Dings 70 Series User manual

70 Series Hazardous

Brake Instructions

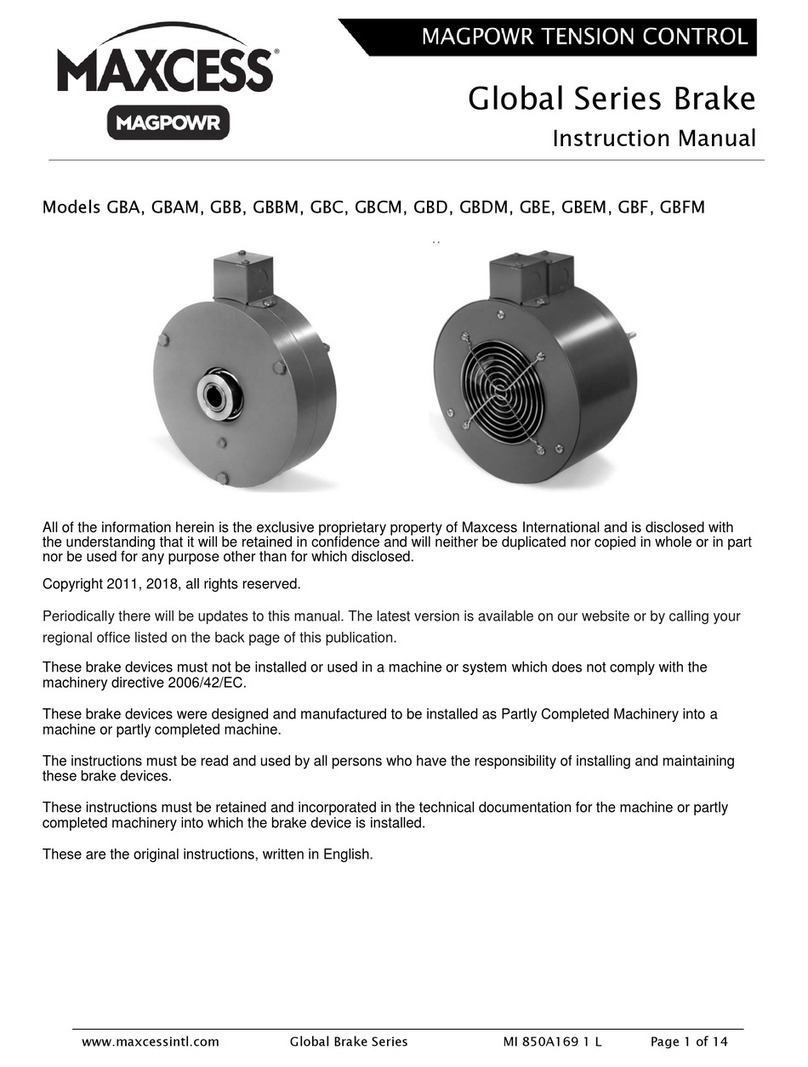

DESCRIPTION

The 70 Series Brake is a direct acting, electro magnetically released, spring set unit that utilizes rotating and stationary

disc contact to supply positive braking action with quick release and setting capabilities at all times. Brakes which are

not provided with a floor mounting bracket are intended to be mounted as an integral part of electric motors listed for

corresponding hazardous locations where the acceptability of the combinations has been determined by Underwriter’s

Laboratories, Inc. The explosion-proof assembly is completed by assembly of the brakes to the motors.

READ THIS BULLETIN CAREFULLY BEFORE INSTALLING OR OPERATING THE

70 SERIES BRAKE. FAILURE TO COMPLY WITH THESE INSTRUCTIONS CANCELS

ALL WARRANTIES SINCE THE SAFETY OF THE UNIT MAY BE ENDANGERED BY

IMPROPER INSTALLATION OR OPERATING PROCEDURES.

Bulletin No. BK4606 (8/07)

4740 WEST ELECTRIC AVENUE MILWAUKEE, WI 53219 PHONE 414/672-7830 FAX 414/672-5354 www. dingsco.com

MOTOR MOUNTED* FOOT MOUNTED

MODEL MODEL

NO. Torque NO. Torque

R71010-9 10 lb. ft. FR71010-9 10 lb. ft.

R71015-9 15 lb. ft. FR71015-9 15 lb. ft.

R72025-9 25 lb. ft. FR72025-9 25 lb. ft.

R73035-9 35 lb. ft. FR73035-9 35 lb. ft.

R74050-9 50 lb. ft. FR74050-9 50 lb. ft.

R75075-9 75 lb. ft. FR75075-9 75 lb. ft.

*If a hazardous location brake is purchased by other than an

authorized electric motor manufacturer, a Foot Mounted brake

must be purchased to obtain the UL label.

CAUTION

DO NOT OPERATE MANUAL RELEASE

OR ENERGIZE BRAKE COIL BEFORE

INSTALLATION IN ORDER TO PRESERVE

PRE-ALIGNMENT OF ROTATING DISCS

FOR EASE OF INSTALLATION.

USE ONLY HUB FURNISHED BY DINGS

SPECIFICALLY FOR USE IN HAZARDOUS

LOCATION BRAKES. DO NOT OPERATE

BRAKES IN EXPLOSIVE ATMOSPHERE

WITH COVER OR COVER BOLTS

REMOVED.

MANUAL RELEASE (See Figure 1)

To manually release brake, push in release knob and rotate

counterclockwise until strikes stop-pin. Brake will remain

released until release knob is pushed in and turned clockwise

or until power is restored, automatically resetting the brake.

THERMAL RELEASE

If the brake overheats, the thermal release mechanism will release

spring pressure on the friction discs, releasing brake. To reset ther-

mal release, allow brake to cool, then push in release knob (17)

and rotate clockwise until it strikes the stop-pin. Check brake

operation as overheating may indicate a broken lead wire or

burned out coil.

The thermal release mechanism has been calibrated at the factory

and the setting of the bimetal element and control rod MUST

NOT BE DISTURBED. If the mechanism does not function

properly, the complete pressure plate assembly (9), complete

magnet plate assembly (3), release gears (34) and items 31

through 50 must be returned to the factory for adjustments.

G060629-006

Figure 1.

Table 1. List of Models

WARNINGS

A. Read this bulletin carefully before installing or operating the brakes. Failure to comply

with the installation or operating instructions cancels all warranties and may cause

injury to personnel and damage to property.

B. DESCRIPTION

The 70 Series brake for hazardous location is a direct acting, electromagnetically

released, spring set brake that utilizes rotating and stationary disc contact to supply

positive braking action. Brakes can be mounted independently of any other equipment

by using a U.L. listed foot mounting bracket, or mounted to an electric motor listed for

hazardous locations. The brakes are equipped with a thermal overload mechanism that

prevents the external surfaces of the unit from exceeding the temperature rating for the

brake.

C. OPERATING INFORMATION

When the external surface of the brake approaches its temperature rating, the thermal

overload mechanism will automatically release the brake and hold it in the released

position. This prevents ignition of gases or suspended solis, assuming that brake’s

temperature rating is less than the air ignition temperature. The thermal overload

mechanism prevents the surface temperature of the brake from rising to a level that

could ignite the surrounding gases or dusts by releasing the brake and therefore,

stopping a further increase in temperature. Once the brake has been released by the

thermal overload mechanism, control over the rotation of the motor and the load is lost.

This uncontrolled rotation of the motor and movement of the load could cause injury to

personnel and damage to property.

2

The thermal overload mechanism can be reset manually after a cooling off period. Before

resetting, the root cause for actuating the thermal overload mechanism needs to be determined

and corrected.

To minimize the possibility of overheating the brake to a point where the thermal overload

mechanism will be actuated, the performance of the brake has to be matched to the requirements

of the application.

When selecting the brake model, consideration has to be given to brake torque, thermal

capacity, electrical power supply, housing material and any unusual conditions.

BRAKE TORQUE

As a general rule, brake torque is matched to the full load motor torque (brake and motor shaft

at the same speed). Depending on the type of application, the torque sometimes is increased by

a safety factor of 1.5 to 2. If factors such as stopping time, travel distance during stopping and

others, are important, the exact torque requirement has to be calculated, using the methods

contained in Dings selection guide.

THERMAL CAPACITY

Thermal capacity describes the capacity of the brake to perform the maximum number of

stops without excessive heat buildup that will actuate the thermal overload mechanism or

damage internal brake parts. The maximum number of stops depends on the rating of the brake,

load to be stopped and speed from which stops are made. To calculate the thermal capacity

requirements of the application, use the methods contained in Dings selection guide.

ELECTRICAL POWER SUPPLY

The coil of the electromagnet, which supplies the releasing force under normal operating

conditions, will operate properly with a tolerance of plus or minus 10% of rated voltage. A volt-

age higher than 110% will shorten the life of the coil considerably due to the higher temper-

ature generated inside the coil. A voltage of less than 90% may prevent the armature from mov-

ing towards the magnet frame. If this occurs, the coil will burn out within months.

UNUSUAL CONDITIONS

Please consult Dings Home Office, if ambient temperature is above 40oC (104oF), brake shaft

speed is over 3600 RPM, or any other unusual conditions exist.

3

Item Description Part

No. No.

1 Cover K070091-001

2 Gap Adjusting Nut W003001-022

3 Magnet & Coil Assembly, 3 Phase K070283-***

3 Magnet & Coil Assembly, 1 Phase K070282-***

4 Gap Adjusting Nut W003008-022

5 Torque Adjusting Nut W003001-023

6 Adjusting Nut Washer W004004-014

7 Torque Spring, 10 & 35 lb. ft. G070011-001

7 Torque Spring, 15 & 75 lb. ft. G070012-001

7 Torque Spring, 25 & 50 lb. ft. G070019-001

8 Stud G070175-***

9 Pressure Plate K070048-002

10 Rotating Friction Disc 10 - 50 lb. ft. H070103-005

10 Rotating Friction Disc 75 lb. ft. H020009-002

11 Stationary Disc 25 - 75 lb. ft. only K070485-001

12 Stud Lock Pin W005005-001

13 Brake Bracket L070066-***

14 Hub Assembly H070044-***

15 Mounting Bolt (not shown) W001013-132

16 Locking Screw W002002-001

17 Manual Release & Reset Knob G070141-003

18 Knob Release Spring G070202-001

19 Knob Roll Pin W005003-044

20 Reset Arm G070156-001

21 Cover Bolts W001013-108

22 Lock Washer W004006-008

23 Wiring Harness Guide G070218-001

24 Wiring Harness Clamp W021001-001

Item Description Part

No. No.

25 Clamp Screw W001002-051

26 Coil, 3 Phase (included in item 3) H070033-***

26 Coil, 1 Phase (included in item 3) H070035-***

27 Insulating Washer, 3 Phase G070037-001

27 Insulating Washer, 1 Phase G070029-001

28 Condulet Assembly G070148-001

29 Nameplate H050020-001

30 Press Nut W003012-024

31 Drive Gear G070167-001

32 Pivot Stud G070153-001

33 Release Rod w/ Snap Ring G070134-002

34 Release Gear G070140-001

35 Release Bearing W009002-001

36 Release Rod Spring G060010-001

37 Release Reset Spring G070159-001

38 Release Stop Stud G070144-001

39 Driver G070152-001

40 Lock Bushing G070119-001

41 Lock Pin G070157-001

42 Lock Spring G070158-001

43 Felt Washer G070162-001

44 Washer W004001-003

45 Control Rod Wiper Assembly*

46 Control Rod Assembly*

47 Thermal Release Bracket Assembly*

49 Driver Spring Stud G070143-001

50 Drive Spring (1, 2, & 3 Disc) G070160-001

50 Drive Spring (4 & 5 Disc) G070160-002

4

*Install only at factory.

***Varies by brake model–provide model and serial number.

INSTALLATION OF BRAKE ON MOTOR

ENDSHIELD (See Figures 2, 3 and Table 4)

Do not operate manual release or energize brake coil before

installation in order to preserve pre-alignment of rotating disc

for easy installation of brake to motor.

Because of the close fit on all joints (bracket, cover, hub), care

should be taken to prevent damage to all machined surfaces.

Do not operate brake in hazardous location with cover removed.

All testing must be done in a non-explosive atmosphere.

1. Remove hub (14) from brake and mount hub with key (not

supplied by Dings) on motor shaft per dimension “BC” shown

in Figure 2. Be sure that hub used is item supplied by Dings

for hazardous location applications. Tighten both set screws to

8-10 lb. ft. torque.

2. Remove four cover bolts (21) and tap cover with soft mallet.

Remove cover (1). Do not operate the manual release (17)

until brake is installed.

3. Inspect motor “C” flange and remove any nicks or burrs. This

will assure a precision fit of brake to motor flange. Slide

brake over hub (14), engaging teeth of rotating disc (10) and

hub.

4. Install four mounting bolts (15) and tighten. Install four

locking set screws (16) and tighten to 40 lb. ft. torque. This

seals flame path around mounting bolts. Check rotation of hub

to make certain it does not rub in bracket (13). Diametrical

clearance or hub outside diameter to bracket bore shall not

exceed .024”.

5. Connect brake leads to power as shown in Figure 3. All

wiring should be positioned to prevent pinching or chafing

and all connections well taped to prevent grounding.

6. Replace cover (1). This may be done more easily by threading

a 3/8” dia. by 5” long stud (threaded one end 3/8-16NC) into

one cover bolt hole in magnet plate assembly (3) as guide.

Slide cover into position using stud as a guide and tap with

soft mallet until cover seats. Use care in assembly. Insert 3

cover bolts (21) and finger tighten. Remove guide stud and

insert fourth cover bolt. Draw up all bolts evenly and tighten

until spring washer (22) is fully compressed. A loose or

missing bolt will render the brake unsafe for operation in

hazardous locations.

INSTALLATION OF BRAKE WITH ADAPTER

ON MOTOR ENDSHIELD (See Figure 4)

7. Inspect motor “C” flange and remove any nicks or burrs. This

will insure a precision fit of adapter to the motor flange.

Mount adapter to motor flange using the four bolts and lock

washers supplied. A soft mallet may be used to tap adapter

into place. All bolts should be drawn up evenly and tight.

8. Check alignment or adapter. Clamp dial indicator to brake

hub (position A) and measure pilot eccentricity. This must

not exceed .006” total indicator reading for a full revolution

of hub. Reposition dial indicator (position B) and check

adapter face runout which must not exceed .006” total

indicator reading a full revolution of the shaft. Remove hub

(14) from brake and mount hub with key (not supplied by

Dings) on motor shaft per dimension shown in Figure 2.

Tighten both setscrews to 8-10 lb. ft. torque. Complete

mounting of brake per paragraphs 2 through 6.

Figure 2. Wiring Connections

Figure 3. Adapter Installation

ITEM PART NO.

NO. DESCRIPTION NO. REQ.

3 Magnet assembly with coils -- 1

26 Magnet coil (3 phase) H070033 6

26A “ “ (1 phase) H070035 2

27 Insulating washer (3 phase) G070037 4

27A “ “ (1 phase) G070029 4

51 Shading coil (1 phase only) G070032 2

Table 2. Electrical Parts List

5

Torque “BC” Spring Shaft Length Magnet Gap “A”

Model Number Lb. Ft. +1/32 -.000 Length “D” “AH” Max. A-Min. A-Max.

R71010-9 10 5/8 1-5/16 3-7/16 .030 .062

R71015-9 15 5/8 1-5/16 3-7/16 .030 .062

R72025-9 25 5/8 1-5/16 3-3/4 .030 .062

R73035-9 35 5/8 1-5/16 4-3/8 .035 .062

R74050-9 50 5/8 1-5/16 5-1/8 .035 .062

R75075-9 75 5/8 1-5/16 5-1/8 .045 .062

INSTALLATION OF FOOT MOUNTING

BRAKE (See Tables 4, 5 & Figure 5)

9. Install bracket (F1) over motor shaft extension and half-

tighten capscrews (F8). The distance from the mounting face

of the bracket (F1) to end of motor shaft must not exceed

dimension “AH” max. (Table 5).

10. Clamp dial indicator “A” to motor shaft and position bracket

(F1) with shims as necessary, by tapping with a soft mallet

until dial indicator does not read over .002” total change in

one full revolution of the shaft. Move dial indicator to “B”

and position bracket until dial indicator does not read over

.004” total change in one full revolution of shaft.

11. Draw all bolts up tight. Recheck alignment with dial indicator.

Readjust if necessary until tolerances are within limits with all

bolts tight. Drill eight 1/4” dia. holes into mating parts and

drive dowel pins (F7) into place.

12. Mount stop bushing (F3) on shaft with clearance of .005” to

.015” between bushing and bracket (F1). Mount hub (14) on

shaft butting firmly against stop bushing. Complete mounting

of brake per paragraphs 2 through 6.

WEAR ADJUSTMENT (See Figure 2 & Table 4)

13. The magnet gap “A” increases as the friction discs wear.

When magnet gap measures “A-Max,” adjust to “A-Min”

using gap adjusting nuts (2) and (4). Magnet gap must never

exceed “A-Max” and must be adjusted periodically.

ITEM DESCRIPTION QTY PART NUMBER

F1 Foot Mtg. Bracket 1 K070066-001

F2 Foot Pad 2 G070180-001

F3 Stop Bushing 1 G070181-*

F4 Set Screw 2 W002001-013

F5 Hx. Hd. Cap Screw 4 W001007-055

F6 Split Lockwasher 8 W004006-008

F7 Roll Pin 8 W005003-170

F8 Hx. Hd. Cap Screw 4 W001007-058

14 Hub 1 H070044-*

15 Mounting Bolt 4 W001013-132

16 Locking Screw 4 W002002-001

*Specify bore

MODEL 71010 71015 72025 73035 74050 75075

“AH” 4-3/4 4-3/4 5-1/16 5-11/16 6-7/16 6-7/16

Table 4. Adjustments

Table 5. Foot Mounting Parts

Figure 5.

6

TORQUE ADJUSTMENT

(See Figure 2 & Table 4)

14. Adjust length of torque springs (7) to dimension “D” for

rated torque. To decrease torque, increase spring length

(“D” max =1-1/2”). Both torque springs must be adjusted

to the same length.

FRICTION DISC REPLACEMENT

(See Figure 2)

15. Remove cover screws (21) and cover (1).

16. Remove pivot stud (32), reset spring (37), drive gear (31),

drive spring (50), and driver (39). Unscrew release gear (34)

and remove release bearing (35). Remove gap adjusting nut

(2), reset spring (37) and drive spring (50).

17. Remove magnet plate (3). Take care not to bend control rod

assembly (45).

18. Remove gap adjusting nut (4), torque nut (5), washer (6) and

torque spring (7). Remove pressure plate (9). The friction

discs (10) may now be replaced.

19. Reassemble brake. Replace pressure plate (9), torque spring

(7), washer (6) and torque nut (5). Set spring length to

dimension “D” (Fig. 2). Assembly gap adjusting nut (4) and

magnet plate (3) taking care not to bend control rod assembly

(46). Set magnet gap to dimension “A” (Fig. 2 and Table 4).

20. Install two release bearings (35) into recesses of magnet

plate (3). Thread two release gears (34) onto release rods (33).

Turn release gears (34) clockwise until snug but do not raise

pressure plate (9). Make certain that release rods (33) are

seated in the pressure plate recesses.

21. Insert lock spring (42) and lock pin (41) in the underside of

the driver (39) and center the driver (39) on magnet plate (3)

at same time engaging lock pin (41) in lock bushing (40).

22. Insert pivot stud (32) into drive gear (31) and driver (39).

Line up marked teeth of release gears (34) and drive gear (31)

and tighten pivot stud into magnet plate (3). Install drive

spring (50) and reset spring (37). Check operation of manual

release mechanism. Mount brake cover (See Paragraphs 2 to

6).

23. Alternate method of lining up release mechanism if markings

not visible: Turn release gears (34) clockwise until both are

tight and magnet gap is fully closed. Rotate release gears (34)

counterclockwise from vertical centerline and center of brake

10 roots (valleys) of teeth. Drive gear (31) is to engage this

tenth root the following number of teeth from top right and

lower left edge of drive gear (31): 1 disc = 5, 2 disc = 6,

3 disc = 7, 4 disc = 8, and 5 disc = 9. Then continue per

paragraph 23. Do not tamper with thermal release mechanism

or control rod setting.

MAGNET COIL REPLACEMENT

(See Figures 2, 3 & 6 and Table 3)

24. Remove magnet assembly (3) (See Paragraphs 15 to 16).

25. Remove shading coils (51) (Single phase brakes only).

26. Coils (26) are held in place by epoxy cement or by bent over

end laminations. Force coil off magnet if held by epoxy. Remove

excess epoxy from magnet surfaces or bend up laminations and

remove coils.

27. Replacement coils are held in place by bending of end lami-

nations (See Figure 6). Insulating washers (27) are used above and

below on replacements. Remember this when ordering replacement

coils.

28. Replace coils. Sequence of black and yellow leads must be

maintained (See Figure 3). Important: Shading coils must be

replaced and held securely by staking in center of shading coil slot

or by cementing with epoxy. Bend down end laminations to

securely hold coils.

29. Reassemble brake (See Paragraphs 19 to 22).

Figure 6. Fastening of Replacement Magnet Coils

7

TROUBLESHOOTING

BRAKE DOES NOT RELEASE

Check for failure of power supply to brake.

Check brake visually for broken or damaged parts.

Check for broken leadwire or bad electrical connection.

Check for correct voltage. Voltage must correspond to that listed

on brake nameplate. If voltage is more than 10% below figure

stamped on nameplate, magnet will not pull in, causing coil to

burn out within minutes. If voltage is more than 10% above,

coil will overheat and burn out.

Check for burned out coils (coils may be charred or burned).

Check for excessive magnet gap (See WEAR ADJUSTMENT).

BRAKE DOES NOT STOP

Check manual release. Drive gear must be turned completely

clockwise.

Check thermal release. Release may have tripped.

Check brake visually for broken or damaged parts.

Check disc wear (See WEAR ADJUSTMENT).

Check for broken friction disc.

Make certain hub has not shifted position on shaft and that all

rotating discs are fully engaged on hub.

BRAKE CHATTERS OR HUMS

Clean magnet faces if dirty. Insert a clean sheet of paper between

magnet faces and energize brake. Move paper around between

faces to dislodge dirt. Finally, remove paper.

Check that magnet faces are parallel in closed position. If not

parallel along length of magnet, adjust (See WEAR

ADJUSTMENT).

Check if shading coil is cracked, broken or out of position.

Check for low voltage. Magnet will not pull in and coil will burn

out if voltage is more than 10% below figure stamped on

nameplate.

SPECIFICATIONS

For NEMA Frames 213TC, 215TC, 254TC, and 256TC.

Adapters available for many other frames.

HEATERS: UL listed heaters available.

VOLTAGES: All standard NEMA 3 phase and single phase

voltages and frequencies available. Other voltages and

frequencies optional. Add suffix “S” to model number to

denote single phase.

TORQUE: 10, 15, 25, 35, 50 and 75 lb. ft. available.

ORDERING INFORMATION

The following information should be furnished with your order for:

REPLACEMENT PARTS

Brake Model Number

Part Number from Pages 2, 3, or 4.

Part Description from Pages 2, 3, or 4. (On hub order, bore

diameter & keyway dimensions. On electrical parts, specify

voltage, phase & frequency.)

REPLACEMENT BRAKE

Model Number

Voltage, Phase & Frequency

Hub Bore & Keyway Dimensions

Mounting - Horizontal or Vertical (If vertical, specify

whether above or below motor. If brake includes foot

mounting bracket or adapter, specify.)

4740 WEST ELECTRIC AVENUE MILWAUKEE, WI 53219 PHONE 414/672-7830 FAX 414/672-5354 www. dingsco.com

WARRANTY

Seller warrants products manufactured by it and supplied

hereunder to be free from defects in materials and work-

manship under normal use and proper maintenance for a

period of twelve months from date of shipment. If within

such period any such products shall be proved to Seller’s

reasonable satisfaction to be defective, such products shall

be repaired or replaced at Seller’s option Seller’s obligation

and Buyer’s exclusive remedy hereunder shall be limited to

such repair and replacement and shall be conditioned upon

Seller’s receiving written notice of any alleged defect no

later than 10 days after its discovery within the warranty

period and, at Seller’s option, the return of such products to

Seller, f.o.b. its factory, when such return is feasible. Seller

reserves the right to satisfy its warranty obligation in full by

reimbursing Buyer for all payments it makes hereunder, and

Buyer shall thereupon return the products to Seller. Seller

shall have the right to remedy such defects. Seller makes

no warranty with respect to wear or use items, such as belts,

chains, sprockets, discs and coils, all which are sold strictly

AS IS.

The foregoing warranties are exclusive and in lieu

of all other express and implied warranties (except of

title) including but not limited to implied warranties

of merchantability, fitness for a particular purpose,

performance, or otherwise, and in no event shall the

Seller be liable for claims (based upon breach of express

or implied warranty, negligence, product liability, or

otherwise) for any other damages, whether direct, immediate,

incidental, foreseeable, consequential, or special.

This manual suits for next models

12

Table of contents