Heinrichs PIT UMF2 User manual

Heinrichs Messtechnik GmbH

OPERATING MANUAL PIT / UMF2B

January 2021

Magnetic-Inductive Flow Velocity Sensor

PIT

UMF2

Operating Manual

Please read the instructions carefully and store them in a save space

Heinrichs Messtechnik GmbH

Page 2 of 23

Operating Manual PIT / UMF2B

Contents

INTRODUCTION.........................................................................................................................................................4

I. Shipping and storage; product inspection................................................................................................................... 4

II. Warranty................................................................................................................................................................................ 4

III. Maintenance, Repair and Hazardous substances..................................................................................................... 4

IV. Disposal ................................................................................................................................................................................. 4

V. Supplementary operating instructions ........................................................................................................................ 4

1STEPS PRIOR TO OPERATION ........................................................................................................................5

2IDENTIFICATION..............................................................................................................................................6

3APPLICATION...................................................................................................................................................7

4MODE OF OPERATION AND SYSTEM DESIGN...............................................................................................8

4.1 Mode of operation .............................................................................................................................................................. 8

4.2 System design ..................................................................................................................................................................... 9

4.2.1 Transmitter mounted on the sensor.............................................................................................................. 9

4.2.2 Remote installation of the transmitter .......................................................................................................10

4.2.3 Sensor versions ..................................................................................................................................................10

5CHARACTERISTICS ....................................................................................................................................... 11

6CONDITIONS OF USE.................................................................................................................................... 12

6.1 Installation conditions .....................................................................................................................................................12

6.1.1 Immersion depth of PIT-*** in the pipe ......................................................................................................12

6.1.2 Removal and installation under process pressure...................................................................................12

6.1.3 Grounding.............................................................................................................................................................13

6.2 Use in hazardous areas...................................................................................................................................................13

6.3 Ambient conditions ..........................................................................................................................................................13

6.4 Medium temperature and pressure............................................................................................................................14

6.4.1 Direct mounted transmitter............................................................................................................................14

6.4.2 Remote mounted transmitter........................................................................................................................14

7DIMENSIONS/WEIGHT ................................................................................................................................ 15

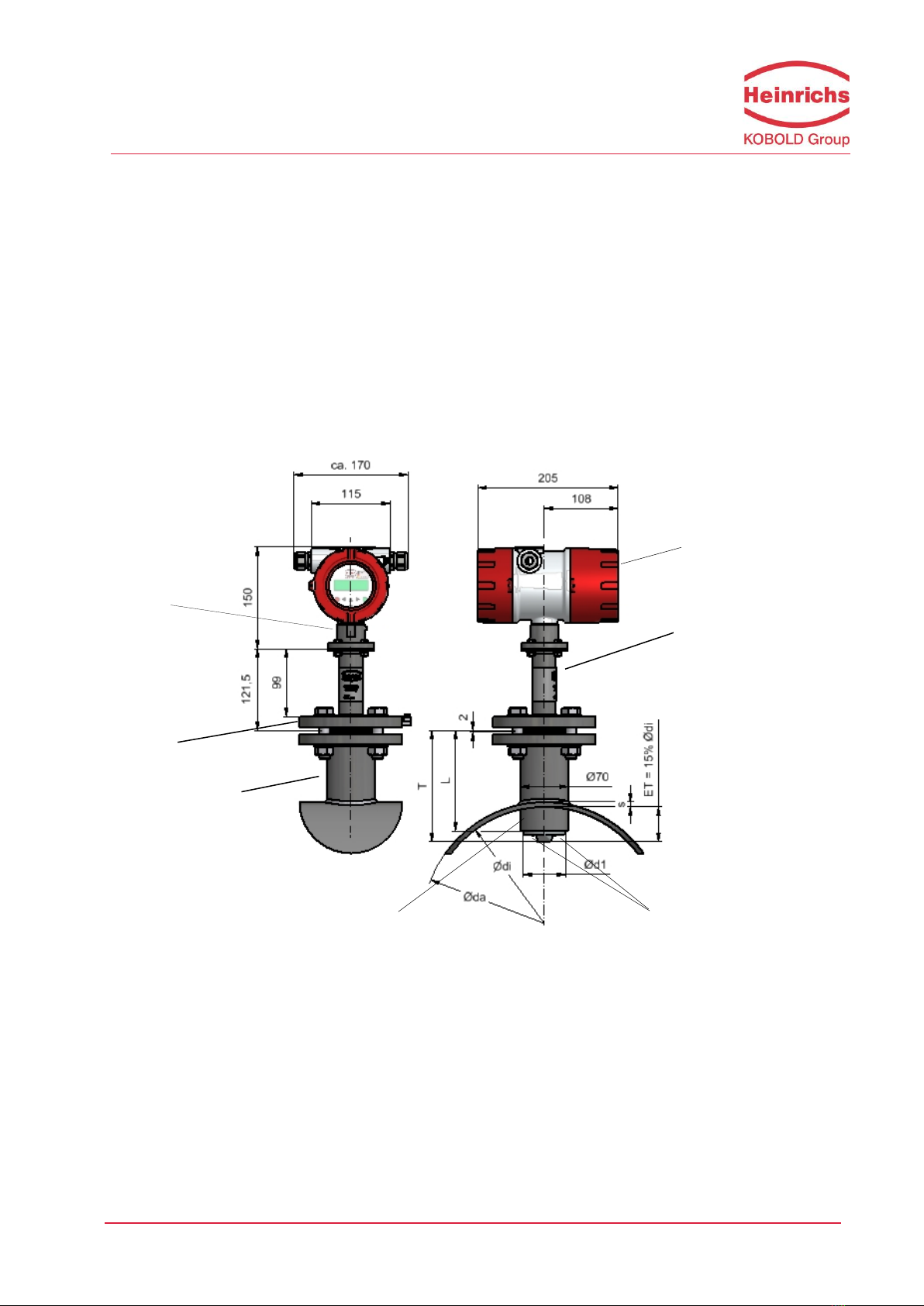

7.1 PIT-UMF2 dimensional drawing for remote transmitter ....................................................................................15

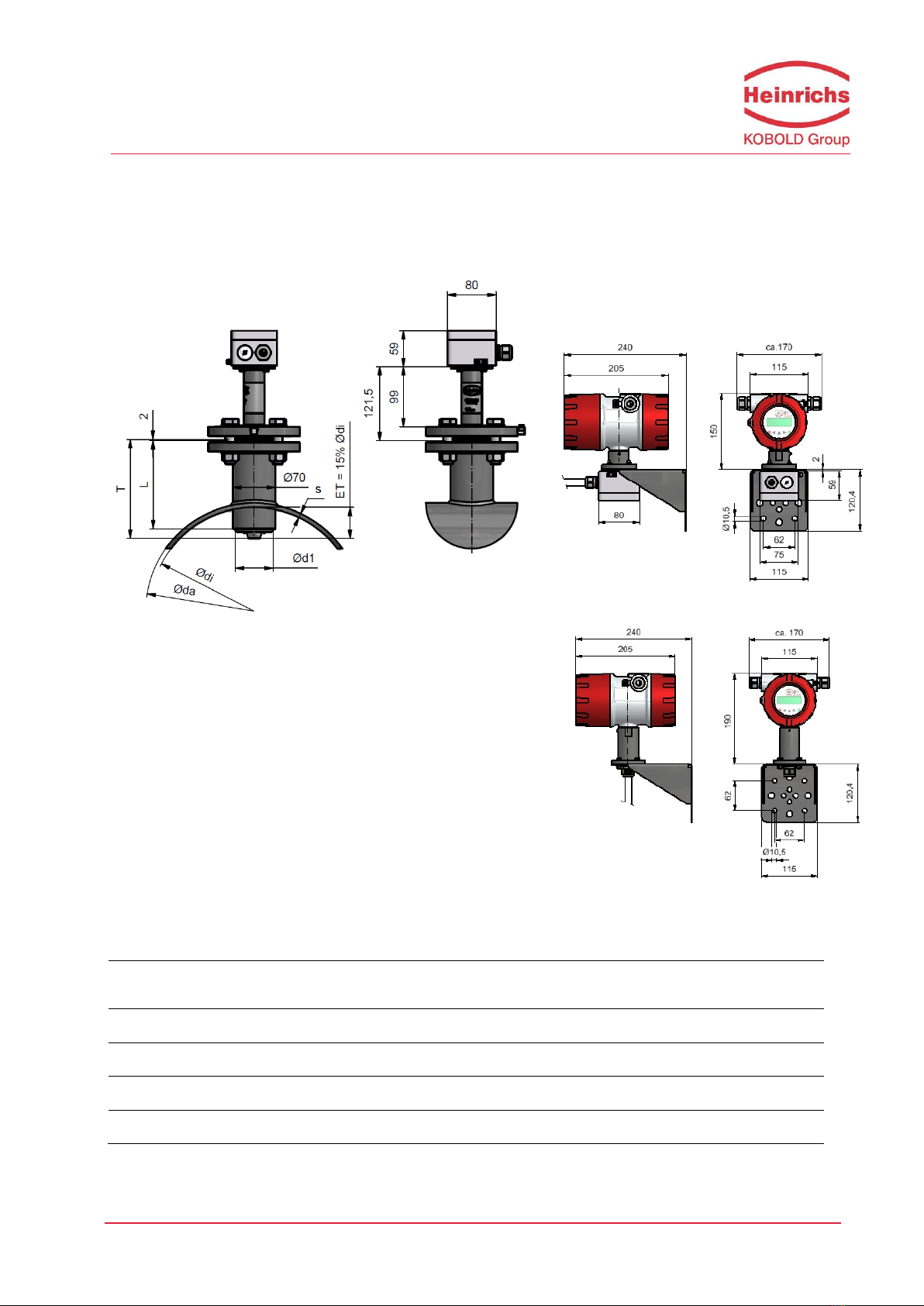

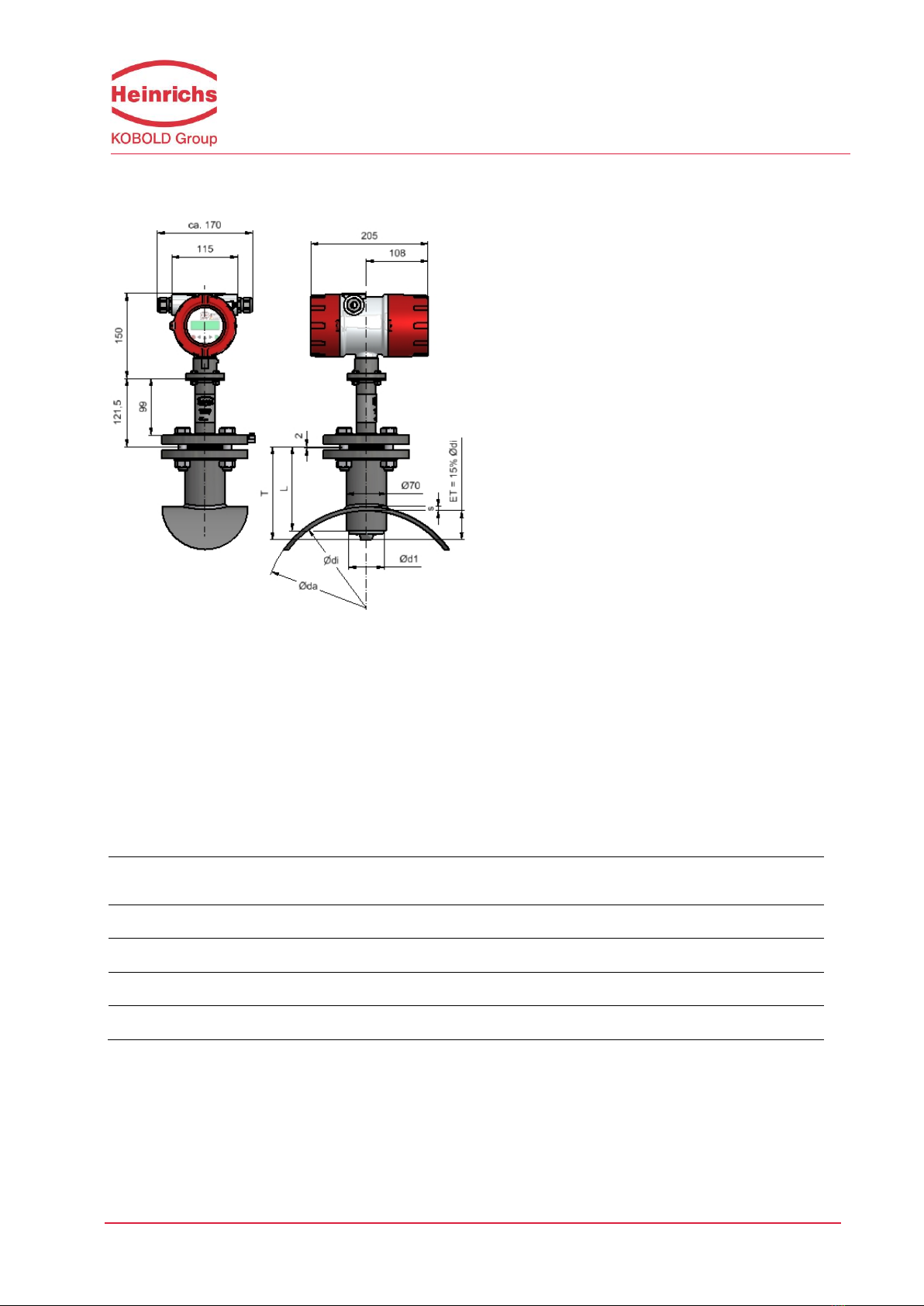

7.2 PIT-** dimensional drawing with direct mounted transmitter UMF2..............................................................16

8POWER SUPPLY / ELECTRICAL CONNECTION ........................................................................................... 17

9SAFETY INFORMATION ............................................................................................................................... 17

9.1 Intended use.......................................................................................................................................................................17

9.2 Installation, start-up and operating personnel........................................................................................................17

Heinrichs Messtechnik GmbH

Operating Manual PIT / UMF2B

Page 3 of 23

10 OPTIONS…………………………………………………………………………..……………………………………………………..18

10.1 Removal and installation under process pressure .................................................................................................18

10.2 PIT (Sensor) Ingress protection IP68 ..........................................................................................................................18

10.2.1 Wiring diagram for remote installation .......................................................................................................19

11 RETURNING THE METER ............................................................................................................................. 20

11.1 Declaration of Decontamination ..................................................................................................................................21

12 DECLARATION OF CONFORMITY ................................................................................................................ 22

Heinrichs Messtechnik GmbH

Page 4 of 23

Operating Manual PIT / UMF2B

Introduction

I. Shipping and storage; product inspection

Shipping and storage

The device is to be safeguarded against dampness, contamination (especially the inside of the flow meter),

impact and damage. Open the packaging with caution to prevent unintentional damage.

Adhere to the temperature limits during storage.

Product inspection

Upon receipt of the product, check the contents of the box and the product particulars against the

information on the delivery slip and order form so as to ensure that all ordered components have been

supplied. Notify us of any shipping damage immediately upon receipt of the product. Any damage claim

received at a later time will not be honoured.

II. Warranty

Your flowmeter was manufactured in accordance with the highest quality standards and was thoroughly

tested prior to shipment. However, in the event any problem arises with your device, we will be happy to

resolve the problem for you as quickly as possible under the terms of the warranty, which can be found in

the terms and conditions of delivery. Your warranty will only be honoured if the device was installed and

operated in accordance with the instructions for your device. Any mounting, commissioning and/or

maintenance work is to be carried out by qualified and authorized technicians only.

III. Maintenance, Repair and Hazardous substances

When used in the intended manner no special maintenance is required. However, the flowmeter should be

checked within the context of routine maintenance of the facility and the pipelines. Should a repair,

calibration or maintenance become necessary, be sure to clean the device thoroughly and follow the steps in

section 11 “Returning the Meter”. before returning the device to Heinrichs Messtechnik.

The operator is liable for any substance removal or personal damage costs arising from inadequate cleaning

of a device sent for repair.

IV. Disposal

Observe the regulations applicable to disposal in the country of installation!

V. Supplementary operating instructions

Supplement operating manuals are available for special features, interfaces and operations relating to your

device, request your copy from our service department.

Heinrichs Messtechnik GmbH

Operating Manual PIT / UMF2B

Page 5 of 23

1Steps prior to operation

It is essential that you read these operating instructions before installing and

operating the device. The device is to be installed and serviced by a qualified

technician only. The UMF2B transmitter is to be used exclusively to measure volume

flow or flow velocity, in conjunction with a Heinrichs Messtechnik EPS, PIT or PITE

sensor.

Downloading of the present document from our web site www.heinrichs.eu and

printing out this document is allowed only for the purposes of using our flowmeters. All rights reserved. No

instructions, wiring diagrams, and/or supplied software, or any portion thereof, may be produced, stored, in

a retrieval system or transmitted by any means, electronic, mechanical, photocopying or otherwise, without

the prior written permission of Heinrichs Messtechnik GmbH.

Although the materials in the present document were prepared with extreme care, errors cannot be ruled

out. Hence, neither the company, the programmer nor the author can be held legally or otherwise

responsible for any erroneous information and/or any loss or damage arising from the use of the

information enclosed.

Heinrichs Messtechnik GmbH extends no express or implied warranty concerning the applicability of the

present document for any purpose other than that described.

We plan to optimize and improve the products described and in so doing will incorporate not only our own

ideas but also, and in particular, any suggestions for improvement made by our customers. If you feel that

there is any way in which our products could be improved, please send your suggestions to the following

address:

Company:

Heinrichs Messtechnik GmbH

HM-EE (R&D Department)

Robert-Perthel-Strasse 9

D-50739 Cologne

Germany

or:

via fax : +49 (221) 49708-178

Note:

We reserve the right to change the technical data in this manual in the light of any

technical progress that might be made.

For updates regarding this product, visit our website at www.heinrichs.eu, where you

will also find contact information for the Heinrichs Messtechnik distributor nearest you.

Heinrichs Messtechnik GmbH

Page 6 of 23

Operating Manual PIT / UMF2B

2Identification

Hersteller:

Heinrichs Messtechnik GmbH

Robert-Perthel-Strasse 9

D-50739 Köln

Deutschland

Produkttyp:

Magnetic –inductive flow sensor based upon Faraday’s law of induction

Produktname:

Sensortyp: PIT

Umformertyp: UMF2B

Dateiname:

pit-umf2b_ba_21.01_en.doc

Version:

21.01, Datum, February 3, 2021

Heinrichs Messtechnik GmbH

Operating Manual PIT / UMF2B

Page 7 of 23

3Application

The magnetic-inductive flow velocity sensor PIT-UMF2 is used to measure or monitor the volume flow of

liquids with and without solids concentration, slurries, pastes and other electrically conductive media while

minimizing pressure drops. The medium must possess a conductivity of at least 20 µS/cm.

Pressure, temperature, density and viscosity do not affect the volume measurements. Smaller portions of

solid particles and small gas bubbles are also measured as part of the volume flow. A larger number of solid

particles or gas bubbles will lead to failures. Special electrodes are available for media that tend to form

greasy films or crusts.

.

Heinrichs Messtechnik GmbH

Page 8 of 23

Operating Manual PIT / UMF2B

4Mode of Operation and System Design

4.1 Mode of operation

It was back in 1832 that Faraday suggested utilizing the principle of electromagnetic induction for

measuring flow velocities. His experiments in the Thames, though unsuccessful due to superimposed

polarization effects, are nonetheless regarded as the first ones in the field of magnetic-inductive flow

measurement.

According to Faraday’s law of electromagnetic induction, an electrical field E is produced in a conductive

liquid moving through a magnetic field B at a velocity v in accordance with the vector product E = [v x B]. A

liquid at flow velocity v and a flow rate Q flows through a meter tube (4), producing a measuring-circuit

voltage Um at the two electrodes (E1 and E2) at right angles to the direction of flow and the magnetic field B

generated by the field coils (3). The size of this measuring-circuit voltage is proportional to the mean flow

velocity and thus the volume flow rate.

Heinrichs Messtechnik GmbH

Operating Manual PIT / UMF2B

Page 9 of 23

4.2 System design

The magnetic-inductive PIT-UMF2 flow measurement system consists of a sensor (PIT), which picks up an

induced measuring signal from the medium flowing through the pipe, and a transmitter (UMF2), which

transforms this signal in standardized output signals (4-20 mA or pulses).

The PIT-*** sensor can be operated with all transmitters for magnetic-inductive flow meters manufactured

by Heinrichs Messtechnik. The sensor is installed (inserted) into the pipe while the transmitter is mounted

directly on top of the sensor or separate remote, depending on the equipment design.

4.2.1 Transmitter mounted on the sensor

This type of construction ensures easy and trouble-free installation

Fitting

Flange

Socket weld

fitting

Sensor

Lining

UMF2B transmitter

housing

Electrodes

Sensor

adapter neck

Heinrichs Messtechnik GmbH

Page 10 of 23

Operating Manual PIT / UMF2B

Junction box

Fitting

Flange

Socket weld fitting

4.2.2 Remote installation of the transmitter

Heinrichs Messtechnik recommends this type of installation when there is little space or the medium

temperatures are high. The sensor and the transmitter are connected by a field coil and an electrode cable.

The electrode cable must be shielded and protected against disturbing interferences.

4.2.2.1 Sensor installation

4.2.2.2 Transmitter mounting

4.2.3 Sensor versions

PIT-S Wetted parts stainless steel / hastelloy / PTFE,

Transmitter neck connection flange stainless steel

PIT-A Wetted parts PFA / hastelloy,

Transmitter neck connection flange stainless steel

PIT-U Version with retraction device

Remote transmitter with terminal connection

box, (For cable length longer than 10 m)

Remote transmitter with direct connected cable

to transmitter, (For cable length of max. 10 m)

(all dimensions in mm)

(all dimensions in mm)

Heinrichs Messtechnik GmbH

Operating Manual PIT / UMF2B

Page 11 of 23

5Characteristics

Accuracy

1.5 % of measured value plus 0.5 % of URV

Conductivity of fluid

20 µS/cm

Influence of ambient temperature

Pulse output 0, 05% pro 10K

Current output 0, 1% pro 10K

Influence of medium temperature

None

Heinrichs Messtechnik GmbH

Page 12 of 23

Operating Manual PIT / UMF2B

6Conditions of use

6.1 Installation conditions

Disturbing elements (e.g. shut-off and control valves) are to be arranged downstream from the sensor. If

this is not possible, flow conditioners must be installed so that no vortexes can reach the pipe section of the

sensor. The mounting location in the pipe system should be selected so that the sensor is continually filled

with the medium. This requirement can be met by using drains and check valves.

In order to stay within the indicated accuracy, the installation must be performed according to EN 29104

"Measurement of Fluid Flow in Closed Conduits –Methods of Evaluating the Performance of Magnetic-

Inductive Flow meters." Based on this standard, the minimum straight run of pipe ahead of the inlet must

be 10 pipe diameters (> 10 x DN) and 5 pipe diameters following the outlet (> 5 x DN) [DN = nominal

diameter of pipe].

In order to prevent serious measuring errors when the pipe is partially filled or when there are gas bubbles

or sediment deposits, the mounting position described above should be chosen.

The limits for the product and ambient temperature must be met at the mounting location. Corrosive

atmospheres must be avoided. Please also take into account the space requirement for a possible removal

of the device.

6.1.1 Immersion depth of PIT-*** in the pipe

In order to suppress the influence of the flow profile as much as possible, the depth of immersion of the

sensor head in the pipe must be 15 % of the inside diameter of the pipe.

The socket weld fitting must not cover the top of the sensor head and must be shortened if necessary.

6.1.2 Removal and installation under process pressure

For easy removal and installation under pressure, a special retraction device is available. When using this

device, the sensor head must not be damaged by closing the valve.

For details, see the Additional Operating Instructions for Removal and Installation the meter under process

pressure Additional Operating Instructions PIT-Druck_BA_0X_eng.doc (see also Section 14 "Options").

Heinrichs Messtechnik GmbH

Operating Manual PIT / UMF2B

Page 13 of 23

6.1.3 Grounding

For safety reasons and to ensure faultless operation of the magnetic-inductive flow meter, earthing of the

flow sensor is important. In accordance with VDE 0100, Part 540, the earthing connections must be

connected to the grounding conductor.

To avoid false measurement, the ground potential must be identical to the ground potential of the medium.

When using insulated and lined pipes or plastic pipes, the metrological grounding of the medium for PIT-S (

SS) is carried out via the wetted part of the sensor head.

All wetted parts of PIT-A ( PFA) are coated with PFA . Therefore it is not possible to ground the medium via

the housing parts. In this case make sure that the PIT-A sensor will be supplied an earthing. If the sensor

does not have an earthing electrode ensure that a suitable earthing disc will be used.

6.2 Use in hazardous areas

The flow meters PIT-…/UMF2 are not intended for use in hazardous areas.

6.3 Ambient conditions

Ambient temperature ranges

-20°C to +60°C, below 0°C the readability of the LCD is limited

Storage temperature

-25°C to +60°C

Climatic category

In accordance with IEC 654-1

Not weather-protected Class D locations exposed directly to open-air climate

Ingress Protection

PIT standard sensor: IP65, option: IP68 / UMF2(b) standard housing IP68 (NEMA 6P)

Caution:

Ingress protection IP68 is only achieved if suitable and tightly screwed down cable glands or

conduits are used. If the cable glands are only tightened manually water may leak into the

terminal compartment in the housing.

Warning:

Particular care must be taken if the window in the housing becomes fogged over or

discolored because moisture, water or product might seep through the wire sheath into the

terminal compartment in the housing!

Caution:

Electromagnetic compatibility is only achieved if the electronics housing is closed. Leaving

the enclosure open can lead to electromagnetic disturbances.

Shock resistance/vibration resistance

The meter should be protected from extreme shocks and vibrations, which could cause damage.

Heinrichs Messtechnik GmbH

Page 14 of 23

Operating Manual PIT / UMF2B

6.4 Medium temperature and pressure

6.4.1 Direct mounted transmitter

Version

Medium temperature

Pressure

PIT-S ( SS / PTFE)

-20°C to 80°C

16 bar

PIT-A ( PFA)

-20°C to 80°C

40 bar

6.4.2 Remote mounted transmitter

Version

Medium temperature

Pressure

PIT-S ( SS / PTFE)

-40°C to100°C

16 bar

PIT-A ( PFA) standard

-40°C to 140°C

40 bar

Heinrichs Messtechnik GmbH

Operating Manual PIT / UMF2B

Page 15 of 23

7Dimensions/weight

7.1 PIT-UMF2 dimensional drawing for remote transmitter

(all dimensions in mm )

Weight: 3, 6 kg

DN: Nominal Diameter

T: Length of sensor

Ød: Diameter of sensor

L Length of socket weld fitting

ET: Immersion depth in % of pipe diameter

Version

DN

T

Ød1

L

PIT-A (PFA)

150-600

163mm

62mm

145mm

PIT-S ( SS / PTFE))

150-600

163mm

60,3mm

145mm

PIT-S ( SS / PTFE))

700-1200

263mm

60,3mm

170mm

PIT-S ( SS / PTFE))

1400-2000

363mm

60,3mm

170mm

Transmitter with

terminal connection box

Transmitter with directly

connected cable ( up to 10 m)

Heinrichs Messtechnik GmbH

Page 16 of 23

Operating Manual PIT / UMF2B

7.2 PIT-** dimensional drawing with direct mounted transmitter UMF2

(all dimensions in mm )

Weight: 5, 5 kg

DN: Nominal Diameter

T: Length of sensor

Ød: Diameter of sensor

L Length of socket weld fitting

Version

DN

T

Ød1

L

PIT-A (PFA)

150-600

163mm

62mm

145mm

PIT-S ( SS / PTFE))

150-600

163mm

60,3mm

145mm

PIT-S ( SS / PTFE))

700-1200

263mm

60,3mm

170mm

PIT-S ( SS / PTFE))

1400-2000

363mm

60,3mm

170mm

Heinrichs Messtechnik GmbH

Operating Manual PIT / UMF2B

Page 17 of 23

8Power supply / electrical connection

See name plate or Operating Instructions of the corresponding transmitter.

9Safety information

9.1 Intended use

The PIT-UMF2 flow meter may be used only for flow measurements of fluids whose conductivity exceeds

20µS/cm. The manufacturer shall not be liable for damages that may result from unintended or

inappropriate use.

When dealing with an aggressive medium, clarify the material durability of all wetted parts.

9.2 Installation, start-up and operating personnel

Only trained specialists authorized by the system operator may carry out the installation, electrical

installations, start-up maintenance and operation. They must read and understand the operating manual

and follow its instructions. Basically, the national conditions and provisions must be followed.

Grundsätzlich sind die in Ihrem Land geltenden Bestimmungen und Vorschriften zu beachten.

Heinrichs Messtechnik GmbH

Page 18 of 23

Operating Manual PIT / UMF2B

10 Options

10.1 Removal and installation under process pressure

In some cases it might be necessary to remove and reinstall the PIT sensor head for cleaning when the pipe

is under process pressure. A special retraction device can be used for this purpose.

When using this device, it is important to ensure that the sensor head will not be damaged by closing the

valve. For a detailed description of this process, see the Additional Operating Instructions (PIT-

Druck_BA_03_eng) for removal and installation the meter under process pressure (Section 5.1.2).

10.2 PIT (Sensor) Ingress protection IP68

A special version of PIT is available with the IP 68 degree of protection. This version is equipped with a

special terminal box, special cable glands and a special cable. The length of the cable must be specified

when placing the order. The terminal box does not need to be opened during the installation. If this should

be necessary, the cover must be remounted carefully. This is the only way to ensure the IP 68 degree of

protection.

The standard immersion depth is 5 m. (Material of terminal box: Aluminum)

optional immersion depth up to 25 m with filling of the terminal box with special “sealing

Compound GHB 1 ” and with factory connected cable at the sensor terminal conn., box.. (Option)

(Material of terminal box: Aluminum)

IP 68 version - seawater resistant: material of terminal box: PE glass-fibre reinforced ,

black 57x75x110 mm (Option)

Heinrichs Messtechnik GmbH

Operating Manual PIT / UMF2B

Page 19 of 23

10.2.1 Wiring diagram for remote installation

The outer shield hast o be connected to the metalized cable glands at both ends. The inner shields are

connected to each other and are plugged into the terminal with the label “Schirm / shield”.

Warning:

Do not connect or disconnect the field coil cable before the mains power of the

transmitter has been disconnected!.

For more details on wiring refer to UMF2B Instruction Manual

Heinrichs Messtechnik GmbH

Page 20 of 23

Operating Manual PIT / UMF2B

11 Returning the Meter

If all attempts to return the device to an operational condition have failed, contact our service department to

arrange the return of your device for repair.

Before sending the device back for repair or servicing, please ensure the following steps have been

performed:

Always enclose a fully completed declaration of decontamination. You will find a template in

section 11.1

Ensure all medium residues have been removed, be sure to clean the seal grooves and recesses

thoroughly.

Provide a description of the encountered problem, providing as much information as possible as

well as a contact person for following correspondence.

Inform us of any special handling requirements you or your processes may have.

Table of contents

Other Heinrichs Accessories manuals