3. Specifications

Your Daken Finishing Mower is designed to cut a variety of grasses and other ground covers. You take the

responsibility if the machine is used for any other purpose.

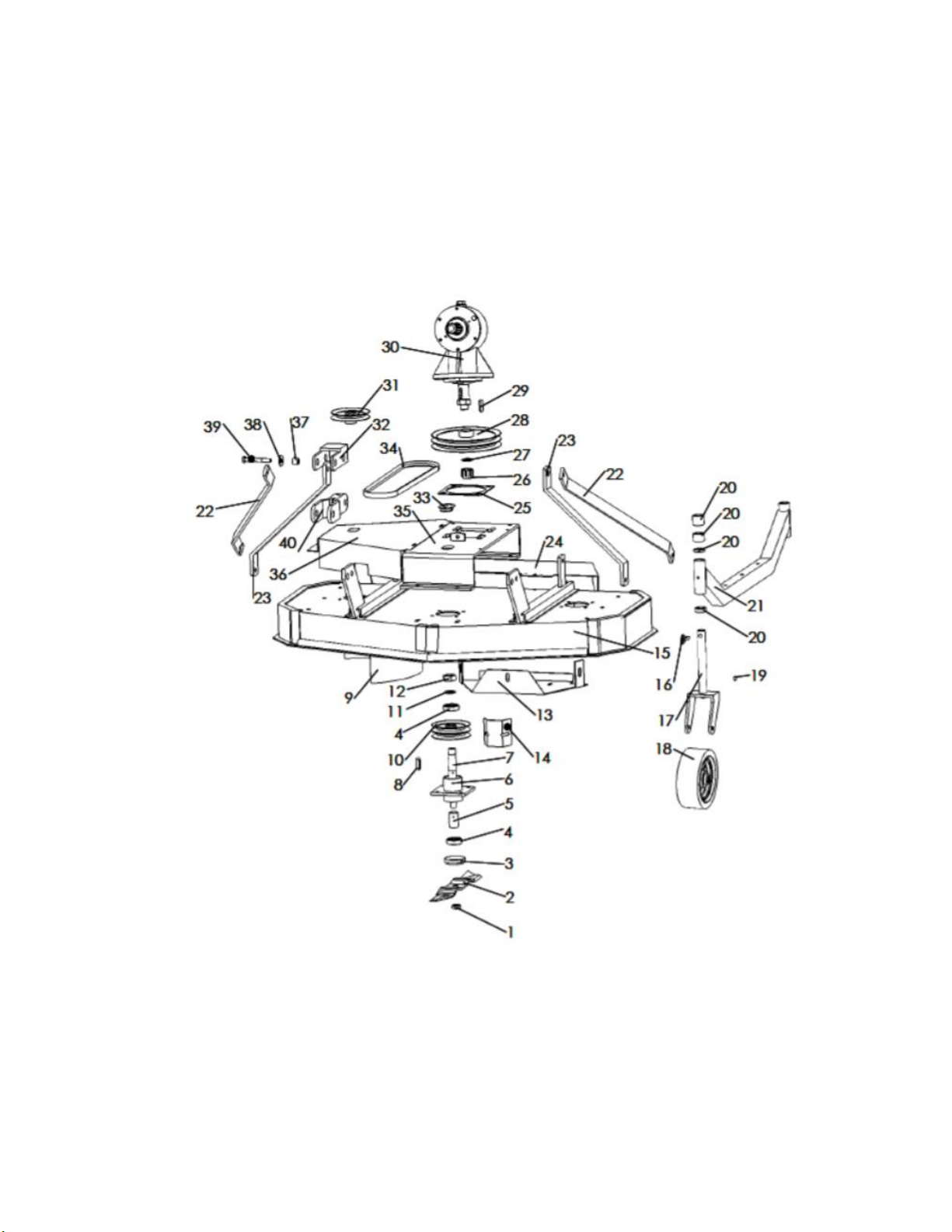

The Finishing Mower consists of three rotating shafts with five three steel blades attached to them. The blades

cut the grass while travelling over the working area. Rotational power to the shaft is provided by the tractor PTO

through the gearbox in the center of themachine.

The Finishing Mower attaches to the 3 point hitch on the tractor.

4. Operation

Checking before Operating

Before operating the machine, the following areas should be checkedoff:

1Before starting up the machine, check and lubricate all external grease points and ensure that all

lubricated parts inside the machine have been oiled.

2Use only an agricultural tractor of horsepower within limits of the machine specified.

3Check that the machine is properly attached to the tractor. Be sure retainers are used on the mounting

pins.

4Check the oil level in the gearbox. Add as required.

5Check that the tractor PTO shaft turns freely and that the machine drive shaft safety cover can telescope

easily.

6Check the blades. Be sure they are not damaged or broken. Repair or replace as required.

7Check and tighten the blade bolts.

8Check for entangled material in all rotating parts. Remove this material.

9Install and secure all guards, doors and covers before starting.

10 The chain on the protective parts of the universal joint shall be guaranteed in good condition, in case,

automatic rotation occurs.

Attaching / Unhooking

The Finishing Mower should always be located on a level, dry area that is free of debris and other foreign objects.

1. Remove protective cover from tractor’s PTO shaft, lower link and suspension mechanics of tractor. It

may be necessary to add weight to the 3 point hitch to lower the lift arms.

2. Reverse tractor at low speed towards the Finishing Mower and raise the lower links to proper level.

3. Connect tractor’s lower links with Finishing Mower’s left and right lower suspension pins. Connect the

tractor’s upper link with Finishing Mower’s upper suspension bracket and insertpin.

4. Attach the machine drive shaft to the tractor’s PTO shaft, slide the universal joint over the shaft and push

on the universal joint until the lock pin clicks into position. Pull on the universal joint to be sure it is locked

in position.

5. Check the length of the PTO drive shaft, there must be at least two thirds engagement to operate correctly.

6. If the drive shaft is too long it may need to be shortened.

7. Make sure the machine drive shaft telescopes easily and the shield rotates freely.

8. Use the 3 pint hitch to raise the machine from the ground before moving the machine.

9. Reverse the above procedure when unhooking the machine from the tractor.