9

Service Manual for Refrigerated Back Bar Model RUF 48

Door Replacement and Adjustment

General

Doorsmaybecomemisalignedduringshipment

butareeasilyadjusted.

1. Foralowhangingdoor,usea3/8”openwrench

totighten,butdonotovertighten,bothtopand

bottomhingescrews.

2. Placeaatscrewdriveragainstoutersideof

bottomhingeandlightlytapwithahammer

untildoorisproperlyaligned.

3. If necessary, place at screwdriver against

inner side of top hinge and tap lightly with

hammeruntildoorisproperlyaligned.

4. Afterproperlyaligningdoors,tightenallhinge

screwssecurely.

Door Gasket Replacement

General

Thedoorgaskethasaretainingpanel.

1. Remove gasket door panel and mounting

screws.

2. Removegasketanddoorpanel.

3. Positionnewgasketandpanelondoor.

4. Securewithmountingscrews.Tightenscrews

evenlyarounddoorpanel.

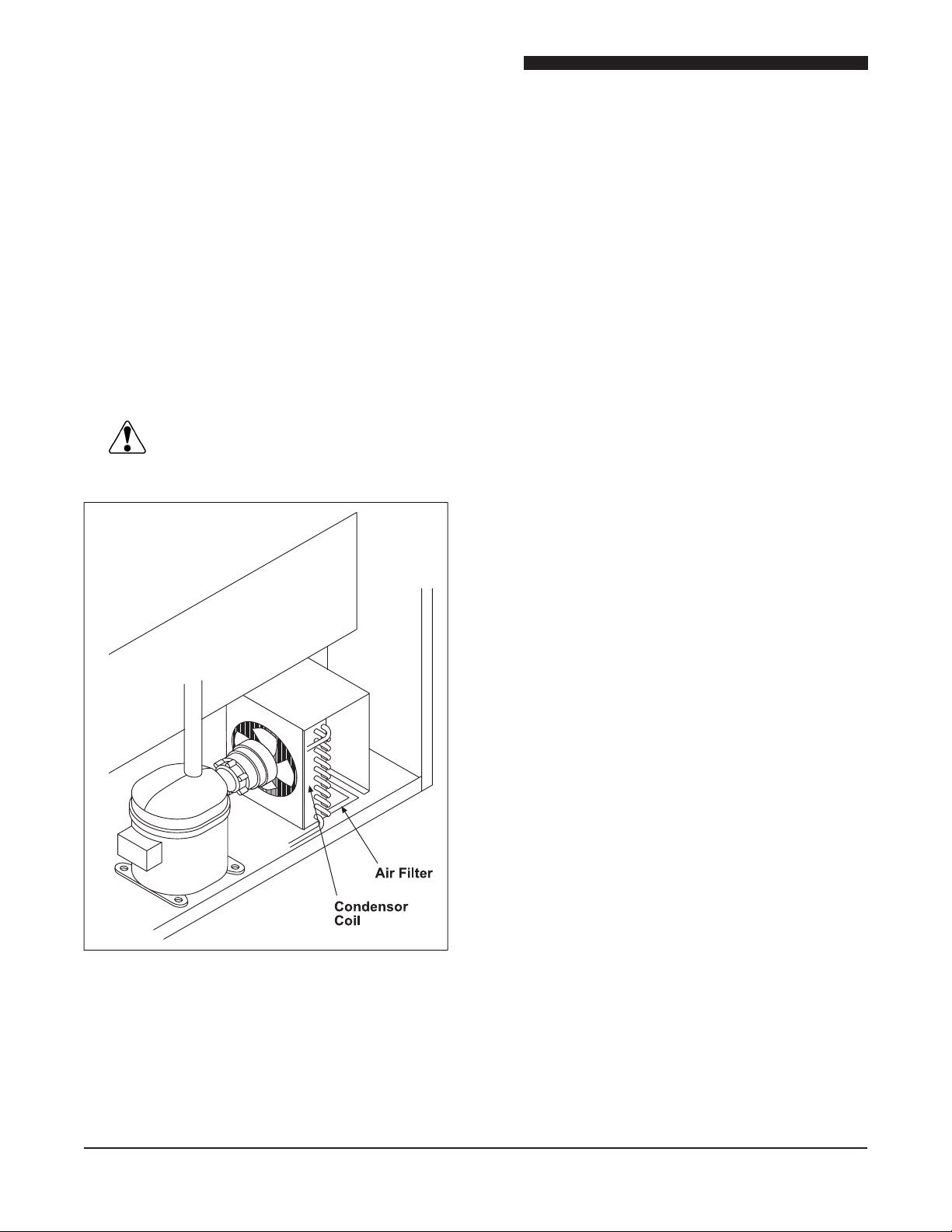

Recharging Refrigeration System

General

To analyze the performance of a refrigeration

system,temperaturereadingsarerecordedand

convertedtopressurereadingsusingastandard

pressure/temperaturechart.

Whenitisnecessarytoserviceafactory-sealed

refrigerationsystemandreturnittoitsproperly

sealedcondition,strictlyadheretothefollowing

approvedprocedure.

Tools

• Standardhandandrefrigerationtools

• RefrigerantType:R-134A,Refertodatatag

foramount

Charging Procedure

NOTE:Priortorefrigerationsystemservice,special

caremustbetakenduringtheevacuationprocessto

removeair,moistureandothernon-condensables

fromthesystem.DukeManufacturingrecommends

thefollowingtripleevacuationmethod.Failureto

followthisproceduremayresultinpoorrefrigeration

systemperformance.

1. Evacuatesystemto1500microns.

2. Breakvacuumto2psigwithdrynitrogen.If

drynitrogenisunavailable,usesametypeof

refrigerantasusedinsystem.

3. Evacuatesystemto500microns.

Thesystemisnowreadytoreceiverefrigerant

chargeaccordingtoinformationondataplate.

CAUTION: Never use oxygen or acetylene in

place of dry nitrogen or refrigerant

forleaktesting.Aviolentexplosion

mayresult,causingpropertydamage,

personalinjuryordeath.Whenusing

nitrogentopressuretest,alwaysuse

apressureregulator.Failuretodoso

willresultinextremelyhighpressure

ofthecompressororothersystem

components and result in property

damage,personalinjuryanddeath.

NOTE: Prior to repair, ensure there is enough

process hose (approximately 12”) present to

completetherepairusingtheaboveprocedure.

Ifnot,installa newprocesshosebeforerepair

sequence.