(1) Install a dedicated electrical circuit to the junction box indicated below.

- Front electrical box by the burner on the CE-140, CE-180, and CE-250

- Back electrical box by the blower on the CE-330

(2) Connect the wires according to the label found on the inside of the junction box cover or in

the wire diagrams section of this manual. Use stranded copper wire to ensure a secure

connection.

19

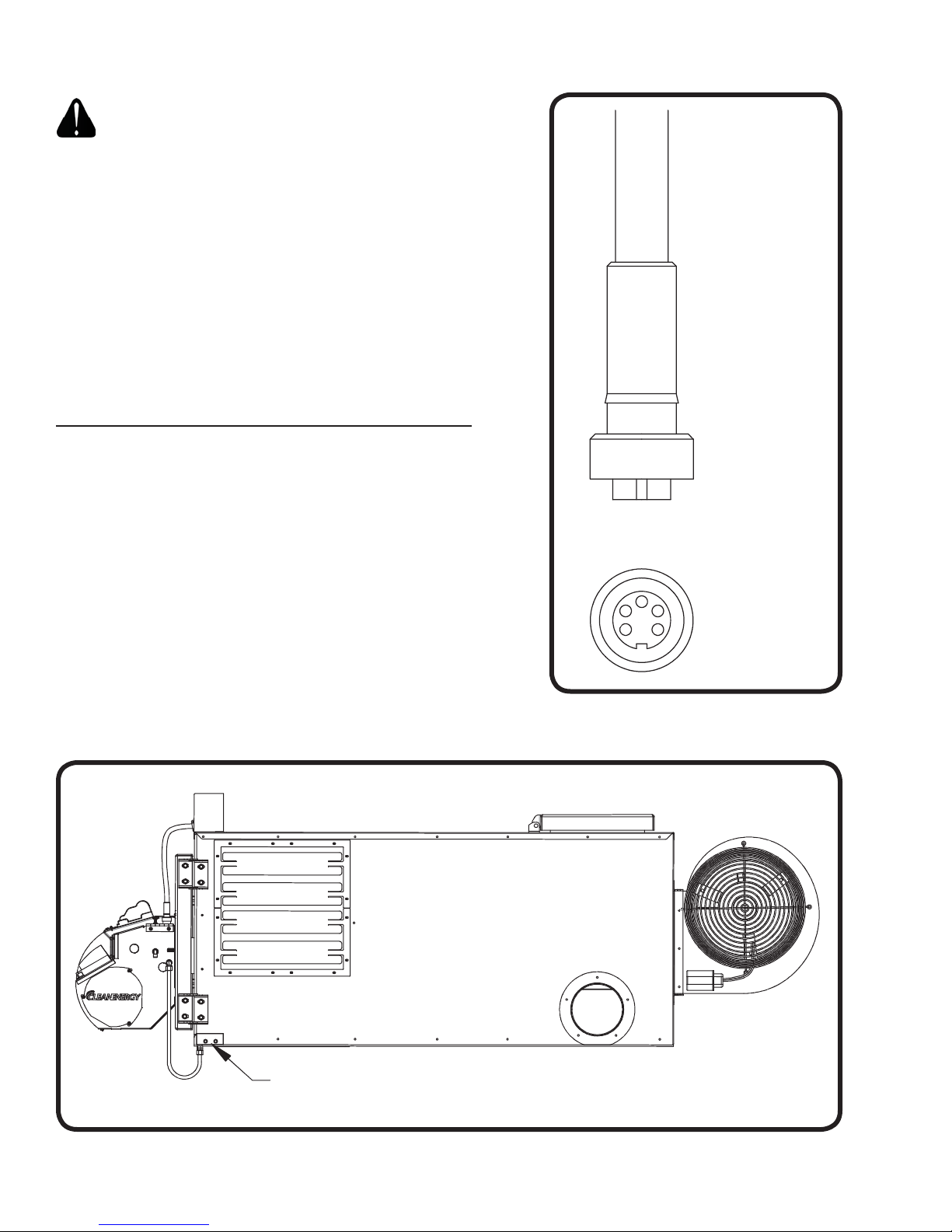

Installing the chimney components:

WARNING: Double wall “Class A” insulated stack must be used through any building

penetration and for any exterior stack. Unapproved stack material and/or installation

can create a fire hazard. Contact Clean Energy Heating Systems, LLC to purchase

approved stack material for your installation.

CAUTION: Using single wall stack on the exterior of your building will cause the stack

gases to cool rapidly and adversely affect the natural draft of the furnace. This will

create a back draft and may damage critical burner components.

(1) Refer to Figure 14 for a typical through-the-roof chimney illustration and Figure 15 for a

typical through-the-wall chimney illustration.

(2) Observe the following requirements when installing the chimney:

• The CE-140, CE-180 and CE-250 furnace models require 6” I.D. stack components.

• The CE-330 furnace model requires 8” I.D. stack components.

• Have a minimum of 10 feet vertical chimney to ensure -.02” w.c. draft over fire.

• Keep horizontal runs short. Slope any horizontal sections at least 1/4” per foot.

• Keep the stack installation simple. Multiple turns and horizontal runs will reduce the

natural draft of the furnace which may damage critical burner components.

(3) Single wall stack may be used inside the building. Observe proper clearances from

combustibles. Do not put single wall stack in areas that may create a burn hazard to

personnel.

(4) Install a barometric damper, as shown in Figures 15 and 16, so that proper draft can be

maintained. Follow the instructions provided with the damper for proper installation.

(5) Use double wall “Class A” insulated stack when making a penetration through the roof or

side wall of your building. Install proper flashing around the exterior penetration of the

stack to make a water tight seal. Clean Energy Heating Systems, LLC recommends

“Dektite” flexible pipe flashing, or equivalent, for through the roof installations.

(6) Install a “Class A” non-restrictive stack cap only.

CAUTION: If your building utilizes an exhaust fan, ensure that there is adequate

make-up air available. Lack of make-up air will create a vacuum in your building

which will result in a back draft at the furnace. A back draft will damage critical burner

components.

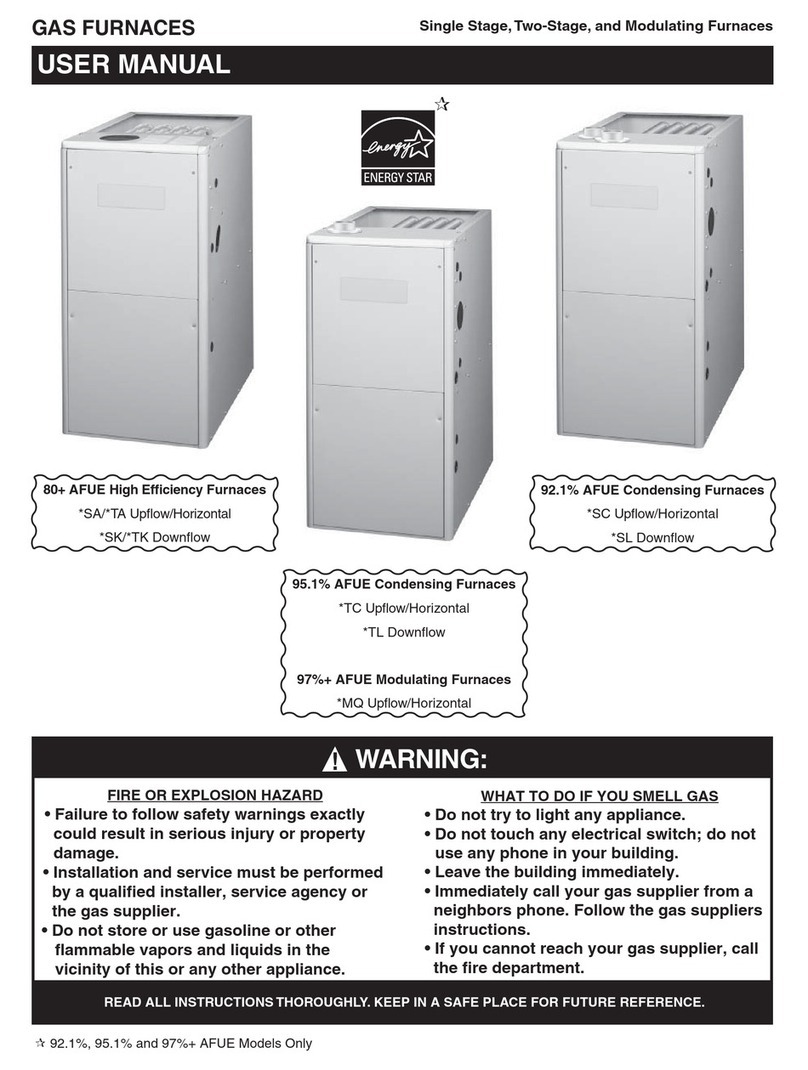

FURNACE INSTALLATION

120 V / 60 Hz

Single Phase

30 Amp dedicated circuit

CE-250 CE-330

230 V / 60 Hz

Single Phase

30 Amp dedicated circuit

NOTE: The CE-330 needs a four wire feed. Two 115V Line voltage legs, a neutral, and a

ground.