Eurotech EWF150 User manual

Washer Owner’s Manual

MODELS EWF150 AND EWF172

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

ENGLISHFRANÇAISESPAÑOL

IMPORTANT!

To get the best performance from

your washer, read all operating

instructions before using it for the

first time.

Version 2

2

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS..................................................... 3

DESCRIPTION OF THE MACHINE ............................................................ 4

INSTALLATION INSTRUCTIONS ............................................................... 5

INSTRUCTIONS FOR USING THE WASHER............................................ 7

CARE LABEL INSTRUCTIONS .................................................................. 8

CONTROL PANEL ...................................................................................... 9

WASHER PROGRAMS............................................................................. 10

CARE AND MAINTENANCE......................................................................11

COMMON LAUNDRY PROBLEMS........................................................... 12

TROUBLESHOOTING .............................................................................. 14

WARRANTY.............................................................................................. 15

QUICK START REFERENCE ................................................................... 16

3

ENGLISH

To reduce the risk of fire, electric shock, or injury to

persons when using your appliance, follow basic

precautions, including the following:

♦Read all instructions before using the appliance.

♦Do not run appliance while you are out of the

home.

♦Donotallowchildrentoplayonor in the appliance.

Childrenshould beclosely supervised whennear

the appliance.

♦Before the appliance is removed from service or

discarded, remove the door to the washing

compartment.

♦Do not reach into the appliance if the drum is

moving.

♦Do not install or store this appliance where it will

be exposed to the weather.

♦Do not tamper with controls.

♦Do not repair or replace any part of the appliance

or attempt any servicing unless specifically

recommended in the user-repair instructions or

in published user-repair instructions that you

understand and have the skills to carry out.

♦Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors

that could ignite or explode.

♦Under certain conditions, hydrogen gas may be

producedin ahot watersystem that hasnot been

used for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE.Ifthehot water systemhasnotbeen

used for such a period, before using a washing

machine or combination washer-dryer, turn on all

water faucets and let the water flow from each

for several minutes. This will release any

accumulated hydrogen gas. As the gas is

flammable, do not smoke or use an open flame

during this time.

IMPORTANT SAFETY INSTRUCTIONS

NOTE: This manual does not cover every possible

condition and situation that may occur. Use

common sense and caution when installing,

operating, and maintaining any appliance.

Do not wash or dry articles that have been

previously cleaned in, washed in, soaked in,

or spotted with gasoline, dry-cleaning

solvents, cooking oils, or other flammable

or explosive substances because they give

off vapors that could ignite or explode.

WARNING!

WARNING!

This appliance must be properly grounded.

Improper connection of the equipment

grounding conductor can result in a risk of

electric shock. Check with a qualified

electrician or serviceman if you are in doubt

as to whether the appliance is properly

grounded.

The plug must be plugged into an appliance

outlet that is properly installed and grounded

in accordance with all local codes and

ordinances.

4

B

A

C

1. Door

2. Stainless steel drum and barrell

3. Stove-enamelled power-coat paint

4. Four adjustable rubber-covered feet

5. Emergency drain and lint filter

DESCRIPTION OF THE MACHINE

The washing machine is a domestic appliance capable of washing any type of fabric.

♦The machine is constructed in sheet steel panels with a treated and painted finish that ensures its

aesthetic quality remains unaltered over time.

♦Themotorand all movingpartshavebeen designed andproducedina manner thatguaranteesminimum

noise levels.

♦The stainless steel drum is large and well mounted to ensure a better quality wash and a longer life of

clothing.

♦The control panel lets you use all the wash and dry programs with ease.

♦The access door has a wide opening to facilitate easy loading and unloading of the washing.

SPECIFICATIONS:

Supply voltage: Single-phase 115 V, 60 Hz

Fuse: 15 Amp

Inlet supply hose: Two 5-ft (1.5 m) fill hoses (hot and cold)

Supply pressure: 15-142 PSI

Outlet hose: 5.5 ft (1.7 m) polypropylene hose, 3/4” ID

CAPACITY:

Model EWF150 Large – 5 kilos (weight of clothes)

Model EWF172 Extra Large –7 kilos (weight of clothes)

DIMENSIONS:

MODEL EWF150

A. Width 23-3/8” 59.37 cm

B. Depth* 21-3/8” 54.29 cm

C. Height 33-1/4” 84.45 cm

* Depth w/door open: 36-7/8” (93.66 cm)

MODEL EWF172

A. Width 23-3/8” 59.37 cm

B. Depth* 23-1/8” 58.74 cm

C. Height 33-1/4” 84.45 cm

* Depth w/door open: 38-3/4” (98.43 cm)

For additional information, see the type plate on the inner door facing.

1

23

4

5

5

ENGLISH

FIG. 2

Z

U

INSTALLATION INSTRUCTIONS

Read these instructions carefully and completely before you install the machine. The installation should be

carried out by a qualified person who is familiar with all local codes and ordinances for electrical and

plumbing connections. Incorrect installation may cause damage and/or injury. If the integrity of the machine

is in doubt, do not use it. Call your dealer for qualified assistance.

The washer can be installed anywhere provided that the temperature is not less than 38°F (3°C) and the

electrical cords and hoses behind the machine are not cramped.

To install the washing machine, follow the steps below:

1. Move the machine to its installation position and remove the outer

wrapping and the polystyrene base.

2. Model EWF150 hasaplastic strip tapedtothe bottom ofthemachine

to secure two cones that prevent the tub from moving during

shipment. This plastic strip and the cones must be removed. To do

this, simply peel away the tape on the bottom sides of the unit that

hold the plastic strip and cones in place.

NOTE: Failure to remove these cones will likely cause the unit to

vibrate excessively during the spin cycles.

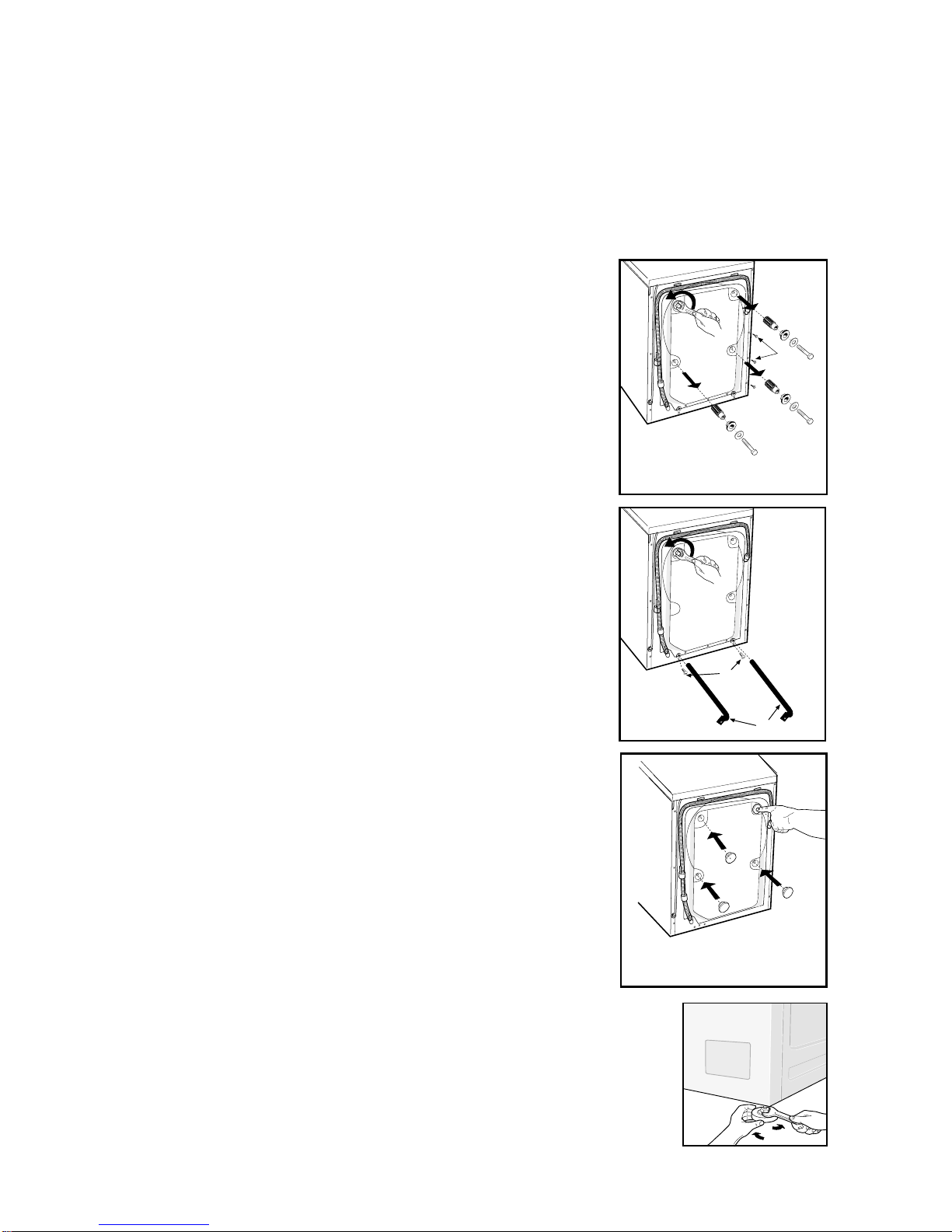

3. The drum on both models is locked in position. Loosen the four

locking bolts and remove them along with the plastic spacers

(Fig. 1).

NOTE: If the plastic spacers cannot be removed, open the side

panel by loosening the screws indicated as “V”in

Fig. 1. Remove the spacers and replace the panel.

4. Next, loosen the two locking screws (Z) and remove the two pins

(U), as illustrated in Fig. 2. Keep the bolts, screws and pins for

future use.

5. Plug the holes with the plastic plugs provided with the unit (packed

inside the drum with the documentation) (Fig. 3).

6. To level the machine, adjust the feet by screwing or unscrewing as

needed. Once the machine is level, tighten the locknuts (Fig. 4).

V

FIG. 1

FIG. 3

FIG. 4

6

ELECTRICAL CONNECTION

Check to make sure the main power supply and the outlet are appropriate to support a 110/120 V, 15 amp

single-phase circuit. The power supply voltage is indicated on the filter door on the bottom right of the

washing machine.

Grounding Instructions

This appliance must be grounded. In the case of malfunction or breakdown, grounding will reduce the risk

of electric shock by providing a path of least resistance for electric current. This appliance is equipped with

a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING!

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. Check with a qualified electrician or serviceman if you are in doubt as to whether the

appliance is properly grounded.

Do not modify the plug provided with the appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

If the power supply cord is damaged in any way please contact the dealer.

Position the appliance so that the plug can be accessed and disconnected easily in case of

emergencies.

WATER SUPPLY CONNECTION

Before making the water supply connection, allow a quantity of water to flow from

the top. The water should be clean and free from impurities, especially where the

system is new or has been left unused for a length of time.

There are two hoses provided with the machine. The hot water hose is indicated

with a red strip running the length of the hose.

Insert the filter/washer supplied (Fig. 5) before connecting the water inlet hose to

the valve. Check that the other end of the hose is tight (Fig. 5A). Turn the supply

valve on (Fig. 5B).

The drain outlet should be positioned at a height of between 23”(60 cm) and 35”

(90 cm) above the floor (Fig. 6).

NOTE: To prevent siphoning, do not seal the drain hose connection into the drain

outlet.

If the machine is not connected to a drain outlet, place the drain hose and bracket

supplied over the edge of a sink or wash basin and anchor it in place.

FIG. 5

FIG. 5A

Cold

Hot

close open

FIG. 5B

FIG.6

23.5" (60 mm) minimum

35" (90 mm) maximum

7

ENGLISH

INSTRUCTIONS FOR USING THE WASHER

1. Before placing the items in the washer, sort the laundry by type of fabric and

care label instructions (see page 8).

2. Make sure nothing is in the garment pockets to avoid damage to clothes, the

machine or the filter.

3. Close zippers and hooks to prevent snagging.

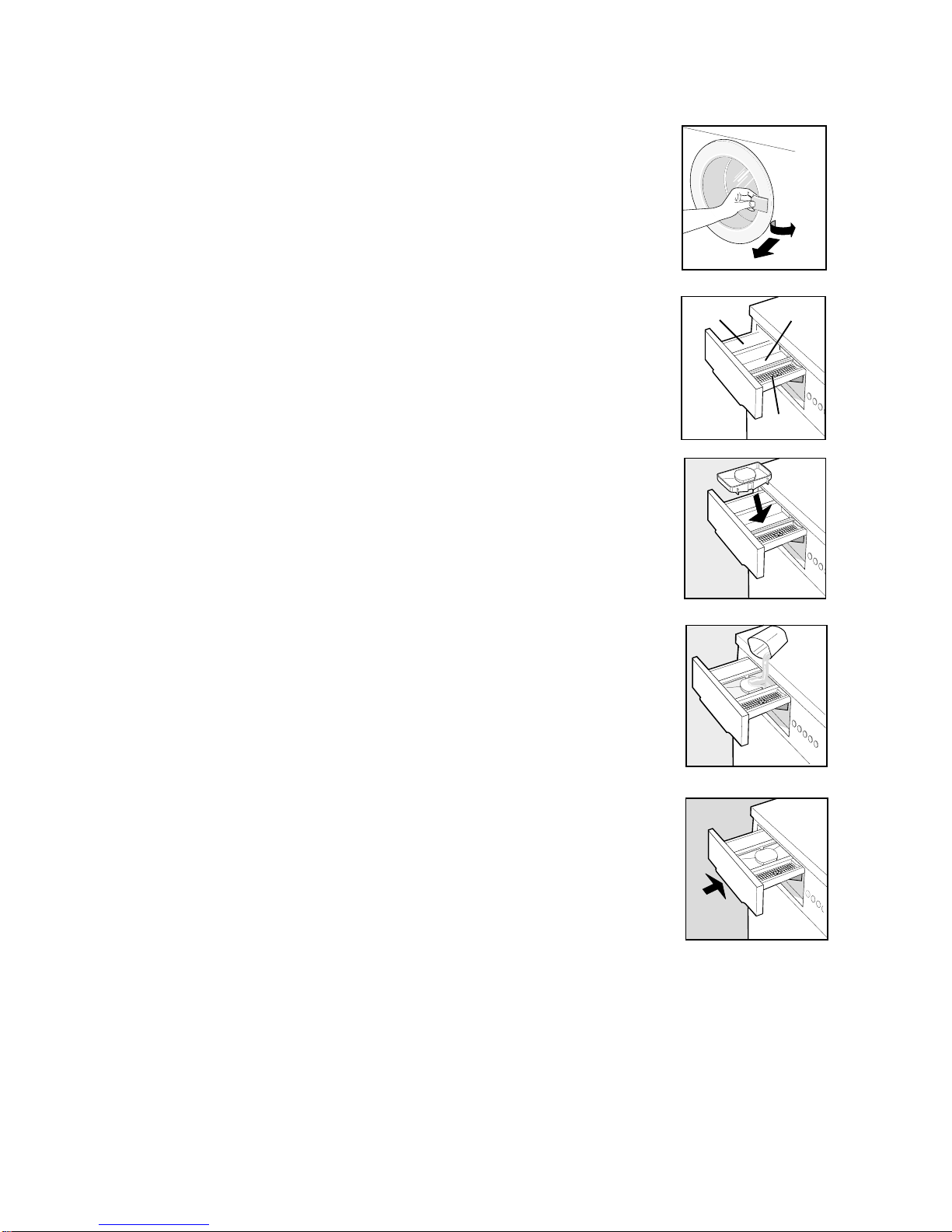

4. Open the door (Fig. 8).

5. Load the laundry and close the door securely.

6. Pour detergent and fabric softener into the appropriate compartments in the

detergent drawer (Fig. 9). Use only low sudsing detergent made for front-

loading washers and follow label instructions.

The amount of detergent varies among the different brands, but for most

detergents, you need only one or two tablespoons. Too much detergent could

leave a residue on your clothes and possibly damage the washer.

NOTE: When using a liquid detergent, insert the special container supplied

with the washer into the main wash compartment (Fig 9a). Pour the

manufacturer’s recommended dosage of liquid detergent into the container

(Fig 9b).

NOTE: Do not add detergent to the prewash compartment unless you are

usinga washprogram that has a prewashcycle; otherwise,the machine could

oversudsandspill ontothefloor. Also, donotuse liquid detergentfora prewash

program because the detergent will be washed out the back of the drawer.

NOTE: It is not recommended that you use bleach in your Eurotech washer. If

you need extra whitening, we recommend that you use a low-sudsing powder

detergent with bleach additive.

NOTE: Excessive use of fabric softener can damage garments.

7. Close the detergent drawer securely (Fig 9c).

Caution! To avoid water spillage, do not open the detergent drawer while the

machine is operating.

8. Select program options (see pages 9 and 10).

9. Turn the Temperature knob to the desired temperature (see pages 9 and 10).

10. Set the Program knob to the desired program (see pages 9 and 10).

11. Press the On button (see page 9). (The power indicator light should come on.)

NOTE: For safety reasons, there will be a two to three minute delay at the end of

the program before you can open the door.

RECOMMENDED LOAD SIZES

To reduce wrinkling, you should determine the load size based on the type(s) of

fabrics being washed.

Cotton and Linen Fabrics—These items should be washed in full loads because

the tumble action of the tub along with the gentle rubbing, lifting and falling

movement of the clothes gives the best cleaning result.

Permanent Press Fabrics—These items need more room to move freely during

washing for the most wrinkle-free results. Therefore, fill the machine only half full

for permanent press items.

Delicate Fabrics—These fabrics, such as machine washable wool and silk, should only be washed in one-

third size loads for the best results.

FIG. 8

FIG. 9

Prewash Main Wash

Fabric

Softener

FIG. 9a

FIG. 9b

FIG. 9c

8

Normal wash setting

Permanent Press or Wrinkle

Resistant setting

Gentle/Delicate setting

Hand wash only

Ironing is necessary

Do not wash

Do not wring. Hang dry,

drip dry, or dry flat

Maximum water temp

200˚F/95˚C

Gentle or Delicate setting

Normal setting

Maximum water temp

160˚F/70˚C

Maximum water temp

140˚F/60˚C

Maximum water temp

120˚F/50˚C

Maximum water temp

105˚F/40˚C

Maximum water temp

85˚F/30˚C

WASH CYCLE

WASH WATERTEMPERATURE

TUMBLE DRY CYCLE

Do not tumble dry

Any heat

TUMBLE DRY HEAT SETTING

High heat

Medium heat

Low heat

No heat/Air fluff

Do not tumble dry

Line dry or hang to dry

SPECIAL DRYING INSTRUCTIONS

Drip dry (do not spin or wring)

Dry flat

Dry in shade.

Do not bleach

Any bleach when needed

Only non-chlorine bleach

BLEACH INSTRUCTIONS

Permanent Press or Wrinkle

Resistant setting

Machine dry

IRONING INSTRUCTIONS

High temperature setting

Medium temperature setting

Low temperature setting

Do not iron or press with heat

Iron without using steam

This symbol indicates the fabric

should be dry cleaned only.

DRY CLEAN SYMBOL

Most clothes and other washable items have permanent care labels. Read these labels carefully! Care label

instructions and warnings should be followed for the best cleaning results.

The table below defines the typical symbols used on fabric care labels. (Note: Some manufacturers may use

slightly different symbols.)

CARE LABEL INSTRUCTIONS

CARE LABEL SYMBOLS

9

ENGLISH

WARM

COLD

SOAK

SPIN

HEAVY STAIN

NORMAL

R

I

N

S

E

S

R

I

N

S

E

S

R

I

N

S

E

S

REGULAR

PERMA PRESS

DELICATE

EXTRA

RINSE NO

SPIN HALF

LOAD ON

OFF

WARM

RINSE HEAVY STAIN

NORMAL

QUICK

WASH

WOOL /

HANDWASH

SPIN

HOT

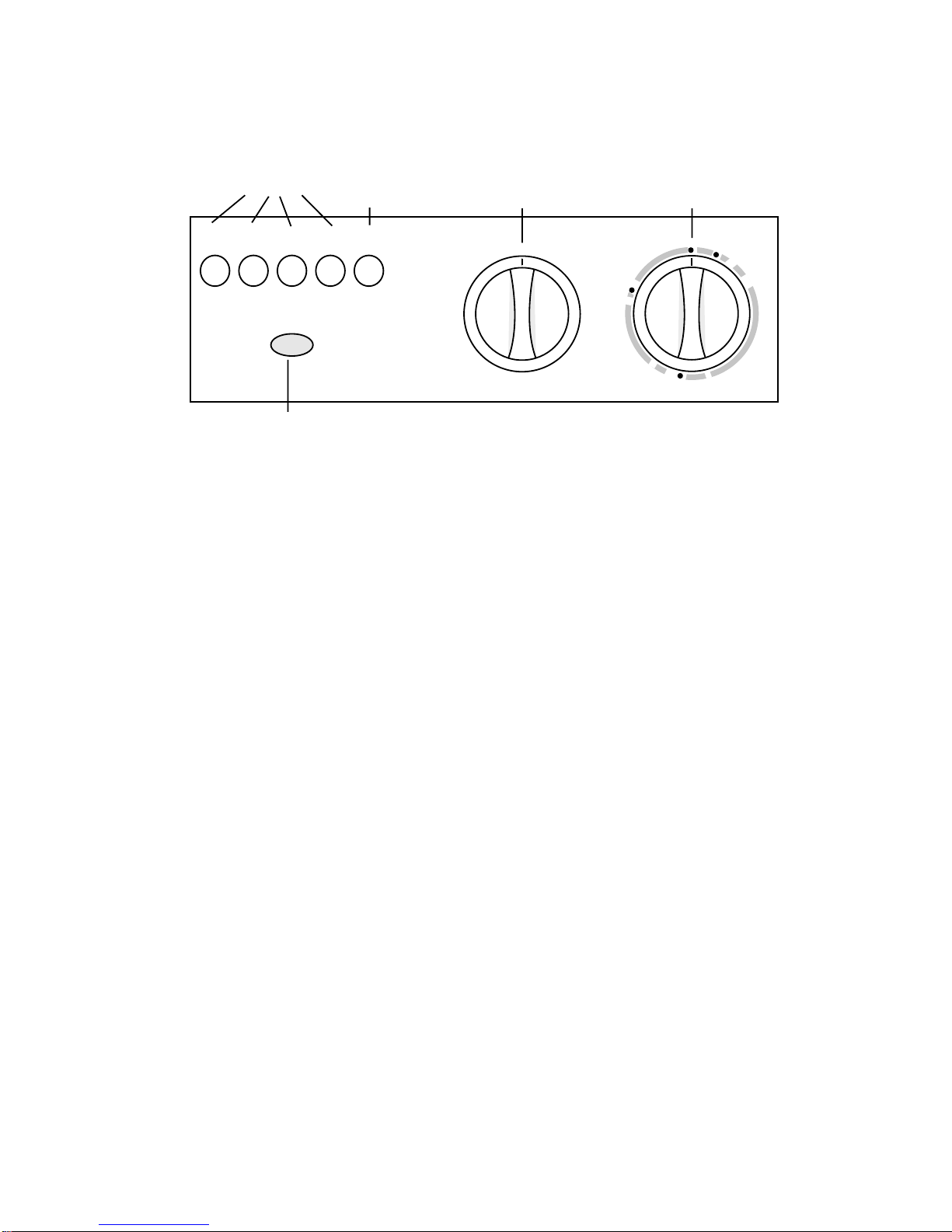

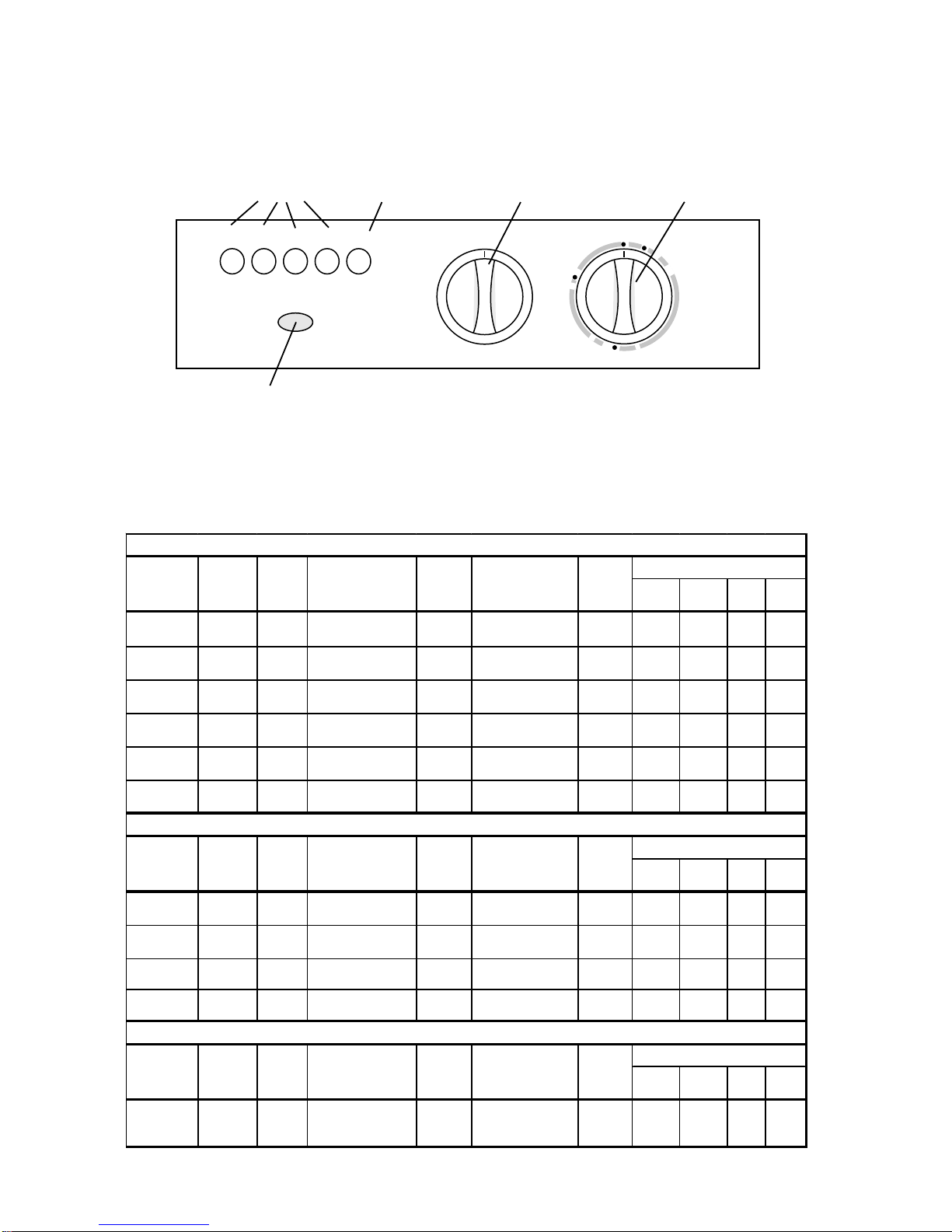

CONTROL PANEL

The control panel is simple to understand and easy to operate.

PROGRAM CONTROL KNOB

Each wash program is specifically designed to give you the cleanest laundry possible. The table on page 10

defines each program in detail, so you can determine which program is best for each type of load.

TEMPERATURE CONTROL KNOB

The Temperature Control Knob lets you select the best wash temperature for each load. The temperature

options are restricted on some of the programs (as shown in the table on page 10). For example, the Wool/

Hand Wash program is restricted to cold or warm. This is to prevent accidentally washing delicate items in

hot water.

OPTION BUTTONS

These buttons give you even more wash options. Be sure to press the option buttons before you set the

Program knob to a wash program. Each option is explained in detail below.

Warm Rinse

If you select this option, the last rinse is with warm water. This function is not available with the Wool/Hand

Wash program.

Extra Rinse

The washing machine has been set up so that water consumption is reduced to a minimum. Two or three

rinses are usually sufficient. If desired, select this button for one additional rinse. This option is not available

with the Quick Wash program.

No Spin

This option omits all of the spin cycles. Recommended for delicate fabrics that should not be spun.

Half Load

This option is designed to save water when you are only washing a small, slightly soiled load. This option is

not available with the Wool/Hand Wash program.

ON/OFF BUTTON

This button merely switches the power to the machine off and on.

POWER INDICATOR LIGHT

This light glows when the power to the machine is on.

CANCELLING A PROGRAM

To cancel a program after it has started, simply turn the Program knob to any one of the dots around the

dial.

Option

Buttons

Power Indicator Light

On/Off

Button Temperature

Control Knob Program

Control Knob

10

NOTES:

(1) For an explanation of the recommended load sizes, see page 6.

(2) Model EWF172 has a maximum 1200 rpm spin speed; Model EWF150 has a 1000 rpm maximum.

(3) When you select the Heavy Stain program with the Temperature knob on Hot, the washer heats the

water to 140°F for the main wash cycle.

(4) To reduce wrinkling, the maximum spin speed for the Permanent Press program is 800 rpm.

(5) The Wool/Hand Wash program has a 500 rpm spin speed to eliminate stress on delicate fabrics.

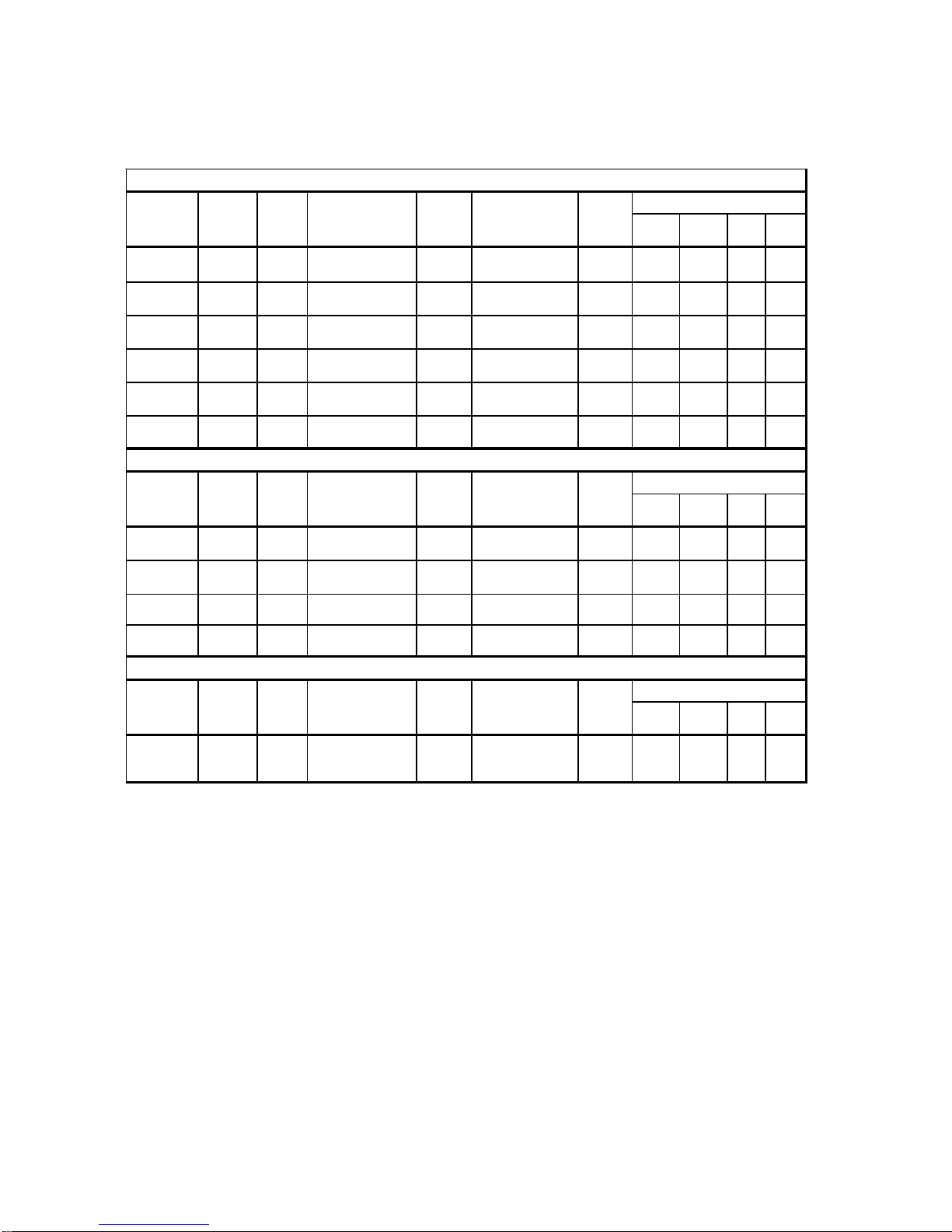

WASHER PROGRAMS

The table below defines each program in detail to help you determine which program is best for each type

of load.

Warm

Rinse Extra

Rinse No

Spin Half-

load

S oak Col d Heavy Any F ull 5-mi nute pre-s oak,

drain, no s pin n/a No No No Yes

Heavy S tain

(Note3) Any Heavy Cottons,Linens Full Longmainwash,3

rinses,drain&spin 1200 Yes Yes Yes Yes

Normal Any Normal Cottons,Linens,

Blends,Synthetics Full Mainwash,3

rinses,drain&spin 1200 Yes Yes Yes Yes

Quick was h Coldor

Warm Light Cottons,Linens,

Blends,Synthetics Full Shortmainwash,2

rinses,drain&spin 1200 Yes No Yes Yes

R ins e Cold Light Cottons , Linens ,

Blends,Synthetics Full 3rinses,drain&

spin 1200 Yes Yes Yes Yes

S pin n/a n/a Cottons , Linens ,

Blends,Synthetics Full Drainandspin 1200 n/a n/a n/a n/a

Warm

Rinse Extra

Rinse No

Spin Half-

load

Heavy S tain

(Note3) Any Heavy Cottons,Linens,

Blends,Synthetics Half Longmainwash,2

rinses,drain&spin 800 Yes Yes Yes Yes

Normal Any Heavy Cottons,Linens,

Blends,Synthetics Half Mainwash,2

rinses,drain&spin 800 Yes Yes Yes Yes

R ins e Cold Light Cottons , Linens ,

Blends,Synthetics Half Rins e, drain, gentle

spin 800 Yes No Yes Yes

S pin n/a n/a Cottons , Linens ,

Blends,Synthetics Half Drainandgentle

spin 800 n/a n/a n/a n/a

Warm

Rinse Extra

Rinse No

Spin Half-

load

Wool/Hand

Was h Coldor

Warm Light Machine-was hable

wool andsilk,nylon One-third High-water level

was h, 2 r i ns es ,

drain,gentlespin

500 No Yes Yes No

L oad

Size

(Note1) Program

Description

Spin

S peed

(Note2)

Options Available

Program Temp

Options Soil

L evel F abrics

L oad

Size

(Note1) Program

Description

Spin

S peed

(Note2)

Options Available

F abrics

Program Temp

Options Soil

L evel F abrics

Options Available

REGULAR

PERMA PRESS

DELICATE

L oad

Size

(Note1) Program

Description

Spin

S peed

(Note2)

Program Temp

Options Soil

Level

11

ENGLISH

CARE AND MAINTENANCE

The washing machine does not require special care; however, to best ensure a long life, certain precautions

are recommended (see page 3).

WARNING! Before performing the operations described below, make sure that the power is off and

the unit is unplugged.

CLEANING THE DETERGENT DRAWER

The drawer should be cleaned periodically with a damp, slightly soapy cloth.

CAUTION: Neverclean the door with cleaning solvents orabrasivecleansers.

You could damage the finish.

You can remove the drawer completely by pressing on the plastic part of the

softener compartment marked “PUSH”(Fig. 10). Clean the drawer with a soft

brush under warm running water.

CLEANING THE LINT FILTER

The lint filter should be cleaned about once a month. Make sure the washer has drained before opening the

filter door.

1. Place a pan or towel under the filter door (Fig. 11), since a small amount of water could spill.

2. Remove the filter by turning it a half turn counterclockwise and pulling outwards (Fig. 12).

3. Clean the filter with a soft brush under running water until all residue is removed.

4. Replace the filter and turn it clockwise until it is securely locked in place (Fig. 13). Give the cap a gentle

tug to confirm that the filter is in securely.

CLEANING THE CONTROL PANEL

To clean the control panel, use only a warm, damp cloth. To prevent penetration of liquid into the door lock

and electrical components, never spray water or cleaning solvents on the control panel. Also, never

use abrasive cleaners or scouring pads on the outer surfaces because they will scratch the finish and could

remove the writing on the control panel. Some paper towels may also scratch the finish.

FIG. 10

FIG. 11

FIG. 12

FIG. 13

12

Most items can be safely washed in a Eurotech washing machine. We recommend that you follow the care

label instructions as closely as possible for the best cleaning results. Should problems occur, some possible

causes and suggested solutions are listed below.

NOTE: Eurotech has no control over what is put in our appliances once installed in a customer’s home. You

are solely responsible for what you wash in your Eurotech washing machine.

COMMON LAUNDRY PROBLEMS

You may need to add slightly more detergent if clothes are heavily

soiled, have oily stains, or if your water is very hard.

Select a hotter temperature setting for each type of load.

Be sure to add a prewash and/or presoak for heavily soiled or oily

items.

Once wet, the clothes must have room to tumble freely, especially

synthetics and permanent press.

Be sure you use a laundry detergent, not a “soap.”Soap reacts with

the minerals in hard water to form a soap curd, which can be

deposited on clothes.

Problem Possible Cause Suggested Solution

Graying Not enough detergent

Water not hot enough

Improperly prewashed or

presoaked

Washer overload

Soap used in hard water

areas

Separate clothes that shed lint (chenille and terrycloth) from clothes

that attract lint (synthetics, corduroy, velveteen).

Non-phosphate detergents can combine with minerals in hard water

and form a residue which can appear to be lint. Use a low phosphate

detergent. If possible, install a water softener.

Read labels. Most softeners should only be used in the final rinse.

Addsoftenertothe softener compartment. If addedtothewash cycle,

softeners can have a reaction with detergents, producing a white

residue.

Pilling, which can look like lint, is produced by normal wear on cotton/

polyester blend fabrics. To reduce pilling, wash these fabrics inside

out. For the best results, wash in the delicate cycle.

Lint or residue

left on clothes Improper sorting of clothes

Non-phosphate detergent

Fabric softener used

improperly

Pilling

Add slightly more detergent.

Use the hottest recommended temperature for each type of load.

If possible, install a water filter. A small amount of Calgon or other

type of water conditioner added once a week is advisable in hard

water areas.

Yellowing Not enough detergent

Water not hot enough

Iron or manganese in

water

Follow garment care label instructions carefully (see page 7). Some

fabrics will shrink no matter how they are washed. Some may be

machine washed but not machine dried.

Shrinkage Improper washing or

drying

Knits tend to shrink more than woven fabrics. If a knit has been

heat-shaped, wash in cool or warm water. Dry with the low setting.

This can occur when special stabilizing finishes are reduced from

wear or repeated washings. Garment may sometimes be reshaped

by pressing after washing and drying.

Shrinkage can occur if the knit fabric was not stretched properly by

the manufacturer. Press back into shape each time garment is

washed and dried.

Knit shrinkage Overheating

Delayed or gradual

shrinkage

Poor construction

Dark clothes, especially cottons, can bleed excess dyes into wash

water. White or light-colored clothes can absorb the dye and discolor.

Separate light items from dark items.

Always empty all pockets before washing.

Cool or cold water is best for retaining dark or bright colors.

Fading and

discoloring Improper sorting

Crayons or pens in pockets

Water too hot

Protein stains, such as milk, egg, blood and soy formula should be

removed in cold water. Oily stains should be washed in the hottest

water recommended for each fabric type.

The longer a stain remains on a fabric, the harder it is to remove.

Treat stains promptly. Do not set stains by machine drying or ironing

fabrics until stains are completely removed.

Stains Incorrect water

temperature

Old stains

13

ENGLISH

COMMON LAUNDRY PROBLEMS (cont’d)

Problem Possible Cause

Empty all pockets and turn inside out before laundering.

Fasten all hooks, snaps, and zippers before laundering to avoid snags.

Remove sharp buckles. Turn knits inside out.

Before washing, rinse harsh chemicals (such as battery acid, hair care

chemicals, cleaning solutions, etc.) from towels and other articles to

avoid holes in fabrics. Do not allow these unrinsed items to contact

other fabrics.

Mend all garments before laundering to prevent enlarging of rips.

These items may fray at edges from normal wear, not the washer.

Wash only in half loads and don’t wash in the same load with heavy

items, such as towels or jeans.

Rips, snags,

excess wear Sharp objects in pockets

Hooks, snaps, zippers,

buckles

Harsh chemicals

Existing rips and tears

Permanent press items

Permanent press items should be washed in half-loads to prevent

wrinkling. If possible, use a slower spin speed.

Use lower wash temperature settings.

Excessive

wrinkling Machine too full

Water too hot

14

TROUBLESHOOTING

Before calling for technical assistance, check that the operations described below have been carried out

correctly; this will save both time and money.

Does not work/Indicator light is not lit

Check that:

1) The On/Off button is pressed in.

2) The plug is correctly inserted in the socket.

3) The main power supply is on.

Indicator light is on but unit does not work

Check that:

1) The door is closed securely.

2) The On/Off button is pressed in.

3) The programmer knob is on a program.

4) The plug is correctly inserted in the socket.

5) The main power supply is on.

6) See “Does not fill with water”below.

Does not fill with water

Check that:

1) There is water in the pipes.

2) The tap to the water source is open.

3) The water supply hose is not kinked.

4) The inlet filter between the valve and water feed hose is clean (see page 6).

Fills and drains continuously

Check that:

1) The drain hose is positioned at the correct height (see page 6).

2) If connected to a sink, the drain hose outlet is not under water.

Does not drain and spin

Check that:

1) The No Spin button is not pressed in.

2) The drain hose is in the correct position.

3) The drain hose is not kinked.

4) The amount of detergent is not excessive.

5) The detergent dispenser is not encrusted with residue.

6) The detergent is low-sudsing specifically for front-loading washers.

Vibrates and is noisy

Check that:

1) Large items have not become entangled (sheets, tablecloths, etc.).

2) The washing machine is level (see page 4).

3) The four packing screws, spacers and two lower rods have been removed (see page 4).

The door will not open

1) For safety reasons, the door remains locked for two to three minutes after the program has finished.

If you think you have resolved the problem, try starting the machine again. If the problem persists, call for

technical assistance (see page 15).

BEFORE CALLING FOR SERVICE

Before calling for service or contacting AM Appliance Group regarding a warranty issue, be prepared to

explain:

1) The washer model number (shown on the detergent dispenser)

2) The serial number of the machine (located on the inner door facing)

3) The specific problem

15

ENGLISH

MODELS EWF150 AND EWF172

Be sure to complete the Warranty Registration Card you received with your appliance and mail it to

AM Appliance Group to validate your appliance warranty.

Cosmetic damage must be reported to your dealer within five days from the date of purchase. After

unpacking the washer, thoroughly check the unit for cosmetic damage.

AM APPLIANCE GROUP WILL NOT PAY FOR:

A. Service calls to:

1. Correct the installation of the appliance.

2. Repair damage due to shipment, delivery, installation, misuse or abuse.

3. Instruct how to use the appliance.

4. Replace house fuses or correct house wiring.

5. Correct house plumbing, including drainage problems related to improper installation.

6. Clean or service air device in drain line.

B. Repair and/orreplacement parts forfailure of productif applianceisused forother than home/residential

use.

C. Damage resulting fromaccident,fire, floods, actsofGod, alteration, misuse,abuse,improper installation,

or installation not in accordance with local electrical or plumbing codes.

D. Any shipping costs for parts during the limited warranty period.

E. Replacement parts or repair labor costs for units operated outside the continental United States.

F. Pickup and delivery. Eurotech appliances are designed to be repaired in the home.

FOR RESIDENTIAL INSTALLATIONS ONLY

One-Year Full

From date of purchase.

LENGTH OF WARRANTY

Ninety-Nine Year Li ited

IN NO EVENT SHALL AM APPLIANCE GROUP BE RESPONSIBLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Somestateswill notallowthe exclusion orlimitationof incidental orconsequentialdamages, so thisexclusion

or limitation may not apply to you. This warranty gives you specific legal rights and you may also have other

rights which vary from state to state.

For warranty service, contact the dealer from whom you purchased the unit or an authorized Eurotech

service agent. Service will be provided during normal business hours. Should you have a service problem

that cannot be resolved locally, contact AM Appliance Group at the numbers listed below. Before calling for

service or contacting AM Appliance Group regarding a warranty issue, make a note of the model, type

name, and serial number (located on the inner door facing).

Eurotech replacement parts (labor costs not included) for the stainless

steel inner or outer drum if either fails to hold water due to a

manufacturing defect, such as rusting or cracking. Service must be

provided by an authorized Eurotech service agent.

Eurotech replacement parts and/or repair labor to correct defect in

materialsor workmanship.Service must be provided byan authorized

Eurotech service agent.

Write to us at:

AM Appliance Group

P. O. Box 851805

Richardson, Texas 75085-1805

Or call our

Customer Service Center at

800-898-1879 or 972-238-0794

Two-Year Li ited

From date of purchase. Eurotech replacement parts (labor costs not included) for all parts due

to defect in materials or wormkanship. Service must be provided by

an authorized Eurotech service agent.

PRODUCT WARRANTY

AM APPLIANCE GROUP WILL PAY FOR:

Five-Year Li ited

From date of purchase. Eurotechreplacement parts (laborcostsnot included)forany defective

solid-statecontrols,timers, motors, orpumps.Replacementof cabinets

that may have rusted through. Service must be provided by an

authorized Eurotech service agent.

FOR NON-RESIDEN IAL INS ALLA IONS

Six-Month Full Warranty

From date of purchase. Eurotech replacement parts and/or repair labor to correct defect in

materials or workmanship. Service must be provided by an authorized

Eurotech service agent.

16

QUICK REFERENCE GUIDE

(Refer to pages 7–10 for detailed operating instructions.)

WARM

COLD

SOAK

SPIN

HEAVY STAIN

NORMAL

R

I

N

S

E

S

R

I

N

S

E

S

R

I

N

S

E

S

REGULAR

PERMA PRESS

DELICATE

EXTRA

RINSE NO

SPIN HALF

LOAD ON

OFF

WARM

RINSE HEAVY STAIN

NORMAL

QUICK

WASH

WOOL /

HANDWASH

SPIN

HOT

Option

Buttons

Power Indicator Light

On/Off

Button Temperature

Control Knob Program Control

Knob

WASHER PROGRAMS

The table below defines each program in detail to help you determine which program is best for each type

of load.

Warm

Rinse Extra

Rinse No

Spin Half-

load

S oak Col d Heavy Any F ull 5-mi nute pr e-s oak,

drain, no s pin n/a No No No Yes

Heavy S tain

(Note3) Any Heavy Cottons,Linens Full Longmainwash,3

rinses,drain&spin 1200 Yes Yes Yes Yes

Normal Any Normal Cottons,Linens,

Blends,Synthetics Full Mainwash,3

rinses,drain&spin 1200 Yes Yes Yes Yes

Quick was h Coldor

Warm Light Cottons,Linens,

Blends,Synthetics Full Shortmainwash,2

rinses,drain&spin 1200 Yes No Yes Yes

R ins e Cold Light Cottons , Linens ,

Blends,Synthetics Full 3rinses,drain&

spin 1200 Yes Yes Yes Yes

S pin n/a n/a Cottons , Linens ,

Blends,Synthetics Full Drainandspin 1200 n/a n/a n/a n/a

Warm

Rinse Extra

Rinse No

Spin Half-

load

Heavy S tain

(Note3) Any Heavy Cottons,Linens,

Blends,Synthetics Half Longmainwash,2

rinses,drain&spin 800 Yes Yes Yes Yes

Normal Any Heavy Cottons,Linens,

Blends,Synthetics Half Mainwash,2

rinses,drain&spin 800 Yes Yes Yes Yes

R ins e Cold Light Cottons , Linens ,

Blends,Synthetics Half Rins e, drain, gentle

spin 800 Yes No Yes Yes

S pin n/a n/a Cottons , Linens ,

Blends,Synthetics Half Drainandgentle

spin 800 n/a n/a n/a n/a

Warm

Rinse Extra

Rinse No

Spin Half-

load

Wool/Hand

Was h Coldor

Warm Light Machine-was hable

wool andsilk,nylon One-third High-water level

was h, 2 r i ns es ,

drain,gentlespin

500 No Yes Yes No

L oad

Size

(Note1) Program

Description

Spin

S peed

(Note2)

Options Available

Program Temp

Options Soil

L evel F abrics

L oad

Size

(Note1) Program

Description

Spin

S peed

(Note2)

Options Available

F abrics

Program Temp

Options Soil

L evel F abrics

Options Available

REGULAR

PERMA PRESS

DELICATE

L oad

Size

(Note1) Program

Description

Spin

S peed

(Note2)

Program Temp

Options Soil

Level

This manual suits for next models

1

Table of contents

Other Eurotech Washer manuals

Popular Washer manuals by other brands

Bauknecht

Bauknecht TRPC 86531 Instructions for use

Electrolux

Electrolux EWF934 EWF734 Instruction booklet

Haier

Haier HW80-B1239N user manual

ROSIERES

ROSIERES RILL 100 H/C User instructions

Indesit

Indesit IWE 61051 Instructions for use

Alliance Laundry Systems

Alliance Laundry Systems Frontload Washer user guide