BUCKEYE

21D-100 & 21D-500 Series Pistol Grip Drills PL32-21D

September 14, 2001

ALWAYS COMPLY WITH:

1. General industry Safety & Health Regulations, Part 1910,

OSHA 2206, available from: Sup’t of Documents; Government

Printing Office; Washington, DC 20402.

2. Safety Code of Portable Air Tools, ANSI B186.1 available from:

American National Standards Institute, Inc.; 1430 Broadway;

New York, NY 10018.

3. State and Local regulations.

Portions of the above codes and regulations are listed below for

quick reference.

THE FOLLOWING EXCERPTS ARE NOT INTENDED TO BE ALL

INCLUSIVE: STUDY AND COMPLY WITH ALL REGULATIONS!

1. TOOL INTENT: Tools shall be used only for purposes intended

in their design (refer to product catalog).

2. AIR SUPPLY: Test and operate tools at 90 PSIG maximum

unless tool is marked otherwise. Use recommended airline

filters-regulators-lubricators.

3. UNUSUAL SOUND or VIBRATION: If tool vibrates or produces

an unusual sound, repair immediately for correction.

4. OPERATOR PROTECTIVE EQUIPMENT: Wear goggles or

face shield at all times tool is in operation. Other protective

clothing shall be worn, if necessary. SEE REGULATIONS.

5. SAFETY MAINTENANCE PROGRAM: Employ a safety

program to provide inspection and maintenance of all phases

of tool operation and air supply equipment in accordance with

“Safety Code for Portable Air Tools.”

Safety First!

The SPEED TOLERANCE is rated speed minus 10%.The tool must NOT have a free speed higher than the

RPM stamped on the housing. Use an accurate tachometer to check the tool speed, with 90 psig air pressure at

the tool with the tool running.

CAUTION: Disconnect the air supply hose before servicing the tool.

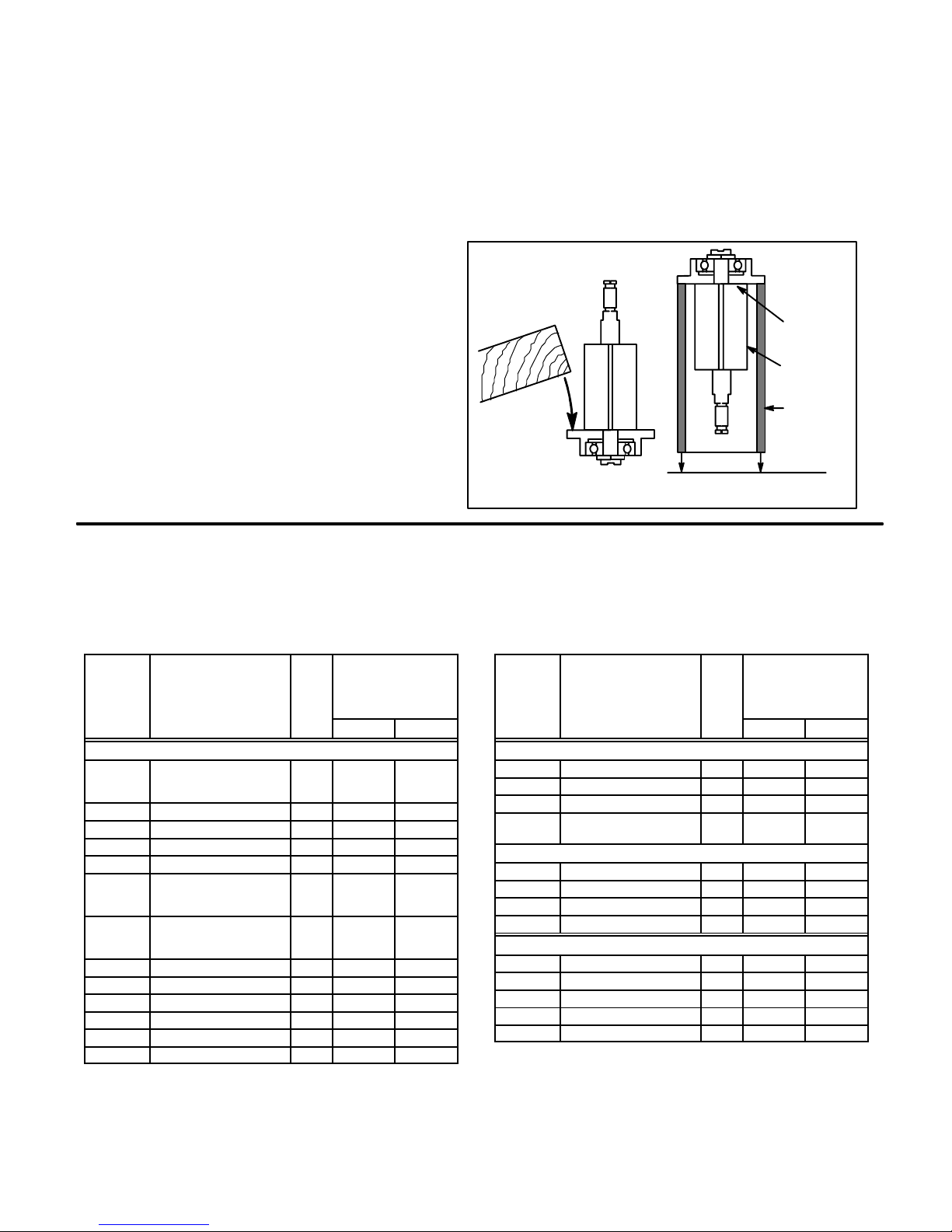

INSTALLATION:

For best performance, a working air pressure of 90 pounds per

square inch is recommended. Pipings, fittings, and hose should be

adequate to maintain 90 psig while the tool in in operation. An air

line filter and lubricator, such as CooperTools’#F02-M Filter (1/4”

NPT) and #L02-EP Lubricator (1/4”NPT) should be used (refer to

product catalog). Hose should be blown out before attaching to tool.

LUBRICATION:

The gears in angle head style tools must be lubricated every 8

hours of operation with high quality gear grease. CooperTools’

grease #45-0980 is recommended. A Grease Gun, #45-1982, is

furnished with each geared tool. Insert the nozzle into the flush type

lube fitting, located on the side or top of the angle head, and pump

four or five times. The motor must be lubricated and moisture free.

Use a high grade SAE #5 spindle oil, such as CooperTools’

Lubricating oil #45-0918 (one quart). Two or three drops per minute

should be sufficient lubrication. NOTE: Turbine motor type tools

(10-90 & 10-95) must NOT be oiled.

LOSS OF POWER:

It is seldom necessary to disassemble this tool for loss of power. A

loss of power may not be related to the tool. First, check the air line

regulator. Also, check the air line pressure; it should be 90 psig at or

near the tool while the tool is running. Check the size of hose and

fittings to be certain they are not causing air restrictions. Make

certain they are not plugged with dirt, rust, or scale.

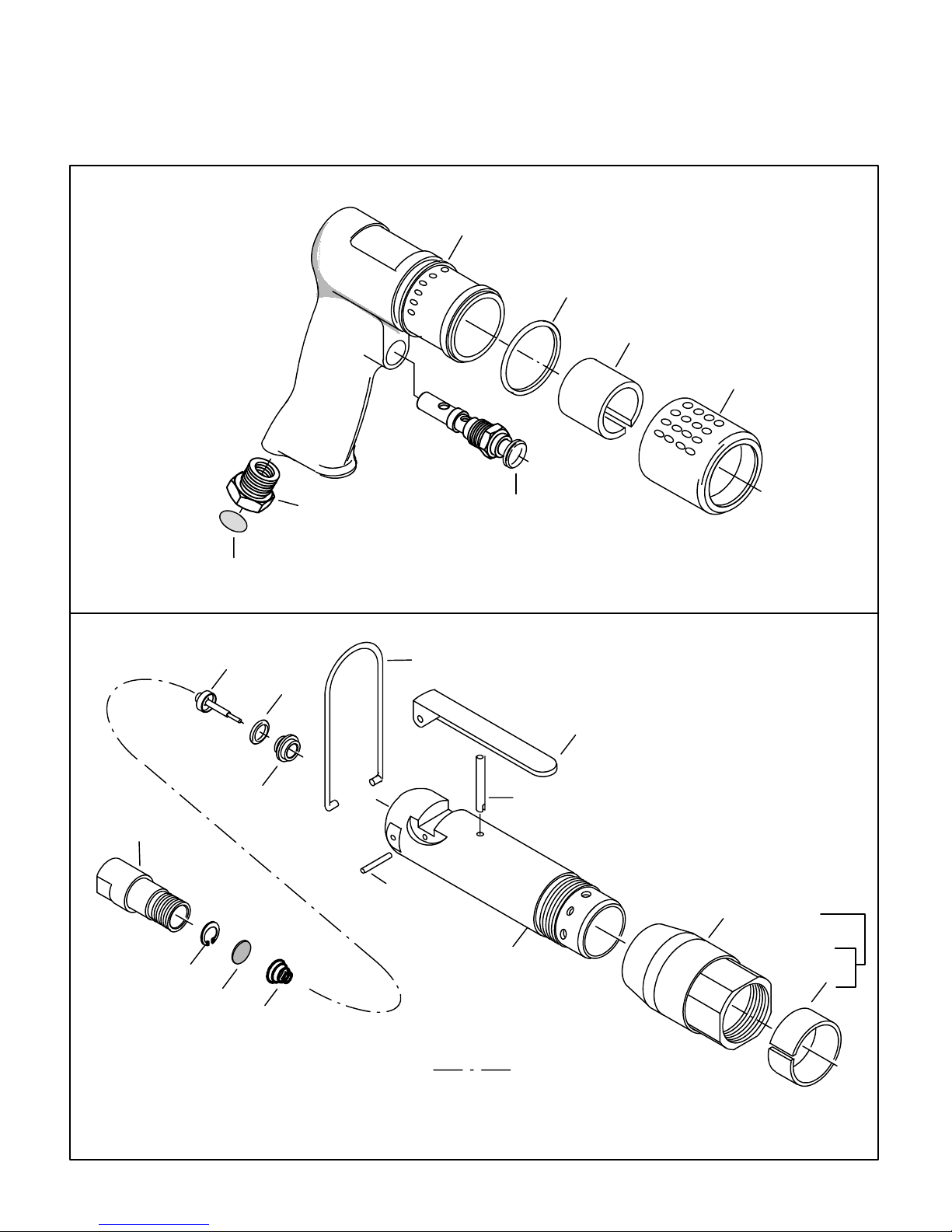

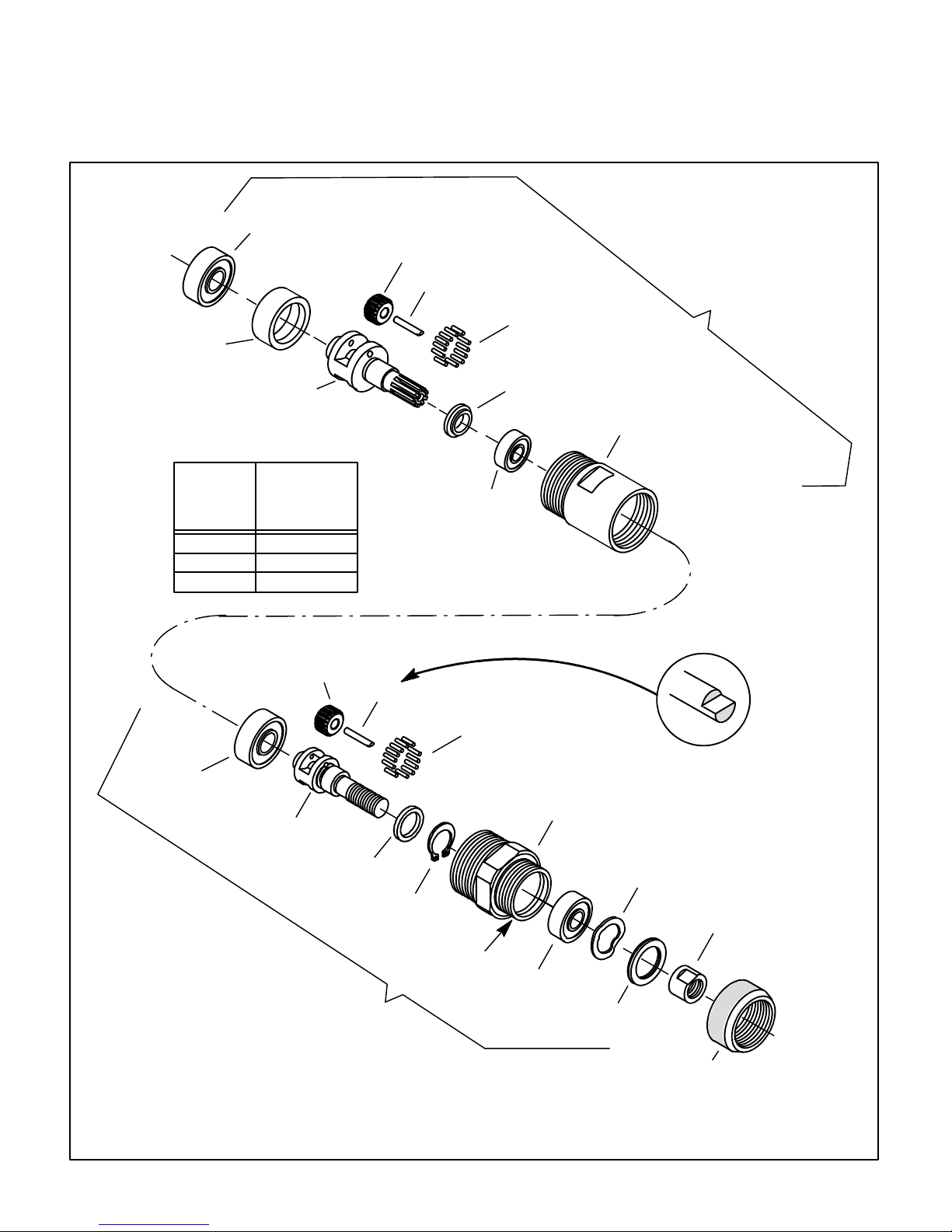

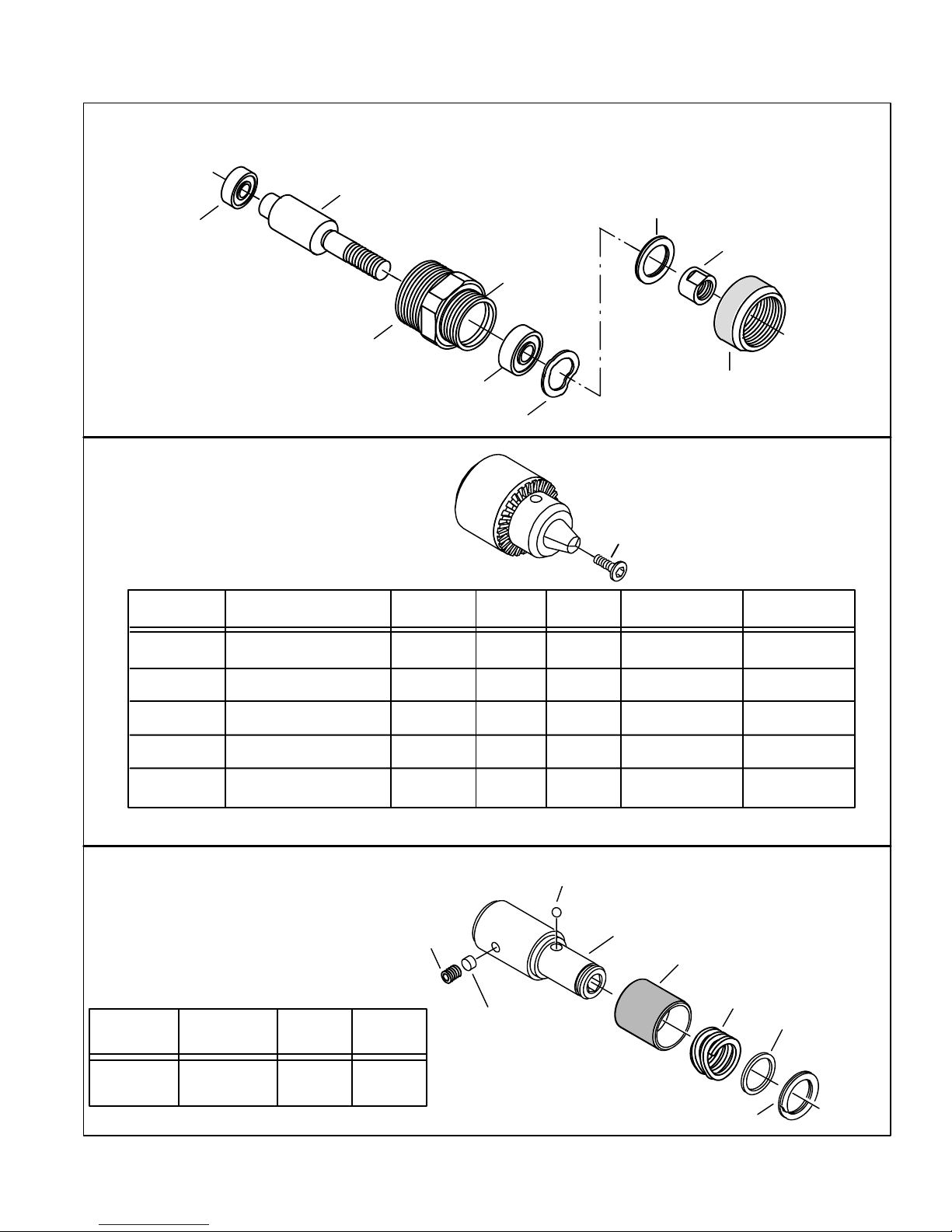

SERVICE INSTRUCTIONS:

The parts of this tool are small and require careful handling. We

recommend the tool be returned to the factory for repair. However, if

the tool is to be repaird in the field, carefully follow instructions. Do

not squeeze the tool or parts in a vise except as specified. Care

must be used during assembly and disassembly. When pressing

bearings onto a shaft, press only on the inner race. When pressing

bearings into a bore, press on the outer race only. NOTE: Ball

bearings are the shielded type. They are lubricated for life by the

bearing manufacturer and should not be washed out with solvents to

clean.

WARNING!

CHECK SPEED OF TOOL WITHOUT WHEEL BEFORE IT IS RELEASED FOR USE.