6

Before the use

Please read through the instructions

carefully before using the unit and

carefully note the safety advice.

Always keep this manual accessible

to any users of the drill.

Area of application

The control unit can be set up in a

cabinet, or can be used as a porta-

ble unit (e.g. in a carry case). It is

suitable for the following scopes:

•

Footcare/Manicure: Milling, trim-

ming and polishing

. (Attention:

Additional spray or suction might

have to be in operation during foot

care in your country).

•Dental technique / -laboratory:

Milling-, trimming and polishing

work at plaster casts and models

(Do not use this unit for dentist

purposes, i.e. working directly on

the patient).

•Industry: Grinding, milling and

polishing works.

Installation Site / location

The installation of the workroom

must correspond to any regulations

according to your country laws. Set

up the control unit, so that the venti-

lation slits are not covered or

blocked, and the exhaust air can

escape well.

The drill and the charging unit may

only be operated in confined spac-

es. Temperature rising of the hous-

ing is normal during operation. Alt-

hough the unit should never be

covered, nor be located near heat-

ing devices or in direct sun impact.

Fully charge the unit before its first

use. Read the instructions in the

following chapter on how to pro-

ceed.

Before first use

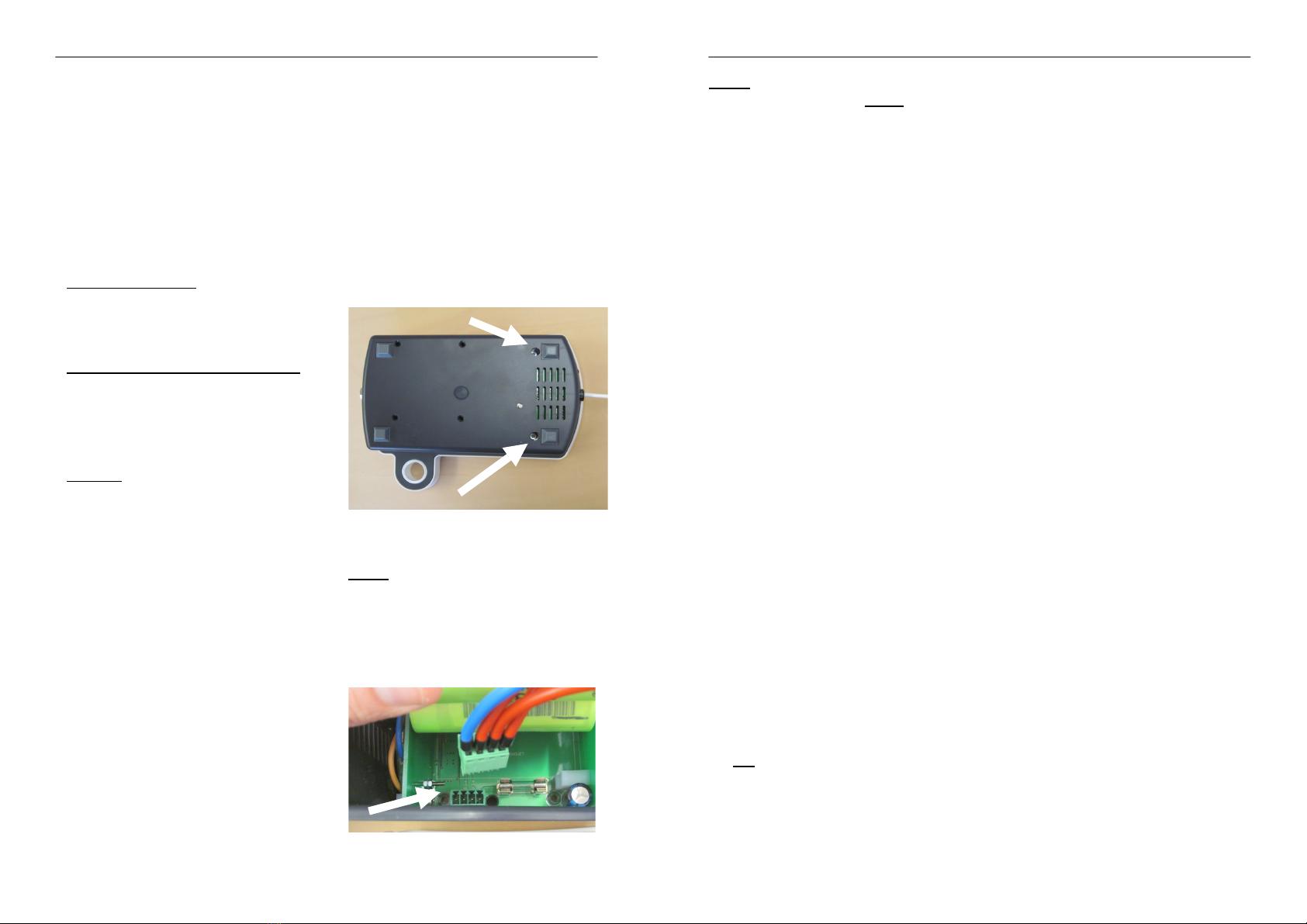

1. Unscrew the screws at the bot-

tom of the unit, and carefully re-

move the lid (upper housing), since

it is connected to the electronic

board.

2. Make sure that the handpiece is

safely secured, so that it will not

move, should the unit be started

accidently. Connect the

accumulators to the electronic

board as shown in the picture. An

acoustic signal will occur.

11

Handling details

Never put the handpiece into any

kind of liquid, and never oil or

grease the handpiece. Clean its

surface with a damped cloth. Pay

attention, that no moisture or liquid

enters the handpiece.

Never put any wet burs or instru-

ments into the handpiece. Its mois-

ture could damage the interior parts

of the handpiece.

Any materials used by hadewe pre-

vent a formation of rust. In cases in

which a rust infestation was found

within the handpiece, thorough in-

spections and examinations always

have proved, that the rust had a

foreign origin (which was usually

caused by the tools used in these

circumstances). Even in high-grade

steel instruments of well known

manufacturers, formation of rust

can appear, e.g., through wrong

treatment with chemical cleaning

and disinfection liquids. This extra-

neous rust affects internal parts of

the handpiece in form of rust bloom

and causes pitting. Therefore, when

you not working with the handpiece,

always remove the bur/ tool from it.

Always make sure that you do not

let the handpiece fall down or ex-

poses it to any shocks. The ball

bearings and the motor could be

damaged by this. Only work with

tools, which are flawless.

Do not work with tools which

- are bent or out of balance,

- whose shaft is worn out or

- are rusty.

Working with faulty tools will cause

a stronger vibration of the hand-

piece. A damage or even devasta-

tion of the ball bearings, clamping

technique or motor could be the

consequence.

Working with high pressure will not

improve the outcome of your work,

since the motor will even be slowed

down. A second disadvantage is the

stronger impact on the ball bearings

and the motor, which will shorten

their life span in the long run.

Always working with maximum

speed might have a similar effect.

Please make sure that the speed

setting you use is according to the

work you are doing and the instru-

ments you are working with.