The type of brush being cut and the ground

conditions will determine the best ground speed and

cutting procedure. The brush mower is designed to

cut short or tall grass, brush and small trees.

IMPORTANT: Before operating the attachment,

perform the service schedule for routine

maintenance.

1. Inspect the cutting area for obstructions such as

stumps, wire, rocks, electrical lines, debris, drop

offs, holes, etc. Remove obstructions from the

cutting area that might be picked up and thrown.

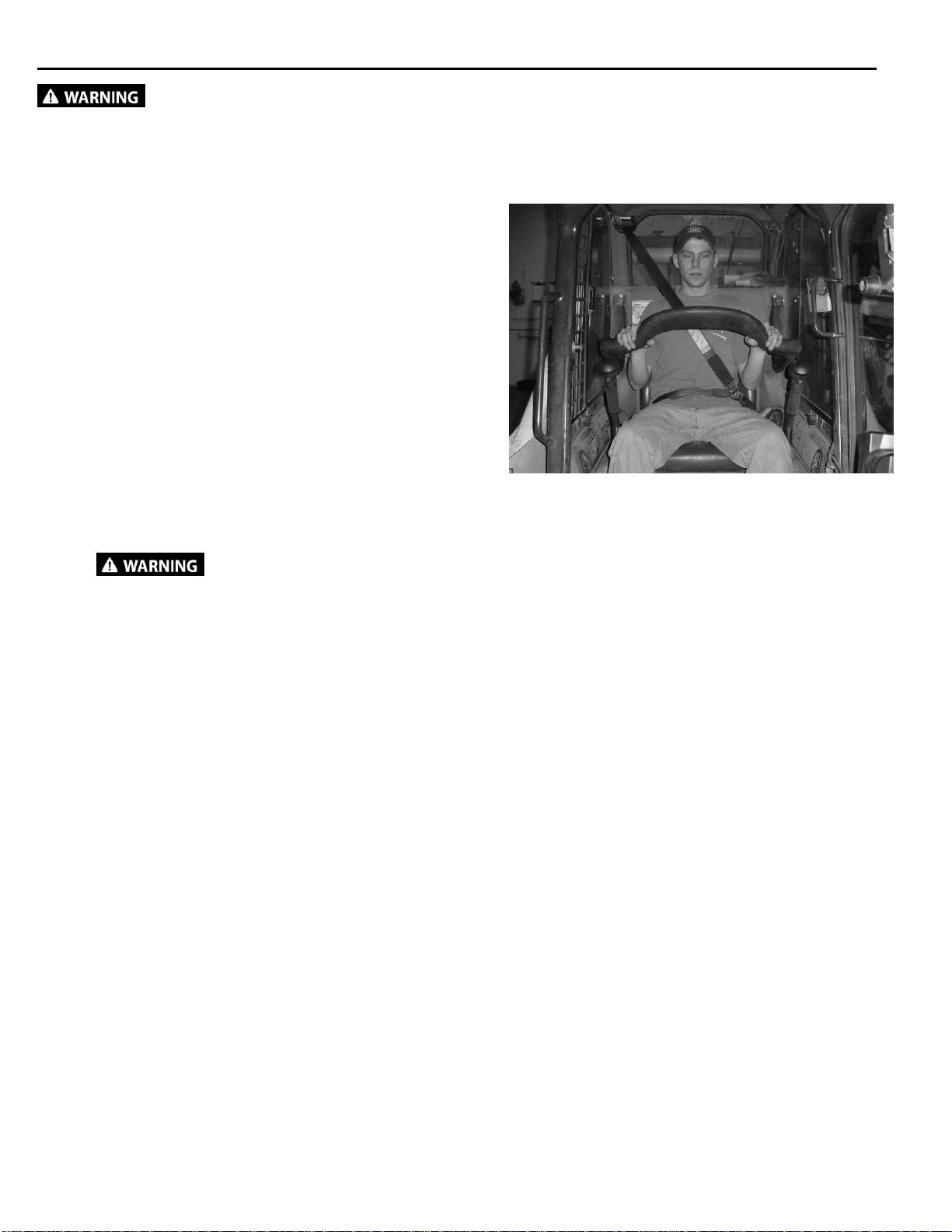

2. With the operator in the seat of the loader, the

seat belt fastened and the seat bar lowered (if so

equipped), start the engine.

To improve stability, always

carry attachment low to the ground while

driving.

3. Activate the auxiliary hydraulic system to start

the blade rotation. Make sure auxiliary hydraulic

circuit is operating in the correct direction.

IMPORTANT: Engine must be at idle speed

when engaging auxiliary hydraulic system.

IMPORTANT: This mower is designed to

operate from 30 to 42 gpm. Operating at higher

flow rates can cause serious damage to the

mower and will void the warranty.

IMPORTANT: Do not operate the brush mower if

excessive vibration is present. Serious damage

can occur. Check blades and gearbox.

NOTE: Certain loaders may not operate in high

flow mode without special wire harnesses.

Others require the control switches to be

operated in a specific way. It may also be

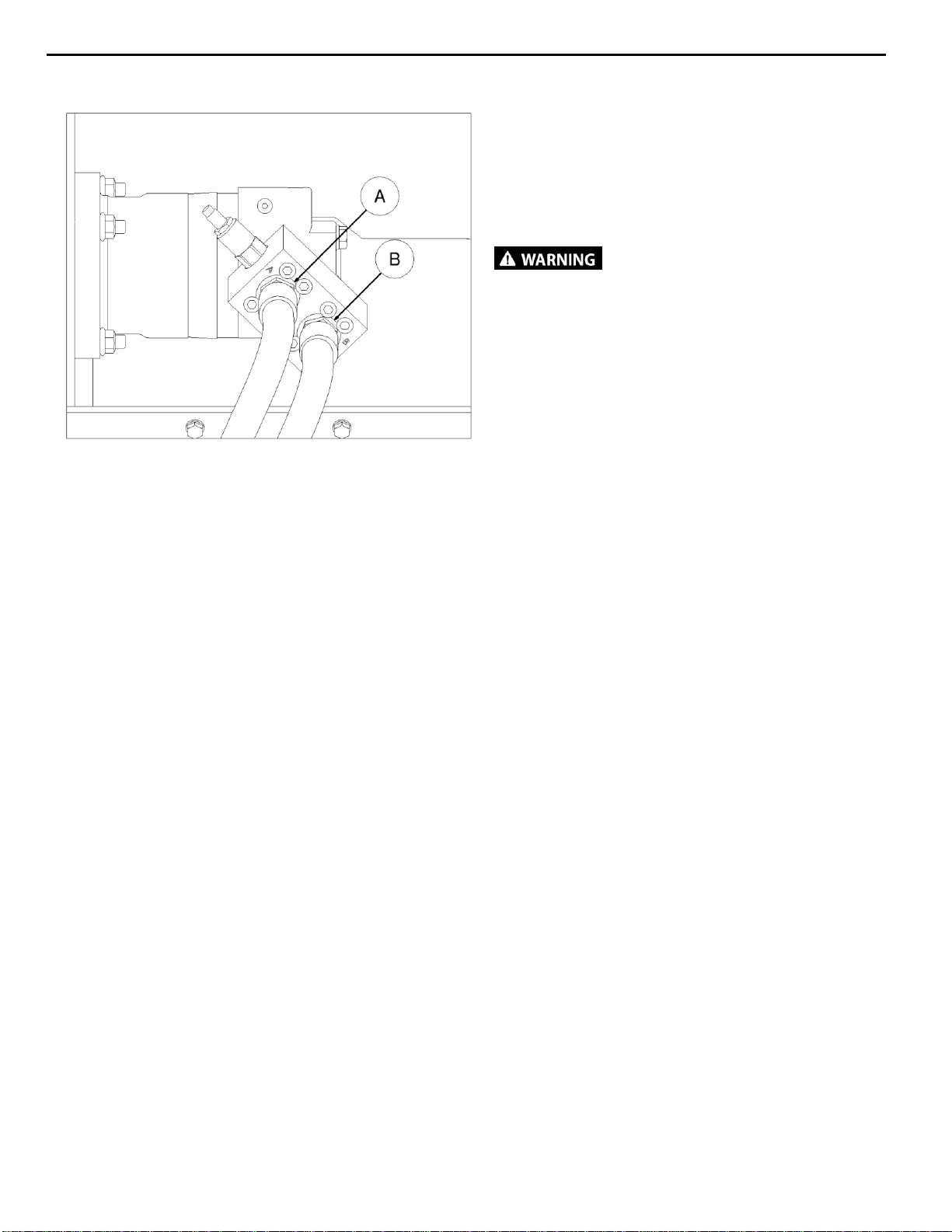

necessary to switch the hose couplers around to

match your loader. (See loader’s operator’s

manual)

4. With the loader boom lowered all the way

and the auxiliary hydraulics engaged, slowly

rotate the loader coupler forward until the

skid plates are parallel to the ground.

NOTE: It may be helpful in certain instances

to keep the front of the mower raised slightly.

5. If desired, the loader lift arms can be put in

the float position. (See loader’s operator’s

manual.)

6. Drive the loader forward into the work area.

NOTE: Raising the front of the brush mower a

few inches may help while driving forward into

thick brush and when turning.