ECCOTARP ET-ROLLER 5 User manual

ET-ROLLER 5

Electric roller for fire hoses up to 5"

INSTRUCTIONS FOR USE US

T1 929-272-2336

Fax 212-683-8516

Eoce@eccotarp.com

www.eccotarp.us

Metal Arsenal s.r.o.

Owner of Eccotarp USA

trade mark

ECCOTARP USA, inc.

357 West 36th Street

New York, NY 10018

USA

Development

and

Production

This document„Instructions for use“ (hereinafter manual) is used to get acquainted with the

operation and characteristics of the ET-Roller 5 – Electric roller for re hoses up to 5" (hereinafter

„the roller“ or„the winder“), and describes themannerof its use and possible risks connected

withitsuse.

It contains important information about how to use the device properly so as to avoid injuries

andincrease its reliability and extend its lifetime.

This document must always be available in the place where the winder is used. Keep it together

with the device at all times.

The operator is responsible for using the device safely and in compliance with the instructions

inthis manual, which applies to any third persons as well. If you have any doubts about operating

the winder, please contact the manufacturer or an authorized dealer.

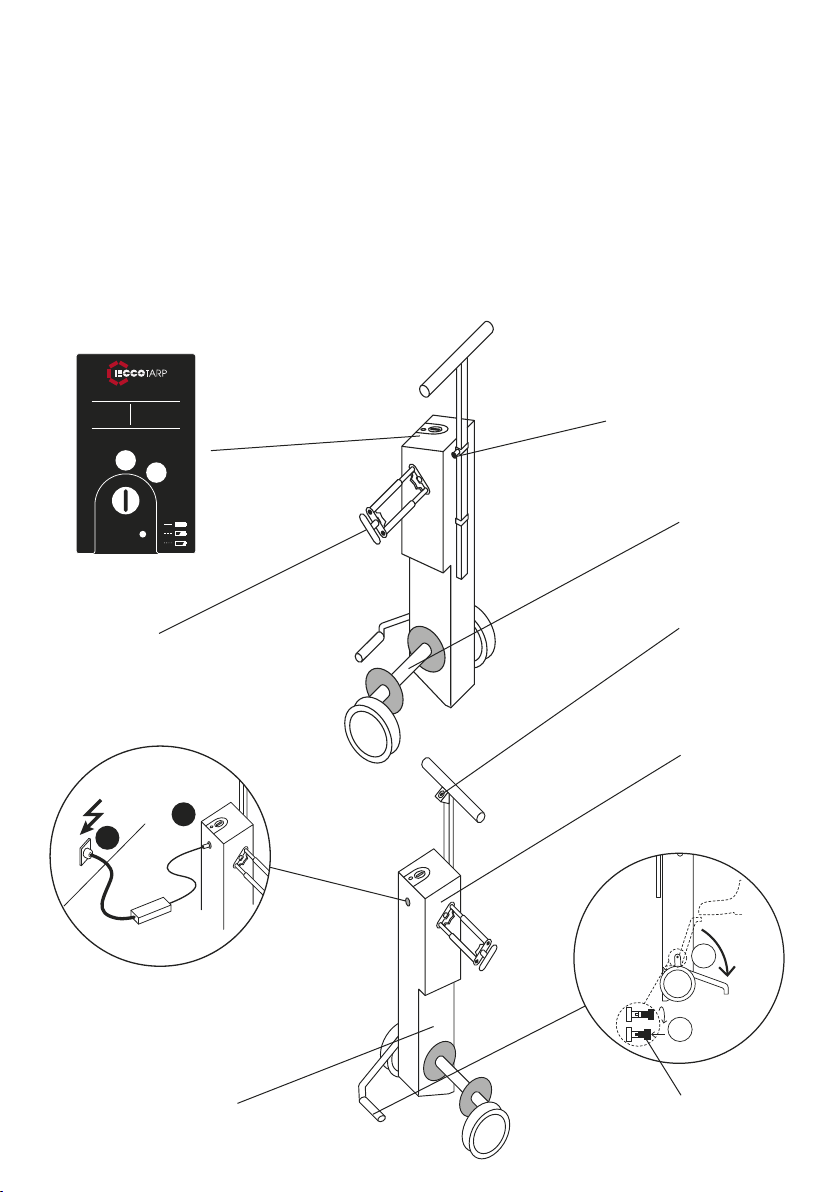

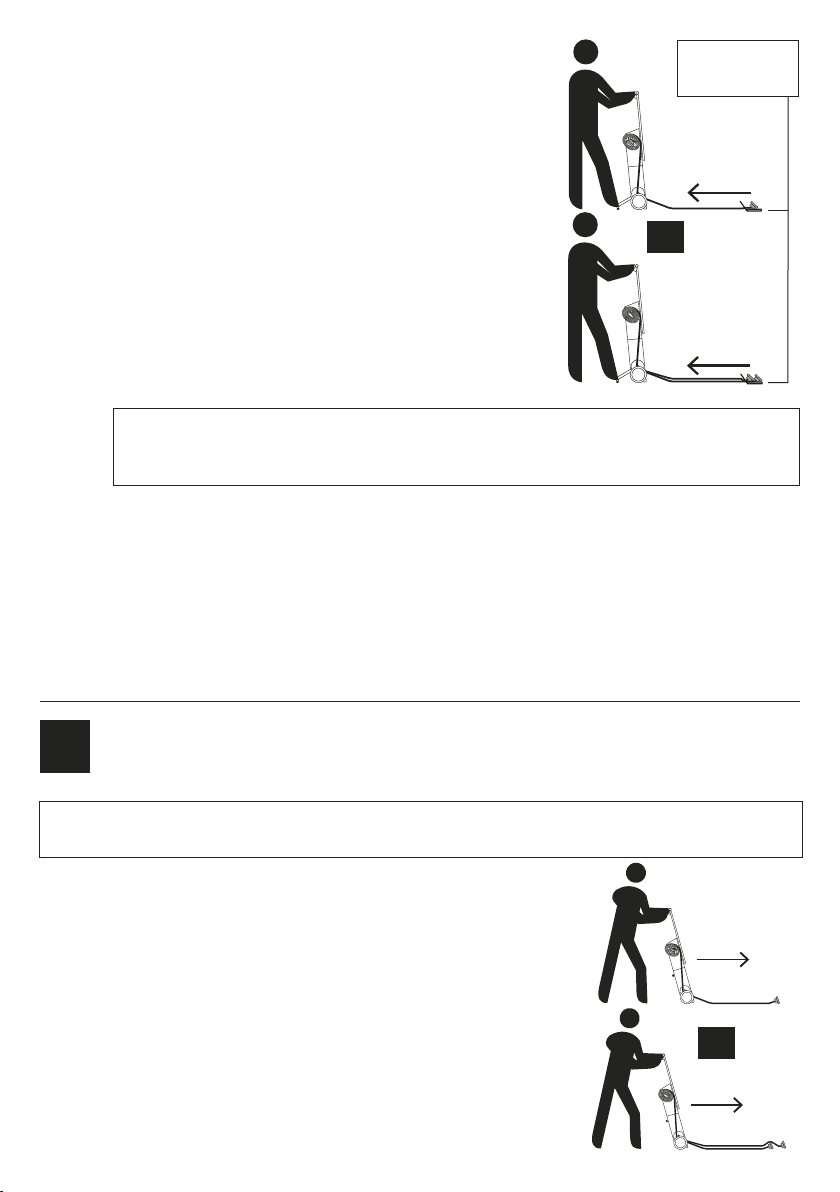

OFF

REVERSE ON

1

SWITCH ON

2

PUSH RED BUTTON

TO WORK

2

1

B

A

Control panel

Handle position

locking pin

Removable carrier fork

with a handle

Built-in battery

Guiding coil

Charging cable socket

Locking pin to secure the position

of the stabilizing fold-out chassis

Stabilizing fold-out chassis

WORK button

Built-in control unit

and motor

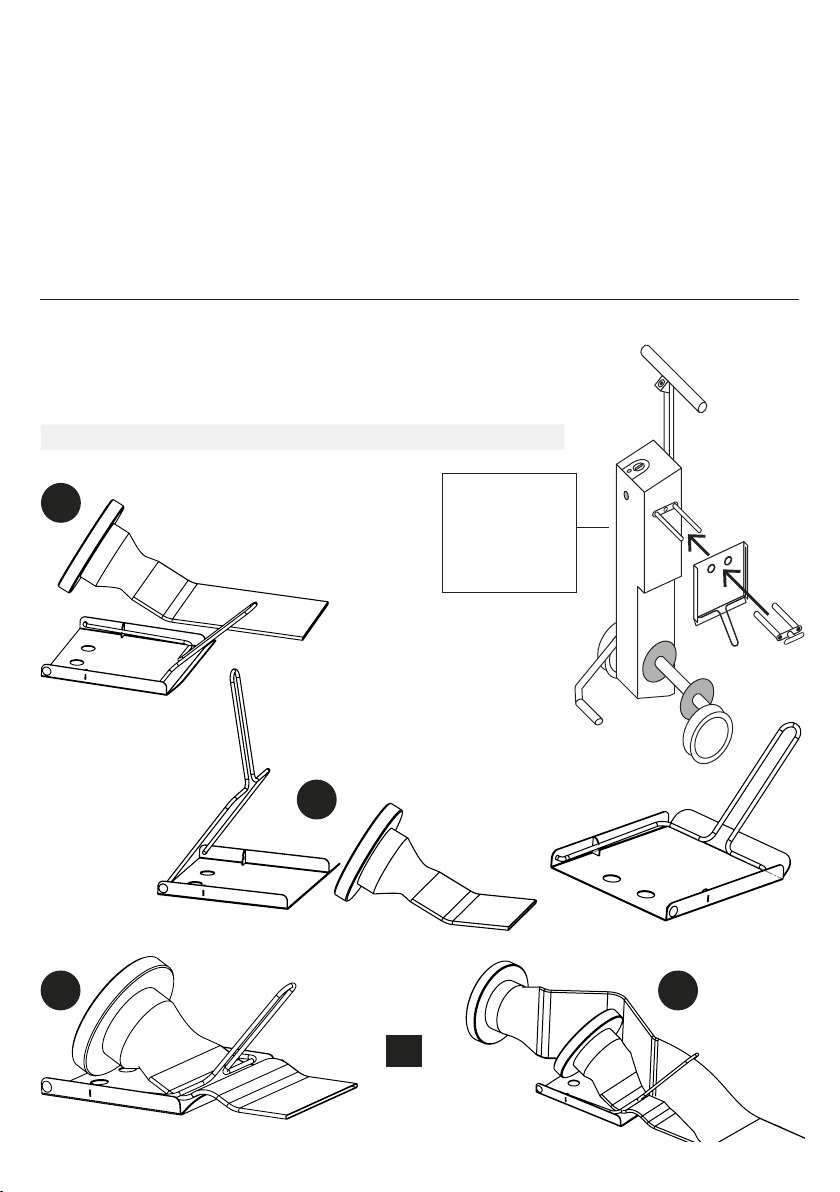

The package includes:

1× ET-Roller 5 – Electric roller for fire

hoses up to 5"

2× Removable carrier fork with

a handle (different sizes)

1× Winder charger 36 V

1× Instructions for use

Technical data

Safety instructions for use

When using the winder, observe these instructions as well as all the safety notices herein.

In the ET-Roller 5 package there are 2 sizes of Removable carrier fork with a handle to ensure the ability to wind different

couplings of fire hose up to 5".

1. The winder is only designed for winding and unwinding

fire hoses and for squeezing remaining water out

of hoses.

2. The winder may only be operated by 1 person (2 persons

in the event of unwinding).

3. The winder must be fully charged by the supplied

charger before it is used for the first time. The battery

reaches full capacity only after several charging cycles.

4. Disconnect the winder from the charger before use.

5. During the winding process, the handle must be held

with both hands and the stabilizing fold-out chassis must

be secured by a leg.

6. Caution! During winding, there is a risk of injury as

a result of clothes or limbs being caught in the carrier.

7. Before the hose is taken away from the carrier, the device

must be turned off.

8. Caution! The device is heavy.

9. Do not disassemble or modify the winder.

10. Never drop the device from a height.

11. Do not expose the device to temperatures over 104 °F for

extended periods of time.

12. Protect the device from direct sunlight.

13. If the winder is excessively hot, allow it to cool down and

only start using it after that.

14. Never throw the device directly into fire.

15. Never immerse the device in water or wash it with water

under pressure, and prevent water and moisture from

entering it directly.

16. Never attempt to charge a damaged winder.

17. In the event of injury resulting from improper use of the

winder take appropriate measures and if necessary seek

medical help.

18. The winder must not be handled or operated by children.

19. The device must not be disposed of with household/

municipal waste. When the device is past its

lifetime, it must be taken to a waste collection

point for environment-friendly disposal or returned

to the manufacturer.

20. The manufacturer confirms the product’s compliance

with EU directives.

Dimensions in use (w × d × h) 19 × 14.2 × 53.5 in

Dimensions of folded roller (w × d × h) 19 × 10.6 × 35.4 in

Height of roller with handle at the maximum 53.5 in

Package dimensions 27 × 13.4 × 36.6 in

Weight without fire hose 50.7 lb (incl. Li-ion battery),

60 lb (incl. VRLA battery)

Types of fire hoses that can be wound up to 5"

Optional accessories Material Dimensions (w × l × h) Weight

Hose protector stainless steel 9 × 14 × 6.3 in 2.4 lb

3

2

1

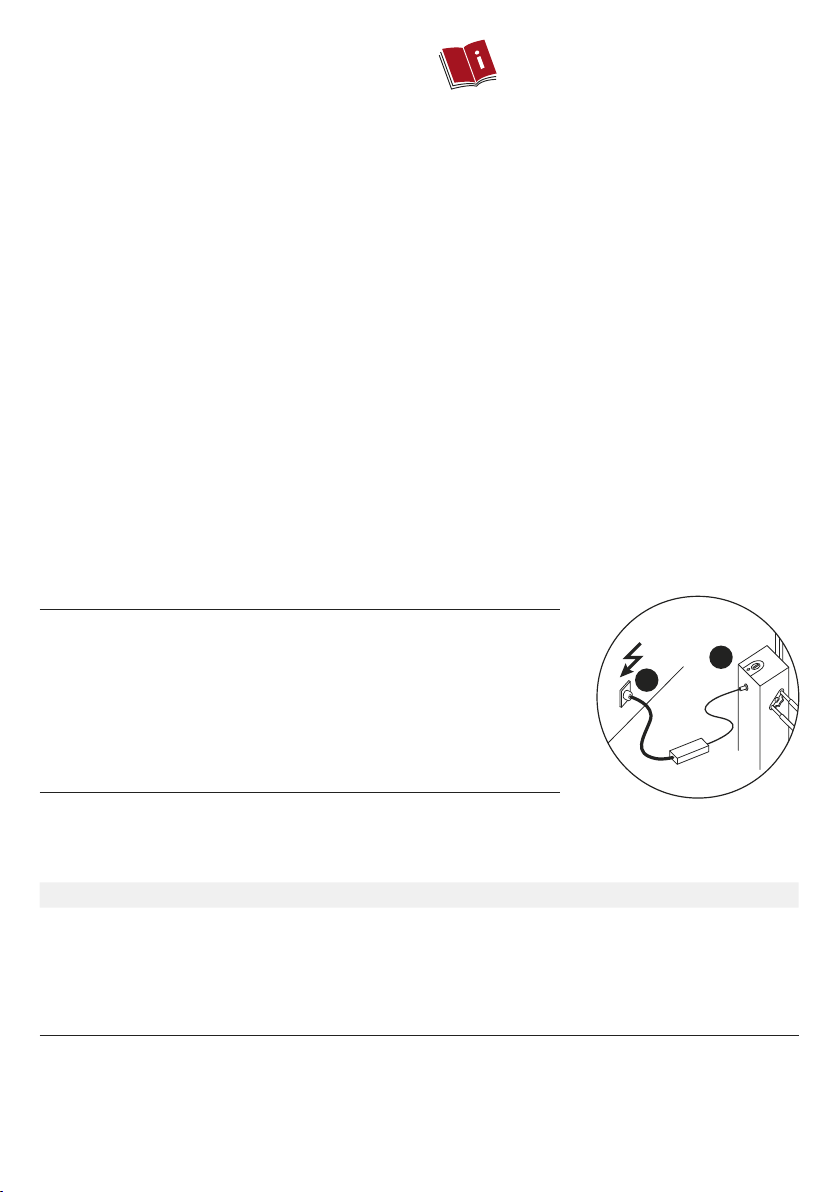

1. Insert the charger connector into the proper hole on the winder.

2. Insert the charger plug into a 100-240 V/50-60 Hz socket. The LED on the charger

lights up red. The winder is fully charged when the red indicator goes off and the

green indicator comes on.

The winder can wind about 15 092 ft. of wet A 110 type hose (230 times wound 66 ft. hose) when the 36V Li-ion battery is

fully charged.

The winder can wind about 11 483 ft. of wet A 110 type hose (175 times wound 66 ft. hose) when the 36V VRLA battery is

fully charged.

Outside the EU, the winders are delivered without batteries. To put the winder into operation, it is necessary to purchase

and install the recommended type of battery according to the enclosed Battery Replacement Instructions.

Specification of battery types

Battery replacement

Illustrated charging instructions

Accumulator battery Li-Ion VRLA

Operating voltage 36 V DC 36 V (3×12V) DC

Safety instructions for charging

1. The winder is completely discharged when a slow

rhythmical sound signal is heard and the WORK button

goes off.

2. Use only the supplied charger type to charge

the winder.

3. The range of permissible temperatures for charging

is between 32 °F and 104 °F. Outside this temperature

range the winder might be damaged or its lifetime

might be shortened.

4. No metal or other objects must be allowed to enter the

charger socket on the winder.

5. Never charge the winder in a wet

or humid environment.

6. Never charge the winder near sources of heat or on

flammable surface.

7. Make sure that the mains voltage corresponds to the

voltage on the charger’s data plate. Otherwise there is

a risk of electrical injury.

8. The winder and the charger become warmer during the

process. This is normal and it is not regarded as a defect.

9. Never cover the charger or the winder during charging.

10. The winder is fully charged when the red indicator goes

off and the green indicator comes on.

11. If the winder is not charged within 5 hours, interrupt

the charging process. Begin charging again

in 12 hours. If the problem persists, please, contact the

manufacturer’s service department.

12. If an unusual smell, overheating, colour or shape

change or any other abnormalities occur during

winder charging/operation, stop the charging process/

operation immediately.

13. Never use a damaged charger. If it is damaged, please,

send it to the manufacturer for repair or replacement.

14. Never open the charger. If there is a defect, please,

contact the winder manufacturer.

15. Battery replacement – if it is necessary to replace the

battery, it can be replaced with a new one by opening

the lid of the device marked„battery“ – instructions for

battery replacement are included.

16. Safety warning: never open the control unit and motor

cover in the upper part of the winder. By opening the

cover you lose warranty.

4

Preparation for winding:

1. The winder should be fully charged by the supplied charger before it is used.

The winder is designed so that it can be permanently connected to the charger while

stored. Use strictly the charger supplied by the manufacturer.

2. Disconnect the winder from the charger before use. Extend the handle into the optimal

position and transport the winder to the place of operation (winding).

3. Tilt and secure the stabilizing fold-out chassis: release the locking pin and turn it by 90 °.

That prevents the winder position from being automatically re-locked. Tilt the fold-out

LED is off – battery is fully charged

LED blinks in longer intervals – battery is half discharged

LED blinks in short intervals – battery is almost completely

discharged and must be charged

Important! One roller must be included with 3 batteries.

Winder battery charging indicator

Charging station specifications

Recomended baterries

Charging station 36 V

Imput voltage 88-264 VAC

Charging time 5 h

Model Yuasa NPH5-12 12V 5Ah Leaftron LTX12-5.4

(12V 5.4AH)

CSB HR 1227W CSB HRL 1225W CSB HR 1221W

Type VRLA Battery VRLA Baterry VRLA Baterry VRLA Baterry VRLA Baterry

Voltage 12V 12V 12V 12V 12V

Capacity 5Ah 5.4Ah 6.2Ah 5.8Ah 5.1Ah

Weight 3.5 Lbs 3.97 Lbs 4.34 Lbs 4.3 Lbs 3.97 Lbs

OFF

REVERSE ON

1

SWITCHON

2

PUSH RED BUTTON

TOWORK

Instructions for Winder Operation

Please, read the safety instructions and this manual before using the winder.

The winder is designed for winding fire hoses of sizes up to a diameter of 5" and a maximum hose length of 164 ft. Thanks to

its output it can also wind wet hoses (not filled with water). The winder can also be used for squeezing remaining water out of

fire hoses (see“Squeezing remaining water out of a fire hose”).

Hoses can be wound in two basic ways:

Winding with the winder stationary – STATIONARY method or while the operator walks – WALKING method.

Both methods make it possible to wind the hose from the centre to the end (option 1) or, thanks to the versatile carrier, from

the beginning to the end (option 2).

Although the operation is intuitive, recommended procedures for both alternatives are described below.

CLICK ON

PIN 90°

CLICK OFF

+ LOCK

PIN 90°

1 2

PULL OUT/

PUSH ON

1

5

chassis so that it is stabilized and turn the locking pin back by 90 ° and let it

slide into the locking hole.

4. Drain the water out from the hose. If, as a result of uneven surface, the hose is

full of water or contains large rest of water after firefighting intervention, see

“Squeezing remaining water out of a fire hose”on p. 11.

5. Prepare the hose in the appropriate position according to how you want to

wind it for storage – see the instructions below („option 1”or„option 2”).

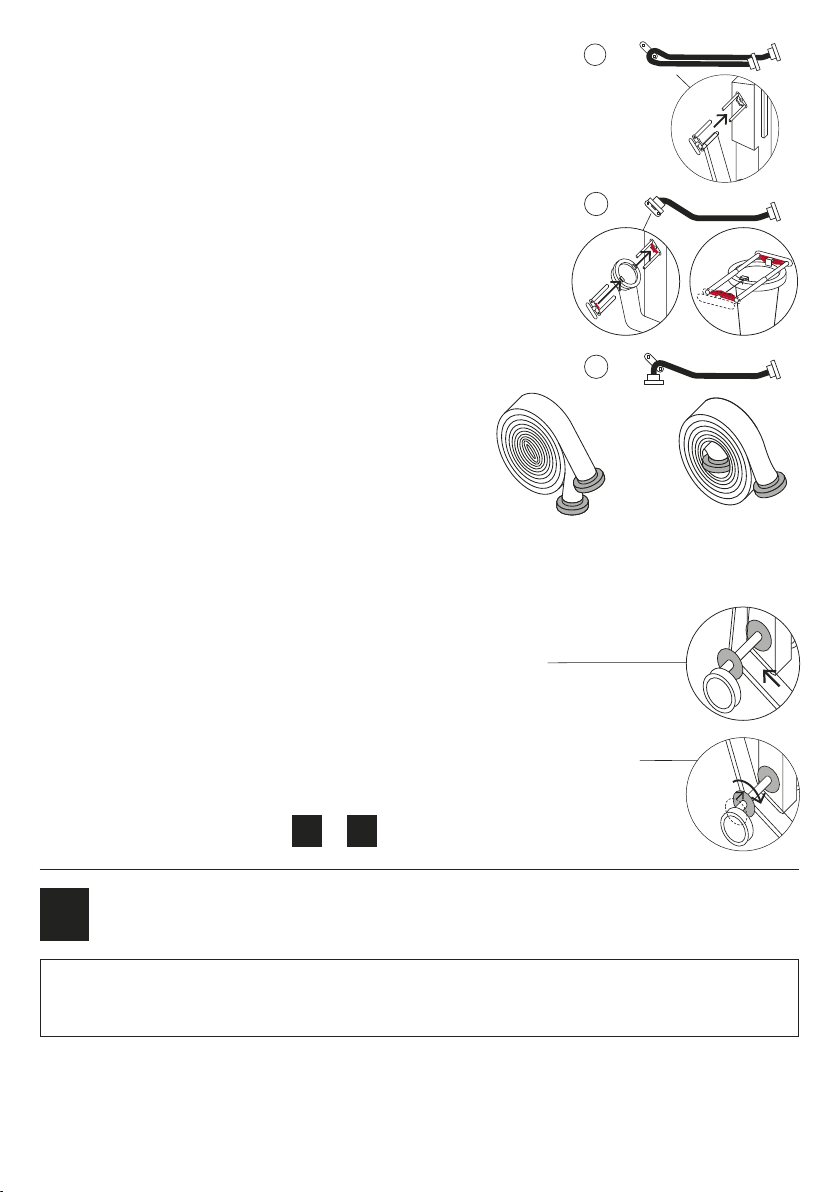

5.1 Option 1: The hose can be folded in half and pulled by the folded

end towards the winder (see figure X). When folded, both parts

of the stretched hose must be put on each other and aligned

and the metal couplings must be positioned in such a way that

the coupling of the upper half lies over the end of the lower half

of the hose. The rule for the overlap length is 1.6 ft. of overlap

per each 33 ft. of folded hose (e.g. with a 66 ft. hose – 33 ft. after

being folded – the upper coupling will overlap the

lower one by 1.6 ft.).

5.2 Option 2: Make the complete length of the hose

straight. An A or B size hose will be reliably wound if

the coupling is put into the jaws of the carrier fork,

which will hold the protrusions on the flange (see

figure Y). If thinner, C or D size hoses, are

to be wound, simply pass the coupling

through (see figure Z). In the ET-Roller 5

package there are 2 sizes of Removable

carrier fork with a handle to ensure the

ability to wind different couplings of fire

hose up to 5“.

6. Pass the end of the hose or the end of its folded part under the guiding coil.

7. Remove the removable fork from the carrier

and put the end or folded centre of the straightened, aligned hose on it according to one of

the alternatives described in section 5 hereof.

8. Using a black plastic plate, adjust the width of the guiding coil to the width of the hose by

turning it on the core of the coil.

9. Switch the winder to the ON position on the control panel.

10. Then follow one of the ways below ( 2or 3)

2Hose winding STATIONARY METHOD

(winder stands and the hose approaches during winding)

1.

2.

2.1 Use both hands to get hold of the winder handles and press the locked tipping part of the stabilization

chassis to the ground in the lower position with your right foot. Turn the switch on the control panel

clockwise into the ON position. The control features will be illuminated in red and the winder is ready

for operation.

Caution! During this procedure, the end of the hose, close to the coupling, which is moved on the surface, may

become chafen through. That is particularly risky in the case of hard surface, such as concrete, paving, etc. Therefore, we

recommend using a“hose protector“ (see optional accessories on page 12) for the free part of the hose end.

Z

Y

X

Hose wound according

tog.X–seeoption1.

Hose wound according

tog.Y–seeoption2.

ADJUST

ADJUST

6

2.2 Push the WORK button on the winder handle.

2.3 The winder starts winding the hose at a speed that

gradually decreases so that the winding speed is safe

even with increasing diameter of the winding. Towards

the end of the winding process, when the couplings get

close to the lower guiding coil, it is recommended that the

hose should be wound in a controlled manner by pressing

the WORK button intermittently until the couplings

come safely close to the guiding coil. After that the hose

couplings must be manually passed under the guiding coil

(tilting the winder to a side in the case of the largest hoses)

and with extreme care, the rest of the hose can be wound by

pressing the WORK button shortly. If the “hose protector“ is

used during winding, it must be removed from the hose end

before passing the hose under the guiding coil so that the

winder does not get damaged.

2.4 When winding is completed, turn the winder OFF.

2.5 Remove the wound hose with the removable part of the carrier from the winder and put it away for

further handling. Remove the removable part of the carrier from the centre and put it back on the carrier.

The hose is now ready to be stored or used.

2.6 When you have finished working with the winder, connect it to the charger so that it is available with its

battery fully charged at all times. After the battery is completely charged, the charger is automatically

turned into standby mode, which prevents the battery from self-discharge.

3Hose winding WALKING METHOD

(the user walks forward with the winder and the hose is stationary on the ground

while being wound)

3.

3.1 Tilt and secure the stabilizing fold-out chassis: Release the locking

pin by hand, turn it 90° to prevent it from engaging automatically

again and locking the position. Tilt the chassis into the transport

position and secure it by turning the pin 90° and letting it slide into

the locking hole.

3.2 Turn the switch on the control panel clockwise into the ON position.

The control features will be illuminated in red. Press the illuminated

WORK button in the middle of the handle and start walking with the

winder immediately towards the free end of the hose. Adapt your

walking speed to the winding speed.

3.3 The winder starts winding the hose at a speed that gradually

decreases so that the winding speed is safe even with increasing

Note: The WORK button can be released at any time during operation in order to stop winding. After it is

pushed again, the winder continues working with the lower revs which it had when it was stopped (see

Graph 1).

If you need to protect the hose against damage during winding without using the“hose protector“, it can be wound

when the user is walking forward with the winder and winding the lying hose.

or

or

Hose protector

– see p. 12

7

CLICK ON

PIN 90°

CLICK OFF

+ LOCK

PIN 90°

PULL OUT/

PUSH ON

1 2

A

B

B

A

PULL

OUT

3

A4

B

A

C

ADJUST

5

Y

X

Z

Illustrated instructions for winder operation

diameter of the winding.Towards the end of the winding process, when the couplings get close to the

lower guiding coil, it is recommended that the hose should be wound in a controlled manner by pressing

the WORK button intermittently until the couplings come safely close to the guiding coil. After that the

hose couplings must be manually passed under the guiding coil (tilting the winder to a side in the case

of the largest hoses) and with extreme care, the rest of the hose can be wound by pressing the WORK

button shortly.

If the“hose protector“ is used during winding, it must be removed from the hose end before passing the

hose under the guiding coil so that the winder does not get damaged.

Note: The WORK button can be released at any time during operation in order to stop winding. After it is

pushed again, the winder continues working with the lower revs which it used when it was stopped (see

Graph 1).

3.4 When winding is completed, turn the winder OFF and tilt the stabilizing fold-out chassis so as to secure

the winder while removing the hose from the carrier.

3.5 Remove the wound hose with the removable part of the carrier from the winder and put it away for

further handling. Remove the removable part of the carrier from the centre and put it back on the carrier.

The hose is now ready to be stored or used.

3.6 When you have finished working with the winder, connect it to the charger so that it is available with its

battery fully charged at all times. After the battery is completely charged, the charger is automatically

turned into standby mode, which prevents the battery from self-discharge.

Tilting and securing

the stabilizing fold-out chassis

Placing hose into

hose carrier

Manners of securing

hose in carrier

ADJUST

Z

Y

X

8

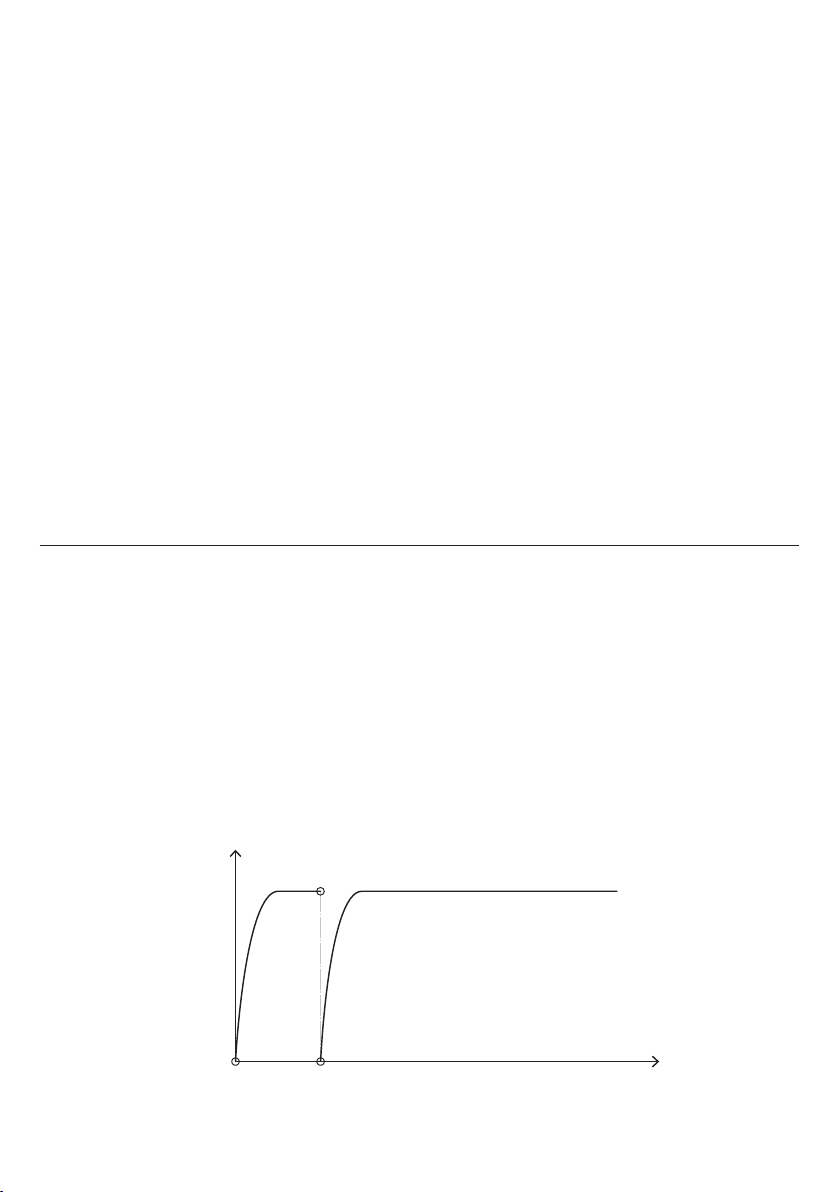

SAFETY FUNCTIONS OF THE WINDER

Certain safety features influence some of the winder’s reactions during

the work:

1. Stopping the winding – If the motor becomes overloaded unexpectedly (e.g. as a result of the hose being obstructed

or stepped on), the winding process is interrupted immediately, the WORK button starts blinking and a fast sound signal

is heard. If you only release the winder’s WORK button (without turning the main switch to the SWITCH OFF position),

then, after the cause of motor overloading is removed and WORK is pushed again, the winder continues working with

the revs which it used at the time of being stopped (see Graph 1). However, in this case of forced interruption, the

controlling software needs a few seconds before it can resume the winding process.

2. Motor overheating – The system has a safety feature that prevents overheating. If the motor becomes excessively

hot (e.g. during work under extreme temperatures), the battery is automatically disconnected. The reason is battery

safety. Place the machine out of reach of the heat source (e.g. in shade). The machine can be turned on again after

it cools down.

3. The OFF-ON switch and the WORK button –

The winder is fitted with a smart revs control

feature for your convenience and safety. Every

time the OFF-ON switch is used, the“Winding”

program is activated (see Graph 1 and 2). It

shows the course of the carrier’s revolving

speed. That happens so that the winding revs

are fast with a small spool diameter and the

winding speed remains approximately the

same and safe while the diameter becomes

larger. When winding is stopped – the WORK

button is released – the winding program is

interrupted. When WORK is pressed again, the

winding speed returns to the previous speed in

a few seconds (see Graph 1).

4. Interrupting the winding process by using

the OFF-ON button – It is clear from the

description above that if the winding process

is interrupted and the OFF-ON button is

used, the winding function starts again at the

beginning. That means that if the winding

process is interrupted and the winder is turned

OFF and then ON again, the highest revolution

speed is activated by pressing the WORK

button (see Graph 2). In spite of that it is still

possible to work safely: you can control the

revs by pressing WORK repeatedly.

Winding speed

Graph 1

OFF–ON –

pressing of WORK

Interruption –

pressing of WORK

Time

Winding speed

OFF–ON –

pressing of WORK

Interruption – ON–OFF –

obstacle removed OFF–ON –

pressing of WORK

Time

Graph 2

PUSHSWITCH

ON

A B

6

OFF

ON

7

Winder activation

Removing carrier fork

from wound hose

9

Smart winding

Your winder has a smart motor control which allows you to adjust the fire hose winding speed. The reason is your

convenience and safety as well as battery protection.

1. How does it work? After WORK is pressed, the motor begins winding at zero speed. Then it switches to the

highest revs very quickly and while the hose is gradually being wound, it starts lowering the revs so that with the

increasing diameter of the wound hose, the winding speed for the free end of the hose remains safe.

2. Release WORK before completing the winding process and by pressing it intermittently you will achieve the lowest safe

winding speed (see Graph 1).

3. Overloading – if the hose gets stuck or stepped on, or for other reasons, the winding force may become excessively high.

In such a case, the system automatically disconnects the battery and warns the user by a fast warning sound and by the

WORK button blinking. After the WORK button is released and the obstacle removed, the machine is ready to be used

again in a few seconds.

4. Overheating – the machine has a recommended working temperature range. When the highest safe temperature

(140 °F) is exceeded, the battery is automatically disconnected from the machine. The reason is battery protection

against overheating. After cooling down, the machine is ready to be used again.

5. Battery discharged – if battery capacity decreases under the safety limit, the battery is disconnected from the device,

a slow warning signal is heard and the WORK button’s light indicator goes off. The reason is battery protection against

destruction. After the battery is recharged, the machine is ready to be used again. The machine comes with the original

charger, which can fully recharge the battery in about 5 hours. The machine is designed in such a way that the charger

can be connected to the winder permanently (charging is automatically stopped when the battery is fully charged).

REVERSE function

By turning on the REVERSE function on the control panel and pressing the WORK button, the reverse run of the carrier is

activated. This function is mainly used for controlled unwinding of an already wound fire hose. Two persons are needed for

this function to be used. One person controls the winder (switching on REVERSE and pressing WORK) while the other person

grips the metal couplings of the wound hose and moves away from the winder in accordance with the winder revs. When

this function is used (both with the unwinding interrupted and uninterrupted), the fire hose is unwound at high speed all the

time (see Graph below). Therefore, it is necessary to be extremely careful.

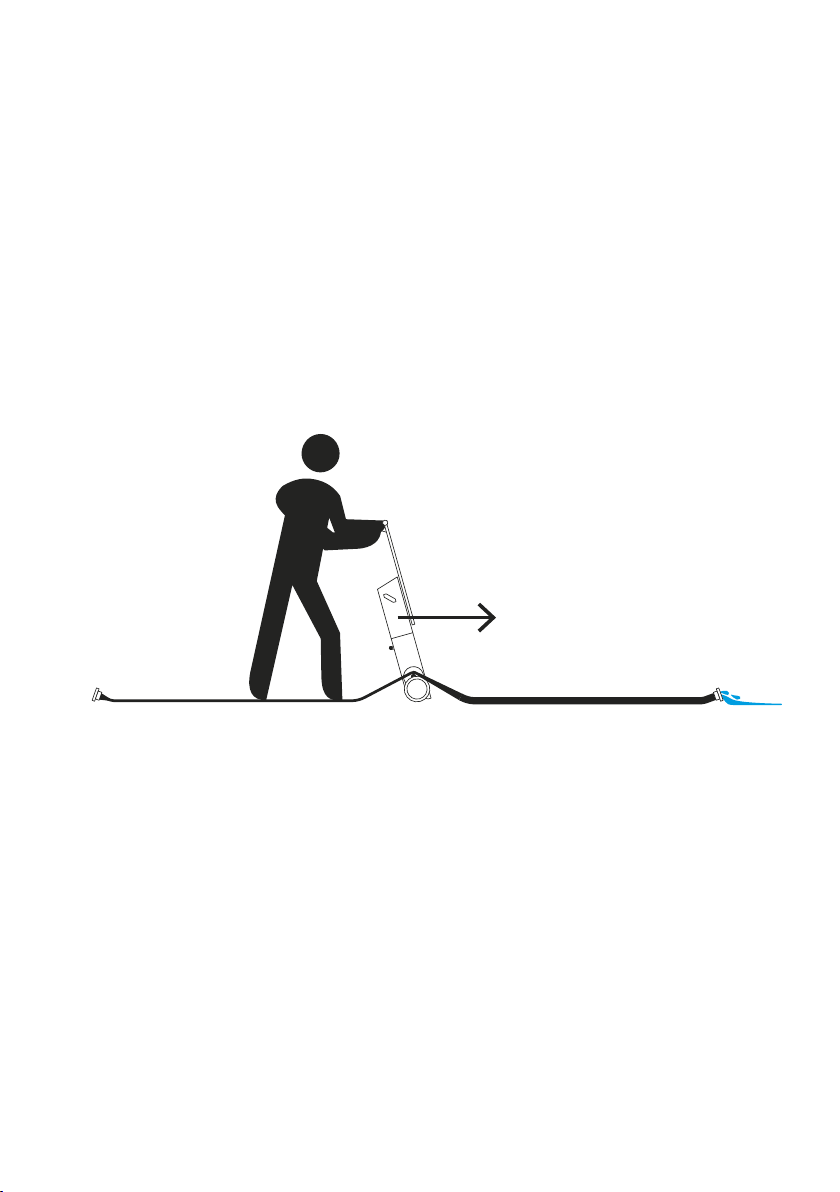

Squeezing remaining water out of a fire hose

Unwinding speed

OFF–REVERSE –

pressing

of WORK button

Interruption –

pressing

of WORK button

Time

10

1. The winder must be turned off – the OFF position on the control panel.

2. Pass one end of the hose over the lower guiding coil so that you can step on this hose end.

3. If the stabilizing fold-out chassis is tilted out, tilt it down so that the winder can stand on it without being supported.

4. Tilt the winder towards yourself and proceed slowly with the discharging (downhill, if possible) so that the hose is rolled

over the coil, which pushes the water in the hose forward, towards the other end, where the water flows out of the hose.

The process of stretching the hose over the coil and of the water flowing out can be intensified by walking on the hose

throughout the process.

5. Make sure that no objects that might prevent the water from flowing out lie on the hose during the process.

6. After the water discharging process is finished, the hose can be placed on the removable carrier fork and wound into

shape for storage as described in the“Instructions for winder operation” chapter.

11

228

220

352,1

160

Instructions for winder charging and storing

1. Store the winder in a dry place.

2. If the winder is not to be used for a long time, it should be stored at room temperature (66–73 °F).

3. The winder system is designed in such a way that the charger can be connected to it permanently and the battery

is safely recharged without any risk of damage. As a result, the charger can be connected during storage as well.

4. When the winder is completely discharged, the system is automatically disconnected from the battery so that the

battery is not completely destroyed. Therefore the battery must be recharged as soon as possible.

5. If stored for a long time without the charger connected to it, the battery must be fully recharged once a year so as

to prevent it from being totally discharged.

Recommended optional accessories

Hose protector Material Dimensions (w × l × h)

for hoses of up to size 5" stainless steel 9 × 13.9 × 6.3 in

We recommend

storing the hose

protector hung

on the winder

carrier fork.

1

2

3 4

or

12

Important contact information

Qualified service:

ECCOTARP USA, inc.

357 West 36th Street

New York, NY 10018

USA

office@eccotarp.com

T: 1 929-272-2336

Repair

Any repair work must always be done by the manufacturer’s qualified personnel. In order to report any faults, spare parts

orders or complaints, please contact only our qualified service department.

Warranty conditions

The warranty period is stated in the warranty certificate, which is delivered with the product. The warranty period is

24 months and begins on the day indicated in the warranty certificate. The warranty does not apply to the normal wear

and tear (e.g. gradual decrease in battery capacity) or to damage caused by improper use or non-compliance with the

information provided in these Instructions for Use.

Disposing of a damaged device or its parts

The device or its parts must not be disposed of with household/municipal waste. At the end of its lifetime, the device must

be taken to a waste collection point for environment-friendly disposal or returned to the manufacturer. A charger, that is past

service, must be taken to an electric waste collection point or returned to the manufacturer.

EU DECLARATION OF CONFORMITY No. 01032020/M

Metal Arsenal s.r.o., Poděbradova 1920, 289 22 Lysá nad Labem, Czech Republic, hereby declares, at its sole liability, that the

following product

ET-ROLLER 5

Electric roller for fire hoses up to 5"

(A winder intended for winding fire hoses with couples of the maximum size of 5" and maximum length of 164 ft. It includes

a 36V DC battery charger.) complies with applicable harmonized standards of the European Union.

The above is verified according to Government regulations no. 118/2016 Sb., which is equivalent to a Council Directive

2014/35/EU Government Regulation no. 117/2016 Sb., which is equivalent to a Council Directive 2014/30/EU, ČSN EN 60335-

1 ed. 2, ČSN EN 61000-6-3 ed. 2, ČSN EN 55014-1 ed. 4.

13

Notes

14

Pictograph meanings

Observe the Instructions for

use for ET-Roller 5.

During the winding process, the

handle must be held with both

hands and the stabilizing fold-out

chassis must be secured by a leg.

Caution! During winding, there is

a risk of serious injury as a result of

clothes or limbs being caught in

the carrier.

Do not wash the

machine with water

under pressure.

1 person only

1. 2.

OFF

Caution! Indicates imminent

danger. Not observing this

warning may cause death

or serious injury.

Before using the winder, read all the safety warnings in this manual. The illustrations in this manual may not fully correspond

to the supplied product. Their purpose is to help you understand the text better. The content of this manual may be changed

without prior notice.

Confirmation of the

machine’s compliance

with EU regulations.

The winder may only be

operated by 1 person.

Before the hose is taken away

from the carrier, the device

must be turned off.

Protect the device from direct

sunlight and do not expose it to

temperatures higher than 104 °F

for extended periods of time.

Table of contents