1

1.0

INTRODUCTION

t is recommended that personnel study this

manual before attempting to operate, clean

or sterilize the MicroPower™ High Speed

Drill and accessories. The safe and effective use

of this equipment requires the understanding of

and compliance with all warnings, cautionary

notices, and instructions marked on the product,

and included in this manual.

1.1 Intended Use

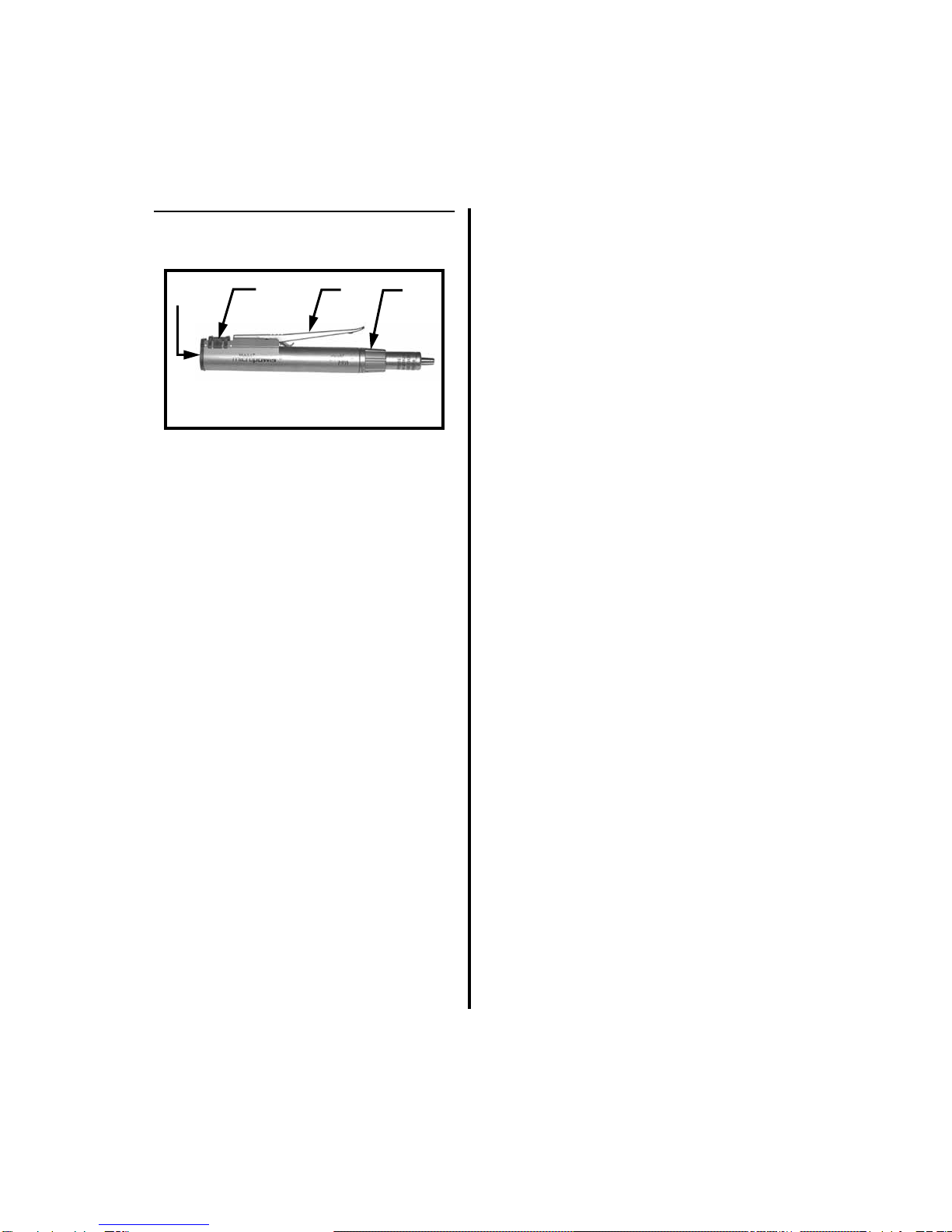

he MicroPower High Speed Drill, which

operates in conjunction with assorted bur

guards, burs and drill bits, is designed to

perform bone cutting, drilling, and soft tissue

resection.

This handpiece can be operated using the

PowerPro

®

(PRO2000/PRO2000I), the E9000

®

(E9000, E9000G, E9000J) or Advantage

®

(D3000, D3000I, D3000J) Controllers.

The MicroPower

High Speed Drill is intended

for small bone procedures such as:

Arthroscopic, Neurosurgical, Orthopedic

(hand, wrist, foot and ankle) and Plastic /

Reconstructive.

1.2 Warnings and Cautions

This equipment is designed for use by medical

professionals completely familiar with the

required techniques and instructions for use of

the equipment.

Read and follow all warning

and cautionary notices and instructions

marked on the product and included in this

manual.

Service intervals, as listed in

“Table 2:

Maintenance Schedule” on page 20

, are

required to keep the MicroPower High Speed

Drill and attachments at their optimum

operating performance.

1.2.1 Warnings

1. Eye protection is always

necessary when operating

equipment. Eye injury may result.

2.

Continually check

all handpieces and

attachments for overheating. If overheating

is sensed, immediately discontinue use and

return equipment for service. Overheating

of the bur, bit or blade may cause damage to

the bur, bit or blade and may cause thermal

necrosis.

3. Do not attach, insert or remove attachments

or accessories while the handpiece is oper-

ating. Serious injury may occur.

Place the

handpiece safety mechanism to the safe

position prior to installation or removal

of items

.

4. Do not immerse handpieces in fluids.

I

T