C0240111-01-06-GB

2

Summary

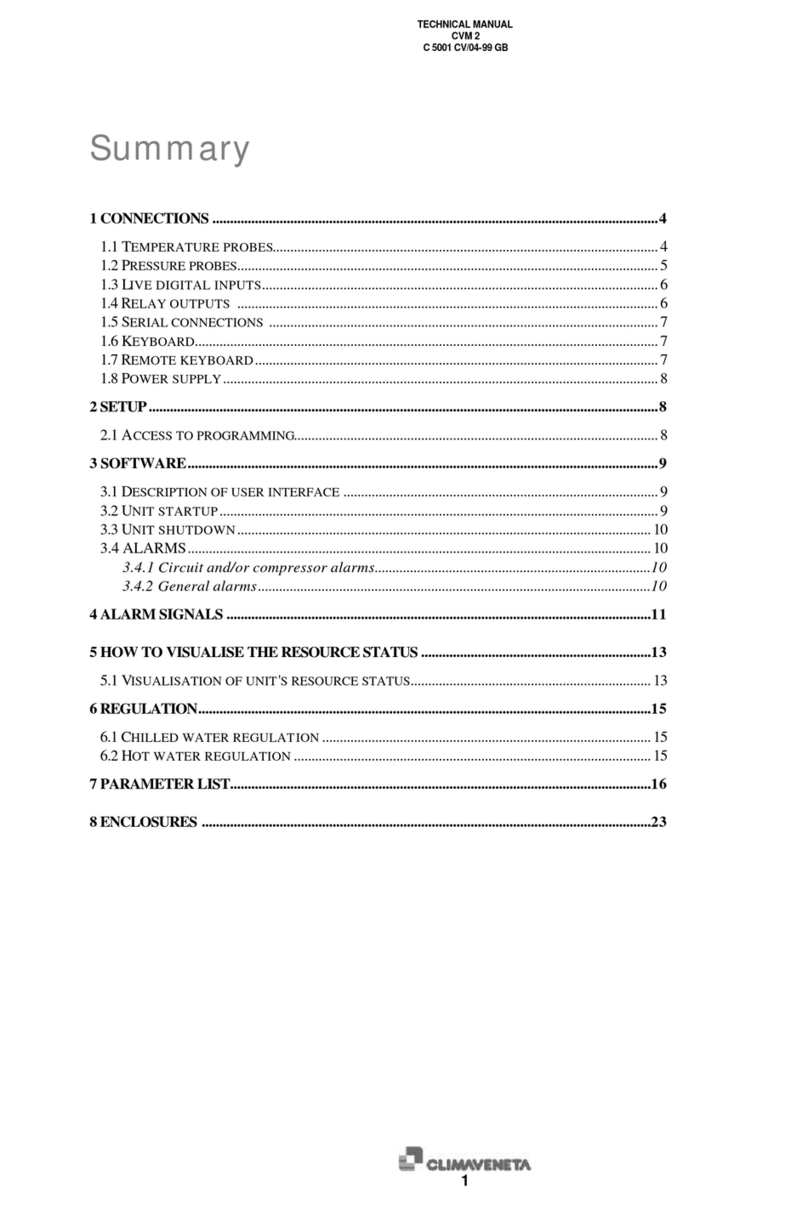

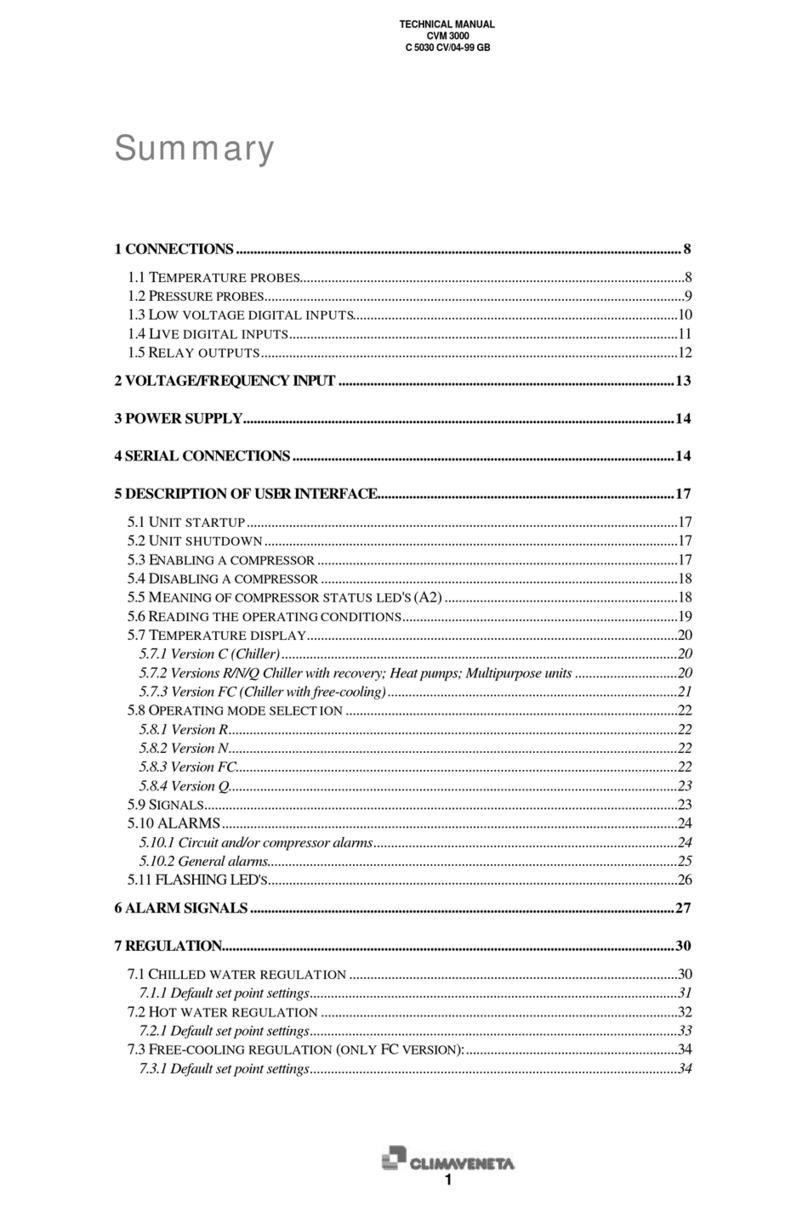

1USER INTERFACE................................................................................................................3

2MENU STRUCTURE .............................................................................................................. 4

3SETTING THE CONNECTIONS..............................................................................................6

3.1 Available hardware ............................................................................................................6

3.2 Connecting more than one unit............................................................................................ 9

3.3 Additional connections ..................................................................................................... 13

3.4 Configuring the terminals ................................................................................................. 14

4SWITCHING THE UNIT ON AND OFF .................................................................................21

5USER PROGRAMMING.......................................................................................................23

5.1) SETTING THE OPERATING MODE ...................................................................................... 23

5.2) USER MENU................................................................................................................... 25

5.2.1 ) ADJUSTMENT............................................................................................................. 25

5.2.2 ) RECOVERY................................................................................................................. 31

5.3) SETPOINT MENU ............................................................................................................ 33

5.4) CLOCK MENU.................................................................................................................33

6MANUFACTURER PROGRAMMING ..................................................................................... 34

6.1) FREECOOLING ............................................................................................................... 35

6.2) CONDENSATION ............................................................................................................ 36

7ALARMS............................................................................................................................38

ANNEX 1A : TABLE OF W3000 MASKS .....................................................................................43

ANNEX 1B : TABLE OF W3000 BASE MASKS .............................................................................66

ANNEX 1C : PARAMETERS TABLE .............................................................................................70

ANNEX 2 : INPUT/OUTPUT TABLE .......................................................................................... 77

“L” HARDWARE: ...................................................................................................................77

“XL” HARDWARE: ................................................................................................................. 82

“B” HARDWARE (for hermetic compressors).............................................................................. 85

EXPANSIONS ....................................................................................................................... 87

Notice: The W3000 controller software is protected by a digital signature.

This means that it can only work on cards supplied by Climaveneta and not on cards

purchased from other dealers.