPERATURE:

53.6 to 379.4 FAHRENHEIT

(12° CELSIUS TO 193° CELSIUS)

SAFETY THERMOSTATS:

ELEMENT: 395 Fahrenheit

(ELEMENT: 202° CELSIUS)

MATERIAL (DIST

ILLATION CHAMBER):

STAINLESS STEEL

PATENT PENDING PROCESS:

1) VAPOR MANAGEMENT SYSTEM.

2) PROCESS CONTROL METHOD.

3) ANTI

-

PRESSURE SYSTEM.

4) DIRECT CONDENSATION METHOD.

DIMENSIONS:

LENGTH:

82 Inches (208 cm)

HEIGHT:

67 Inches (170 cm)

WIDTH:

30.5 I

nches (77.5 cm)

DISTILLATION TIME:

6

-

10 HOURS

COOL DOWN TIME:

9-

12 HOURS.

INTRODUCTION:

In dealing with liquid hazardous waste companies have had to pay a costly rate for pick-

up

and repurchase of new chemicals for their process. This recycler reduces these costs.

The means of accomplishing the above is through a process known as distillation. Each

group of chemicals has a vapor temperature, which we utilize to separate from

contaminants. This unit is explosion proof, which means it can be used for flammable and

non

-

flammable solvents ranging from acetone to water.

SAFETY FEATURES:

The unit comes equipped with the following patent pending safety features:

A)

Automated temperature and time setting. The unit will automatically set its own time

and temperature in accordance with the requirements of the particular solvent or

solvents poured into its distillation chamber for recycling. The result being the

operator only needs to pour the solvent in and press START .

B)

Oil immersion

element.

C)

Element control and safety probes.

D)

Oil maintenance timer and indicator. The unit will automatically indicate when oil

requires to be changed. If oil is not changed within a safe time period, the unit will

automatically shut down indicating the word OIL on its display panel until oil is

changed. This ensures proper and safe operation of the unit for years to come.

E)

Intrinsically safe controls.

F)

Self

-

cooling condensation drum.

G)

A superior vapor management system. The vapor management system limits VO

C

emissions during distillation, resulting in a safe healthy working environment with an

ultimate recovery of solvent.

H)

OFF button for manual shut off at any time. If the unit is in cycle and the stop

button is pressed the unit will shut off and automatically go into cool down mode

with yellow light flashing and digital displaying temperature until the unit reaches

134.6

Fahrenheit (57° Celsius). The yellow light and display will turn off and green

light will come on indicating unit is safe to open and re

-

start cycle.

I)

Automatic shut off when cycle is complete.

J)

Unit operates at zero pressure. Cover will release at 0,15 Bar (2 PSI).

L)

Temperature Probes check each other 256 times per second to ensure the other is

working within 50 degrees Fahrenheit (10 deg

rees Celsius) of itself.

M)

Temperature Probes are linked to an Analog circuit as well as the microprocessor.

In the event the processor malfunctions, the Analog circuit will turn the unit off at

395 degrees Fahrenheit (202 degrees Celsius) until the unit

cools.

N)

Fuse Protection.

O)

Overfill protection. Float sensor automatically shuts elements down in the event

that the collection drum becomes overfull and displays Er10 .

PLEASE NOTE THE FOLLOWING:

1.

This unit is designed to distill solvent with a boiling temperature less than 356 degrees

Fahrenheit (180 degrees Celsius).

2.

This unit should never be used to distill any chemical with an auto-ignition temperature

below 437 degrees Fahrenheit (225 degrees Celsius). Before initiating the distillatio

n

process always consult the appropriate chemical data sheet.

3.

The distilled solvent must be collected in the drum provided with unit, caution should be

taken that solvent not be accidentally spilled.

4.

If distilling water, system must be flushed of all solv

ents prior to operation.

5.

NITROCELLULOSE must

never

be distilled in this unit, as this may cause conditions of

danger.

6.

Residues must be disposed of in accordance to local laws.

7.

When cleaning residues from unit use only non

-

sparking tools.

8.

Opening cover befo

re allowed time will cause gasket swelling & dislocation.

9.

Operators should wear anti

-

static clothing.

10.

Operating staff must be fully educated on the safe and correct use of unit and

protection devises.

11.

Gasket of the lid is to be replaced every 2 years.

12.

Thi

s unit is not equipped with a plug, the proper connection must be implemented in

accordance with the local authority.

13.

Unit must be operated with the provided collection drum connected to the condensation

drum. (see figure 1)

FAILURE TO FOLLOW ANY OF THE ABOVE COULD CAUSE PERSONAL INJURY

AND PROPERTY DAMAGE.

INSTALLATION OF UNIT:

Figure 1

1.

LOCATION:

Caution- To reduce the risk of fire or explosion, install, operate, and

maintain this equipment in accordance with this instruction manual. This unit is for use

in 104oF (40oC) environment with no forced ventilation. Under these conditions, the

unit shall be spaced a minimum 3 feet (0.914m) from potential sources of ignition such

as electrical receptacles, switches, pilot lights, fixtures, contacts, and other similar

equipment that can produce sparks. If the equipment is used in higher ambient

temperatures, an increase in spacing to sources of ignition shall be considered. This

unit has only been investigated for use with solvent with a maximum ignition

temperature of 437

o

F (225

o

C).

This unit is designed for use in Class 1, Division 1. Note: This unit is not equipped

with a plug, the proper connection must be implemented in accordance with the local

authority.

2.

ELECTRICAL REQUIREMENTS:

The A18 unit is to be either plugged or wired into an

electrical source with 200

250 volts and on a 25 amp circuit.

3.

OIL AIR RELEASE VALVE: Open front door and replace oil cap marked with an X

with oil cap found in distillation chamber. The oil cap in distillation chamber has a hole

in center of cap.

4.

PREPARING THE CONDENSATION

DRUM:

The condensation drum acts as the main

means for condensing the distilled vapors. The condensation drum is shipped empty

and must be filled with the intended solvent (the solvent that will be distilled in the unit)

1.

Vent mount

2.

Lid clamp

3.

Lid

4.

Condenser column

5.

Front door

6.

Condensation drum

fill hole

7.

Condensation drum

8.

Collection drum

prior to operation. Remove the 2 plug from the condensation drum fill hole. Pour 36

gallons of intended solvent into hole using a funnel (not provided). Unit can be over

filled and then drained to the correct level by connecting the collection can and fully

draining any excess.

Be sure to empty collection can prior to operating unit.

5.

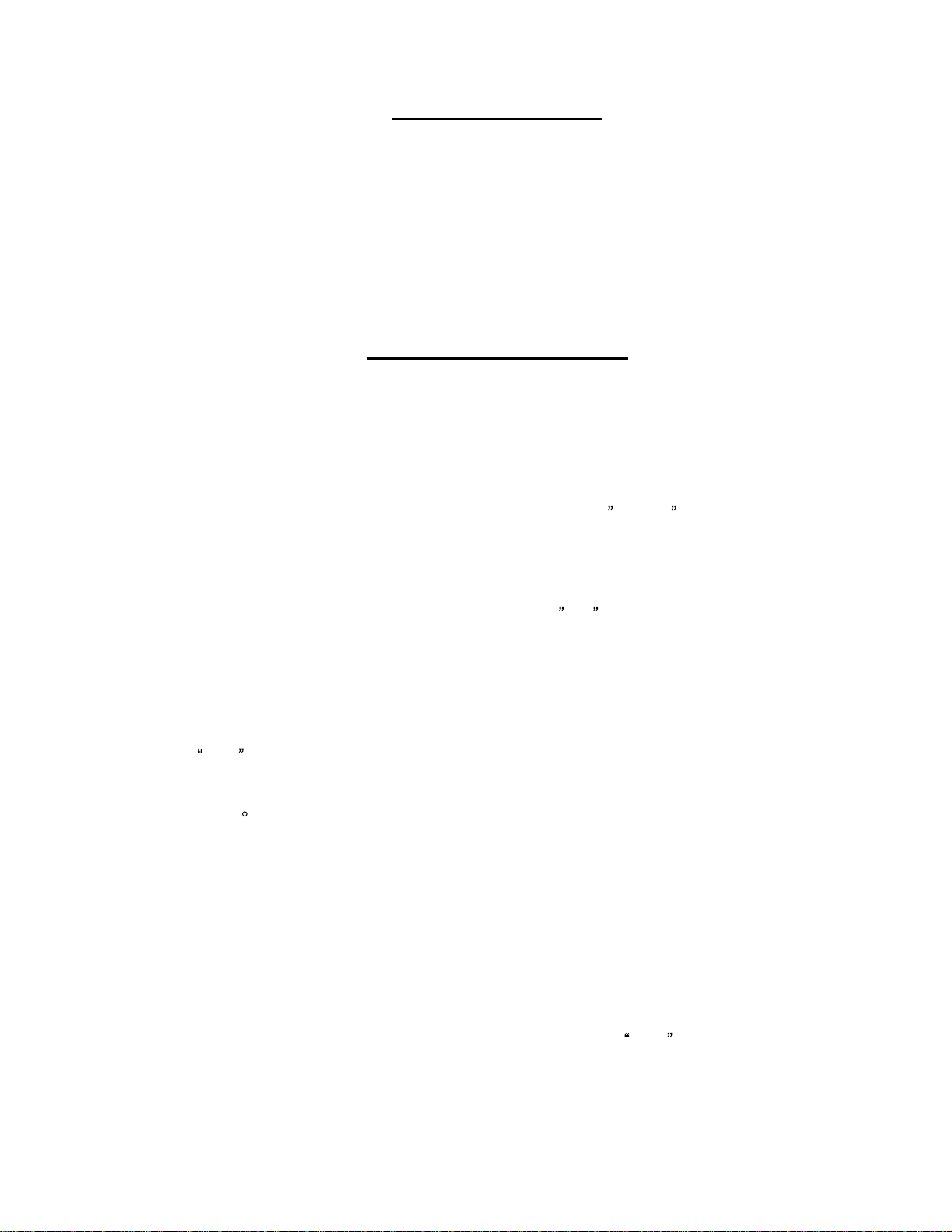

PREPARING CONDENSER COLUMN (MAGIC BOX) AND CONNECTING THE

VENT: The condenser column or magic box acts as a vent for the system and as a

secondary condensing module. The condenser column is shipped empty and must be

filled with tap water prior to operation. Rotate the column lid, pour water into container

until water level is 1 below top of container. Replace lid and attach vent hose to vent

mount on column (see figure 2). Attach other end of vent hose to a formidable vent

away from any source of ignition.

Figure 2

6.

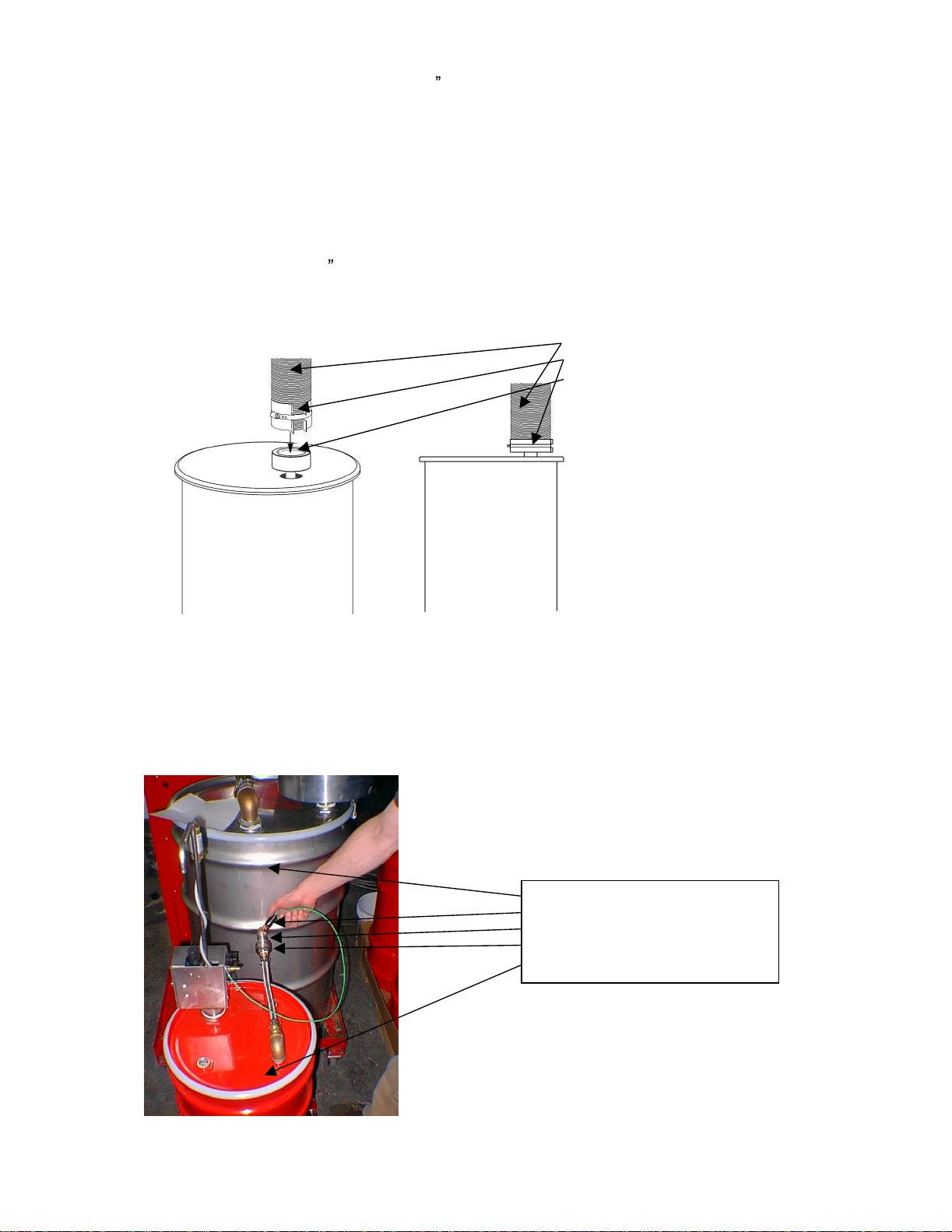

ATTACHING COLLECTION DRUM: The collection vessel is a fully mobile unit

complete with its own pump and grounding attachment. The collection vessel must be

connected to the condensation drum via the solvent line quick-connect and the

grounding clamp attached to the condensation drum connector prior to each cycle (see

figure 3).

Figure 3

1.

Condensation drum

2.

Grounding attachment

3.

Condensation drum connector

4.

Solvent line quick connect

5.

Collection drum

VENT HOSE

VENT CLAMP

VENT MOUNT

7.

GET

TING READY: Connect power. Press START button and green light will come

on. The green light signifies the unit is ready to work and is safe to open.

INSTALLATION OF BAGS:

1.

Open cover.

2.

Remove bag holder.

3.

Open bag and place inside bag holder.

4.

Fold t

op of bag over the top ring of bag holder.

5.

Squeezing top ring, fit bag holder and bag into unit making sure bag is held open once

installed.

6.

Make sure bag is under the vapor manifold, and waste intake valve making sure they

are not blocked or covered (see figure 4).

Figure 4

7.

Pour solvent waste into receptacle bag. Maximum level is 1.5 Inches (3.8 cm) below

top of bag holder. The unit is designed for a maximum volume of 18 US Gallons (68.14

litres).

Over filling will result in overflow into vapo

r manifold resulting in dirty recycled solvent.

Over filling will also cause paint getting in behind the bag. This will make it difficult to

remove the bag, as the paint will act as glue making the bag stick to the bottom. If sticking

happens press START

and let unit warm up for 5 minutes. Press OFF and gently pull

bag out.

We recommend the use of CHEMCHAMP BAGS; other types of bags may deteriorate

during cycle and create a hard residue at the bottom of distillation chamber that will

be difficult to remove.

1.

Lid

2.

Distillation chamber

3.

Waste bag

4.

Bag

holder (behind

waste bag)

OPERATION OF UNIT:

1.

Connect power.

2.

Press START button and green light will come on. The green light signifies the

unit is ready to begin a new batch and is safe to open.

3.

Open lid.

4.

Remove bag holder.

5.

Place new waste

bag inside holder.

6.

Fold overlap of bag over the top of the holder.

7.

Place bag and holder inside distillation chamber.

8.

Pour a maximum of 18 US Gallons (68.14 litres) of waste solvent into bag, making

sure not to pour any liquid into outlet manifold or behind waste bag. The maximum

level is 1.5 Inches (3.8 cm) below the top of the bag holder

9.

Close lid and clamp the lid clamp down.

10.

Ensure collection drum is empty and properly connected to the condensation drum

(see figure 3).

11.

Press START , yellow light and digital display will come on. The display shows the

temperature of the thermal oil.

12.

Green light will stay on with yellow light until temperature of the thermic oil reaches

140 degrees Fahrenheit (60 degrees Celsius). At this point the green light will turn

off. Unit will automatically set temperature and time in accordance to the solvent or

solvents to be recycled.

13.

Once distillation is complete the unit will automatically shut off and the yellow light

will begin flashing indicating the unit is OFF and is cooling down. The yellow light

will flash until the unit has fully cooled. At this point the yellow light and the digital

display will turn OFF and the unit is ready for the next cycle. The green light will

come on once the unit is safe to open.

14.

Open cove

r and remove bag residue. Place residue bag into proper collection drum.

* Please note that by using bags in the distillation chamber, you eliminate the cleaning

process.

** Please use necessary safety precautions when following these steps.

*** Very Im

portant: Eye wear, boots, gloves and masks should be worn at all times.

****CAUTION: Unit surfaces will be hot when in use.

*****Cover should not be open unless green light is on.

******Waste bag should be changed between each cycle.

OIL MAINTENANCE:

OIL CHANGE

The unit will automatically indicate it requires an oil change by flashing the word OIL on

its display panel.

1.

Disconnect power.

2.

Open front door of unit.

3.

Remove top and middle oil cap.

4.

Place collection pan under Oil Drain.

5.

Remove bottom oil cap & drain.

Caution:

Make sure when emptying oil that the unit is

completely cooled

6.

Replace bottom oil cap.

7.

Hang a collection pail on middle oil nipple.

8.

Using a flexible funnel, refill oil with ChemChamp Heating Oil through top oil nipple. Fill

unit unt

il oil begins to drain from middle oil nipple.

9.

Allow excess to fully drain from middle oil nipple.

10.

Replace middle and top oil caps, NOTE: the top oil cap has a hole in it.

11.

Reconnect power.

12.

Press the START button for 20 seconds. All lights will come on and the screen will

display Clr and then 8888 , indicating self-diagnostic and reset of unit is complete.

13.

Disconnect power.

14.

Reconnect power and you are ready to set the unit for solvent or water mode.

OIL TOP

-

UP

1.

Disconnect power.

2.

Open front door of uni

t.

3.

Remove top and middle oil cap.

4.

Using a flexible funnel, refill oil with ChemChamp Heating Oil through top oil nipple. Fill

unit until oil begins to drain from middle oil nipple.

5.

Allow excess to fully drain from middle oil nipple.

6.

Replace middle and top

oil caps, NOTE: the top oil cap has a hole in it.

7.

Reconnect power.

COLLECTION DRUM:

The collection drum provided with unit is the only vessel to be used for collection of

distilled solvent. This drum holds a maximum of 18 US Gallons (68.14 litres). It is fully

mobile and has its own pump. The pump is pneumatically powered and is operated with a

push button. The unit must be connected to an air supply of at least 80 psi for the pump to

function properly. The collection drum comes equipped with a grou

nding clamp to connect

the unit to a suitable ground whenever stationary.

The collection drum must be empty and connected to the condensation drum via the

solvent line quick connect for the duration of a distillation cycle. The collection drum must

be

attached to a suitable ground during a cycle. The condensation drum connector is a

suitable ground.

TROUBLE SHOOTING:

Problem

Reason

Solution

Bag hard to pull out.

-

Dirty Inner Bucket.

- Turn machine on until

it reaches 131

degrees Fahrenheit

(55 degrees Celsius),

remove bag and

clean.

Machine will not

come on.

-

Surge in power.

-

Replace fuse or fuses

in explosion proof

box.

Dirty Distillate.

Rust colored solvent.

-

Dirty manifold.

-

Dirty collection drum.

-

Rusty drum.

-

Clean manifold.

-

Replace or clean

drum.

-

Replace collection

drum.

Gasket swelling and

dislocating.

-

Lid was opened

before unit finished its

cool down mode.

-

Replace gasket

immediately.

Control panel error

message.

-

System failure.

-

Take note of error

message number i.e.)

Er01.

-

See error cod

e

section on following

page.

-

Contact ChemChamp.

Waste residues are

becoming soupy

-

Unit low on oil

-

Top unit up with oil

- See OIL

MAINTENANCE

SECTION

Unit smells during

operation

-

Increased vapor

losses

-

Add water to

condensation column

ERROR MESSAGES

CODE

ERROR

Er01

Probe 1 fault (Invalid temperature values). Room temperature is less

than 50 Fahrenheit

Er02

Probe 2 value too different from probe 1.

Er03

Probe 1 value too different from probe 2.

Er04

Over temperature fault (Hardware overte

mp trip).

Er05

Over temperature fault (From A/D read).

Er10

Condensation drum is overfull. Either the collection drum is full and

needs to be emptied or the collection drum is not connected during

cycle.

Table of contents