ELK Golf GT LITHIUM V1 Instruction manual

GTLITHIUMV1Workshopmanual 1

©2013ElkingtonGolfPtyLtd

GTLITHIUMV1

Workshopmanual

ForApprovedE•L•KGolfServiceCentres

GTLITHIUMV1Workshopmanual 2

©2013ElkingtonGolfPtyLtd

GTLITHIUMV1Workshopmanual

TABLEOFCONTENTS

1/REMOVINGTHETOPHANDLE………………………………………………………………….Page3

2/REPLACINGTHESPEEDCONTROLSWITCH……………………………………………….Page3–11

3/REPLACINGTHEPCBBOARD/DISPLAYINTHETOPHANDLE……………………Page11

4/REFITTINGTHETOPHANDLE……………………………………………………………………Page12

5/REPLACINGOFTHEMOTORCONTROLLER……………………………………………….Page13–16

6/REPLACINGTHEMOTOR…………………………………………………………………………..Page16–18

7/REPLACINGTHEAXLEDRIVEPINS…………………………………………………………….Page19

8/REPLACINGTHESTEMCABLE……………………………………………………………………Page20–26

9/REPLACINGTHEAXLEBEARINGS……………………………………………………………….Page26–28

10/REPLACING/REMOVALOFTHEBATTERYTRAY……………………………………….Page28–29

11/REPLACING/REMOVALOFTHEDRIVEAXLE……………………………………………Page29–33

12/REPLACINGTHEGEARBOX……………………………………………………………………….Page33–35

13/REPLACINGTHEUPPERBAGSUPPORT…………………………………………………….Page36–37

14/REPLACINGTHELOWERBAGSUPPORT……………………………………………………Page37–38

15/REPLACINGTHEFRONTWHEEL&HOUSINGASSEMBLY…………………………..Page39

16/ADJUSTINGFRONTWHEELTRACKING………………………………………………………Page39–40

GTLITHIUMV1Workshopmanual 3

©2013ElkingtonGolfPtyLtd

1/REMOVINGTHETOPHANDLEASSEMBLY

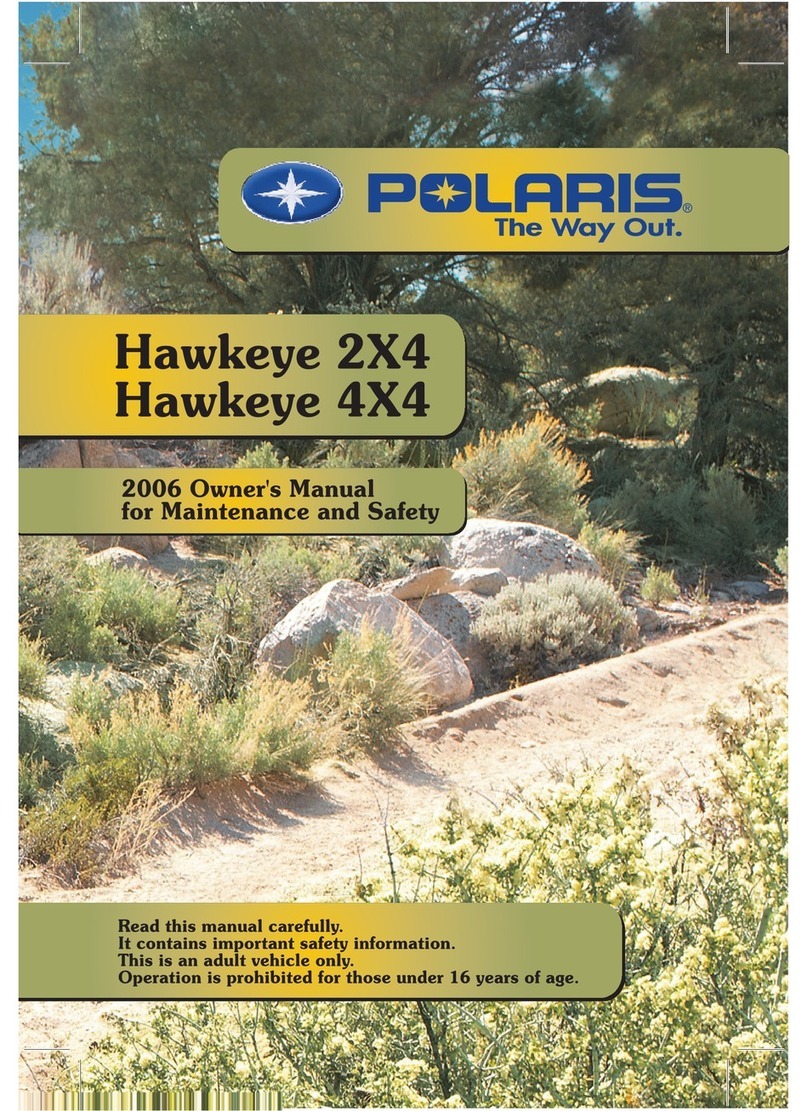

Thereare6screwswhichsecuretheTopHandleassemblytotheMainFrameUpperTubeasshown

bythearrowsinfigure‐No1PLEASENOTE–Thereare3sleeves/busheswhichsitbetweenboth

sectionsofthehandleandUppermainframetube.Ensuretheyareinplacebeforerefittingthe

handle.RefertoFigureNo15A.

FigureNo1

2/REPLACINGTHESPEEDCONTROLSWITCH

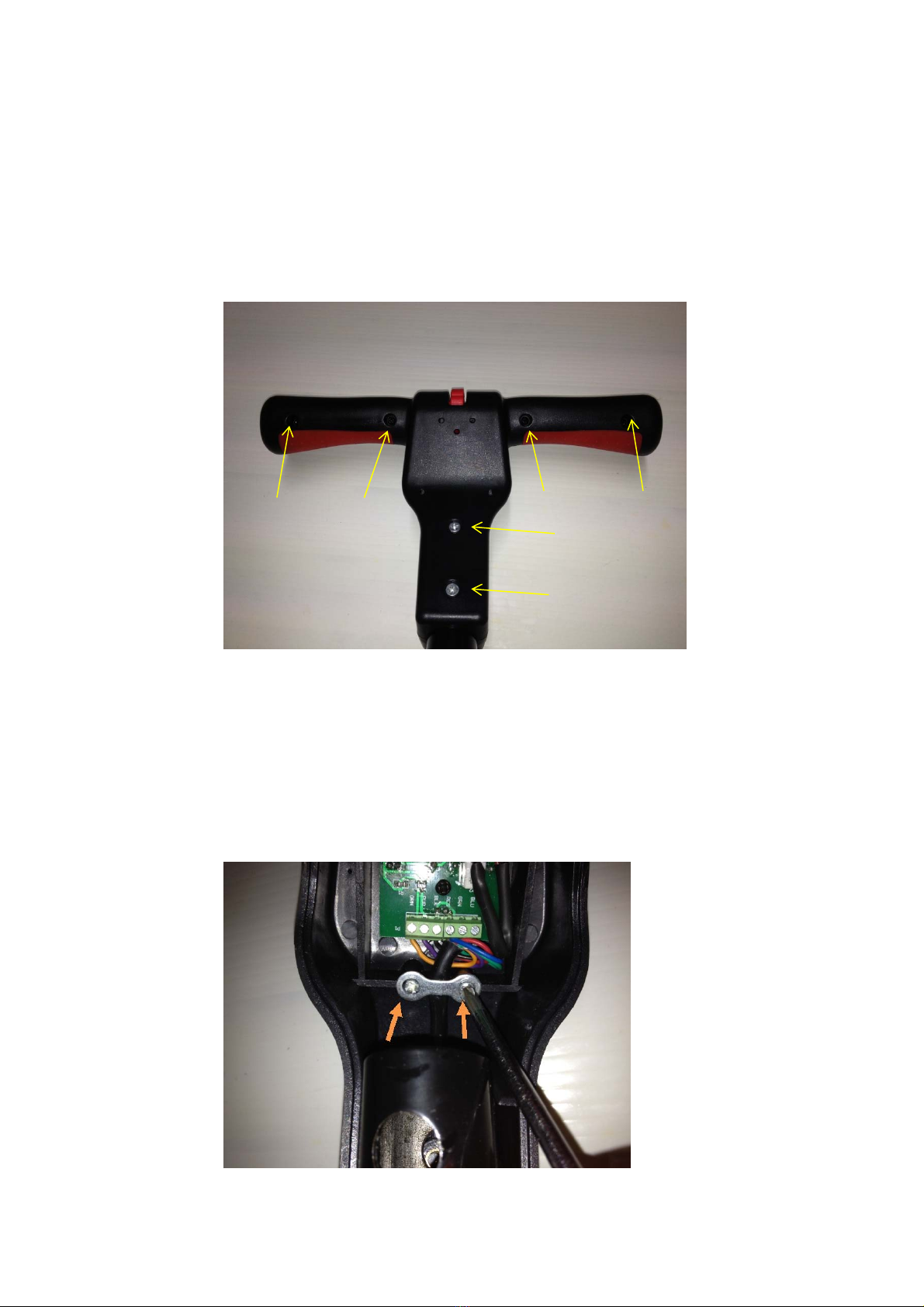

Withthetophandleassemblyremovedfromthemaintube,itwillnowseparateintotwohalves.

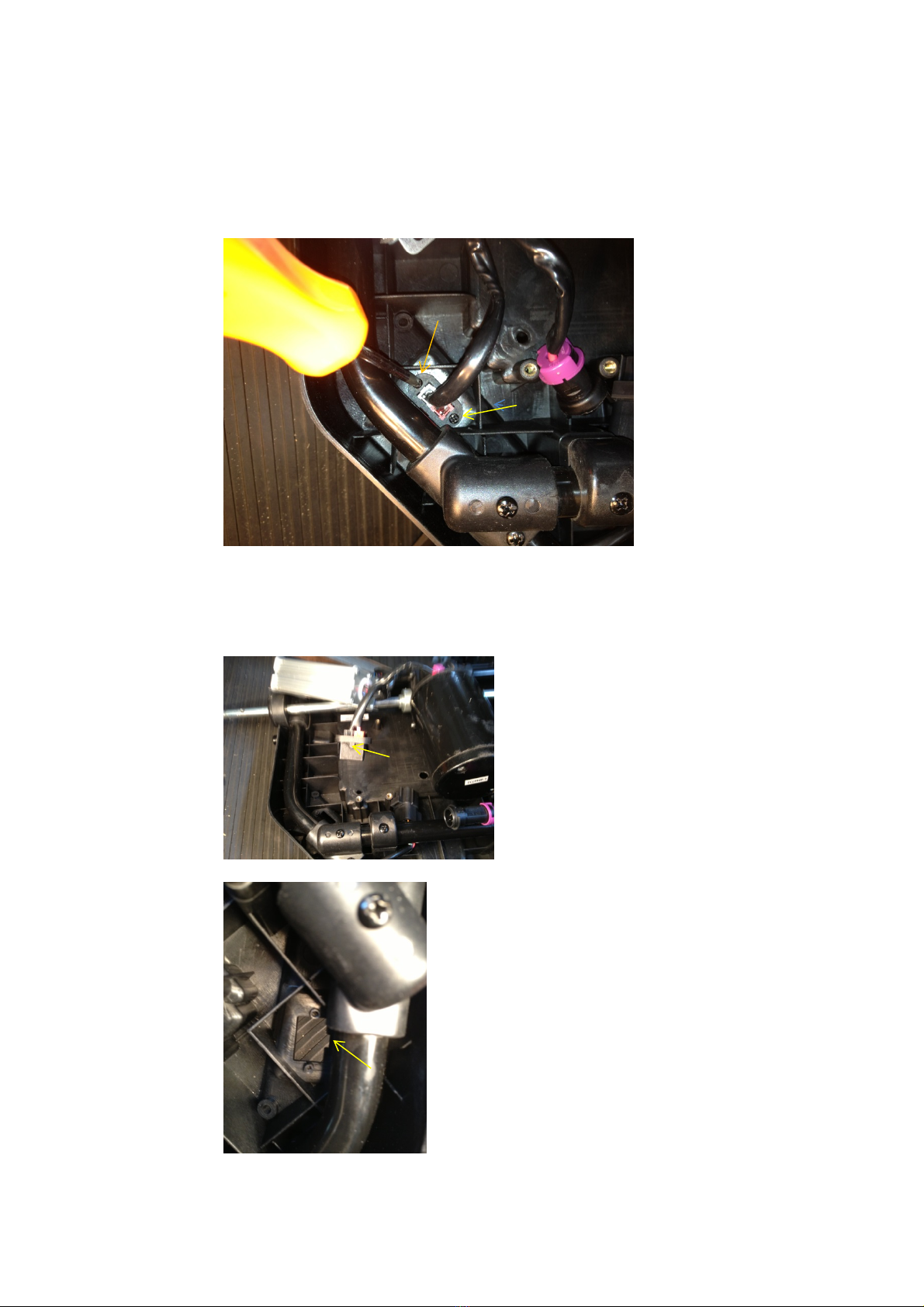

WhilesupportingtheuppersectionoftheTopHandleAssemblyastoavoiddamagingthestem

cablewiring,removethetwoPhillipsscrewsindicatedbyarrows,securingthecablesupportbracket

aspicturedinFigureNo2.

FigureNo2

GTLITHIUMV1Workshopmanual 4

©2013ElkingtonGolfPtyLtd

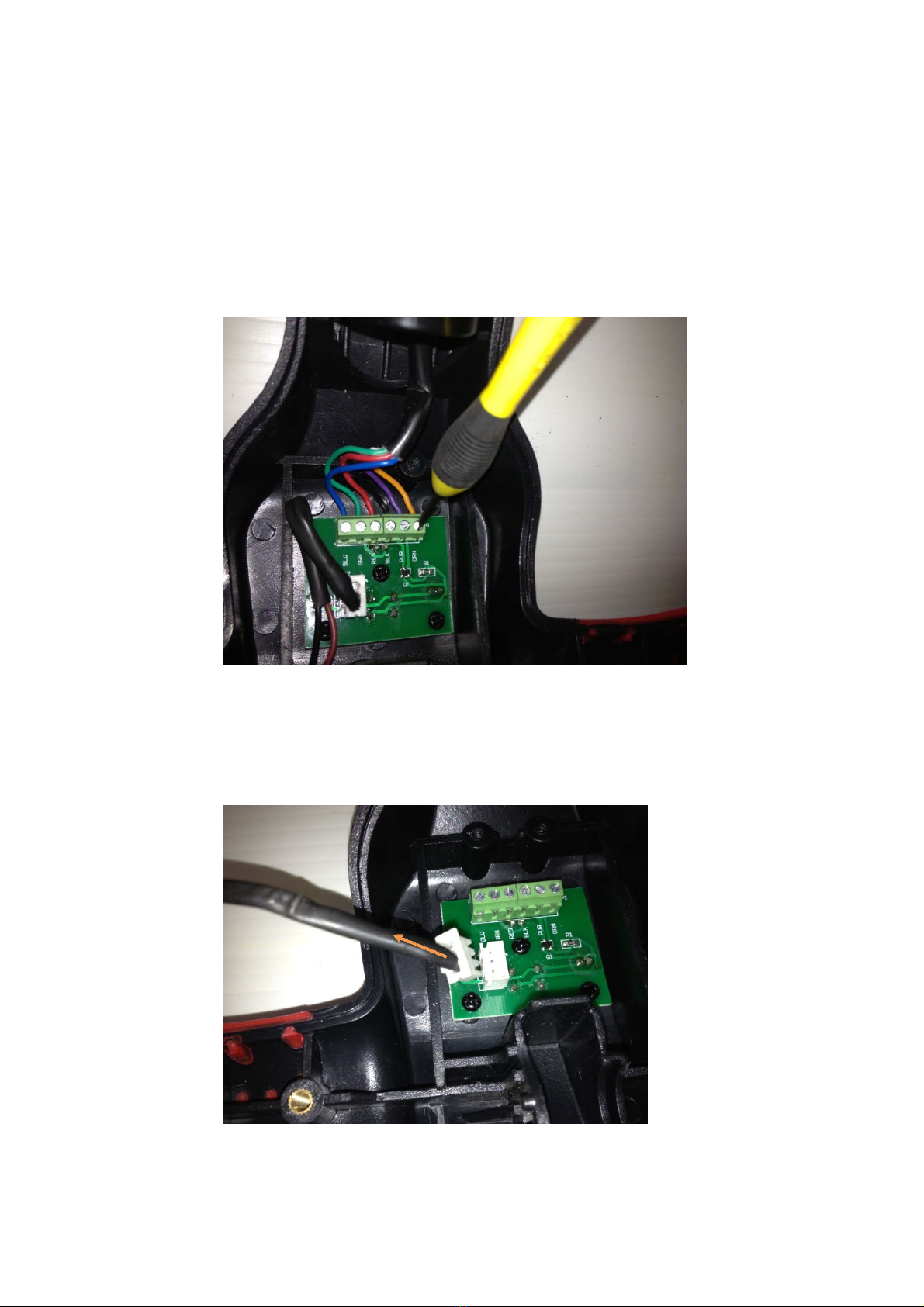

LoosenthescrewswhichsecuretheStemCableWiringtotheTerminalBlockandremovetheStem

CableWiringfromtheTerminalBlockaspicturedinFigureNo3.

PLEASENOTE–TheStemCableWiringiscolourcodedandthecolourofeachwiremustcorrespond

withthecoloursprintedontheTerminalBlockaspicturedinFigureNo3.

FigureNo3

Unplug/DisconnecttheSpeedSwitchWiring,fromthePCBBoardaspicturedinFigureNo4.

FigureNo4

GTLITHIUMV1Workshopmanual 5

©2013ElkingtonGolfPtyLtd

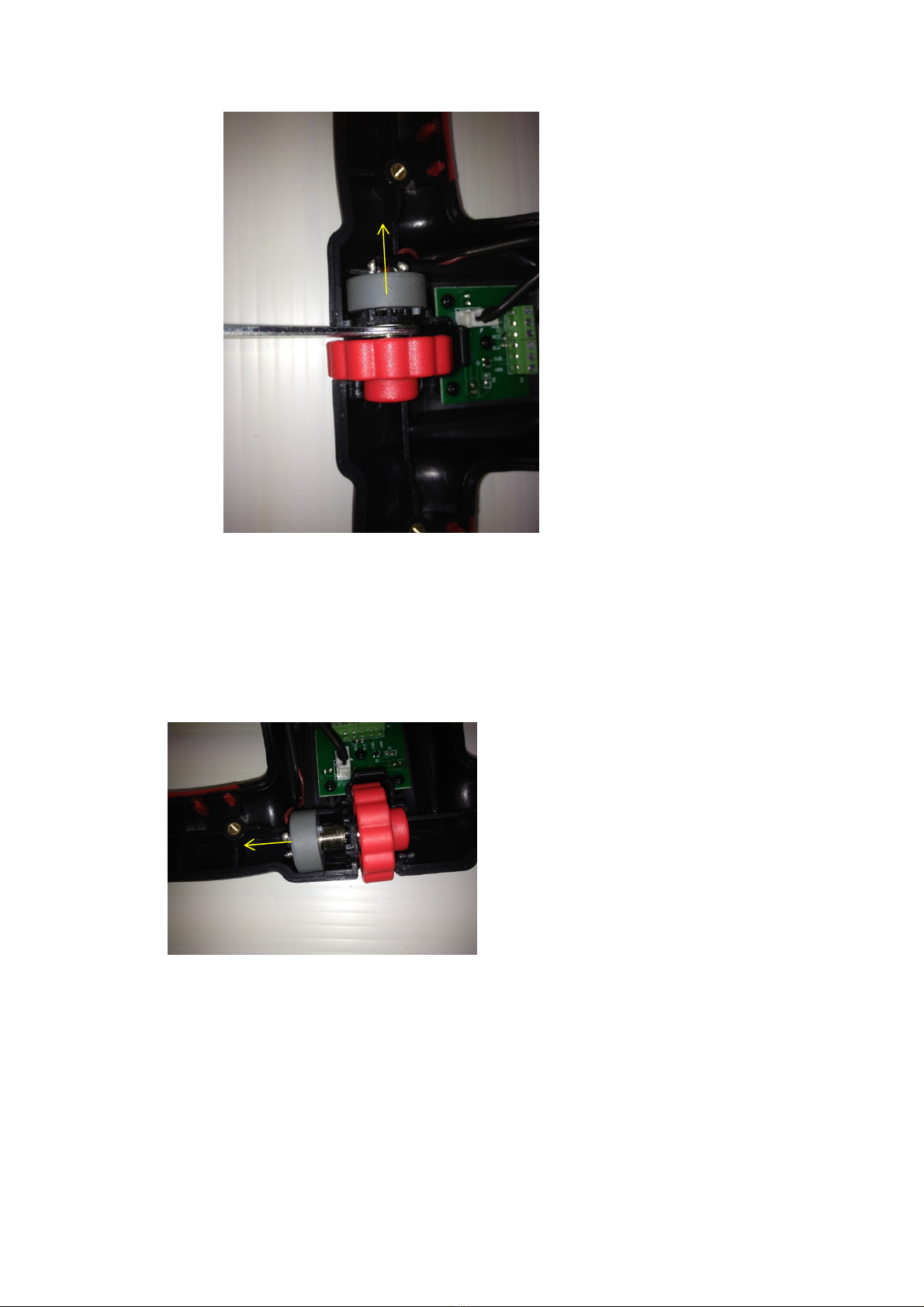

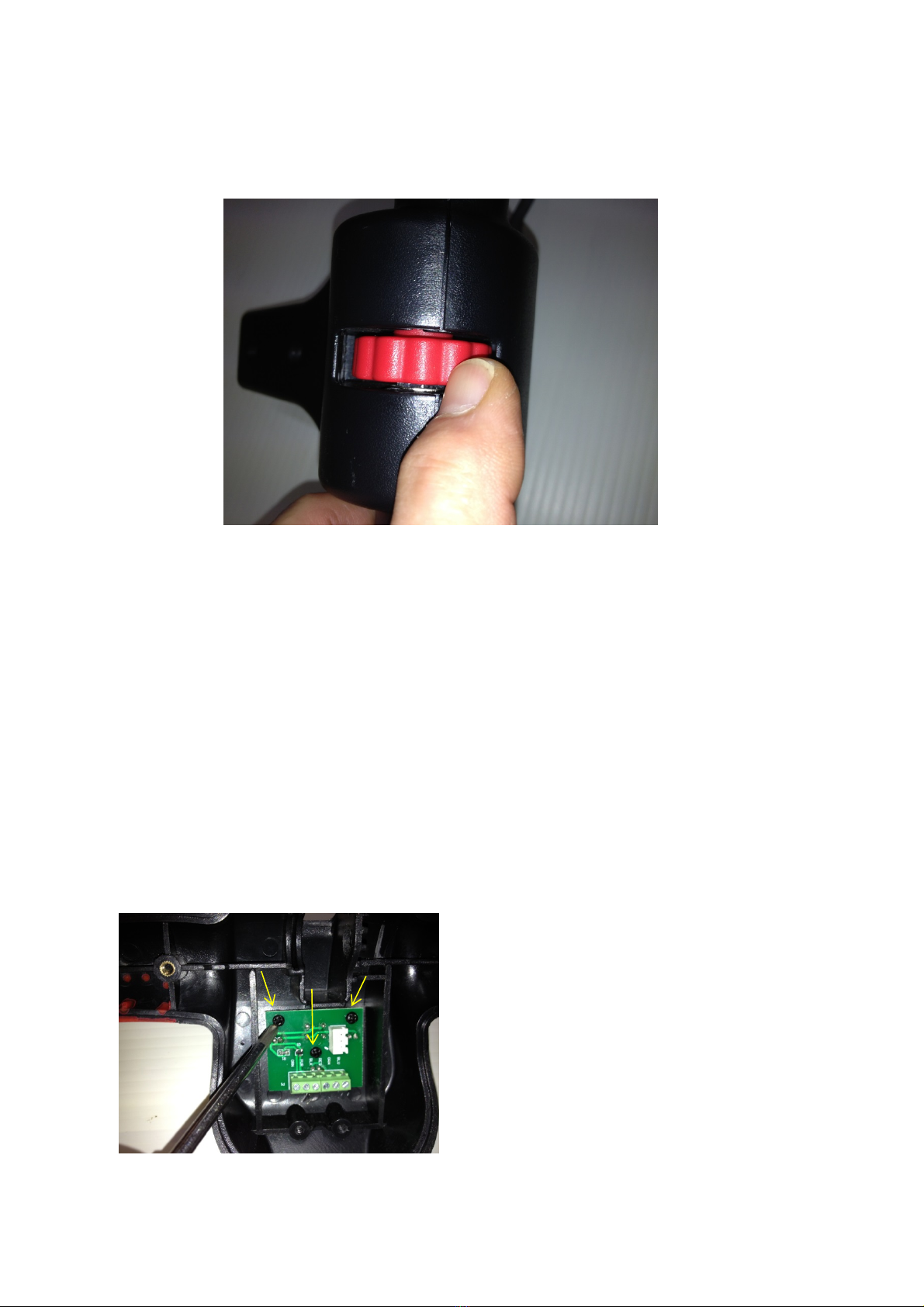

BeforeyoucanloosentheretainingnutwhichsecurestheSpeedSwitchtotheUpperHandle,you

mustfirstslidetheRedSpeedDialasfaraspossibletotheright,whichwillallowyoutoaccesstothe

securingnut.Tocarryoutthisprocess‐placeascrewdriverinthepositionaspicturedinFigureNo5

andgentlyshiftthespeeddialinthedirectionofthearrowsshown,asfarasyoucantotherightby

rotatingthescrewdriver.

PLEASENOTE–Beextremelycarefulwhilecarryingoutthispartoftheprocedure,astoavoid

damagingtheTopHandleAssembly.

FigureNo5

OnceyouhavecarriedouttheprocedureaspicturedinFigureNo5,youwillbeabletoseeandhave

accesstotheSpeedSwitchsecuringnut,aspicturedinFigureNo6andindicatedbythearrow.

GTLITHIUMV1Workshopmanual 6

©2013ElkingtonGolfPtyLtd

FigureNo6

LoosentheSpeedSwitchsecuringnutbyusingthespeciallysuppliedSpannerwhichwassuppliedto

you,withyourServiceCentreStartUpKitaspicturedinFigureNo7.

PLEASENOTE–Whilelooseningthesecuringnut,youwillneedtoslidetheSpeedSwitchinthe

directionofthearrowinFigureNo7&7Aatthesametime,whichwillallowcompleteremovalof

theSpeedSwitch.

GTLITHIUMV1Workshopmanual 7

©2013ElkingtonGolfPtyLtd

FigureNo7

OncetheSpeedSwitchsecuringnuthasbeencompletelyloosened,keepslidingtheSpeedSwitch,in

thedirectionofthearrowaspicturedinFigureNo7A,untilitiscompletelyfreefromtheTopHandle

AssemblyaspicturedinFigureNo8

FigureNo7A

GTLITHIUMV1Workshopmanual 8

©2013ElkingtonGolfPtyLtd

FigureNo8

BeforebeginningtofitthenewSpeedSwitch,itisimportanttonote‐ThattheshaftontheSpeed

Switch,hasa“flat”sectiontoallowtheSpeedDialtolocateontheshaftandalocating“lug”onthe

housingoftheswitchaspicturedinFigureNo9.Thelocating“lug”ontheswitchneedstobe

positionedcorrectlyintotheTopHandleAssemblyaspicturedanddefinedinthesectionoftheTop

HandleassemblyasindicatedbythearrowonFigureNo10.TofitthenewSpeedSwitch,beginby

slidingtheSpeedSwitchthroughthemountingholeintheTopHandleAssemblyandplacingthe

washerandnutontotheshaftaspicturedinFigureNo9.

FigureNo9

GTLITHIUMV1Workshopmanual 9

©2013ElkingtonGolfPtyLtd

FigureNo10belowshowsthepositionthatthelocating“lug”ontheSpeedSwitchmustlocateinto

ontheTopHandleassemblydefinedbyanarrow.

FigureNo10

OncetheSpeedSwitchisplacedintothetophandleaspreviouslyshowninFigureNo9,theSpeed

DialmustbeplacedontotheshaftoftheSpeedSwitch,aligningtheflatsectionontheSpeedSwitch

shaftwiththeflatsectionontheSpeedDialandthelocatingluginthecorrectpositionaspicturedin

FigureNo11.

FigureNo11

.

GTLITHIUMV1Workshopmanual 10

©2013ElkingtonGolfPtyLtd

BeforeyoucantightenthesecuringnutontheSpeedSwitch,youwillhavetostartthenutonthe

threadoftheSpeedSwitchbyusingasmallscrewdrivertoturnthenutaspicturedinFigureNo12.

Thispartoftheprocesscanbealittletrickyandrequiresasteadyhandandalittlepatience.Be

verycarefulnottotryandforcethenutonwithaspannerandcrossthreadthenut.

PLEASENOTE–ItisextremelyimportanttoensuretheLocatingLugontheSpeedSwitchislocated

correctlyintotheslotontheTopHandleassembly.

FigureNo12

OnceyouaresurethatthenuthasstartedcorrectlyonthethreadoftheSpeedSwitch,youarenow

abletotightenthesecuringnutwiththespecialspannerprovidedaspicturedinFigureNo13.Once

thenutistight,youwillneedtopushtheSpeedDialfurtherontotheshaftuntilitiscorrectly

centredintotheopeningoftheTopHandleassembly.

FigureNo13

GTLITHIUMV1Workshopmanual 11

©2013ElkingtonGolfPtyLtd

BeforeyourefittheTopHandleassemblybackontothebuggy,itisadvisabletoplacethetwohalves

ofthehandletogetherandensurethattheSpeedDialinnotbindingontheTopHandleassembleas

picturedinFigureNo14

FigureNo14

OnceyouarecertainthattheSpeedDialisturningcorrectlywithoutinterference,thenreconnect

theSpeedSwitchwiringtothePCBboardandreconnectthestemcablewiring,ensuringthateach

colouredwirecorrespondswiththecolourprintedontheterminalblock.FittheStemCablesecuring

bracketandrefitthehandletothebuggybyreferringtoparagraphNo4.Testtheoperationofthe

speedswitchandensurethatitisfunctioningcorrectlyandtheSpeedDialisnotfoulingontheTop

Handleassembly.

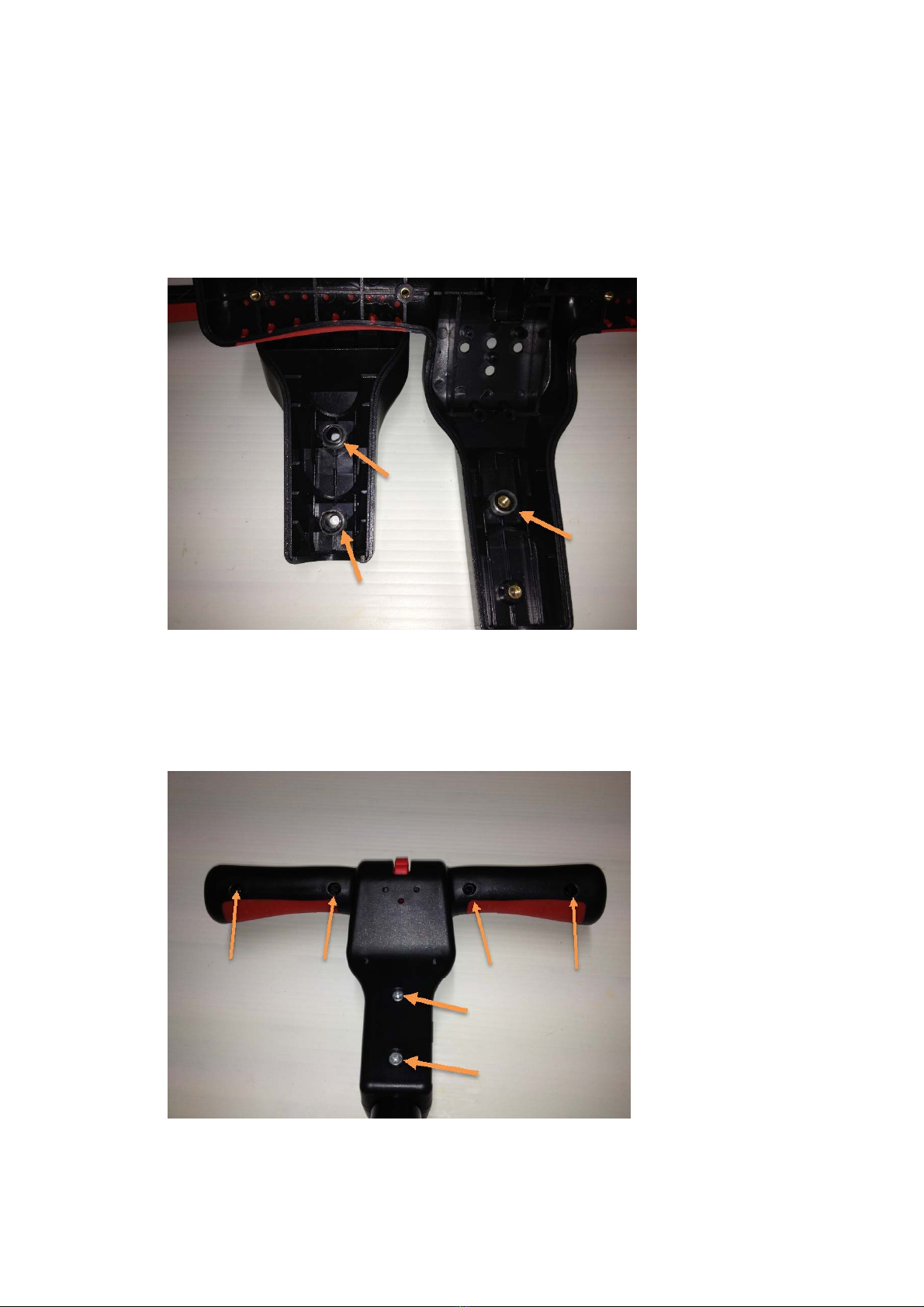

3/REPLACINGTHEPCBBOARD/DISPLAYINTHETOPHANDLE

Tocarryoutthisprocess,followthestepsasperFigures1to4thenremovethe3screwsindicated

byarrows,whichsecurethePCBboardasperFigureNo15andreplacethePCBboard.

Tocompletethisprocedure,reversethestepsofFigures1to4andtestthatthePCBboardis

operatingcorrectlyandallthreedistancesettingsarefunctioningcorrectlyalso.

FigureNo15

GTLITHIUMV1Workshopmanual 12

©2013ElkingtonGolfPtyLtd

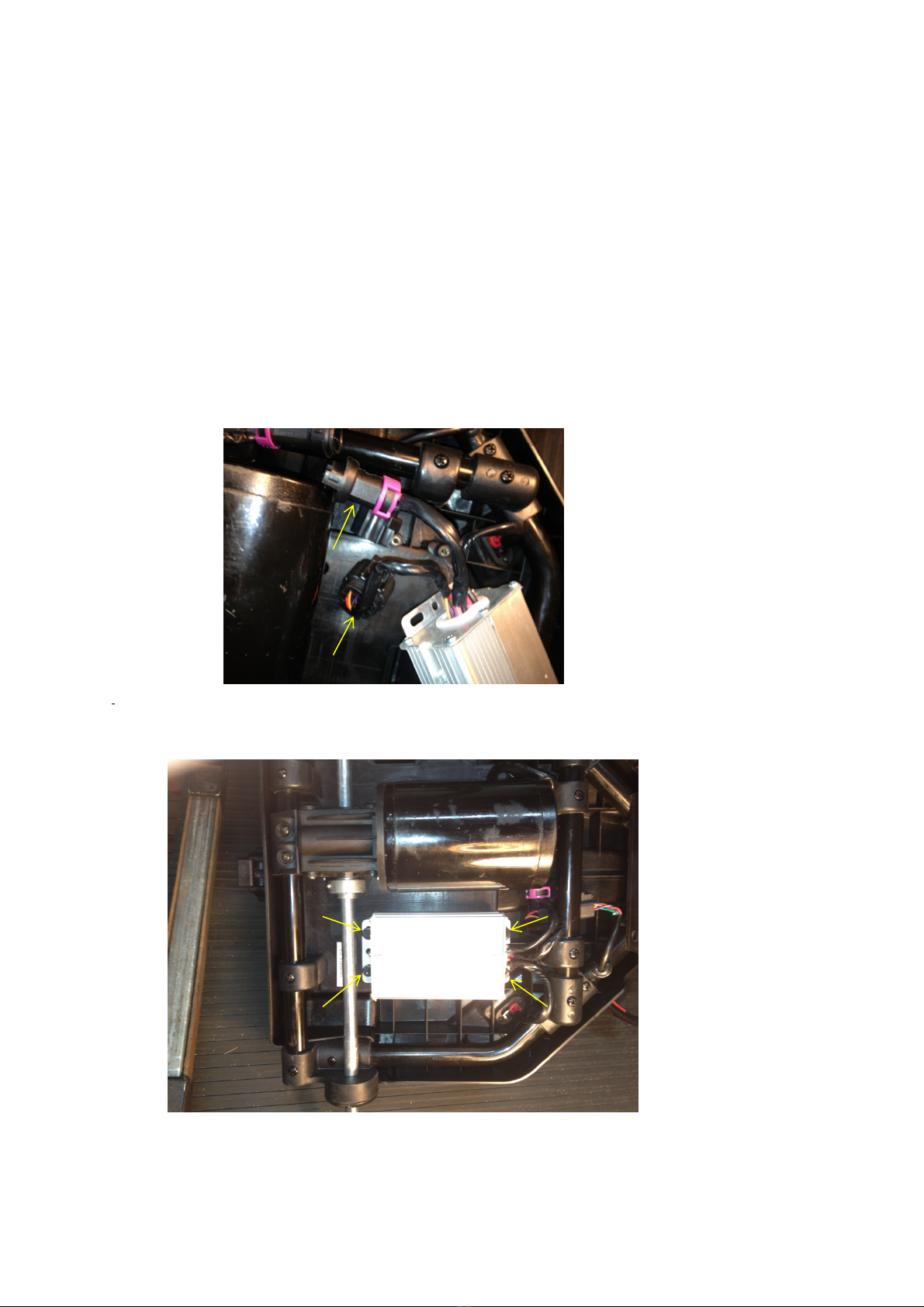

4/REFITTINGTHETOPHANDLE

Beforerefittingthetophandle,pleaseensurethatthe3bushes/sleevesareinplace(onsome

modelsonly,asindicatedbyarrowsonFigureNo15A

Pleasebecarefulnottodropthesebushesintothemainupperframetubewhenrefittingthe

handle.

FigureNo15A

RefitandtightenthescrewsasindicatedbyarrowsonfigureNo15B

FigureNo15B

GTLITHIUMV1Workshopmanual 13

©2013ElkingtonGolfPtyLtd

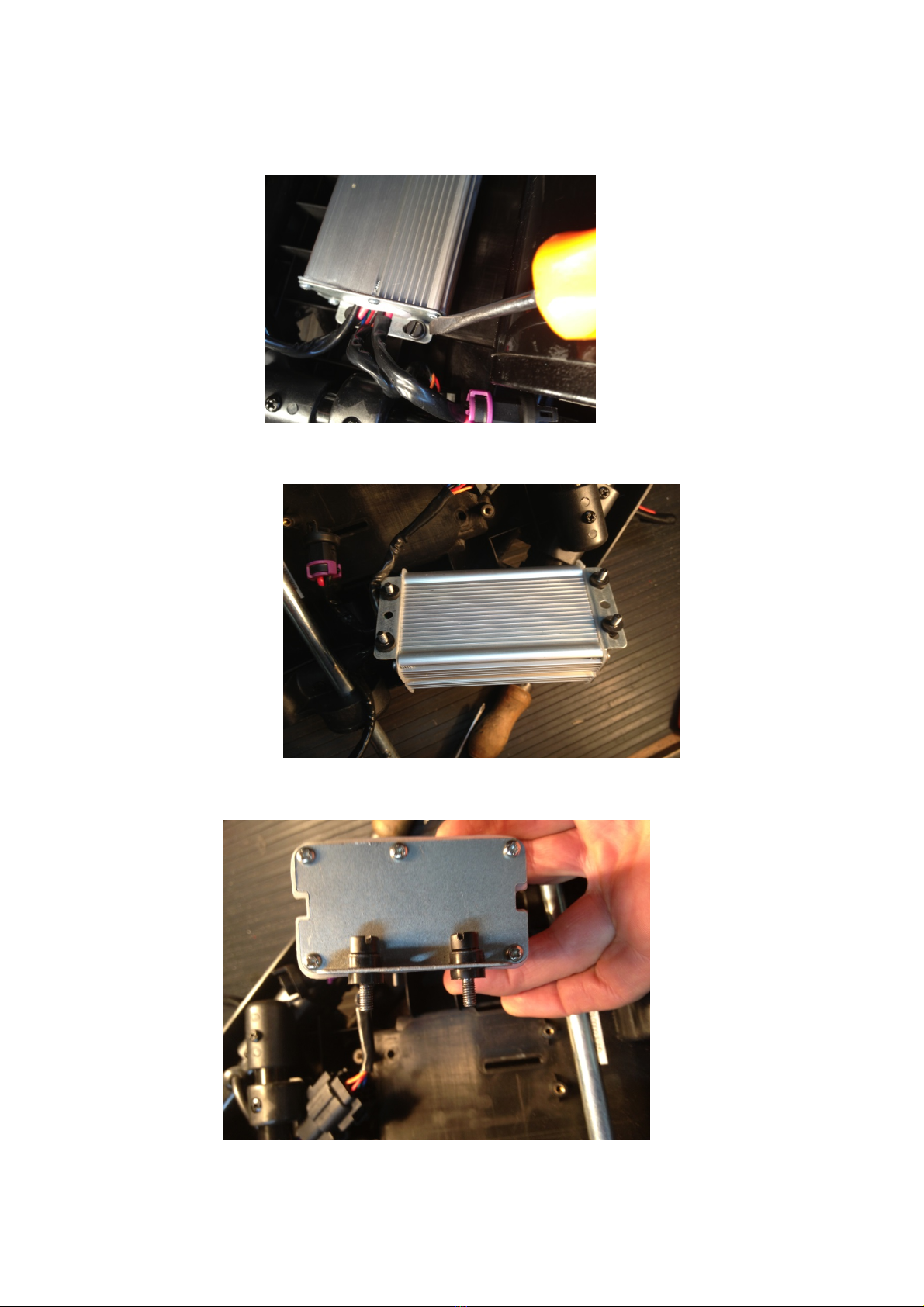

5/REPLACINGOFTHEMOTORCONTROLLER

ToreplacetheMotorController,firstlyturnthebuggyupsidedown.

AftermanyyearsofextensiveresearchintofailedMotorControllers,itwasdiscoveredthatoneof

themaincausesforfailureisrepeatedshock.Forthisreason,theGTLithiumMotorControlleris

rubbermountedandtherubbermountingsthatarepositionedonthemountingscrewsofthe

MotorController,MUSTbeputbackinplacewhenreplacingtheunit.

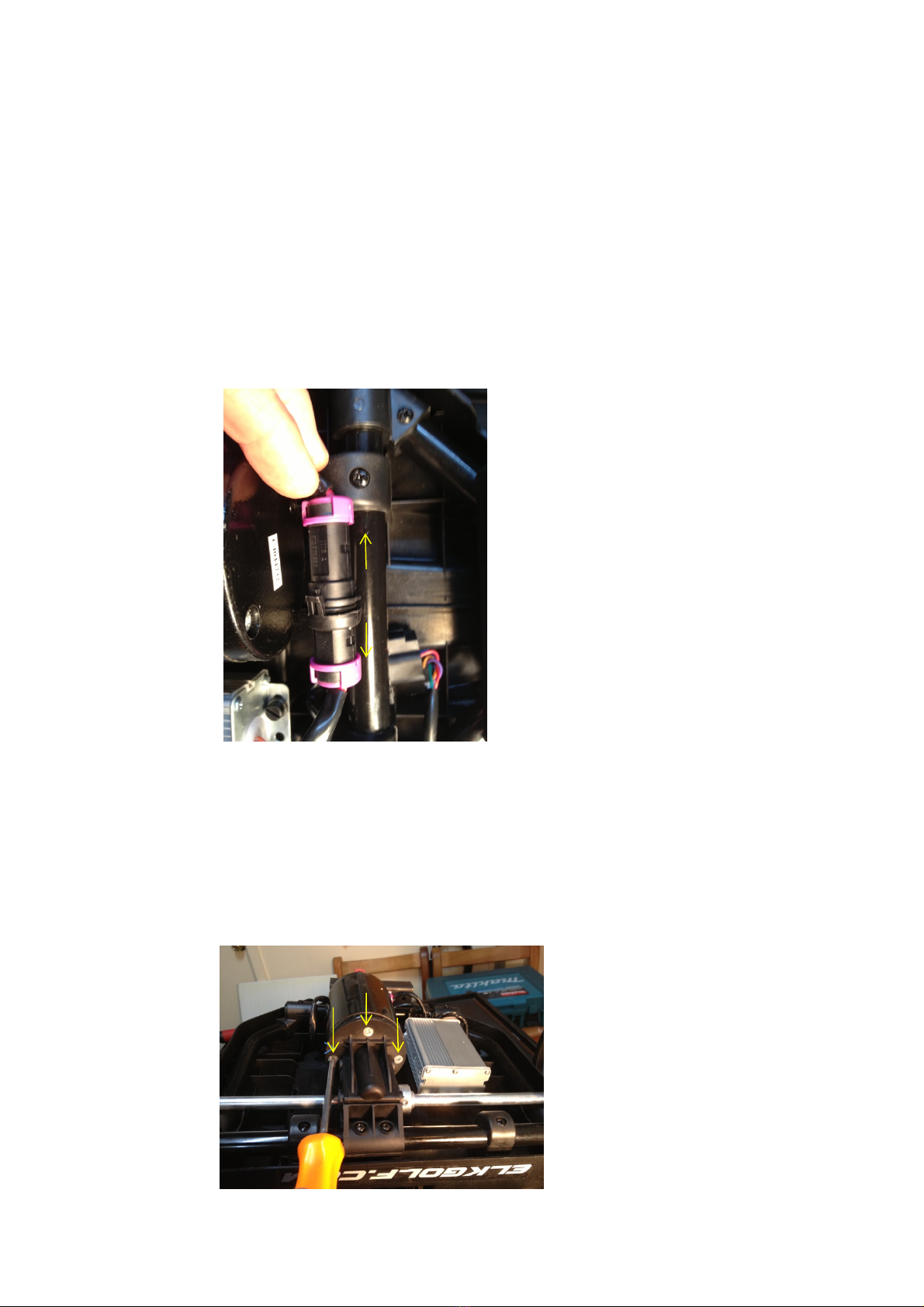

ToremovethemotorController,firstlyyoumustremovethecableties,securingthewiringtothe

undersideoftheBatteryTrayanddisconnectthewiringfromtheMotorandStemCableindicatedby

arrowsaspicturedonFigureNo16Below.

Fffffffff

Loosenthe4screwsthatsecuretheMotorControllerasindicatedinFigureNo17

FigureNo17

GTLITHIUMV1Workshopmanual 14

©2013ElkingtonGolfPtyLtd

LoosenScrewsenoughtofreeMotorControllerformthebatterytray,butdonotremovethescrews

completelyastherubberbusheswillfallofftheretainingscrews.RefertoFiguresNo18,19&20

FigureNo18

FigureNo19

FigureNo20

GTLITHIUMV1Workshopmanual 15

©2013ElkingtonGolfPtyLtd

NowdiconnecttheBatteryconnectionwiringwhichhousesthe2AndersonConnectors,byremoving

the2retaingscrews,indicatedbyarrowsonFigureno21.

TheMotorControllerisnowfreetoberemoved.Makesurethatyoudonotlooseanyrubber

bushesintheprocess.

FigureNo21

TofitthenewMotorController,startbyrefitingtheBatteryConnectionwiring.Pleaseensurethat

locatinglugonthehousingofthisplugcorrespondswiththecutoutintheBatteryTrayasindicated

byarrowsonFiguresNo22&23.

FigureNo22

FigureNo23

GTLITHIUMV1Workshopmanual 16

©2013ElkingtonGolfPtyLtd

Fitthe2screwswhichsecurethisplugandensurethatthesescrewsarenotovertigtened,causing

damagetotheBatteryTray.

Pleaseensurethattherubberbushesareplacedon4screwsasperFigureNo20,beforeattempting

torefittheControllerandmakesurethatall4screwsarestartedcorrectlyandnotcrossthreaded

beforetighteningcompletely.Onceall4srewsaretight,reconnecttheStemCableWiringand

Motorwiring,thenfit3newcabletiesandsecurethewiring.

6/REPLACINGTHEMOTOR.

BeginbyremovingthecabletiessecuringtheMotorwiringtotheframe,thenunplugingtheMotor

Wiring,fromtheMotorControlleraspicturedinFigureNo24

FigureNo24

Removethe3ScrewswhichsecuretheMotortotheGearBoxasindicatedbyarrows

onFigureNo25

FigureNo25

GTLITHIUMV1Workshopmanual 17

©2013ElkingtonGolfPtyLtd

TheMotorcannowbeseperatedfromtheGearbox.Becarefulnottoloosetherubbersealthatsits

betweentheMotorandtheGearboxaspicturedinFigureNo26.Beawarethatthissealmaystay

stucktotheMotorwhentheMotorisremoved.

FigureNo26

BeforefittingthenewMotor,ensurethatthesealiscorrectlypositionedontheflangeofthe

Gearbox.Itisadviseabletouse,eithersiliconeorgreasetohelpkeepthissealinplacepriorto

fittingthenewMotorasperFigureNo27.

FigureNo27

Ensurethatthe3holesintherubberseal,lineupwihthe3holesintheGearboxflangeasindicated

byarrowsinFigureNo27

YoucannowbegintoinserttheMotorintothegearbox.Youmayneedtoturntheaxleslightly,to

allowthewormdrivegearstomatchcorrectlyandtheMotorbodytomatchupcorrectlywiththe

GearboxFlangeasperFigureNos28&29.

GTLITHIUMV1Workshopmanual 18

©2013ElkingtonGolfPtyLtd

FigureNo28

Fitthe3MotorretaingscrewsandensurethattheMotoriscorrectlyseatedagainsttheGearbox

flangebyholdinginwardpressureontheMotorandthentightenthe3screwsevenly.Referto

FigureNo29.

FigureNo29

ReconnecttheMotorwiringasperFigureNo24andrefitcableties,tosecurewiringtotheframe.

GTLITHIUMV1Workshopmanual 19

©2013ElkingtonGolfPtyLtd

7/REPLACINGTHEAXLEDRIVEPINS

Thisisaverysimpleprocessandallyouwillrequireisasmallhammeranda4mmpinpunch.Begin

byremovingthewheelbydepressingtheRedwheelreleasetabonthewheelasperfigureNo30.

ToremovetheoldDrivepinusea4mmpunchaspicturedinFigureNo31.ToinstallnewDrivepin,

useasmallhammerandgentlytapthepinintotheaxle,beingverycarefulnottobendtheaxle

duringthisprocessaspicturedonFigureNo32.Itisrecommendedthatyouusealittleloctiteon

theDrivePinwheninstalling.

FigureNo30

FigureNo31

FigureNo32

GTLITHIUMV1Workshopmanual 20

©2013ElkingtonGolfPtyLtd

8/REPLACINGTHESTEMCABLE

ToBeginthisprocess,firstlybeginbyremovingtheTopHandleassemblyasperFigureNos1to4.

OncetheTopHandlehasbeenremovedfromthebuggy,folddowntheframeandbegintopullout

theStemCableinthedirectionofthearrow,whichishousedwithinaflexibleprotectivetubeas

showninFigureNo33.

FigureNo33

Keeppullingoutwardontheflexibletubeinthedirectionofthearrow,untiltheStemCableis

releasedfromtheuppersectionoftheMainFrame,asperFigureNo34.

FigureNo34

OncetheStemcablehasbeenfullyreleasedfromtheUpperMainFrametube,slidetheflexible

protectivecoverfullyofftheStemCable,buttakespecialnotewhichwayyouhaveremovedthis

cover,asitwillneedtoberefittedthesamewayitwasoriginally,referFigureNo35.

Table of contents

Popular Offroad Vehicle manuals by other brands

Gravely

Gravely Atlas JSV 3000 EFI Owner's/operator's manual

Arctic Cat

Arctic Cat TRV 2015 Operator's manual

Arctic Cat

Arctic Cat 2010 700 Diesel SD Operator's manual

Yamaha

Yamaha Big Bear YFM400R owner's manual

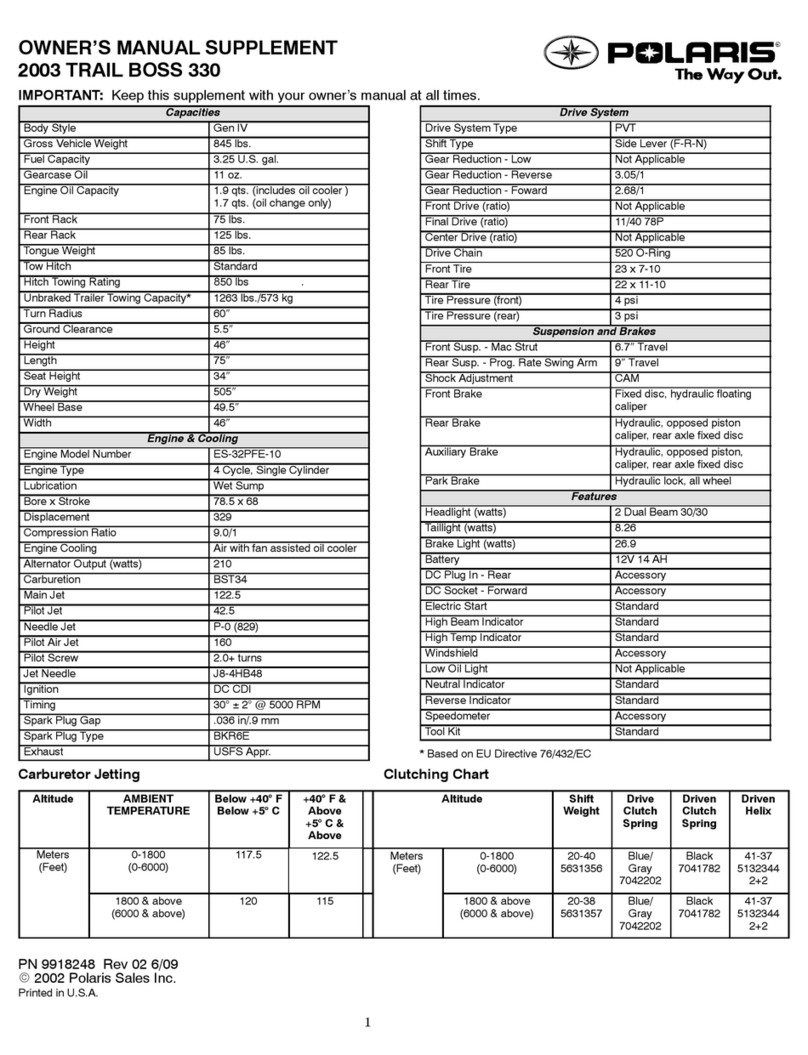

Polaris

Polaris Trail Boss 330 Quadricycle Specification sheet

Polaris

Polaris 600 IQ Racer owner's manual

Polaris

Polaris Sportsman Touring 570 2022 owner's manual

Polaris

Polaris SNOWMOBILE 2001 Owner's safety and maintenance manual

Tracker Off-Road

Tracker Off-Road 800SX Service manual

Arctic Cat

Arctic Cat DVX 250 2007 Service manual

Polaris

Polaris RZR Trail S 2022 owner's manual

Ontario Drive & Gear

Ontario Drive & Gear Centaur V2001G Operator's manual