Chongqing Huansong HS700 Manual

FOREWORD

Brief introduction to maintenance handbook of

HS700/600/500ATV

The handbook is edited by Technical Center of Chongqing Huansong Industries

(Group) Co., Ltd., and is supplied to dealers and technicians as document of technique.

Mainly, the handbook gives methods to check, maintain and repair four wheel

all-terrain vehicles (ATV), and supplies some relevant technique and performance data.

Some techniques and method inside may be used to check, maintain and repair other

models of ATV, although it is mainly for HS700ATV.

Please read the handbook through and fully understand it; otherwise, any improper

repairing and amounting would bring you problems, and accident may occur in your use.

Proper use and maintenance can guarantee ATV being driven safely, reduce its

malfunction, and help the vehicle remain its best performance.

The standards, performances and specifications mentioned in interpretation are

based on the sample in design, and they are subject to changes according to the

product's improvement without prior notice.

Third version ,Apri1,2011

Published by Chongqing Huansong Industries (Group) Co., Ltd.

Chongqing Huansong Industries (Group) Co., Ltd holds the copy right.

No publishing and reprinting without permission.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

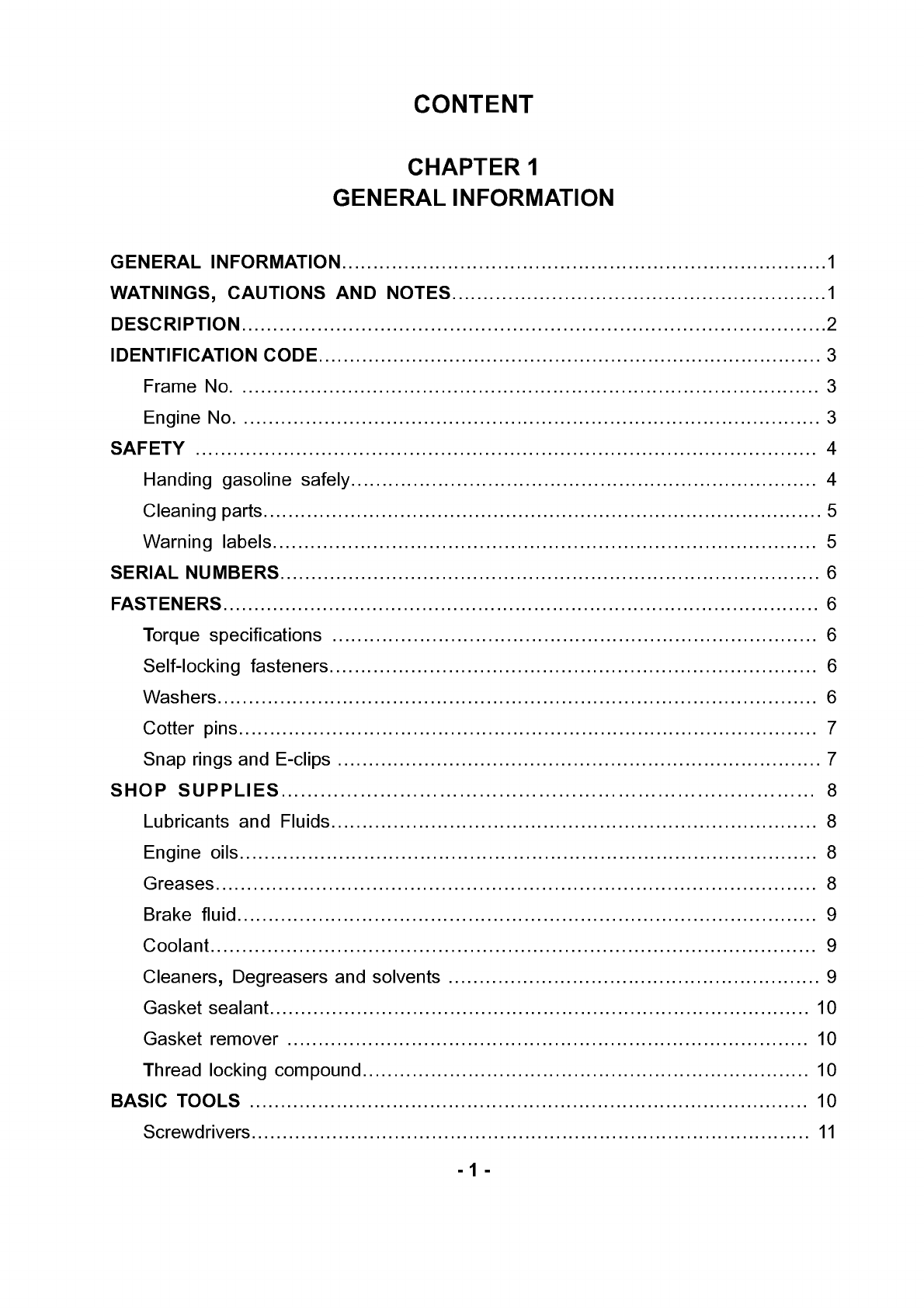

CONTENT

CHAPTER 1

GENERAL INFORMATION

GENERAL INFORMATION 1

WATNINGS, CAUTIONS AND NOTES 1

DESCRIPTION 2

IDENTIFICATION CODE 3

Frame No. 3

Engine No. 3

SAFETY 4

Handing gasoline safely 4

Cleaning parts 5

Warning labels 5

SERIAL NUMBERS 6

FASTENERS 6

Torque specifications 6

Self-locking fasteners 6

Washers 6

Cotter pins 7

Snap rings and E-clips 7

SHOP SUPPLIES 8

Lubricants and Fluids 8

Engine oils 8

Greases 8

Brake fluid 9

Coolant 9

Cleaners, Degreasers and solvents 9

Gasket sealant 10

Gasket remover 10

Thread locking compound 10

BASIC TOOLS 10

Screwdrivers 11

1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Wrenches 12

Adjustable wrenches 12

Socket wrenches, ratchets and handles 13

Impact drivers 13

Allen wrenches 14

Torque wrenches 14

Torque adapters 14

Pliers 16

Snap ring pliers 16

Hammers 16

Ignition grounding tool 17

PRECISION MEASURING TOOLS 17

Feeler gauge 17

Calipers 18

Micrometers 18

Adjustment 19

Care 20

Metric micrometer 20

Standard inch micrometer 21

Telescoping and small bore gauges 22

Dial Indicator 22

Compression gauge 23

Multimeter 23

ELECTRICAL SYSTEM FUNDAMENTALS 23

Voltage 24

Resistance 24

Amperage 24

BASIC SERVICE METHODS 24

Removing frozen fasteners 26

Removing broken fasteners 26

Repairing damaged threads 26

Stud Removal/Installation 27

Removing hoses 27

Bearings 27

2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Removal 28

Installation 29

Interference fit 29

Seal replacement 31

STORAGE 31

Storage area selection 31

Preparing the motorcycle for storage 32

Returning the ATV to service 32

TROVBLESHOOTING 32

ENGINE PRINCIPLES AND OPERATING REQUIREMENTS 33

STARTING THE ENGINE 34

Engine is cold 34

Engine is warm 34

Starting the engine after a fall or after the engine stalls 34

Flooded engine 34

Engine cold with air temperature 35

Engine cold with air temperature above 35°C (95° F) 35

Cold engine with air temperature below 10 °C(50° F) 35

Engine is hot 36

Starting the engine after a fall or after the engine stalls 36

Flooded engine 36

ENGINE WILL NOT START 37

Identifying the problem 37

Spark test 38

Starter does not turn over or turns over slowly 39

POOR ENGINE PERFORMANCE 39

Engine starts but stalls and is hard to restart 39

Engine backfires, cuts out or misfires during acceleration 39

Engine backfires on deceleration 40

Poor fuel mileage 40

Engine will not idle or idles roughly 40

Low engine power 41

Poor idle or low speed performance 42

Poor high speed performance 42

3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

FUEL SYSTEM 43

Rich mixture 43

Lean mixture 43

ENGINE 44

Engine smoke 44

Black smoke 44

Blue smoke 44

White smoke or steam 44

Low engine compression 44

High engine compression 45

Engine overheating (cooling system) 45

Engine overheating (engine) 45

Preignition 46

Detonation 46

Power loss 46

engine noises 46

ENGLNE LUBRICATION

HIGH OIL CONSUMPTION OR EXCESSIVE 47

Exhaust smoke 47

Low oil pressure 47

High oil pressure 48

No oil pressure 48

Oil level too low 48

Oil contamination 48

CYLINDER LEAK DOWN TEST 48

ELECTRICAL TESTING 51

Preliminary checks and precautions 51

Intermittent problems 52

Electrical component replacement 53

Test equipment 53

Ammeter 53

Self-powered test light 53

Ohmmeter 54

Jumper wire 54

4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

TEST PROCEDURES 55

Voltage test 55

Voltage drop test 55

Peak voltage test 56

Continuity test 56

Testing for a short with a self-powered test light or ohmmeter 57

Testing for a short with a test light or voltmeter 57

BRAKE SYSTEM 57

Soft or spongy brake lever or pedal 57

Brake drag 59

Hard brake lever or pedal operation 59

Brake Grabs 59

Brake squeal or chatter 60

Leaking brake caliper 60

Leaking master cylinder 60

CHAPTER 2

SPECIFICATIONS

HOW TO USE CONVERSION TABLE OF UNIT 61

How to use conversion table 61

Definition of unit 61

GEBERAR SPECIFICATIONS 62

ENGINE SPECIFICATIONS 65

CHASSIS SPECIFICATIONS 71

ELECTRICAL SPECIFICATIONS 72

TIGHTENING TORQUES 75

Engine tightening torques 75

Chassis tightening torques 78

GENERAL TIGHTENING TORQUE SPECIFICATIONS 81

LUBRICATION PIONTS AND LUBRICANT TYPES 82

Engine 82

Chassis 83

HYDROGRAPHIC CHART 84

5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

LUBRICATION OIL WAY 85

CHAPTER 3

MAINTENCE AND ADJUSTMENT OF THE ATV

MAINTENANCE SCHEDULE 86

ENGINEAdjusting the valve clearance 88

Idle adjustment 90

Adjusting the throttle cable 91

Adjusting the starter cable 92

Checking the spark plug 93

Checking the ignition timing 93

Measuring the compression pressure 95

Checking the engine oil level 96

Changing the engine oil 97

CHASSIS

Cleaning the air filter 100

Checking the coolant level 101

Changing the coolant 102

Checking the coolant temperature warning light 105

Checking the v-belt 106

Cleaning the spark arrester 107

Adjusting the brake pedal 108

Checking the brake fluid level 109

Checking the front brake pads 110

Checking the rear brake pads 110

Checking the brake hoses and brake pipes 111

Bleeding the hydraulic brake system 111

Adjusting the select lever shift rod 113

Adjusting the brake light switch 113

Checking the final gear oil level 114

Changing the final gear oil 114

Checking the differential gear oil 115

6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Changing the differential gear oil 115

Checking the constant velocity joint dust boots 116

Checking the steering system 117

Adjusting the toe-in 117

Adjusting the front shock absorbers 119

Adjusting the rear shock absorbers 119

Checking the tires 120

Checking the wheels 121

Checking and lubricating the cables 122

ELECTRICAL

Checking and charging the battery 123

Adjusting the headlight beam 129

Changing the headlight bulb 129

Changing the tail/brake light bulb 130

CHAPTER 4

ENGINE

ENGINE NOTE 132

ENGINE REMOVAL 133

CYLINDER HEAD AND CYLINDER HEAD COVER 135

ROCKER ARMS AND CAMSHAFT 140

VALVES AND VALVE SPRINGS 146

CYLINDER AND PISTON 152

ENGINE COOLING FAN AND A.C. MAGNETO 156

BALANCER GEARS AND OIL PUMP GEARS 160

PRIMARY AND SECONDARY SHEAVES

Primary and secondary sheaves 163

Primary sheave 164

Secondary sheave 165

CLUTCH 170

CRANKCASE

Starter motorand oil filter 174

Crankcase 175

7

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Crankcase bearings 176

CRANKSHAFT AND OIL PUMP

Crankshaft and oil pump 181

Oil pump 182

TRANSMISSION

Transmission 184

Drive axle assembly 185

MIDDLE GEAR

Middle drive shaft 189

Middle driven shaft 190

CARBURETOR 194

CHAPTER 5

CHASSIS

MALFUNCTION INSPECTION 199

STEERING OPERATION SYSTEM 202

The structure of the steering 202

The steering handle and cable 204

The handle switch and lever 207

Diassembling the parts of steering bar 209

Diassembling the parts of steering column 209

Checking and the steering operation system 211

Installing the steering operation system 212

Installing the steering handle 215

BRAKE SYSTEM 216

Preparation for checking before the maintenance of the brake system 216

Disk brake components 217

Front disk brake fuel pump 219

Front brake caliper 221

Checking the front brake disc 223

Replacing the front brake pads 224

Disassembling the front brakecalipers 226

Assembling the front brake calipers 227

8

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Installing the front brake calipers 227

Rear master cylinder 229

Rear brake caliper 233

Checking the rear brake disc 235

Replacing the rear brake pads 236

Disassembling the rear brake caliper 237

Assembling the rear brake caliper 238

Installing the rear brake caliper 239

Checking the master cylinder 240

Assembling the brake master cylinder 240

Installing the brake master cylinder 241

FOOTREST ASSEMBLY 242

WHEEL AND TYRE PARTS 244

Front wheels 244

Rear wheels 245

Front and rear wheel rim 246

Checking the wheel tyre 247

Checking the wheel hub 247

Installing the wheel hub 248

Installing the wheel tyre 248

Specification of wheel and tyre 249

TRANSMISSION SYSTEM 250

Front bridge 250

Disassembling the universal joint 255

Removing the differential gear assembly 255

Checking the joints 256

Checking the differential gear 256

Checking the gear motor 257

Assembling the universal joint 258

Adjusting the differential gear lash 258

Assembling the differential gear 259

Rear bridge 260

REVERSE MECHANISM PARTS 266

Adjusting reverse mechanism parts 268

9

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Checking and service of reverse mechanism 269

SUSPENSION 270

Front Suspension and arm 270

Disassembling, service and assembly the supporting rocker parts 273

Checking the front arms 274

Checking the front shock absorber 274

Installing the front arms and front shock absorber 275

Rear suspension 276

Rear arm shaft 277

Checking and service of rear suspension 279

Checking the stabilizer 280

Checking the rear arms 280

Checking the rear shock absorber 280

Installing the rear arms and rear shock absorber 281

COOLING SYSTEM 282

Radiator 282

Checking the radiator 284

Installing the radiator 285

Water pump 286

Disassembling the water pump 288

Checking the water pump 289

Assembling the water pump 290

SEAT 291

Dissassembling the seat 292

FUEL TANK 293

Fuel tnak cover parts 293

Fuel tnak parts 295

CHAPTER 6

ELECTRICAL COMPONENTS

ELECTRICAL SYSTEM MALFUNCTION INSPECTION 298

ELECTRICAL 299

ELECTRICALCOMPONENTS 299

-10-

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

CHECKING THE SWITCH

Checking the switch 301

Checking the switch continuity 302

CHECKING THE BULBS AND BULB SOCKETS 303

IGNITION SYSTEM 304

CIRCUIT DIAGRAM 304

TROUBLESHOOTING 305

ELECTRIC STARTING SYSTEM 309

CIRCUIT DIAGRAM 309

TROUBLESHOOTING 310

STARTER MOTOR 312

Checking the starter motor 313

Assembling the starter motor 314

CHARGING SYSTEM 315

CIRCUIT DIAGRAM 315

TROUBLESHOOTING 316

LIGHTING SYSTEM 318

CIRCUIT DIAGRAM 318

TROUBLESHOOTING 319

CHECKING THE LIGHTING SYSTEM 320

If the headlights fail to come on 320

If the taillights fail to come on 321

SIGNALING SYSTEM 322

CIRCUIT DIAGRAM 322

TROUBLESHOOTING 323

CHECKING THE SIGNAL SYSTEM 324

If the brake lights fail to come on 324

If the neutral lights fail to come on 325

If the parking brake indicator light fails to come on 326

If the reverse indicator light fails to come on 327

If the coolant temperature warning 328

If the differential gear lock indicator light fails to come on 330

If the four-wheel drive indicator light fails to come on 332

COOLING SYSTEM 334

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Circuit diagram 334

Troubleshooting 335

2WD/4WD SELECTING SYSTEM 338

Circuit diagram 338

Troubleshooting 339

CHAPTER 7

ENGINE MANAGEMENT SYSTEM

INTRODUCTION

Ems (engine management system) 343

Typical components of EMS 343

Layout of EMS components 344

COMPONENTS OF EMS

Electronic control unit 345

Multec 3.5 injectors 346

Throttle body assembly(with stepper motor) 350

Engine coolant temperature sensor 352

Intake air pressure and temperature sensor 353

Oxygen sensor 353

Ignition coil 353

Fuel pump module 357

EMS FAULT DIAGNOSIS

EME fault diagnosis 363

Fault code list 363

CHAPTER 8

TROUBLESHOOTING

STARTING FAILURE/HARD STARTING 365

Fuel system 365

Electrical system 365

Compression system 366

POOR IDLE SPEED PERFORMANCE 367

-12-

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Poor idle speed performance 367

POOR MEDIUM AND HIGH-SPEED PERFORMANCE 367

Poor medium and high-speed performance 367

FAULTY GEAR SHIFTING 367

Shift lever does not move 367

Jumps out of gear 368

OVERHEATING 368

Overheating 368

FAULTY BRAKE 368

Poor braking effect 369

SHOCK ABSORBER MALFUNCTION 369

Malfunction 369

UNSTABLE HANDLING 369

Unstable handling 369

LIGHTING SYSTEM 370

Head light is out of work 370

Bulb burnt out 370

CHAPTER 9

HS600ATV SERVICE MANUAL

HS600ATV SUPPLEMENTARY 371

SPECIFICATIONS 372

Geberar specifications 372

Engine specifications 372

CHAPTER 10

HS500ATV SERVICE MANUAL

HS500ATV SUPPLEMENTARY 374

SPECIFICATIONS 375

Geberar specifications 375

Engine specifications 375

HS700ATV/HS600ATV/HS500ATV WIRING DIAGRAM 380

-13-

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

WARNING:

GENERAL INFORMATION

GENERAL INFORMATION

The text provides complete information on maintenance, tune-up repair and overhaul, Hundreds

of photographs and illustrations created during the complete disassembly of four wheel all-terrain

vehicles (ATV) guide the reader through every job, All procedures are in step-by-step format and

designed for the reader who may be working on the ATV for the first time.

WARNINGS, CAUTIONS AND NOTES

The terms WARNING, CAUTION and NOTE have specific meaning in this manual.

emphasizes areas where injury or even death could result from negligence.

Mechanical damage may also occur. WARNINGS are to be taken seriously

CAUTION: emphasizes areas where equipment damage could result. Disregarding a

CAUTION could cause permanent mechanical damage. though injury is

unlikely.

provides additional information to make a step or procedure easier or clearer.

Disregarding a NOTE could cause inconvenience. but would not cause

equipment damage or injury.

NOTE:

1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

GENERAL INFORMATION

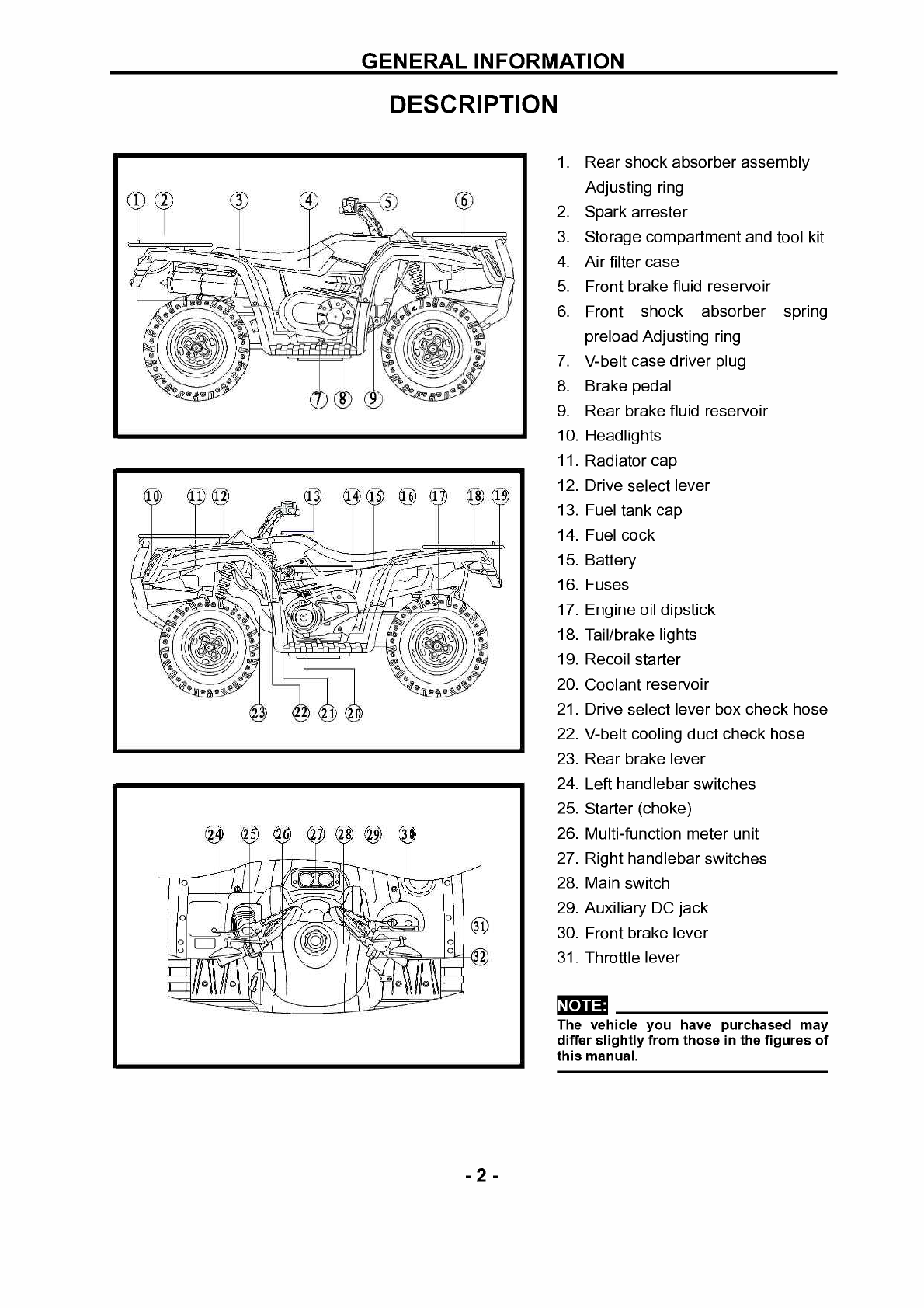

DESCRIPTION

2

1. Rear shock absorber assembly

Adjusting ring

2. Spark arrester

3. Storage compartment and tool kit

4. Air filter case

5. Front brake fluid reservoir

6. Front shock absorber spring

preload Adjusting ring

7. V-belt case driver plug

8. Brake pedal

9. Rear brake fluid reservoir

10. Headlights

11. Radiator cap

12. Drive select lever

13. Fuel tank cap

14. Fuel cock

15. Battery

16. Fuses

17. Engine oil dipstick

18. Tail/brake lights

19. Recoil starter

20. Coolant reservoir

21. Drive select lever box check hose

22. V-belt cooling duct check hose

23. Rear brake lever

24. Left handlebar switches

25. Starter (choke)

26. Multi-function meter unit

27. Right handlebar switches

28. Main switch

29. Auxiliary DC jack

30. Front brake lever

31. Throttle lever

NOTE:

The vehicle you have purchased may

differ slightly from those in the figures of

this manual.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

GENERAL INFORMATION

SAFETY

Professional mechanics can work for years and never sustain a serous injury or mishap. Follow

these guidelines and practice common sense to safely service the utility terrain venires

1. Do not operate the utility terrain venires in an enclosed area venires The exhaust gasses

contain carbon monoxide. an odorless, colorless and tasteless poisonous gas. Carbon

monoxide levels build quickly in small enclosed areas and can cause unconsciousness and

death in a short time. Make sure to properly ventilate the work area or operate the ATV side

2. Never use gasoline or any extremely flammable liquid to clean parts. Refer to cleaning parts

and handling Gasoline Safely in this section

3. Never smoke or use a torch in the vicinity of flammable liquids, such as gasoline or cleaning

solvent.

4. If welding or brazing on the ATV the fuel tank to a safe distance at least 50ft.(15m) away.

5. Use the correct type and size of tools to avoid damaging fasteners.

6. Keep tools clean and in good condition. Replace or repair worn or damaged equipment.

7. When loosening a tight fastener, be guided by what would happen if the tool slips.

8. When replacing fasteners, make sure the new fasteners are the same size and strength as the

original ones.

9. Keep the work area clean and organized.

10. Wear eye protection anytime the safety of the eyes is in question. This includes procedures that

involve drilling, grinding, hammering, compressed air and chemicals.

11. Wear the correct clothing for the job. Tie up or cover long hair so it does not get caught in

moving equipment.

12. Do not carry sharp tools in clothing pockets.

13. Always have an approved fire extinguisher available. Make sure it is rated for gasoline (Class B)

and electrical (Class C) fires.

14. Do not use compressed air to clean clothes, the ATV or the work area. Debris may be blown

into the eyes or skin. Never direct compressed air at anyone. Do not allow children to use or

play with any compressed air equipment.

15. When using compressed air to dry rotating parts, hold the part so it does not rotate. Do not allow

the force of the air to spin the part. The air jet is capable of rotating parts at extreme speed. The

part may disintegrate of become damaged, causing serious injury.

16. Do not inhale the dust created by brake pad and clutch wear. These particles may contain

asbestos. In addition, some types of insulating materials and gaskets may contain asbestos.

Inhaling asbestos particles is hazardous to one's health.

17. Never work on the ATV while someone is working under it.

Handling Gasoline Safely

Gasoline is a volatile flammable liquid and is one of the most dangerous items in the shop.

Because gasoline is used so often, many people forget it is hazardous. Only use gasoline as fuel

for gasoline internal combustion engines. Keep in mind when working on the machine, gasoline is

always present in the fuel tank, fuel line and carburetor. To avoid a disastrous accident when

4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

GENERAL INFORMATION

working around the fuel system, carefully observe the following precautions:

1. Never use gasoline to clean parts. Refer to Cleaning Parts in this section.

2. When working of the fuel system, work outside or in a well-ventilated area.

3. Do not add fuel to the fuel tank or service the fuel system while the ATV is near open flames,

sparks or where someone is smoking .Gasoline vapor is heavier than air, it collects in low areas

and is more easily ignited than liquid gasoline.

4. Allow the engine to cool completely before working on any fuel system component.

5. Do not store gasoline in glass containers. If the glass breaks, a serious explosion of fire may

occur.

6. Immediately wipe up spilled gasoline with rags. Store the rags in a metal container with a lid until

they can be properly disposed of, or place them outside in a safe place for the fuel to evaporate.

7. Do not pour water onto a gasoline fire. Water spreads the fire and makes it more difficult to put

out. Use a class B, BC or ABC fire extinguisher to extinguish the fire.

8. Always turn off the engine before refueling. Do not spill fuel onto the engine or exhaust system.

Do not overfill the fuel tank. Leave an air space at the top of the tank to allow room for the fuel to

expand due to temperature fluctuations.

Cleaning Parts

Cleaning parts is one of the more tedious and difficult service jobs performed in the home garage.

Many types of chemical cleaners and solvents are available for shop use. Most are poisonous and

extremely flammable. To prevent chemical exposure, vapor buildup, fire and serious injury, observe

each product warning label and note the following:

1. Read and observe the entire product label before using any chemical. Always know what type of

chemical is being used and whether it is poisonous and/or flammable.

2. Do not use more than one type of cleaning solvent at a time. If mixing chemicals is required,

measure the proper amounts according to the manufacturer.

3. Work in a well-ventilated area.

4. Wear chemical-resistant gloves.

5. Wear safety glasses.

6. Wear a vapor respirator if the instructions call for it.

7. Wash hands and arms thoroughly after cleaning parts.

8. Keep chemical products away from children and pets.

9. Thoroughly clean all oil, grease and cleaner residue from any part that must be heated.

10. Use a nylon brush when cleaning parts. Metal brushes may cause a spark.

11. When using a parts washer, only use the solvent recommended by the manufacturer. Make sure

the parts washer is equipped with a metal lid that will lower in case of fire.

Warning Labels

Most manufacturers attach information and warning labels to the ATV. These labels contain

instructions that are important to personal safety when operating, servicing, transporting and storing

the ATV. Refer to the owner's manual for the description and location of labels. Order replacement

5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

WARNING

GENERAL INFORMATION

labels from the manufacturer if they are missing or damaged.

SERIAL NUMBERS

Serial and identification numbers are stamped on various locations on the frame, engine and

carburetor body. Record these numbers in the Quick Reference Data section in the front of the

manual. Have these numbers available when ordering parts.

FASTENERS

Proper fastener selection and installation is important to ensure the motorcycle operates as

designed and can be serviced efficiently. The choice of original equipment fasteners is not arrived at

by chance. Make sure replacement fasteners meet all the same requirements as the originals

Many screws. Bolts and studs are combined with nuts to secure particular components. to

indicate the size of a nut. Manufactures specify the internal diameter and the thread pitch

The measurement across two flats on a nut or bolt indicates the wrench size

Do not install fasteners with astrength

classification lower than what was originally

installed by the manufacturer doing so may

cause equipment failure and or damage

Torque Specifications

The material used in the manufacturing of the ATV may be subjected to uneven stresses if the

fasteners of the various subassemblies are not installed and tightened correctly. Fasteners that are

improperly installed or work loose can cause extensive damage. it is essential to use an accurate

torque wrench as described in this chapter

Self-Locking Fasteners

Several types of bolts. Screws and nuts incorporate a system that creates interference between

the two fasteners. Interference is achieved in various ways. The most common types are the nylon

insert nut and a dry adhesive coating on the threads of a blot.

Self-locking fasteners offer greater holding strength than standard fasteners, which improves

their resistance to vibration. All self-locking fasteners cannot be reused. The materials used to from

the lock become distorted after the initial installation and removal. Discard and replace self-locking

fasteners after removing them. Do not replace self-locking fasteners with standard fasteners.

Washers

The two basic types of washers are flat washers and lock washers. Flat washers are simple discs

6

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

This manual suits for next models

5

Table of contents

Other Chongqing Huansong Offroad Vehicle manuals