© HAMM AG 2009 1

GENERAL

1 GENERAL

1.1 INTRODUCTION

1.1.1 General

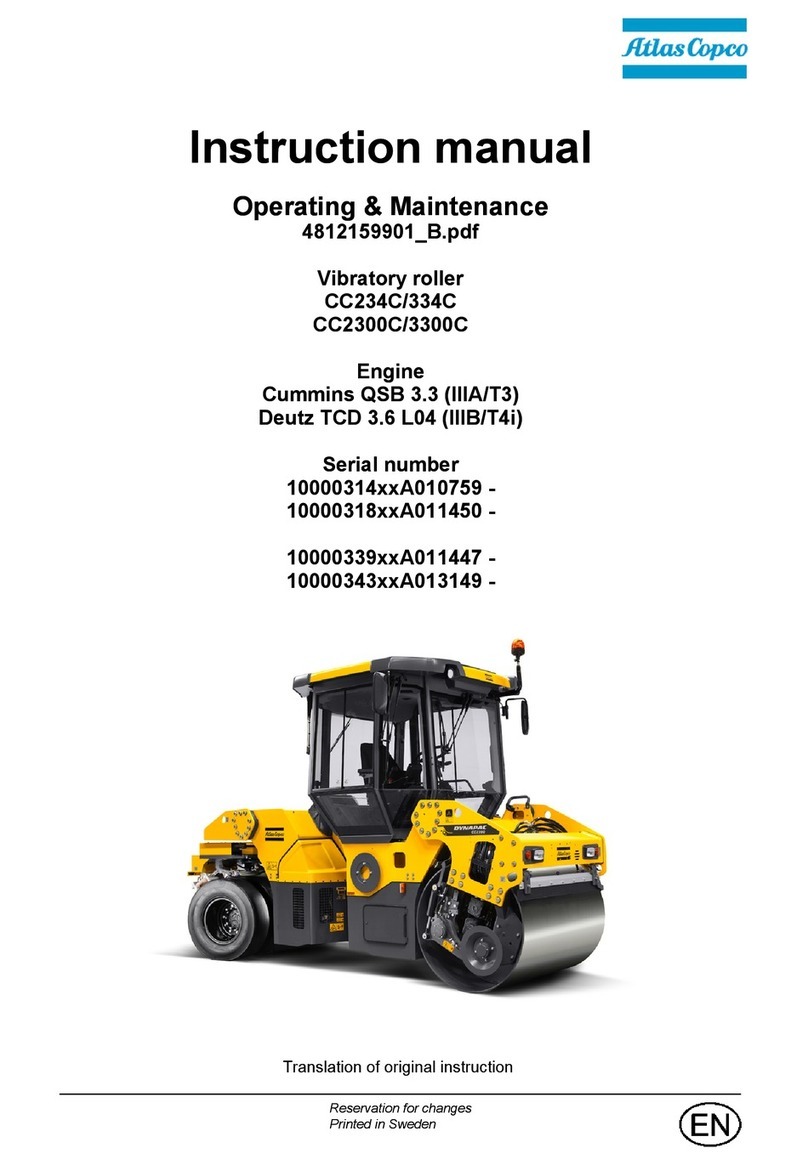

You have purchased a HAMM Quality product.

All parts of this machine have been tested and

verified carefully. They correspond to the quali-

ty you expect.

This machine has been built according to the

current state-of-the-art and the current safety

regulations. However it is indispensable to

read and to observe the safety notes as well as

the operating and the maintenance instructions

prior to start-up. Every inappropriate use, or

use not according to the intended use, of the

machine will cause:

• Dangers to life and health of the user or to

third parties

• Impairment of the machine and further

properties of the user

• Dangers to the efficient work of the ma-

chine

The operating instructions of the combustion

engine is a part of the overall operating instruc-

tions. Maintenance and care of the engine

have to be performed according to these oper-

ating instructions. Any safety notes have to be

followed.

Even if the regulations for safety, use and

maintenance are followed, residual dangers

will remain. Due to the high operating weight

and to the high distance of gravity centres of

the machine, there is considerable danger of

tilting, in particular during travels in transversal

direction to slopes. The smooth surface of the

drums or the tyres, respectively, decreases lat-

eral stability of wet, uneven ground. Operation

is not admitted on snow and ice. When driving

on hard surfaces, and in particular when driv-

ing in transversal direction so slopes, lateral

stability is decreased when the vibration is

switched on (danger of falling).

The high reliability of the machine is preserved

through correct use and careful maintenance.

This includes the use of the obligatory operat-

ing resources and the use of original HAMM

spare parts.

This manual will introduce you to the operation

of the machine. You will find the following in it:

• Regulations for your safety

• The introduction of the machine and its

characteristics

• The operation

• The maintenance instructions

• Indication on spare parts management

and customer service

Our representations will help you to keep your

roller in perfect operating condition.

Our representations will be at your disposition

with consulting and service even after the war-

ranty period. They will provide our original

HAMM spare parts which do not only corre-

spond to the technical requirements but also

ensure exchangeability and quality.

Our customer service training centre holds

courses for roller drivers.

It will give drivers:

• General safety information

• Information on use and maintenance of

the machine

• Information on the practical use of the roll-

er

• Information of a more rational use with

add-on devices

Furthermore, our specialist sales advisors are

always at your disposition. They will offer you

the optimum product solution for your applica-

tion. The safety, operation and maintenance

notes included in this manual are intended to

be used by roller drivers and mechanics.

Thus, keep this manual always at hand!