forest river Starcraft Bus User manual

Maintenance Manual

TABLE OF CONTENTS

Sections Pages

Chapter 1 – Chassis & Frame 2 – 3

Chapter 2 – Exterior 3 – 5

Chapter 3 – Systems 5 – 8

Chapter 4 – Interior 8 – 9

Chapter 5 – Wheelchair Lift 9 – 11

Chapter 6 – Wheelchair Tie Downs 11 – 12

Chapter 7 – Entry Doors 12 – 13

Chapter 8 – Emergency Exit / Escape Hatch 13 – 14

Chapter 9 – Child Checkmate System 15

Customer Bus Information 16

Helpful Contacts 16

MAINTENANCE MANUAL

This booklet has been designed and written to supply information regarding

maintenance requirements for all makes and models built by Starcraft Bus.

As the owner of a new Starcraft Bus product, it is important to recognize the

importance of performing routine maintenance during the warranty period.

Just like oil changes, if proper maintenance is not performed, the warranty

coverage can be denied.

Familiarizing yourself with this manual will help you make sure that proper

maintenance is performed. Please remember, routine maintenance is not

covered by warranty.

With proper and scheduled maintenance on your Starcraft Bus, we believe

you will enjoy your Starcraft Bus for many years to come.

FLASH DRIVE

In an effort to provide our dealers and end user customers with the most

current and up-to-date information on your bus, Starcraft Bus has provided

you with a ash drive. This ash drive contains a large amount of important

information regarding your specic vehicle. Please take time to review the

material housed on the drive.

You will nd this ash drive in a small manila folder within your new bus

packet.

The information provided in this maintenance manual is neither

intended to nor should it be used to replace the chassis

and other component manufacturers’ service,

warranty and care information.

IMPORTANT:

CONTACT YOUR SELLING DEALER PRIOR TO HAVING ANY

WARRANTY WORK PERFORMED ON YOUR BUS.

CHAPTER 1 – CHASSIS AND FRAME

Axles, Bearings, Brakes and Hubs

• Verify that all linkages, cables, levers, and clevis points under the vehicle

are covered with grease to prevent rust.

• Move trucks at least 25 feet every 15 days to lubricate working parts and

prevent corrosion.

• *For more information please refer to your Ford, GM, or International

Owner’s and maintenance manuals that came with your bus.

CHAPTER 2 – EXTERIOR

Metal

• Aluminum skin is painted and prepared by Starcraft Bus with an automo-

tive paint nish. To clean, use a mild detergent soap and water.

• Use an automotive type wax or polish; same as you may use on your

personal vehicle. By waxing your bus once a year, it retains its nice, new

appearance.

Fiberglass – Gel Coat

• Fiberglass skin is painted and prepared by Starcraft Bus with an automo-

tive paint nish. To clean, use a mild detergent and warm water using a

soft brush or rag.

• Use an automotive type wax or polish; same as you may use on your

personal vehicle. By waxing your bus once a year, it retains its nice, new

appearance.

TPO / ABS

• TPO / ABS can come in a wide range of textures and colors. It is a strong

plastic compound (ABS) or rubber compound (TPO) commonly used

for molded articles within the manufacturing industry and is used for a

wide range of production components inside and outside of your Starcraft

Bus. The most common exterior components are fender ares on your

Starcraft commercial shuttle bus.

• TPO / ABS components are lightweight and strong,however the surface is

not as hard as berglass and can scratch easily.

• The proper care, cleaning and maintenance of your TPO and ABS

components is quite simple because of the basic properties and longevity

of the material itself.

• Periodic cleaning is the primary maintenance. Starcraft Bus suggests

using Murphy’s Oil Soap with a soft nylon brush or sponge. DO NOT USE

solid or granulated cleaners, as they will mar the natural nish.

Page 3

CHAPTER 1 – CHASSIS AND FRAME

Your Starcraft Bus vehicle is designed to be as maintenance free as

possible. However, all vehicles require some care to reduce the possibility

of unwanted breakdowns during travel. Maintenance to your bus may not

seem necessary at the time of purchase, yet it is very important to keep

your bus in its best condition for your enjoyment and use. Normal mainte-

nance is required to maintain warranty coverage, reduce wear, and prolong

the life of your bus.

Engine

• Start the engine every 15 days.

• Run it at fast idle until it reaches normal operating temperature.

• Shift the transmission into all gears while engine is running.

Fuel System

• Regularly move vehicles short distances to mix fuel anti-oxidation agents.

• For vehicles being stored for prolonged periods, a commercial gasoline or

diesel fuel stabilizer should be used.

• *For more information please refer to your Ford, GM, or International

Owner’s and Maintenance Manuals that came with your bus.

Tires & Wheels

• Tires installed on your bus are matched to the weight of your vehicle

according to the rating of the tires. The most important item in tires is

to inspect and check air pressure no less than once per week, perhaps

daily during travel. Correct PSI air pressure is listed on each tire as per

rating (shown on data sticker on the driver side door jamb). When air

pressure is not maintained as specied, tires will run hot, especially in

summer months and blow outs can occur. Pressure must always be

checked when tires are cold, preferably in the morning. DO NOT adjust

or lower tire pressure when warm, as it will be too low when cool. All tire

pressures rise when tires are moving on roadway. A tire is considered

“cold” after 3 hours of not moving. Again, please refer to your Ford, GM, or

International Owner’s and Maintenance Manual for torque specications,

cleaning procedures, etc.

• Alignments are NOT performed by Starcraft Bus. Please conrm with your

selling dealer to determine if an alignment has been completed on your

Starcraft Bus (alignments are not a warrantable expense with Starcraft

Bus).

Page 2

Page 1

CHAPTER 2 – EXTERIOR

• Corner and roof extrusions have “putty tape” sealant between the

components. This material can and will also dry and/or crack from

weather elements, permitting leakage and eventually major deterioration.

Starcraft Bus advises the owner to have these extrusions removed, and

have the old putty tape replaced with new sealant material every ve

years.

• Windows, entrance doors, and cargo doors (but not limited to) may also

use a closed cell foam seal. The seal may also deteriorate over time,

lose its memory, shrink with weather conditions, etc., over a period of ve

years.

• All sealants must be maintained to prevent failure plus leakage damage.

For best results, sealant requirements are:

- Resistant to checking

- Resistant to shrinking

- Dries rapidly

- Adheres to metal, TPO, and berglass

- Expands and contracts with temperature changes

- Color should match

- For suggested sealants, please contact your Starcraft Bus

servicing dealer.

• AT LEAST THREE TIMES PER YEAR, INSPECT ALL ROOF SEAMS;

FRONT, REAR AND ALL AROUND VENTS AND ATTACHMENTS.

Remove any loose sealant and reseal these areas. For a list of recom-

mended sealants, please contact our authorized Starcraft Bus dealer.

FAILURE TO INSPECT AND CORRECT CAN VOID THE WARRANTY

COVERAGE, CLASSIFIED AS NEGLIGENCE.

CHAPTER 3 – SYSTEMS

Batteries

• As a manufacturer, we suggest you have your bus inspected each spring

to check for any loose wires and/or loose connections in the load center

and have tightened if loose. Also, have the fuses inspected for continuity

and operation.

• Maintaining the state-of-charge while vehicles are in storage or not being

used is the bus owner’s responsibility.

Page 5

CHAPTER 2 – EXTERIOR

• Do not use Armor All or other oil solvent base cleaners on your TPO or

ABS components as they will leave a slick surface.

• A good thorough cleaning should keep your TPO and ABS components

looking good and remove most stains. For more stubborn stains, you

should contact your Starcraft Bus authorized dealer.

• DO NOT use citrus based cleaners on ABS materials. The ABS will break

down and become brittle.

Exterior Roof

• To clean, use a mild detergent and warm water using a soft brush or rag.

• Use an automotive type wax or polish; same as you may use on your

personal vehicle. By waxing your bus once a year, it retains its nice, new

appearance.

Underbody

• Most individuals are aware of the effects that prolonged exposure to

salt and ice melting chemicals have and the adverse effects on any

coated metal surfaces, our chassis are no exception. The effects of these

corrosives are magnied with time and therefore should be removed

from the chassis as soon as possible after a unit has been on the road.

• Washing the frame is especially important during the winter driving

season. The danger of exposure to road chemicals is not limited to only

the northern snow states. Many southern states use salt and ice melt

solutions as well, and any vehicle which originates from a northern state

has potential exposure.

Extrusions and Vents

• All components installed on the exterior of your bus have some type or

form of “putty/foam tape” placed between the mounting ange or surface

to guard against water entry and leakage.

• Additional sealant, referred to as “cap seal” is used to protect along the

edges of extrusions or be a secondary surface sealant. All of these seal-

ants are subject to weather elements such as UV rays from the sun, rain,

snow, cold, heat, air pollution, frost and other exposures causing dry-out,

shrinkage and possible cracking.

• Cap seal must be examined each year, preferably each spring and fall, for

looseness, cracking, and separation from any attached surface. If upon

inspection you nd the above conditions, repairs must be made. These

conditions will permit water to enter slowly and eventually cause water

damage.

Page 4

CHAPTER 3 – SYSTEMS

• USE EXTREME CAUTION AROUND ENGINE COMPARTMENT AND

ANY OTHER MOVING PARTS. HAVE SYSTEM MAINTENANCE AND

SERVICE PERFORMED BY A QUALIFIED TECHNICIAN.

• For the below information, refer to the illustration on Page 6.

1 = Charge Level / Pressure

• Recharging MUST be done by a QUALIFIED TECHNICIAN.

2 = Evaporator Filters

• A properly maintained, clean lter maximizes air ow and system

performance.

• Filters should be inspected visually every month and cleaned/replaced as

needed.

2 = Evaporator Coil(s)

• A properly maintained, clean evaporator coil will ensure maximum heat

transfer and system performance.

2 = Evaporator Blower(s)

• Proper air ow across evaporator coil allows for efcient heat transfer.

Be sure to check to make sure all blowers are actually operating.

3 = Evaporator Drain Line(s)

• Prevents water from collecting in the evaporator drain pan. On a hot

humid day the evaporator should drip water under the vehicle.

4 = Sight Glass / Moisture Indicator(s)

• Deep Green OR Purple = Absence of Moisture.

• Yellow OR Pink = Moisture is present – IMMEDIATE SYSTEM SERVICE

IS REQUIRED TO PREVENT SYSTEM DAMAGE.

5 = Condenser Coil(s)

• A properly maintained, clean condenser coil will ensure maximum heat

transfer and system performance. Clean with non-caustic cleaner.

5 = Condenser Fan(s)

• Proper air ow across condenser coil allows for efcient heat transfer.

Check to make sure all fans are actually operating when compressor is

engaged.

6 = Hoses / Piping

• Properly supported hoses prevent the possibility of refrigerant leaks.

Check for residue around connections (sign of refrigerant leak) / hose

wear from rubbing other objects / loose or missing clamping.

7 = Wiring Harness(es)

• Properly supported and protected harnesses prevent the possibility of

electrical issues.

Page 7

CHAPTER 3 – SYSTEMS

• Check the battery state-of-charge every 15 days. If the battery eye is

“red,” recharge the battery until the eye turns green. Check battery condi-

tion for possible storage damage using either a Bear or Midtronics battery

tester. Batteries without an eye – recharge if the voltage is less than 12.40

volts.

• Batteries, whether supplied from manufacturer or dealer, require

constant inspection and maintenance. To preserve long life in any battery,

three important functions are required: Charge battery every 30-60 days

to keep fully charged during non-use, especially during winter months.

Certain types require water to be checked and added as necessary. Keep

water above cell mass to avoid permanent damage. Store battery in a

cool place when not in use, around 40 degrees Fahrenheit.

• A fully charged battery will measure at 1.265 specic gravity. A discharged

battery will measure at 1.120 specic gravity or 11.7 volts DC. A hydrom-

eter is required to measure “specic gravity.”

• Most batteries with deep cycle rating require water to be added as

needed. This depends on the amount of draw time that is on that specic

battery.

• Use distilled water if possible as it is nearly mineral free. Not keeping

batteries charged will result in shorter life expectancy.

• Be sure to keep all battery terminals clean at all times to ensure good

contact.

Air Conditioning

Page 6

CHAPTER 4 – INTERIOR

Flooring

• To care for and clean your oor covering, use a mild soap in water and a

damp cloth. DO NOT pour water on oors as it may seep under / in attach-

ment points in the buses oor.

Seating – Vinyl

• To clean, use a mild solution of soap and water with a sponge or soft

cloth. DO NOT use any abrasive cleaner as scratching of vinyl could

occur, causing dull colors and/or scratches. Avoid cleaners with bleach.

For stubborn stains you may need a strong all purpose spray cleaner

which will need to be sprayed on and QUICKLY wiped off.

Seating – Fabric

• To clean fabric seat covering of dust, use a soft attachment of a vacuum

cleaner. To remove solid spots on fabric use clear Ivory dish washing

liquid and water.

*For more stubborn stains you may need to contact your authorized

Starcraft Bus dealer.

Windows

• On window(s) which have opening sliders, there are “weep or drain”

holes at lower sections of frame extrusions, generally at the end of each

moveable panel. Dirt, debris, insects, etc. can and will accumulate,

potentially plugging up these weep holes. Should water accumulate

(stand in threshold of window), your weep holes and / or channels in win-

dow have become plugged. Be sure to keep these draining areas open

at all times.

CHAPTER 5 – WHEELCHAIR LIFT

• Regular maintenance of the wheelchair lift will help optimize its perfor-

mance and reduce the need for repairs. This chapter contains cleaning

and lubrication instructions.

• Lubrication

Lubrication should be performed at least every six months, or sooner

depending on usage. Lubricate lift at torsion springs (both sides with

penetrating oil); knuckle links (both sides with penetrating oil), and; the

hinge (with penetrating oil). Lubricate the outer barrier (both sides with a

dry graphite lubricant).

Page 9

CHAPTER 3 – SYSTEMS

8 = Compressor Belt(s)

• Properly tensioned belts ensure maximum compressor performance and

belt life.

CHAPTER 4 – INTERIOR

TPO / ABS

• TPO / ABS can come in a wide range of textures and colors. It is a strong

plastic compound (ABS) or rubber compound (TPO) used commonly for

molded articles within the manufacturing industry and is used for a wide

range of production components inside and outside of your Starcraft Bus.

The most common interior components are front bulkhead window trims

on your Starcraft School bus / MFSAB vehicles.

• TPO / ABS components are lightweight and strong, however the surface

is not as hard as berglass and can scratch easily.

• The proper care, cleaning and maintenance of your TPO and ABS

components is quite simple because of the basic properties and longevity

of the material itself.

• Periodic cleaning is the primary maintenance. Starcraft Bus suggests

using Murphy’s Oil Soap with a soft nylon brush or sponge. DO NOT USE

solid or granulated cleaners, as they will mar the natural nish.

• Do not use Armor All or other oil solvent based cleaners on your TPO or

ABS components as they will leave a slick surface.

• A good thorough cleaning should keep your TPO and ABS components

looking good and remove most stains. For most stubborn stains, you

should contact your Starcraft Bus authorized dealer.

• DO NOT USE citrus based cleaners on ABS materials. The ABS will break

down and become brittle.

Wall / Ceiling Covering – Vinyl

• To clean, use a mild solution of soap and water with a sponge or soft

cloth. DO NOT use any abrasive cleaner as scratching of vinyl could

occur, causing dull colors and/or scratches. Avoid cleaners with bleach.

For stubborn stains, you may need a strong all-purpose spray cleaner

which will need to be sprayed on and QUICKLY wiped off.

Wall / Ceiling Covering – Fabric

• To clean fabric wall covering of dust, use a soft attachment of a vacuum

cleaner. To remove solid spots on fabric use clear Ivory dish washing

liquid and water.

Page 8

CHAPTER 5 – WHEELCHAIR LIFT

• 1800 Cycles

- Clean lift with mild soap and water and wipe dry. Prevent rust by

coating all surfaces with a light weight oil. REMOVE EXCESS OIL.

- Spray penetrating oil where specied in the Lubrication section in

this chapter. Remove excess from surrounding areas.

• 3600 Cycles

- A certied technician must perform the following safety check(s).

- Check hydraulic cylinder for evidence of leaks.

- Inspect hydraulic hoses for damage.

- Verify that all ttings are tight.

CHAPTER 6 – WHEELCHAIR TIE DOWNS

The “Q’Straint, M-series or QRT MAX” systems are very exible in ac-

commodating most wheelchair styles as shown below.

It is recommended that Tri-Wheeler users transfer to an ambulatory seat.

However, if this procedure is not possible, securement of the Tri-Wheeler

and its occupant can be accomplished by using the optional Q’Straint rear

middle belt G5-5010 and fastening it to a solid frame member on the base

of the Tri-Wheeler chair and then by following all regular Q’Straint secure-

ment instructions.

• Auxiliary wheelchair equipment should be effectively secured to the

wheelchair or removed from the wheelchair and secured in the vehicle

during transport so as to not break free and cause injury in an impact.

• Whenever possible, items attached to the wheelchair in front of the

passenger should be removed and secured separately during transporta-

tion to prevent potential injury to the passenger.

Child Stroller Wheelchair –

Rear Attachments

Standard Power Wheelchair –

Front Attachments

Page 11

CHAPTER 5 – WHEELCHAIR LIFT

• Cleaning

Regular cleaning with mild soap (i.e. dish soap, car wash liquid) and

drying thoroughly will protect the lifts’ painted surfaces. Cleaning is

especially important in areas where roads are salted in winter. Make sure

that lift pivot points remain clear and clean prior to lubrication.

Maintenance Schedule

• Under normal operation conditions, maintenance inspections are required

at least every six months (1750 cycles).

• Service should be increased under conditions of heavier use (more than

10 cycles per day).

• 10 Cycles

- Listen for abnormal noises as lift operates (i.e. grinding or binding

noises).

- Verify that control pendant is undamaged and cable connector is tight.

- Verify that system properly detects objects in threshold area and

actuates the audible alarm.

- Verify that sensor inhibits downward movement of platform when a

weight is present on lowered bridgeplate.

• 150 Cycles

- Inspect electrical wiring for frayed wires, loose connectors, etc.

- Place vehicle in non-interlock mode and verify that lift does not operate.

- Verify that lift decals are properly afxed, clearly visible, and legible.

Replace, if necessary.

- Verify that armrest fasteners are properly tightened.

- Verify that mounting and support points are undamaged.

- Verify that mounting bolts are sufciently tight and free of corrosion.

- Verify that link pins on arms are properly installed, free from damage,

and locked in position.

- Verify that bridgeplate operates without binding during lift functions.

- Verify that bridgeplate deploys fully when platform stops at oor level.

- Verify that bridgeplate rests at against baseplate.

- Verify that rollstop is opened completely when platform is at ground

level.

- Verify that rollstop closes and locks when platform leaves ground.

Page 10

CHAPTER 7 – ENTRY DOORS

- Inspect torque arm attaching rivets for looseness. Replace as needed

(this can be handled through an authorized Starcraft Bus dealer).

- Inspect lower door hinge pivot for any defects and repair or replace as

required (this can be handled through an authorized Starcraft Bus

dealer).

- Inspect door leaf center overlap seal for damage. Clean only with a

mild detergent.

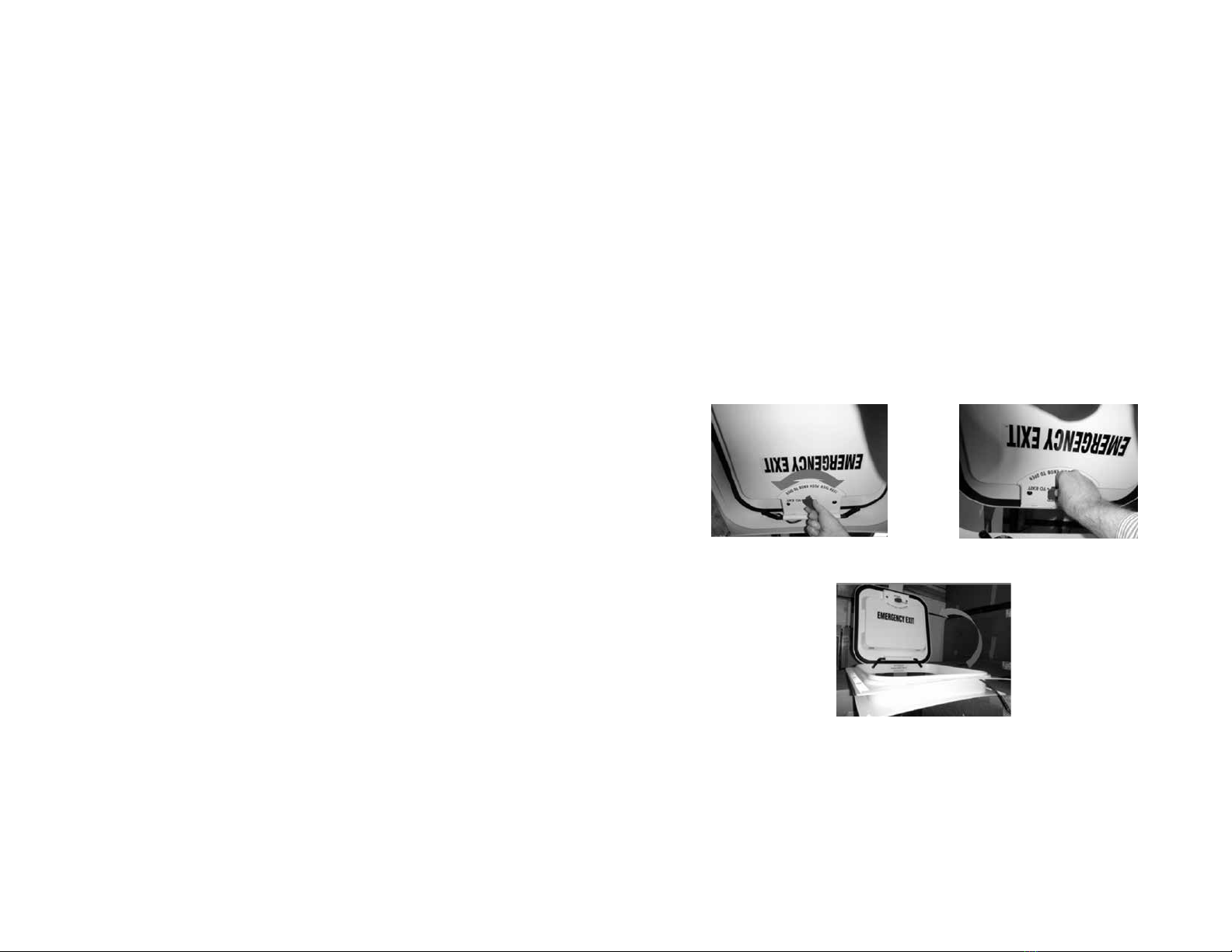

CHAPTER 8 – EMERGENCY EXIT / ESCAPE HATCH

Emergency Exit / Escape Hatch

All Starcraft Bus products are equipped with an EMERGENCY EXIT hatch.

Please review and understand fully the information in this chapter.

Opening an Emergency Hatch

2. Push the red knob into the lid.

3. Continue to push the lid to the

fully open position.

Page 13

1. Rotate the red knob 90 degrees

in either direction.

CHAPTER 6 – WHEELCHAIR TIE DOWNS

Maintenance

• Inspect your Q’Straint, M-Series and/or QRT Max series regularly, before

and after every use.

• The Q’Straint, M-Series and/or QRT Max series must be replaced if

suspected to have been in use during impact or show ANY sign(s) of

damage or excessive wear and tear. Belts should be replaced if they have

been worn during impact, even if the damage is not obvious.

• Prevent contamination of belt webbing from oil, gases, polishes and

chemicals, in particular – battery acid.

• Be sure to visually inspect the wheelchair tie down tracking for dirt and

debris after every use. This should be cleaned out with a shop vac as

needed.

CHAPTER 7 – ENTRY DOORS

Six-month Actuator Maintenance Schedule

- Lubricate the main gears with white lithium aerosol grease.

- Lubricate all other moving parts with white lithium grease.

- Inspect the open limit switch actuating tab for proper adjustment.

Ensure that it is limiting the operator from driving the doors past 90

degrees while opening. Adjust as required (this can be performed by

an authorized Starcraft Bus dealer).

- Inspect the operation of the current sensing system built into the motor

control board. The red LED must illuminate when the door reaches

the fully closed position.

- Inspect for bent push-pull rods; replace as necessary (replacement

and parts for replacement should be handled through an authorized

Starcraft Bus dealer).

- Inspect the entire system for loose fasteners or components. Repair as

required (this can be handled by an authorized Starcraft Bus dealer).

- Inspect for tightness of the set screws binding the actuator arms to the

door leaf drive hex. Tighten or replace as needed.

- Inspect emergency release lever for proper operation.

Lubricate the shaft running through the center of the body with WD-40

or equivalent.

Six-Month Door Leaf Maintenance Schedule

- Inspect all door frame mechanical joints for looseness. Tighten as

needed.

Page 12

Page 15

CHAPTER 9 – CHILD CHECKMATE SYSTEM

EP1 Operation Check List

• Upon starting the bus, the EP1 Alarm Unit will emit an audible noise

indicating that the system is now operational.

• Close the front door and turn on the master switch. Open the front door

and the red overhead lights will ash.

- Expect an audible sound from the EP1 Alarm Unit as the red lights are

activated.

• Close the front door and the overhead lights will stop ashing.

• Turn the ignition to the “OFF” position. The system’s alarm, a high-pitched

beep, will begin to sound. After approximately eight seconds, the bus horn

will begin to sound on and off.

• Turn the ignition back to the “ON” position. The EP1 Alarm Unit will sound

a high pitched tone three times at 30 second intervals (90 seconds)

reminding the driver to perform their child check.

• Proceed to the rear of the bus and depress the RVT Reset Button for at

least three seconds. You will hear the deactivation signal, a rapid chirping

sound from the EP1.

- Note: The Child Checkmate EP1 system’s deactivation process is

designed so that the ignition key must remain in the “OFF” position for at

least one second before switching to the “IGNITION” or “ACCESSORY”

position.

• The system has now been deactivated and the key can be removed safely

from the ignition.

DOME LIGHT OPTION — IF EQUIPPED

• Turn the ignition to the “ON” position to illuminate dome lights for 20

seconds.

• Once the system has been activated, turn the ignition to the “OFF”

position and the dome lights will illuminate.

• Turn ignition to the “ON” position. The dome lights will remain illuminated.

Proceed to the rear of the bus to deactivate the system.

• The dome lights will remain on for two minutes.

• Stepping on the brake pedal will trigger an audible sound. This will also

turn the dome lights off.

CHAPTER 8 – EMERGENCY EXIT / ESCAPE HATCH

7. Rotate the red knob back into

position.

8. The red knob should be in this

position during normal operation

of the vehicle.

Page 14

1. If the hatch was opened with

the lid in the fully closed position,

the release hinge will still be in

the down position.

Closing an Emergency Hatch

2. Push the release hinge

upward to the position shown

above.

3. Lower the lid into position.

4. Guide the release hinge into the handle base on

the lid as shown above.

5. Pull down on the top of the lid

to force the release hinge and the

lid together until you hear “clicks.”

This will be the spring loaded

handle setting in place.

6. Grasp both sides of the lid and

pull down to fully close the hatch.

CUSTOMER BUS INFORMATION

VIN # _____________________________________________________

Body # ____________________________________________________

HELPFUL CONTACTS

Ford Chassis 800.392.3673

GM Chassis 800.353.3867

International Chassis 888.633.8380

Braun 800.946.6158 or www.braunlift.com

Ricon 800.322.2884 or www.riconcorp.com

Trans Air 800.673.2448 or transairmfg.com

Carrier 717.767.3341 or www.mcc-hvac.com

A & M 574.225.5000 or www.anmsystems.com

Q’Straint USA or Canada

Phone 800.987.9987 or fax: 954.986.0021

Child Checkmate 877.494.8222 or www.childcheckmate.com

Page 16

2367 Century Drive, Goshen, Indiana 46528 • 1.800.348.7440 • www.starcraftbus.com

Uncontrolled When Printed

Form_751-02-06 Implemented on 4/1/14

Other manuals for Starcraft Bus

1

Table of contents

Other forest river Automobile manuals