Heatmaster C Series User manual

Other manuals for C Series

2

This manual suits for next models

2

Other Heatmaster Furnace manuals

Heatmaster

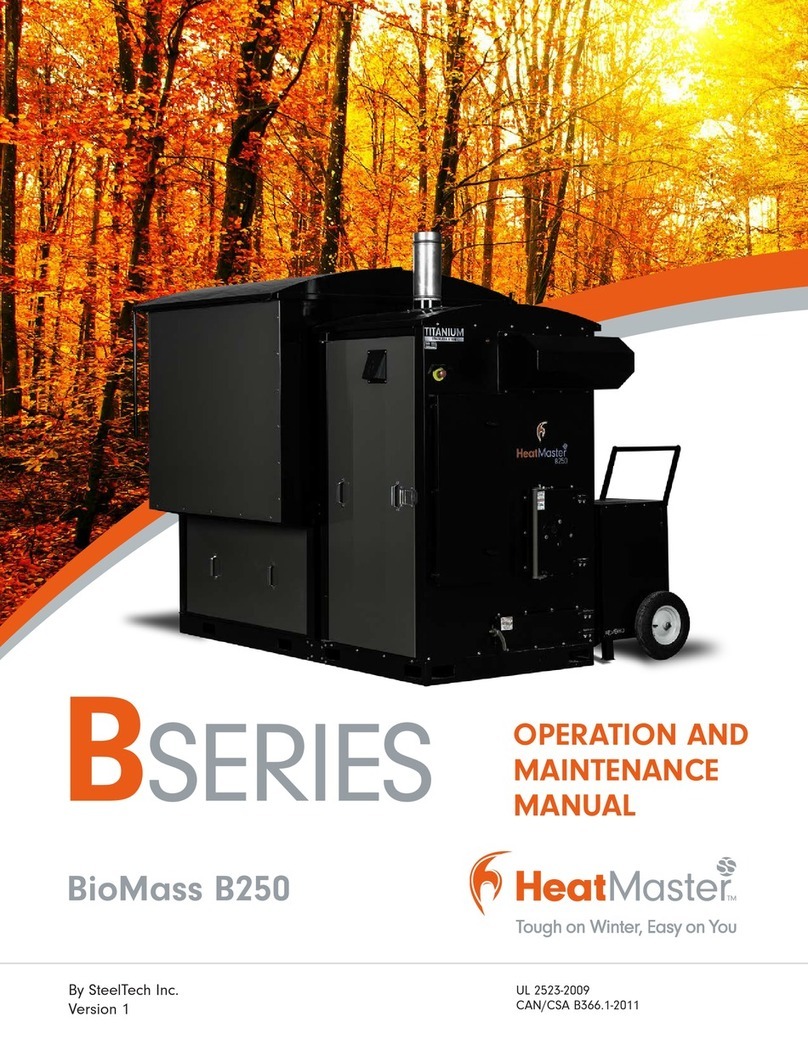

Heatmaster B Series User manual

Heatmaster

Heatmaster C Series User manual

Heatmaster

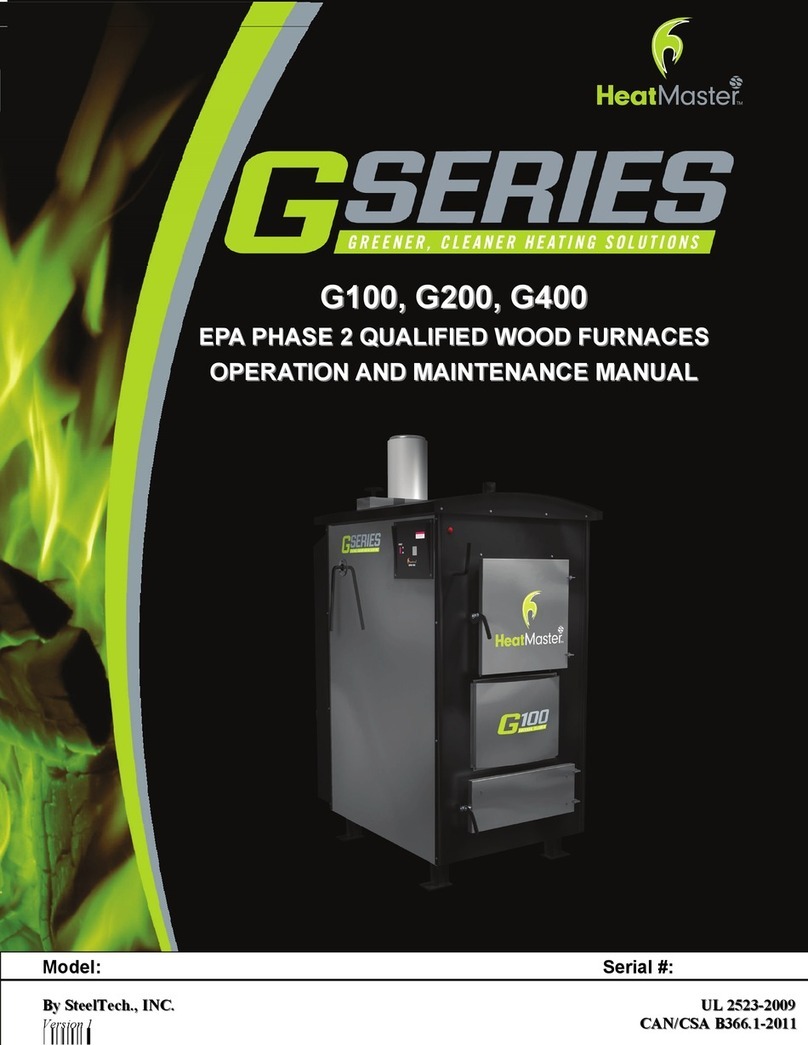

Heatmaster G Series User manual

Heatmaster

Heatmaster G100 User manual

Heatmaster

Heatmaster C-150 User manual

Heatmaster

Heatmaster MF Series User manual

Heatmaster

Heatmaster MF-3000 User manual

Heatmaster

Heatmaster G100 User manual

Popular Furnace manuals by other brands

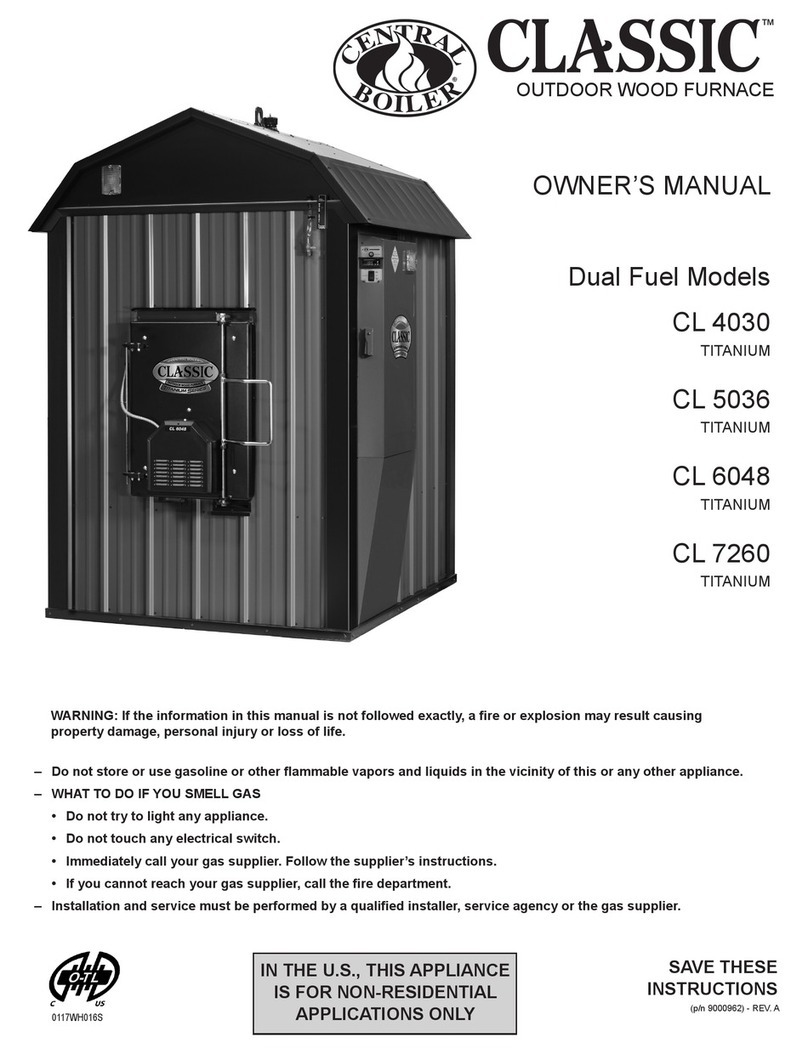

Central Boiler

Central Boiler CL 4030 owner's manual

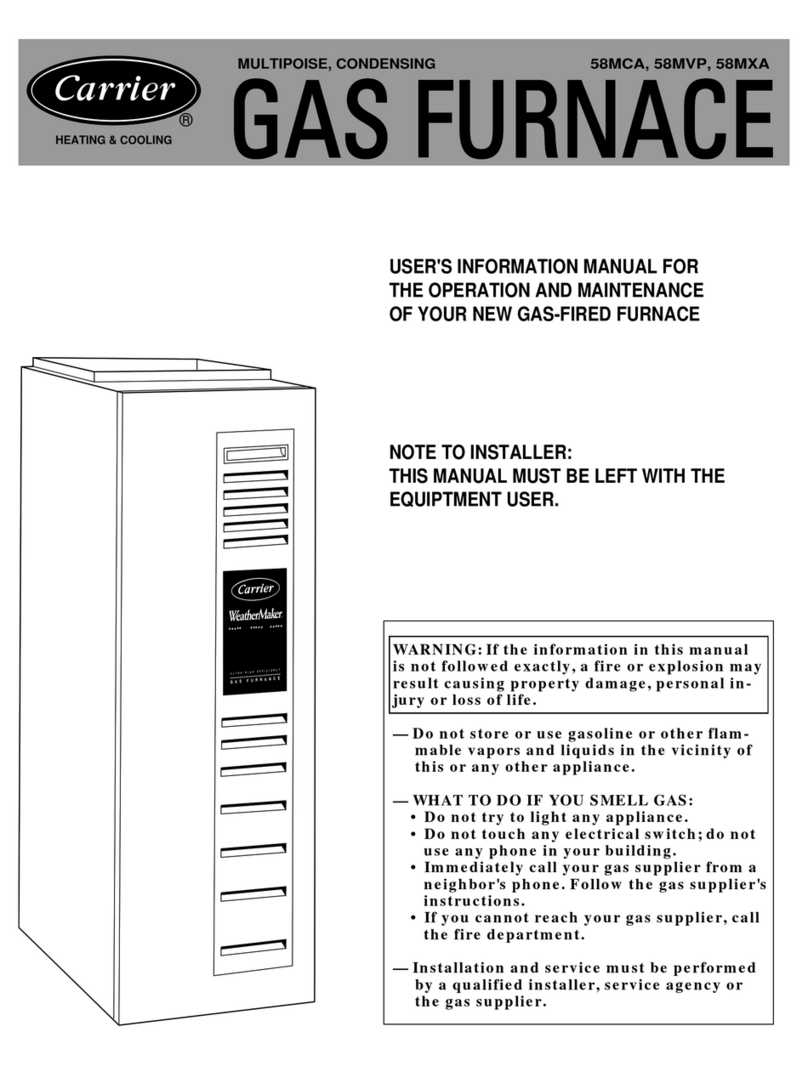

Carrier

Carrier 58MCA Users information manual for the operation and maintenance

VERDER

VERDER CARBOLITE GERO CFM 14/1 Installation, operation and maintenance instructions

Payne

Payne C Series Installation, start-up, operating and service and maintenance instructions

Bryant

Bryant 313AAV PLUS 80X Product data

Dettson

Dettson Supreme Comfort Series Installation instructions and homeowner's manual

Thermo Pride

Thermo Pride OME Series installation instructions

Carrier

Carrier 110 Series Installation, start-up, and operating instructions

Lifebreath

Lifebreath CAF-U-S4A-24-P16 Operation, sizing and installation manual

Adams

Adams UFO Installation, maintenance & operating instructions

Carrier

Carrier 58UXT Series operating instructions

England's Stove Works

England's Stove Works 24-G Installation and operation manual

Carrier

Carrier GAS FURNACE 58MXA Product data

Zirkon zahn

Zirkon zahn ZIRCONFEN 600 Operator and maintenance manual

Carrier

Carrier 58UVB series Installation, start-up, and operating instructions

Lennox

Lennox EL296DFV SERIES User's information manual

Payne

Payne 349FAZ Quick manual

International comfort products

International comfort products C Series installation instructions