Cleanware HT-E Setup guide

INSTALLATION, OPERATION,

AND SERVICE MANUAL

HT-E

HT-E Manual • 07610-004-64-85-A

UNDERCOUNTER DISHMACHINES

DRAFT

iii

REVISION HISTORY

Revision

Letter

Revision

Date Made by Applicable ECNs Details

A DRAFT JH N/A DRAFT

iv

The manufacturer provides

technical support for the

dishmachine detailed in

this manual. We strongly

recommend that you refer to

this manual before making a

call to our technical support

sta. Please have this manual

open when you call so that our

sta can refer you, if necessary,

to the proper page. Technical

support is not available

on holidays.

Contact technical support toll-

free at 1-888-800-5672.

Technical support is available

for service personnel only.

HT-E

Undercounter dishmachine; high-temperature, hot-water

sanitizing, with a booster tank, drain pump, and

detergent and rinse-aid dispensers.

NOMENCLATURE

v

TABLE OF CONTENTS

GUIDES

Symbols...................................................................................................................................... 1

Abbreviations.............................................................................................................................. 1

SPECIFICATIONS

Machine Dimensions .................................................................................................................. 2

Operating Parameters ................................................................................................................ 3

Electrical Requirements ............................................................................................................. 4

INSTALLATION

Installation Instructions............................................................................................................... 5

Inspection......................................................................................................................... 5

Unpacking........................................................................................................................ 5

Plumbing.......................................................................................................................... 5

Water Supply Connections .............................................................................................. 5

Pressure Regulator.......................................................................................................... 6

Shock Absorber ............................................................................................................... 6

Connecting the Drain Line ............................................................................................... 6

Plumbing Check............................................................................................................... 6

Electrical Power Connections .......................................................................................... 7

Voltage Check.................................................................................................................. 7

Surrounding Area............................................................................................................. 7

Thermostats..................................................................................................................... 8

Chemical Feeder Equipment ........................................................................................... 8

Priming Chemical Feeder Pumps .................................................................................... 8

Leveling............................................................................................................................ 8

OPERATION

Operating Instructions ................................................................................................................ 9

Preparation ......................................................................................................................9

Filling the Wash Tank.......................................................................................................9

Ware Preparation.............................................................................................................9

Washing a Rack of Ware ...............................................................................................10

Operational Inspection...................................................................................................10

Alarms............................................................................................................................10

Draining.......................................................................................................................... 11

Shutdown & Cleaning .................................................................................................... 11

Deliming.........................................................................................................................13

Detergent Control...........................................................................................................14

vi

MAINTENANCE

Preventative Maintenance........................................................................................................ 15

Drain Pump Cleanout ............................................................................................................... 15

TROUBLESHOOTING

Troubleshooting........................................................................................................................ 16

PARTS

Tub & Frame............................................................................................................................. 18

Electrical................................................................................................................................... 20

Hoses ....................................................................................................................................... 22

Wash & Rinse Arms.................................................................................................................. 24

Plumbing Options ..................................................................................................................... 26

Miscellaneous Parts ................................................................................................................. 27

SCHEMATICS

208-230 V, 60 Hz, 1 Phase....................................................................................................... 28

TABLE OF CONTENTS

1

07610-004-64-85-A

GUIDES GUIDES

SYMBOLS

!

CAUTION

!

WARNING

NOTICE

- Risk of Injury to Personnel

- Risk of Damage to Equipment

- Risk of Electrical Shock

- Lockout Electrical Power

- Reference Data Plate

- Important Note

i

- Caustic Chemicals

ABBREVIATIONS & ACRONYMS

ANSI - American National Standards Institute

CFM - Cubic Feet per Minute

dBA - Decibels Adjusted

GHT - Garden Hose Thread

GPH - Gallons per Hour

GPM - Gallons per Minute

GPG - Grains per Gallon

HP - Horse Power

Hz - Hertz

ID - Inside Diameter

kW - Kilowatts

MCA - Minimum Circuit Ampacity

MOP - Maximum Overcurrent Protection

NFPA - National Fire Protection Association

NPT - National Pipe Thread

OD - Outside Diameter

PRV - Pressure Regulating Valve

PSI -Pounds per Square Inch

V- Volts

- Instructions Hyperlink

07610-004-64-85-A 2

SPECIFICATIONS

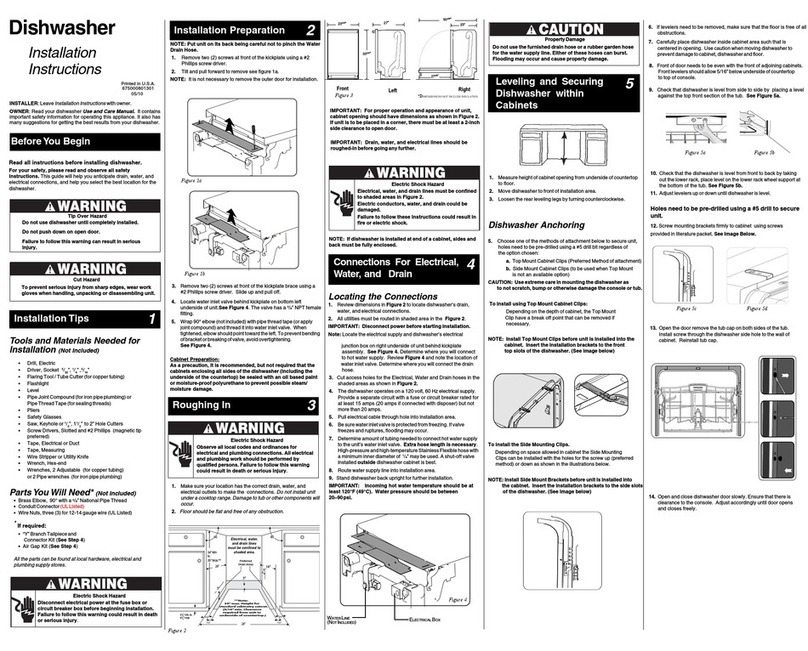

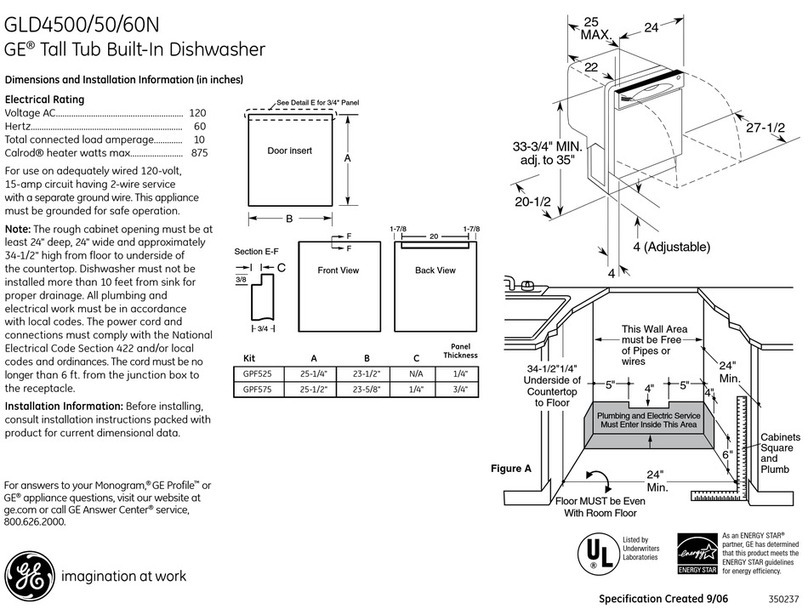

MACHINE DIMENSIONS

243/4

[629mm]

1/4

[7mm]

401/2

[1029mm]

153/4

[400mm]

DOOROPEN

23 3/4

[603mm]

321/8

[816mm]

17/8

[48mm]

23/8

[60mm]

3

[76mm]

63/8

[162mm]

14

[356mm]

CLEARANCE

3 1/8

[79 mm]

3

[76 mm]

8 1/4

[210mm] 11 7/8

[302 mm]

AD

B

C

A

D

C

B

TOP BACK

FRONT SIDE

LEGEND

A - Electrical Connection

B - Water Inlet (connection actually at end of pre-installed hose)

C - Drain Connection

D - Chemical Connection

All dimensions from the floor can be increased

2” using the machine’s adjustable feet.

07610-004-64-85-A 3

OPERATING PARAMETERS

SPECIFICATIONS

Operating Capacity (without Load Time): HT-E

Racks per Hour 32

Dishes per Hour 800

Glasses per Hour 1152

Operating Capacity (with Load Time):

Racks per Hour 25

Dishes per Hour 625

Glasses per Hour 900

Tank Capacity (Gallons):

Wash Tank XX

Booster Tank XX

Electrical Loads (as applicable):

Wash Motor HP 3/4

Wash Heater kW (208 V) 3.2

Wash Heater kW (230 V) 4.5

Booster Heater kW (208 V) 3.9

Booster Heater kW (230 V) 5.5

Always refer to the machine data plate for specic electrical and water requirements.

The material provided on this page is for reference only and is subject to change

without notice.

Sound Level:

Workplace-related Emission Value (dBA) 66

Water Temperatures (°F):

Minimum Wash Temperature 150

Minimum Rinse Temperature 180

Minimum Incoming Water Temperature 110

Water Consumption:

Gallons per Rack 0.69

Gallons per Hour 22.1

Other Water Requirements:

Water Flow Pressure (PSI) 20 ± 5

Flow Rate Minimum (GPM) 4.6

Water Line Connection Size 3/4" GHT

Water Line Size (NPT) 1/2"

Drain Line Size (NPT) 1" ID

1 3/8" OD

NOTICE

i

4

07610-004-64-85-A

ELECTRICAL REQUIREMENTS

SPECIFICATIONS

All electrical ratings provided in this manual are for reference

only. Always refer to the machine data plate to get exact electrical

information for this machine. All electrical work performed on

machines should be done in accordance with applicable

local, state, territorial, and national codes. Work should only

be performed by qualied electricians and authorized service

agents.

Note that all electrical wiring used in the HT-E must be rated, at

a minimum, for 212 °F (100 °C), and that only copper conductors

must be used.

Where applicable, heating element amperage draws have been

adjusted for the assumed input voltage. The manufacturer

assumes incoming voltages will be either 208 or 230 Volts. Some

heating elements used in the machines are rated for other voltages,

such as 240 Volts and 480 Volts. Always verify the amperage

draw of the machine in operation when sizing circuit protection.

Available Electrical Characteristics:

• 208 V, 60 Hz, Single-phase

• 230 V, 60 Hz, Single-phase

VOLTS 208 230

PHASE 1 1

FREQ 60 60

WASH

MOTOR

AMPS

3.8 A 3.8 A

DRAIN

MOTOR

AMPS

0.3 A 0.3 A

RINSE

MOTOR

AMPS

1.8 A 1.8 A

WASH

HEATER

AMPS

15.2 A 16.8 A

BOOSTER

HEATER

AMPS

21.7 A 24.0 A

TOTAL

LOAD 25.8 A 27.8 A

MCA 26.8 A 28.8 A

MOP 30.0 A 30.0 A

NOTICE

iHT-E

Electrical Characteristics

07610-004-64-85-A 5

INSTRUCTIONS

INSTALLATION

WATER SUPPLY

CONNECTIONS:

WATER HARDNESS

HIGHER THAN 3 GPG

Before installing machine, check packaging and machine for damage. Damaged

packaging might be an indication of damage to the machine. If there is any type

of damage to both packaging and machine, do not throw away the packaging. The

machine has been inspected at the factory before shipping and is expected to arrive

in new, undamaged condition. However, rough handling by carriers or others might

result in damage to the machine while in transit. If this occurs, do not return machine to

the manufacturer. Instead, contact the carrier and ask them to send a representative

to the site to inspect the damage and request that an inspection report be completed.

Contact the carrier within 48 hours of receiving the machine as well as the dealer that

sold you the machine.

The machine should be unpacked and removed from the pallet before installing. Open

the front door and remove all materials from inside. Once unpacked, verify there are no

missing parts. If a part is missing, contact the manufacturer immediately.

All plumbing connections must adhere to local, state, territorial, and national codes.

The installing plumber is responsible for ensuring the incoming water lines are ushed

of debris before connecting to the machine. Note that chips and materials from cutting

processes can become lodged in the solenoid valves and prevent them from opening

or closing. Any valves found to be fouled or defective because of foreign matter

left in the water line, and any subsequent damage, are not the responsibility of the

manufacturer.

A water hardness test must be performed. If water hardness is higher than 3 GPG,

install a water softener or install the optional Scale Prevention System (SPS). See the

next section and the Plumbing Options page for more information on the SPS.

If water hardness is higher than 3 GPG and a water softener is not being used, install

the SPS into the water line between the facility water line and machine water line.

Observe proper inlet/outlet water directions. A water shut-o valve should be installed

before installing the SPS to allow access for service. The water supply must be

capable of the minimum “ow” pressure at the recommended temperature indicated

on the data plate.

Example

INSPECTION

UNPACKING

PLUMBING

A water hardness test

must be performed.

The plumber must ush

the incoming water line!

Shut-off

Valve

Adapter AdapterSPS Machine

Water Line

Facility

Water Line

*Adapters needed will vary.

i

Do not throw away

packaging if damage is

evident!

6

07610-004-64-85-A

INSTRUCTIONS

INSTALLATION

WATER SUPPLY

CONNECTIONS:

WATER HARDNESS

LOWER THAN 3 GPG

PRESSURE

REGULATOR

SHOCK ABSORBER

CONNECTING THE

DRAIN LINE

If water hardness tests at 3 GPG or lower, connect the machine water line (installed

at the factory, 3/4" Male GHT connected to a true 1/2” ID line) to the facility water line.

A water shut-o valve should be installed in the water line between the facility supply

and the machine to allow access for service. The water supply line must be capable

of the minimum “ow” pressure at the recommended temperature indicated on the

data plate.

The manufacturer has an optional Pressure Regulating Valve (PRV) to accommodate

areas where water pressure uctuates or is higher than the recommended pressure.

Take care not to confuse static pressure with ow pressure. Static pressure is line

pressure in a “no ow” condition (all valves and services are closed). Flow pressure is

the pressure in the ll line when the valve is open during the cycle. See the Plumbing

Options page.

A shock absorber (not supplied) should be installed on the incoming water line. This

prevents water hammer or hydraulic shock—induced by the solenoid valve as it

operates—from causing damage to the equipment. See the Plumbing Options page.

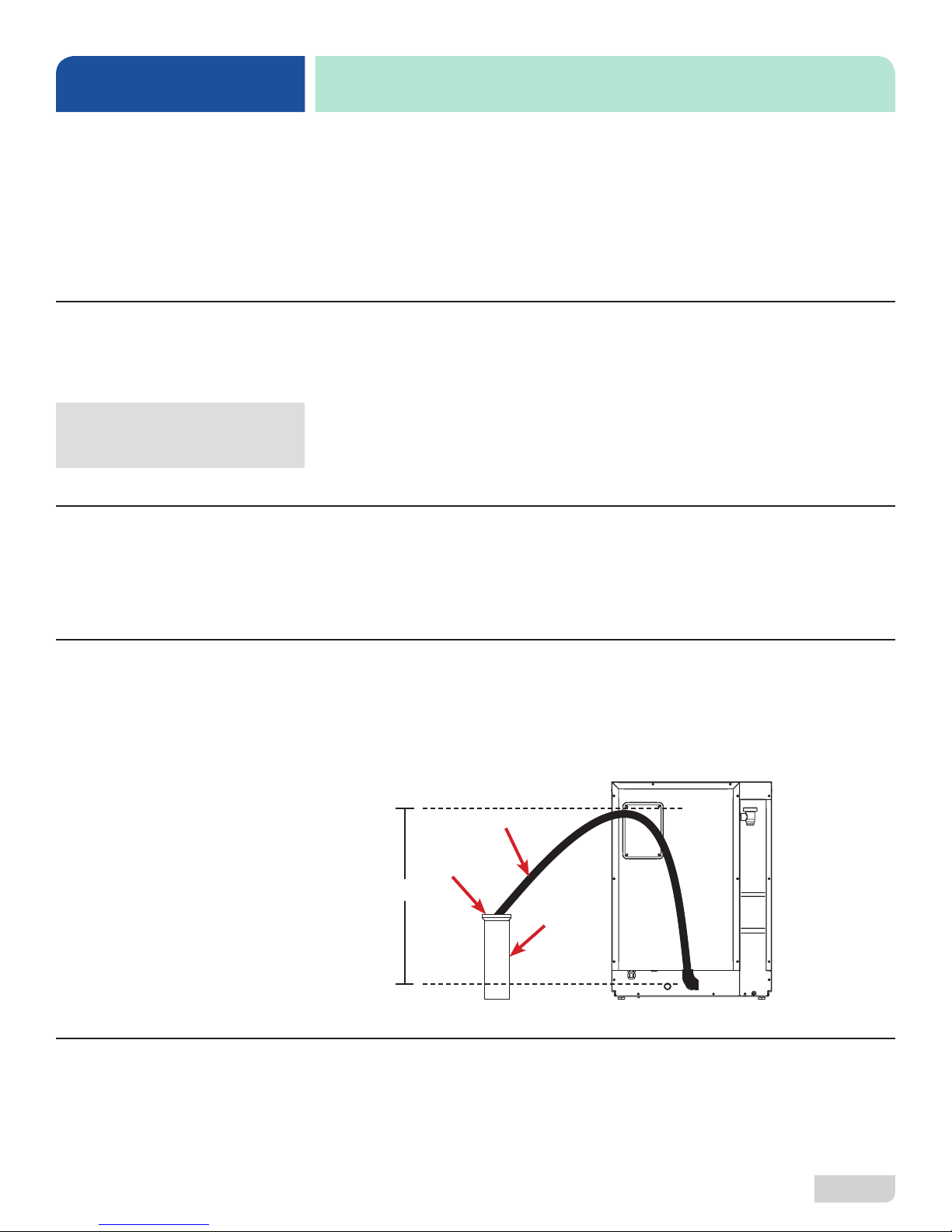

The machine has a pumped (pressure) drain capable of pumping waste water to

a height of 24” above the machine's drain pump and is supplied with a drain hose.

There must be an air-gap between/around the machine drain hose and the oor drain

or sink. The oor drain or sink must be at least 1.5 times larger than the machine drain

hose. If a grease trap is required by code, it should have a ow capacity of 12 GPM.

After installing the incoming water line and the drain line, slowly turn on the water

supply to the machine. Check for any leaks and repair as required. All leaks must be

repaired before operating the machine.

Take care not to confuse

static pressure with

ow pressure!

PLUMBING CHECK

≤24”

Air-gap

Floor Drain

or Sink

Drain Hose

7

07610-004-64-85-A

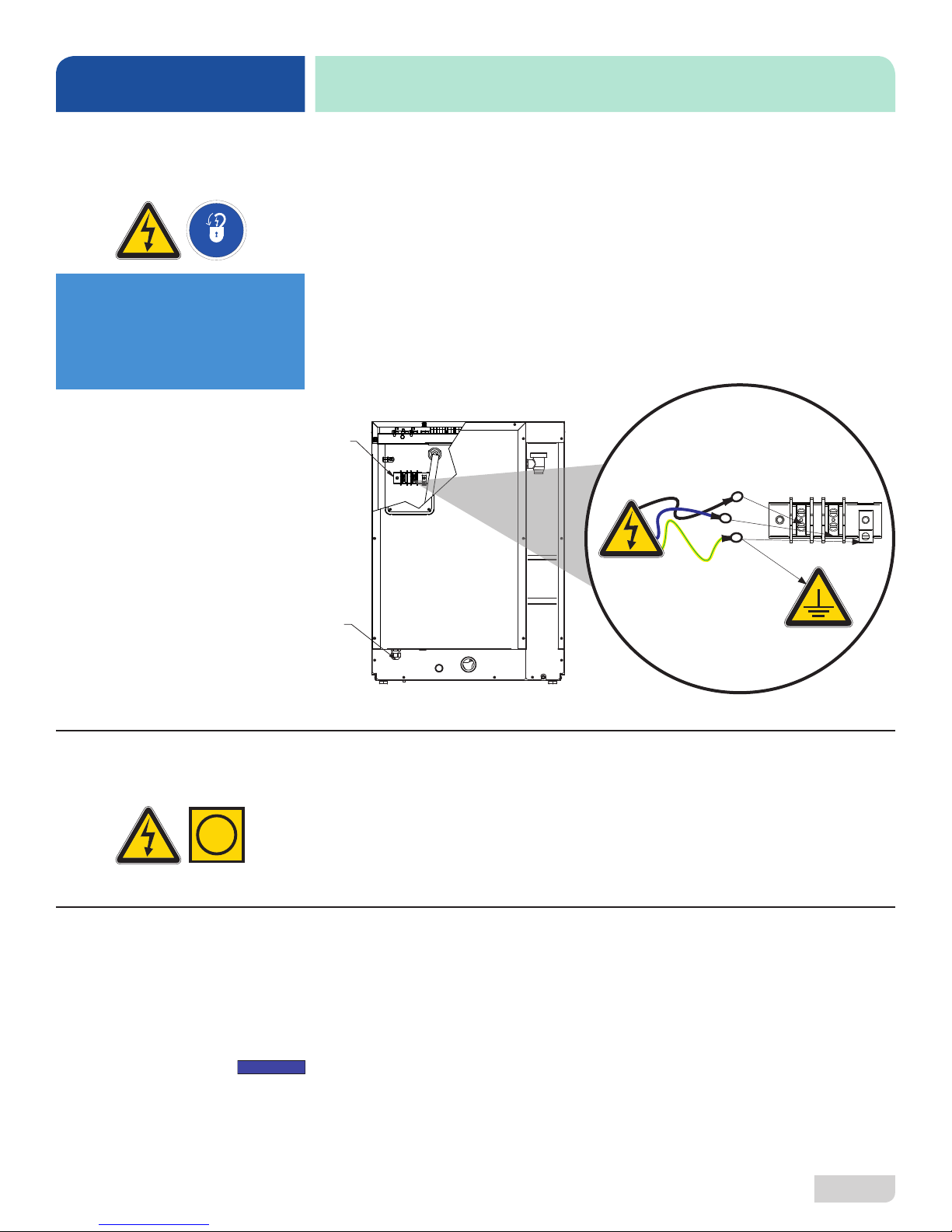

Electrical and grounding conductors must comply with the applicable portions of the

National Electric Code ANSI/NFPA 70 (latest edition) and/or other electrical codes.

Refer to the data plate for machine operating requirements, machine voltage, total

amperage, and serial number.

Remove the back panel. Route power wires through indicated hole and connect to

power block and grounding lug. Install the service wires (L1 and L2) to the appropriate

terminals as they are marked below. Install the grounding wire into the lug provided.

It is recommended that “DE-OX” or another similar anti-oxidation agent be used on

all power connections.

Apply power to machine. Check incoming power at the terminal block and ensure it

corresponds with the voltage listed on the data plate. If not, contact a qualied service

agency to examine the problem. Do not run machine if voltage is too high or too low.

Shut-o the service breaker and advise all proper personnel of the location of the

breaker and any problems.

This is a commercial machine and reaches temperatures that can exceed those

generated by a residential machine. Surrounding countertops, cabinets, and ooring/

subooring material must be designed and/or selected with these higher temperatures

in mind.

Any damage to surrounding area that is caused by heat and/or moisture to materials

that are not recommended for higher temperatures will not be covered under warranty

or by the manufacturer.

INSTRUCTIONS

INSTALLATION

ELECTRICAL POWER

CONNECTIONS

Disconnect electrical

power at the breaker or

disconnect switch and

tag-out in accordance with

procedures and codes.

SURROUNDING

AREA

VOLTAGE CHECK

NOTICE

i

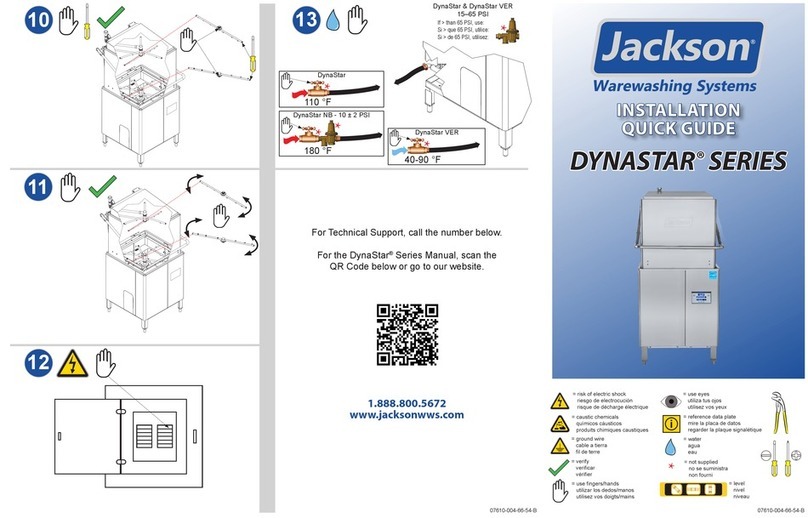

BACK

Hole

for

Wires

Power

Block

L1 L2 GROUND

07610-004-64-85-A 8

INSTRUCTIONS

INSTALLATION

CHEMICAL FEEDER

EQUIPMENT

PRIMING CHEMICAL

FEEDER PUMPS

WARNING! Some of the

chemicals used in

dishwashing might cause

chemical burns if they

come in contact with skin.

Wear protective gear when

handling these chemicals.

If any contact with skin

occurs, immediately

follow the treatment

instructions provided

with the chemicals.

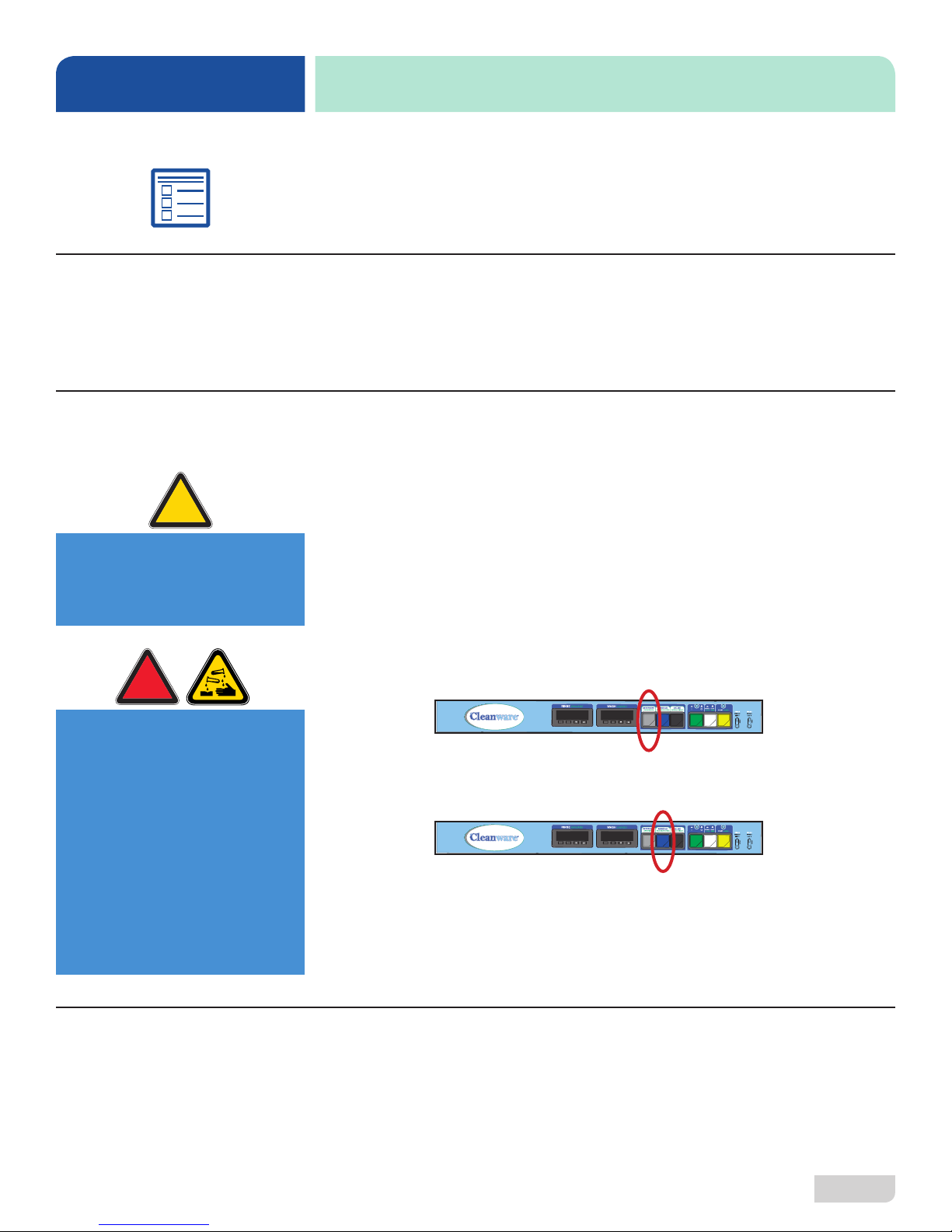

The thermostats on this machine have been set at the factory. They should only be

adjusted by an authorized service agent.

If adjustments are necessary, click here for instructions.

The HT-E dishmachine is supplied with detergent and rinse-aid chemical feeder

pumps. The pumps have regulating screws to adjust the amount of chemicals being

dispensed. Locate the open ends of the chemical tubes and place each one in the

appropriate container. The tubes are labeled "Detergent" and "Rinse-Aid."

The bottom of chemical containers cannot be located any higher than 8” from the

oor. Chemical feeder pumps need priming when the machine is rst installed or if

the chemical lines have been removed and air was allowed to enter.

1. Verify that the proper chemical tube stiener inlet is in the proper container.

2. Use the prime buttons located on the control panel to prime each pump. The

buttons are clearly marked DETERGENT and RINSE-AID.

3. To prime the pumps:

• Detergent - hold the DETERGENT button down until detergent is seen

entering the wash tank.

• Rinse-aid - hold the RINSE AID button down for two minutes.

A level machine is important to prevent any damage to the machine during operation

and to ensure the best possible results. The machine comes equipped with adjustable

bullet feet which can be turned using a pair of pliers. Since this machine is an

undercounter machine, it should be leveled as close as possible to the machine's

location before it is pushed under the counter.

THERMOSTATS

!

WARNING

!

CAUTION

set set

set set

LEVELING

CAUTION! Water

must be in the sump

and wash tank before

chemicals are dispensed!

9

07610-004-64-85-A

INSTRUCTIONS

OPERATION

Before operating machine, verify the following:

1. Standpipe is seated in place and clean.

2. Strainers (shown removed for clarity) are in place and clean.

3. Wash and rinse arms are securely in place and rotate freely.

4. Chemical levels in chemical containers are correct.

1. Close the door.

2. Push the POWER button.

3. The power light will illuminate and the tank and booster will begin filling.

4. The rinse and wash lights will illuminate. Once the tank and booster have filled

and reached the minimum temperature, the rinse and wash lights will go out.

Proper ware preparation will help ensure good results and fewer re-washes. If not

done properly, ware might not come out clean and the eciency of the machine

will be reduced. Putting unscraped dishes into the machine aects its performance,

so scraps should always be removed from ware before being loaded into a rack.

Pre-rinsing and pre-soaking are good ideas, especially for silverware and casserole

dishes. Place cups and glasses upside-down in racks so they don't hold water during

the cycle. The machine sanitizes as well as cleans. To do this, ware must be properly

prepared before being placed in the machine.

PREPARATION

WARE

PREPARATION

FILLING THE

WASH TANK

set set

POWER BUTTON POWER LIGHT

RINSE LIGHT WASH LIGHT

07610-004-64-85-A 10

INSTRUCTIONS

OPERATION

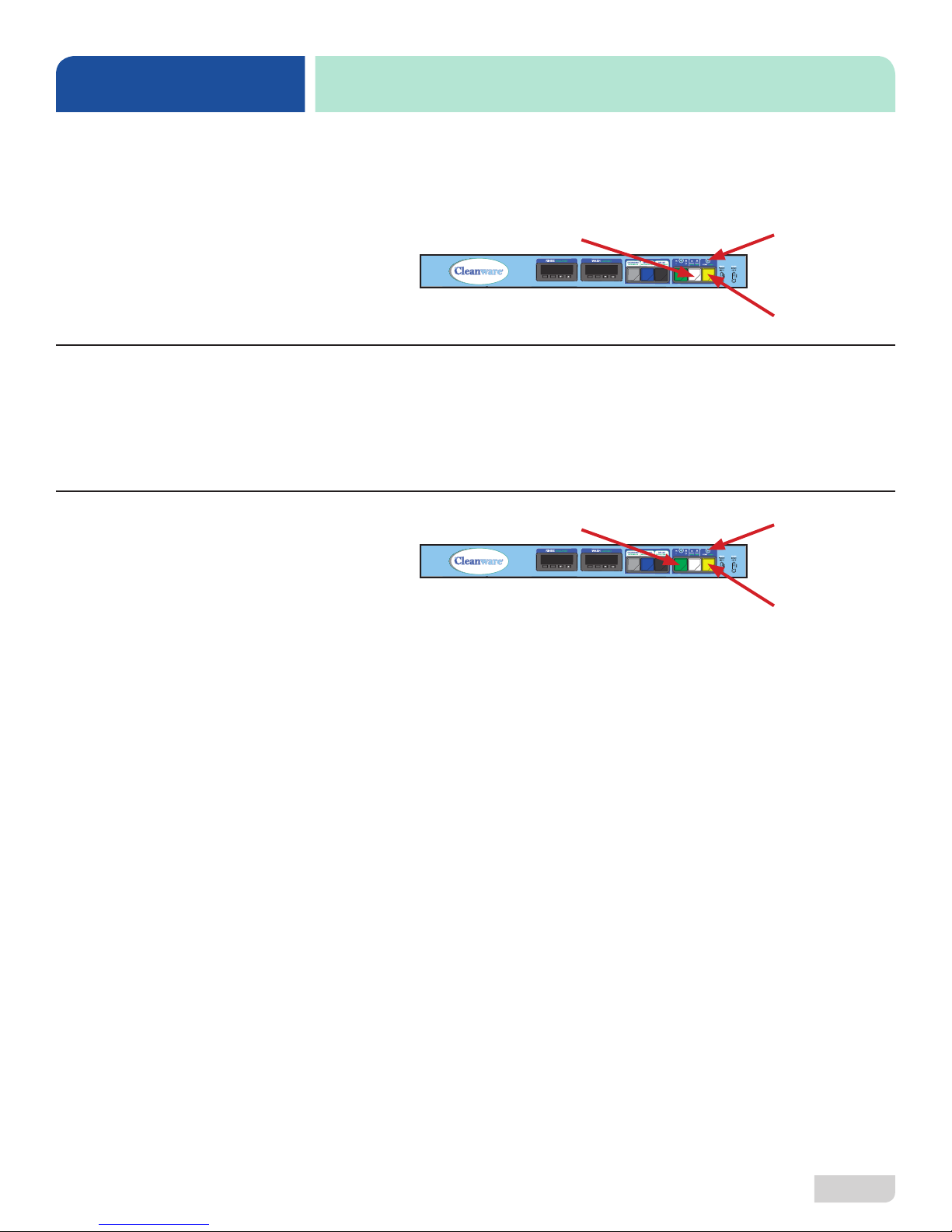

Open the door completely, slide a rack into the machine, and close the door. Choose

the wash cycle with the CYCLE button. Press the START button and the cycle light

will illuminate. When the cycle is complete, the cycle light will turn o. Open the door

and remove the rack.

Based on use, the strainers might become clogged with soil and debris as the

workday progresses. Operators should regularly inspect the strainers to ensure they

have not become clogged. If clogged, the washing capability of the machine will

be reduced. Instruct operators to clean out the strainers at regular intervals or as

required by workload.

Time-out Tank Filling: If the level in the wash tank has not been reached within ve

minutes and ten seconds, the lling solenoid valve is disconnected and the cycle light

starts blinking with a frequency of 0.5 seconds. To restart lling and to disconnect the

alarm, push the START button or turn the machine o and on by pressing the POWER

button twice.

Determine the reason for machine not lling and x (see Troubleshooting section)

before switching the machine on.

Booster Heating (with Thermo Stop): If the minimum booster temperature has not

been reached within eight minutes, the machine will pause and a rinsing phase will

follow. The cycle light starts blinking with a frequency of 0.3 seconds and keeps blinking

after the cycle ends. To disconnect the alarm, turn the machine o and on by pressing

the POWER button twice.

Determine the reason for temperature not being reached and x (see Troubleshooting

section) before switching the machine on.

Open Door: If door is opened at any time during the wash cycle, the cycle stops, all

machine functions are cut o (except heating elements), and the cycle light starts

blinking with a frequency of 0.5 seconds. If door is closed, the cycle restarts from the

stopping point and the cycle light stays on.

If alarm activates with the door closed, ensure the door switch is in correct position and

works properly.

WASHING A RACK

OF WARE

OPERATIONAL

INSPECTION

ALARMS

set set

POWER BUTTON CYCLE LIGHT

START BUTTON

set set

CYCLE BUTTON

START BUTTON

CYCLE LIGHT

11

07610-004-64-85-A

DRAINING 1. With machine on, open the door.

2. Remove the standpipe.

3. Hold the START button for about ve seconds.

4. When the cycle starts, close the door.

5. Total tank draining takes about three minutes.

6. After draining is complete, turn machine o by pushing the POWER button.

Leave machine o for at least ten seconds (this resets machine to normal

function).

1. Follow the Draining section.

2. Once machine is drained, turn power o and remove all debris from the strainers.

3. Remove rinse and wash arms.

4. Verify the rinse arms are not clogged. If so, remove end-caps with a 12 mm

wrench, clean nozzles with a brush, and flush with fresh water. Inspect end-cap

o-rings and replace if damaged. Replace end-caps and tighten.

INSTRUCTIONS

OPERATION

SHUTDOWN &

CLEANING

set set

set set

WARNING! Water

will be hot!

!

WARNING

Removing End-cap O-RingNozzles

07610-004-64-85-A 12

INSTRUCTIONS

OPERATION

SHUTDOWN &

CLEANING

5. Verify the wash arms are not clogged. If so, clean nozzles with a brush and flush

with fresh water.

6. Remove strainers.

7. Rinse strainers with water and wipe-out with a rag. Use a toothpick to dislodge any

stubborn debris.

8. Spray or wipe-out interior of machine. Ensure all debris is removed from tub

bottom.

9. Replace the strainers and ensure they are correctly seated.

10. Replace wash arms, rinse arms, and standpipe.

11. After cleaning is complete, stainless steel polish can be used to clean and

protect the outside of the machine.

Nozzles

13

07610-004-64-85-A

DELIMING To perform a deliming operation, follow the steps below. The tank capacities of the

machine can be found in the Specications section of this manual.

1. Follow the Filling the Wash Tank section.

2. Once rinse and wash lights have gone out, press the DELIME button to turn o

the chemical feeder pumps.

3. Add deliming solution to wash tank per chemical supplier's instructions.

4. Close the door.

5. Use the CYCLE button to select the heavy cycle.

6. Push the START button.

7. The cycle light will illuminate. When cycle is complete, the cycle light will go out.

8. Wait until cycle is complete and inspect the inside of the machine. If the

machine is not delimed, run again.

9. If the machine is delimed, follow the Draining section.

10. After draining is complete, turn machine o by pushing the POWER button.

Leave machine o for at least ten seconds (this resets machine to normal

function).

11. Press the DELIME button to turn the chemical feeder pumps back on.

12. Press the POWER button.

13. Run two cycles with no ware to remove residual deliming solution.

If this machine is equipped

with the SPS scale

prevention and corrosion

control device and lime is

becoming a frequent

problem, the cartridge

needs to be replaced.

To order a replacement

cartridge, call the

manufacturer.

NOTICE

INSTRUCTIONS

OPERATION

set set

set set

set set

set set

!

CAUTION

set set

set set

CAUTION! This equipment

is not recommended for

use with deionized water

or other aggressive uids.

Use of deionized water or

other aggressive uids

will result in corrosion

and failure of materials/

components and will

void the manufacturer’s

warranty.

07610-004-64-85-A 14

Detergent usage and water hardness are two factors that contribute greatly to how

eciently this machine will operate. Using detergent in the proper amount can

become a source of substantial savings. A qualied water treatment specialist can

determine what is needed for maximum eciency from the detergent.

1. Hard water greatly aects the performance of the machine, causing the amount

of detergent required for washing to increase. If the machine is installed in an

area with hard water, the manufacturer recommends the installation of water

treatment equipment.

2. Deposited solids from hard water can cause spotting that will not be removed

with a drying agent. Treated water will reduce this occurence.

3. Treated water may not be suitable for use in other areas of operation and it

could be necessary to install a water treatment unit for the water going to the

machine only. Discuss this option with a qualied water treatment specialist.

4. Operators should be properly trained on how much detergent to use per cycle.

Meet with a water treatment specialist and chemical supplier to discuss a

complete training program for operators.

5. This machine requires that chemicals be provided for proper operation and

sanitization. Contact a chemical supplier with any questions.

6. Water temperature is an important factor in ensuring the machine functions

properly, and the machine's data plate details what the minimum temperatures

must be for the incoming water supply, the wash tank, and the rinse tank. If

minimum requirements are not met, there is a possibility that dishes will not be

clean or sanitized.

7. Instruct operators to observe the required temperatures and to report when they

fall below the minimum allowed. A loss of temperature can indicate a larger

problem.

DETERGENT

CONTROL

i

INSTRUCTIONS

OPERATION

Other manuals for HT-E

1

Table of contents

Other Cleanware Dishwasher manuals