14. Provide a means of pressure relief if the pump dis-charge can be shut off or

obstructed. Pumps operat-ing against a closed discharge can create very hot pumped

liquid, which can cause burns.

15.Do not operate this product while unattended.

16. Product is portable, and not intended to be permanently installed outdoors.

If installed outdoors, care should be taken to protect the unit from rain and other

elements of the weather.

17.According to the state of California (Prop 65), this product contains chemicals

known to the state of California to cause cancer and birth defects or other reproduc-

tive harm

1. Make certain that the power source conforms to the requirements of the equipment

as stated on the product nameplates.

2. Check hoses for weak or worn conditions before use and make certain that all

connections are secure.

3. Periodically inspect the pump for damage and perform routine maintenance as

required.

4. The maximum temperature of the pumped liquid must not exceed 120° F. The

minimum allowable temperature is 40° F.

5. Use a screen or strainer on the inlet to prevent solids from entering the pump.

6. To avoid internal pump damage, pump should not be run for more than five minutes

while attempting to prime.

DESCRIPTION

This portable utility pump is designed to be used as a transfer pump for such applica-

tions as emptying water heaters, swimming pools, livestock tanks, boats, etc. Pump

can also be used for an intermittent pressure booster for applications such as

washing cars, cleaning driveways, etc. The motor is air cooled. It is NOT designed to

operate under water.

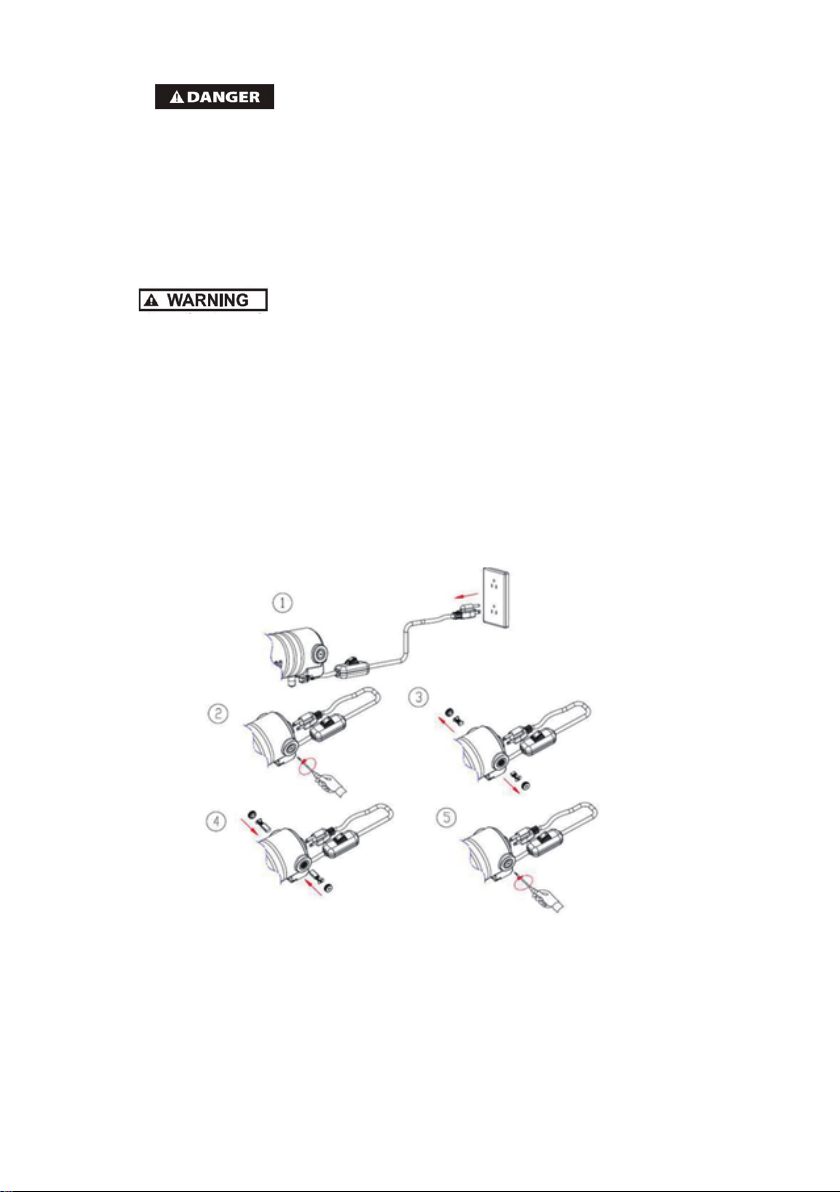

INSTALLATION

Always disconnect power source before attempting to install,

service or maintain the pump. Never handle a pump with wet hands or when standing

on wet or damp surface or in water. Fatal electrical shock could occur.

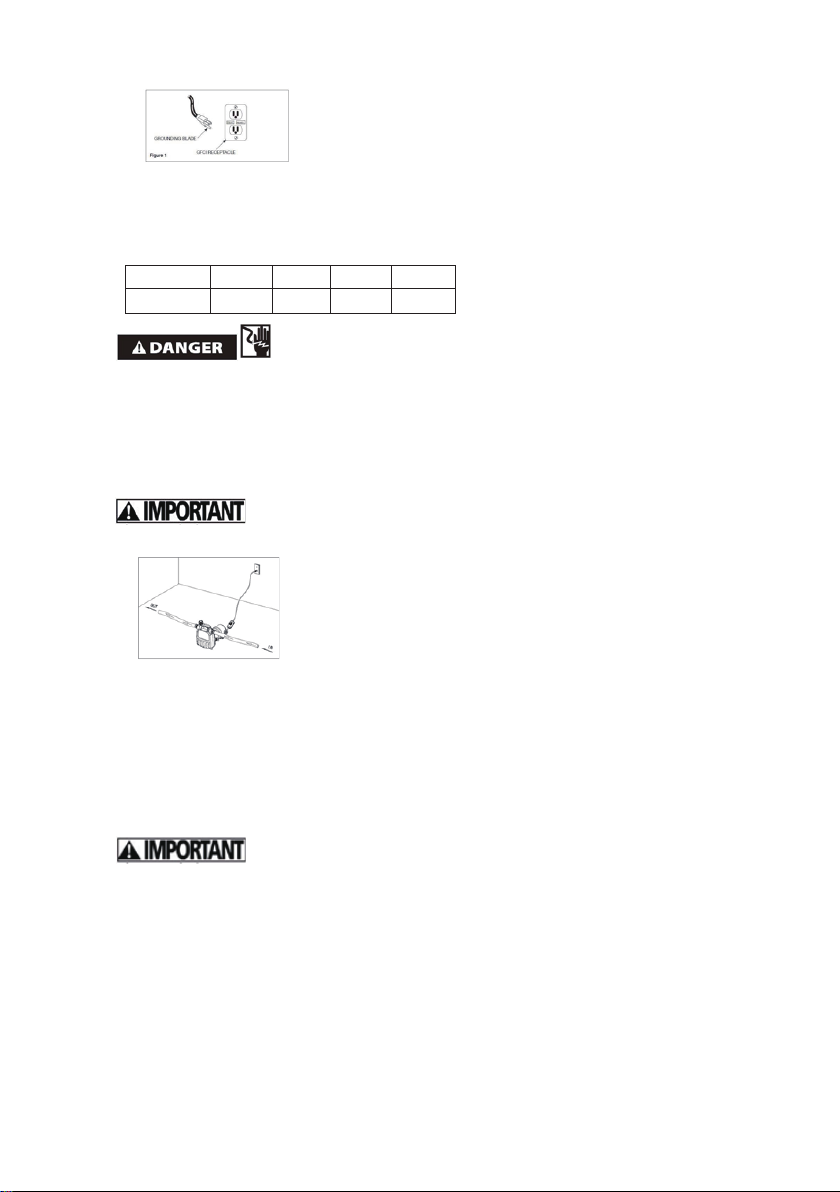

1.A ground fault circuit interrupter (GFCI) is recommended.

Risk of electrical shock. This pump is supplied with a grounding conductor and

grounding type attachment plug. A grounded receptacle in conformance with current

NEC and local codes must be used

2.Figure 1

-2-