Hino 600 Instruction manual

FOREWORD

This workshop manual has been prepared to provide information regarding repair procedures on Hino Trucks.

Applicable for HINO 238, 258LP, 268, 338 series, equipped with J08E-VB and J08E-VC engine

When making any repairs on your vehicle, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Driver’s / Owner’s Manual.

All information and specifications in this manual are based upon the latest product information available at the time of printing.

Hino Motors Sales U.S.A., Inc. reserves the right to make changes at any time without prior notice.

Please note that the publications below have also been prepared as relevant workshop manuals for the components and sys-

tems in these vehicles.

Manual Name Pub. No.

Chassis Workshop Manual S1-UNAE11A 2/2

J08E-VB, VC Engine Workshop Manual S5-UJ08E11A

Trouble Shooting Workshop Manual

S7-UNAE11A 1/3

S7-UNAE11A 2/3

S7-UNAE11A 3/3

MENU

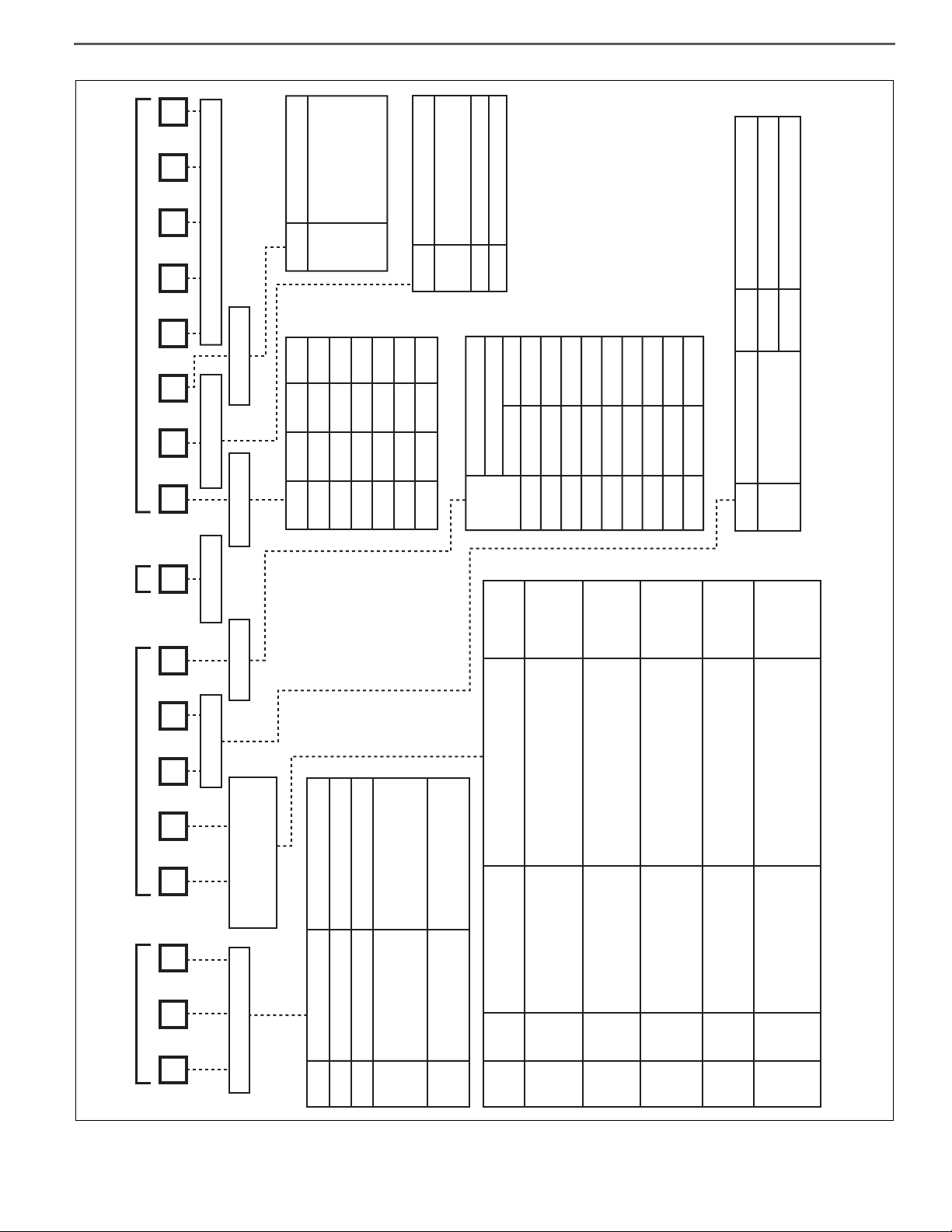

CHAPTER REFERENCES REGARDING THIS WORKSHOP MANUAL

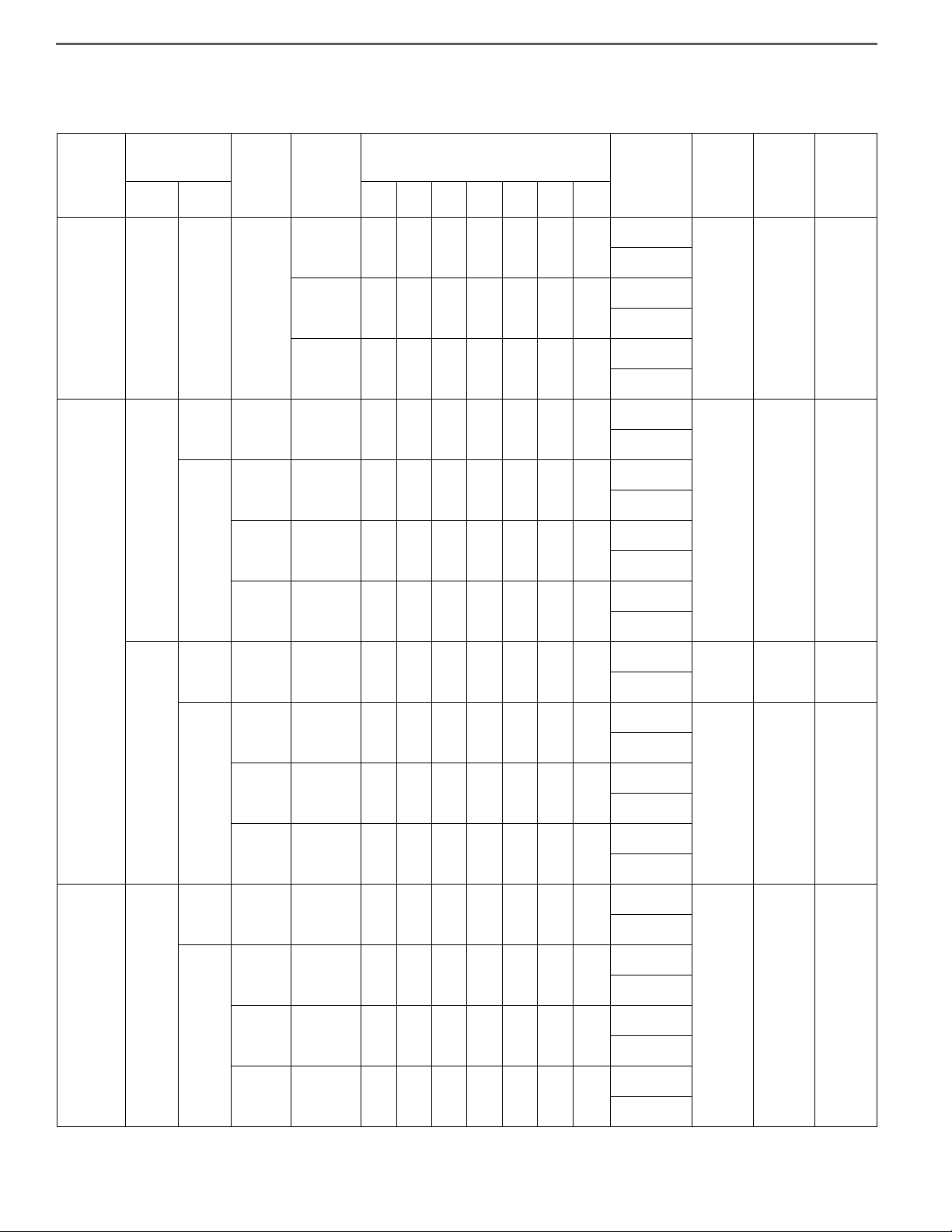

Use this chart to the appropriate chapter numbers for servicing your particular vehicle.

CHAPTER

MANUAL NO. S1-UNAE11A 1/2 (U.S.A.), S1-CNAE11A 1/2 (CANADA)

MODELS HINO 238, 258LP, 268, 338, 358

Production Model

Code NE8J, NF8J, NJ8J, NV8J

GENERAL INTRODUCTION GN02-001

CLUTCH MAIN UNIT CL02-001 CL02-002

CLUTCH CONTROL CL03-001

TRANSMISSION MAIN UNIT TR02-001

AUTOMATIC TRANSMISSION TR04-001 TR04-002

TRANSMISSION/TRANSFER CONTROL

TR06-001 TR06-002

PROPELLER SHAFT PP02-001

DIFFERENTIAL CARRIER DF02-001

BRAKE EQUIPMENT BR01-001 BR01-002

SERVICE BRAKE BR02-001 BR02-002

ABS (ANTI-LOCK BRAKE SYSTEM) BR03-001 BR03-002

EXHAUST BRAKE BR05-001

PARKING BRAKE BR07-001

STEERING EQUIPMENT SR01-001

STEERING UNIT SR02-001

POWER STEERING SR03-001

FRONT AXLE AX02-001

REAR AXLE AX03-001

WHEEL & TIRE AX04-001

SUSPENSION SU02-001

CHASSIS FRAME FC02-001

CAB CA02-001

ELECTRICAL EQUIPMENT EL01-001

ELECTRIC WIRE EL02-001

This manual does not contain items on half-tone dot meshing.

CLUTCH EQUIPMENT

CLUTCH MAIN UNIT

CLUTCH CONTROL

TRANSMISSION EQUIPMENT

TRANSMISSION MAIN UNIT

TRANSFER MAIN UNIT

AUTOMATIC TRANSMISSION

PTO (POWER TAKE-OFF)

TRANSMISSION / TRANSFER CONTROL

PROPELLER SHAFT

DIFFERENTIAL EQUIPMENT

DIFFERENTIAL CARRIER

INDEX: CHASSIS GROUP 1/4

PROPELLER SHAFT EQUIPMENT

BRAKE EQUIPMENT

SERVICE BRAKE

ABS

GENERAL INTRODUCTION

WORKSHOP

MANUAL

CAB EQUIPMENT

CAB

INDEX: CHASSIS GROUP 3/4

ELECTRICAL EQUIPMENT

ELECTRIC WIRE

HYBRID SYSTEM

ENGINE CONTROL

FUEL CONTROL

BRAKE CONTROL

SUSPENSION CONTROL

CAB EQUIPMENT CONTROL

OTHERS

INDEX: CHASSIS GROUP 4/4

GENERAL INTRODUCTION (CHASSIS) GN02–1

GN 0 2

GENERAL INTRODUCTION (CHASSIS) GN02-001

GENERAL INTRODUCTION.....................GN02-2

GENERAL PRECAUTIONS.............................GN02-2

IDENTIFICATION INFORMATION ...................GN02-5

HOW TO USE

THIS WORKSHOP MANUAL.........................GN02-12

PRECAUTIONS .............................................GN02-15

SEALANT ON THE TAPERED SCREW

FOR PIPING ..................................................GN02-18

NYLON TUBE REPLACEMENT METHOD ...GN02-19

METRIC INFORMATION ...............................GN02-21

SPECIFIED TORQUE

FOR STANDARD BOLTS AND NUTS ...........GN02-23

SPECIFIED TORQUE

FOR FLANGE BOLTS AND NUTS ................GN02-23

RECOMMENDED LUBRICANTS ..................GN02-25

VEHICLE LIFT

AND SUPPORT LOCATIONS........................GN02-27

INFORMATION DISPLAY ..............................GN02-29

SYMPTOM SIMULATION ..............................GN02-34

GLOSSARY ...................................................GN02-36

GLOSSARY OF SAE AND HINO TERMS.....GN02-39

GENERAL INTRODUCTION (CHASSIS)GN02–2

GENERAL INTRODUCTION

GENERAL PRECAUTIONS

EN00Z00020100001

Some recommended and standard maintenance services for your vehicle are included in this section. When performing main-

tenance on your vehicle be careful not to get injured by improper work. Improper or incomplete work can cause a malfunction

of the vehicle which may result in personal injury and/or property damage. If you have any question about performing mainte-

nance, please consult your Hino dealer.

DEFINITION OF SAFETY TERMS

WARNING

When working on your vehicle, observe the following general precautions to prevent death, personal injury and/or

property damage in addition to the particular DANGERS, WARNINGS, CAUTIONS and NOTICES in each chapter.

•Always wear safety glasses or goggles to protect your eyes.

•Remove rings, watches, ties, loose hanging jewelry and loose clothing before starting work on the vehicle.

•Bind long hair securely behind the head.

•When working on the vehicle, apply the parking brake firmly, place the gear shift lever in "Neutral" or "N" and

block the wheels.

•Always turn off the starter switch to stop the engine, unless the operation requires the engine running. Remov-

ing the key from the switch is recommended.

•To avoid serious burns, keep yourself away from hot metal parts such as the engine, exhaust manifold, radia-

tor, muffler, exhaust pipe and tail pipe.

•Do not smoke while working on the vehicle since fuel, and gas from battery are flammable.

•Take utmost care when working on the battery. It contains corrosive sulfuric acid.

•Large electric current flows through the battery cable and starter cable. Be careful not to cause a short which

can result in personal injury and/or property damage.

•Read carefully and observe the instructions specified on the jack before using it.

•Use safety stands to support the vehicle whenever you need to work under it. It is dangerous to work under a

vehicle supported only by a jack.

•If it is necessary to run the engine after the hood is raised (tilted), make sure that the parking brake is firmly

applied, the wheels are blocked, and the gear shift lever is positioned in "Neutral" before staring the engine.

•Run the engine only in a well-ventilated area to avoid inhalation of carbon monoxide.

•Keep yourself, your clothing and your tools away from moving parts such as the cooling fan and V-belts when

the engine is running.

•Be careful not to damage lines and hoses by stepping or holding your feet on them.

•Be careful not to leave any tool in the engine compartment. The tool may be hit by moving parts, which can

cause personal injury.

Indicates an extremely hazardous situation if proper procedures are not followed and could

result in death or serious injury.

Indicates a potential hazardous situation if proper procedures are not followed and could

result in death or serious injury.

Indicates a hazardous situation if proper procedures are not followed and could result in

serious injury or damage to parts/equipment.

Indicates the need to follow proper procedures and to pay attention to precautions so that

efficient service is provided.

Provides additional information to help you to perform the repair efficiently.

GENERAL INTRODUCTION (CHASSIS) GN02–3

TOWING

•When being towed, always place the gear shift lever in "Neutral" and release the parking brake completely. In order to

protect the bumper, fit a protection bar against the lower edge of the bumper and put a wood block under the frame near

the No. 1 cross member when attaching the towing chain. Never lift or tow the vehicle if the chain is in direct contact with

the bumper.

1. Towing procedures

(1) Make sure that the propeller shaft of the vehicle to be towed is removed. When the differential gear or rear axle shaft is

defective, remove both right and left rear axle shafts, then cover the hub opening to prevent loss of axle lubricant and

entry of dirt or foreign matter.

(2) Use a heavy duty cable or rope when towing the vehicle. Fasten the cable securely to the towing hook on the frame.

(3) The angle of pulling direction of the cable fastened to the towing hook must not exceed 15in horizontal and vertical

directions from the straight ahead, level direction. Avoid using the hook in a way that subjects it to jerk, as in towing a

vehicle trapped in a gutter.

(4) Keep the gear shift lever in Neutral.

(5) Make sure that the starter switch is kept in the "ON" position, if the engine is not running.

(6) Make sure that the engine of the towed vehicle is kept running. If the engine is off, no compressed air/ no vacuum will be

available for the brake. This is dangerous, as the brake system does not function if the engine is not running.

In addition, the power steering system will not function. The steering wheel, therefore, will become unusually hard to turn,

making it impossible to control the vehicle.

(7) Note that the engine brake and exhaust brake cannot be applied, if the propeller shaft is removed.

(8) Make a slow start to minimize shock. Towing speed should be less than 30 km/h {18 mile/h}.

2. If the engine of the towed vehicle is defective, make sure that the vehicle is towed only by a tow truck designed

for that purpose.

(1) Front end towing (with front wheels raised off the ground)

When towing from the front end with the front wheels raised off the ground, remove the rear axle shafts to protect the

transmission and differential gears from being damaged. The hub openings should be covered to prevent the loss of axle

lubricant or the entry of dirt or foreign matter. The above-mentioned precautions should be observed for vehicles

equipped with either manual or automatic transmission, and for even short distance towing. After being towed, check and

refill the rear axle housing with lubricant if necessary.

(2) Rear end towing

When being towed with the rear wheels raised off the ground, fasten and secure the steering wheel in a straight-ahead

position.

CLEAN AIR ACT

1. Heavy-duty engine rebuilding practices.

§ 86.004-40

•The provisions of this section are applicable to heavy-duty engines subject to model year 2004 or later standards and are

applicable to the process of engine rebuilding (or rebuilding a portion of an engine or engine system). The process of

engine rebuilding generally includes disassembly, replacement of multiple parts due to wear, and reassembly, and also

may include the removal of the engine from the vehicle and other acts associated with rebuilding an engine. Any deviation

from the provisions contained in this section is a prohibited act under section 203(a) (3) of the Clean Air Act (42 U.S.C.

7522(a) (3)).

(1) When rebuilding an engine, portions of an engine, or an engine system, there must be a reasonable technical basis for

knowing that the resultant engine is equivalent, from an emissions standpoint, to a certified configuration (i.e., tolerances,

calibrations, specifications) and the model year(s) of the resulting engine configuration must be identified. A reasonable

basis would exist if:

a. Parts installed, whether the parts are new, used, or rebuilt, are such that a person familiar with the design and func-

tion of motor vehicle engines would reasonably believe that the parts perform the same function with respect to emis-

sions control as the original parts; and

b. Any parameter adjustment or design element change is made only:

In accordance with the original engine manufacturer's instructions; or

Where data or other reasonable technical basis exists that such parameter adjustment or design element change,

when performed on the engine or similar engines, is not expected to adversely affect in-use emissions.

(2) When an engine is being rebuilt and remains installed or is reinstalled in the same vehicle, it must be rebuilt to a configu-

ration of the same or later model year as the original engine. When an engine is being replaced, the replacement engine

must be an engine of (or rebuilt to) a configuration of the same or later model year as the original engine.

GENERAL INTRODUCTION (CHASSIS)GN02–4

(3) At time of rebuild, emissions-related codes or signals from on-board monitoring systems may not be erased or reset with-

out diagnosing and responding appropriately to the diagnostic codes, regardless of whether the systems are installed to

satisfy requirements in § 86.004-25 or for other reasons and regardless of form or interface. Diagnostic systems must be

free of all such codes when the rebuilt engine is returned to service. Such signals may not be rendered inoperative during

the rebuilding process.

(4) When conducting a rebuild without removing the engine from the vehicle, or during the installation of a rebuilt engine, all

critical emissions-related components listed in § 86.004-25(2) not otherwise addressed by paragraphs (1) through (3) of

this section must be checked and cleaned, adjusted, repaired, or replaced as necessary, following manufacturer recom-

mended practices.

(5) Records shall be kept by parties conducting activities included in paragraphs (1) through (4) of this section. The records

shall include at minimum the mileage and/or hours at time of rebuild, a listing of work performed on the engine and emis-

sions-related control components including a listing of parts and components used, engine parameter adjustments, emis-

sions-related codes or signals responded to and reset, and work performed under paragraph (4) of this section.

a. Parties may keep records in whatever format or system they choose as long as the records are understandable to an

EPA enforcement officer or can be otherwise provided to an EPA enforcement officer in an understandable format

when requested.

b. Parties are not required to keep records of information that is not reasonably available through normal business prac-

tices including information on activities not conducted by themselves or information that they cannot reasonably

access.

c. Parties may keep records of their rebuilding practices for an engine family rather than on each individual engine

rebuilt in cases where those rebuild practices are followed routinely.

d. Records must be kept for a minimum of two years after the engine is rebuilt.

2. Maintenance instructions.

§ 86.010-38

(1) For each new diesel-fueled engine subject to the standards prescribed in § 86.007-11, as applicable, the manufacturer

shall furnish or cause to be furnished to the ultimate purchaser a statement that

"This engine must be operated only with ultra low-sulfur diesel fuel (meeting EPA specifications for highway die-

sel fuel, including a 15 ppm sulfur cap)."

GENERAL INTRODUCTION (CHASSIS) GN02–5

IDENTIFICATION INFORMATION

EN00Z00020200001

1. VEHICLE IDENTIFICATION NUMBER

•VEHICLE IDENTIFICATION NUMBER (VIN) is comprised of 17 digits and letters. The VIN label is affixed to the left pillar

of the cab.

These numbers are used for identification purposes when you have a vehicle registered or inspected. Please quote these

numbers when ordering spare parts or reporting technical matter to receive prompt service attention.

•The following is an explanation of the items that are listed on the VIN label.

VIN

label

GENERAL INTRODUCTION (CHASSIS)GN02–6

(1) VIN

See VEHICLE IDENTIFICATION NUMBER (VIN) STRUCTURE on the following page.

(2) P.S. (PRODUCTION SERIES) AND VEHICLE COMPONENTS

MODEL

(CLASS)

PRODUC-

TION CODE CLUTCH

SIZE

TRANS-

MIS-

SION

SERIES

TRANSMISSION RATIO REAR

AXLE

SERIES

SER-

VICE

BRAKE

PARK-

ING

BRAKE

SUSPEN-

SION

MODEL SERIES 1st 2nd 3rd 4th 5th 6th Rev.

HINO238

(6) NE8J HBC -

2200HS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

RS17-145

HD

L

or

A

RS19-145

2200RDS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

RS17-145

RS19-145

2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

RS17-145

RS19-145

HINO258

(6)

NE8J

GBC 350mm FS5406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

RS17-145

HD

L

or

A

RS19-145

HBC

- 2200HS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

RS17-145

RS19-145

- 2200RDS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

RS17-145

RS19-145

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

RS17-145

RS19-145

NJ8J

JBC 350mm FS5406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

RS17-145

FWA

RS19-145

KBC

- 2200HS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

RS17-145

FW

L

or

A

RS19-145

- 2200RDS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

RS17-145

RS19-145

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

RS17-145

RS19-145

HINO268

(6) NE8J

GBC 350mm FS5406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

RS17-145

HD

L

or

A

RS19-145

HBC

- 2200HS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

RS17-145

RS19-145

- 2200RDS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

RS17-145

RS19-145

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

RS17-145

RS19-145

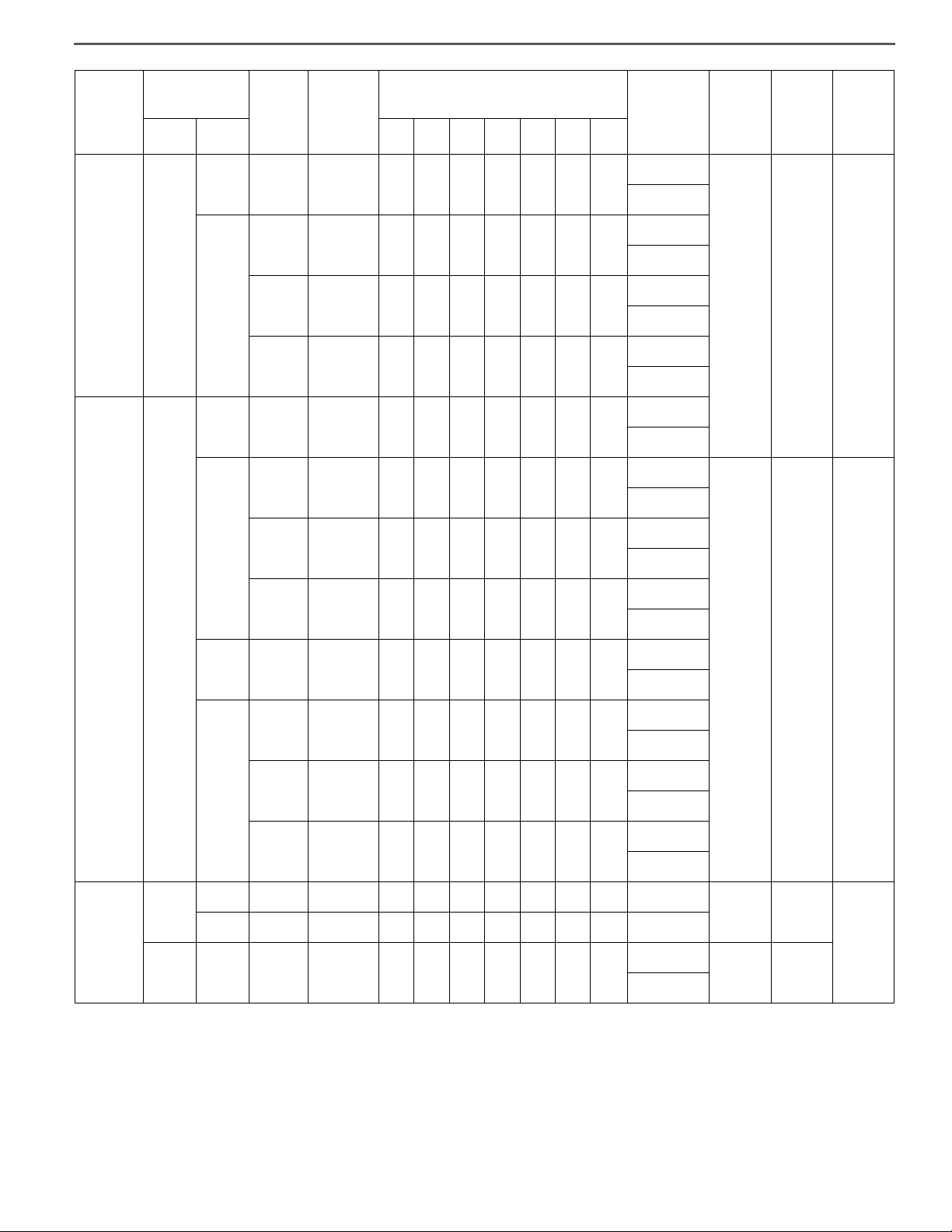

GENERAL INTRODUCTION (CHASSIS) GN02–7

HINO268

(6) NJ8J

JBC 350mm FS5406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

RS17-145

FWL

or

A

RS19-145

KBC

- 2200HS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

RS17-145

RS19-145

- 2200RDS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

RS17-145

RS19-145

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

RS17-145

RS19-145

HINO268

(7)

NV8J

NBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

RS21-145

RS23-160

PBC

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

RS21-145

FW

L

or

A

RS23-160

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03

RS21-145

RS23-160

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00

RS21-145

RS23-160

TBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

RS21-145

RS23-160

SBC

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

RS21-145

RS23-160

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03

RS21-145

RS23-160

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00

RS21-145

RS23-160

HINO338

(7)

NF8J

DBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63 RS21-145

HDL

or

A

EBC - 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09 RS21-145

NV8J NBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

RS21-145

FW

RS23-160

MODEL

(CLASS)

PRODUC-

TION CODE CLUTCH

SIZE

TRANS-

MIS-

SION

SERIES

TRANSMISSION RATIO REAR

AXLE

SERIES

SER-

VICE

BRAKE

PARK-

ING

BRAKE

SUSPEN-

SION

MODEL SERIES 1st 2nd 3rd 4th 5th 6th Rev.

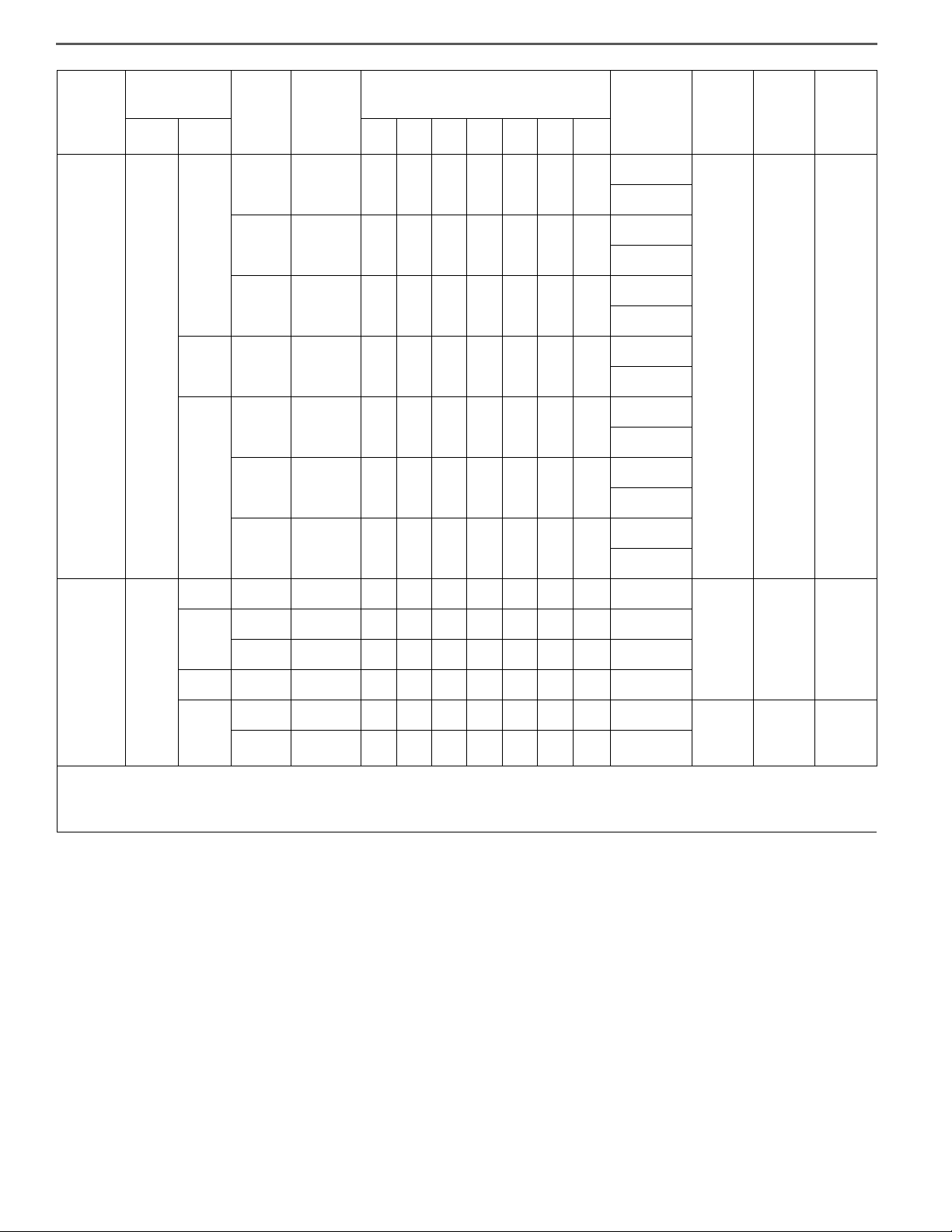

GENERAL INTRODUCTION (CHASSIS)GN02–8

HINO338

(7) NV8J

PBC

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

RS21-145

FW

L

or

A

RS23-160

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03

RS21-145

RS23-160

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00

RS21-145

RS23-160

TBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

RS21-145

RS23-160

SBC

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

RS21-145

RS23-160

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03

RS21-145

RS23-160

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00

RS21-145

RS23-160

HINO358

(8)

NH8J

NBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63 RS23-160

FW

L

or

A

PBC

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03 RS23-160

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00 RS23-160

TBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63 RS23-160

SBC

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03 RS23-160

FW

L

or

A

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00 RS23-160

CODE SERVICE BRAKE

H: Hydraulic

F: Full air

PARKING BRAKE CONTROL CODE

D: ACTING ON DIFFERENTIAL

W: ACTING ON REAR WHEEL

SUSPENSION

L: LEAF

A: AIR

MODEL

(CLASS)

PRODUC-

TION CODE CLUTCH

SIZE

TRANS-

MIS-

SION

SERIES

TRANSMISSION RATIO REAR

AXLE

SERIES

SER-

VICE

BRAKE

PARK-

ING

BRAKE

SUSPEN-

SION

MODEL SERIES 1st 2nd 3rd 4th 5th 6th Rev.

GENERAL INTRODUCTION (CHASSIS) GN02–9

HINO VEHICLE IDENTIFICATION NUMBER (VIN) STRUCTURE FOR U.S.A. and CANADA (2015MY)

WMI VDS CD VIS

12 3 4 56 78 9 10111213141516

5P V N J 8 J T 4 F 4 S1 0 0 0

17

1

MANUFACTURER TYPE MAKE, MODEL

LINE & CAB/BODY TYPE,

SERIES, BRAKE SYSTEM

MODEL YEAR

ASSEMBLY PLANT

ENGINE MODEL

WHEEL BASE

CHECK DIGIT

MODIFICATION

SEQUENTIAL NUMBER

CODE

JHA

JHB

TRUCK

INCOMPLETE VEHICLE

TYPEMANUFACTURER

HINO MOTORS, LTD.

HINO MOTORS, LTD.

5PV INCOMPLETE VEHICLE

HINO MOTORS

MANUFACTURING

U.S.A., INC.

2AY INCOMPLETE VEHICLE

HINO MOTORS

CANADA, LTD.

CODE

P

CODE

2023

YEARYEAR

R 2024

S 2025

T 2026L 2020

M 2021

N 2022

H 2017

J 2018

K 2019

F 2015

G 2016

CODE

8J J08E-VC

MODEL

7.6 LITERS, DIESEL 220HP

J08E-VB 7.6 LITERS, DIESEL 260HP

DESCRIPTIONMANUFACTURER

HINO MOTORS, LTD.

CODE

G 3,861

LENGTH

NE - NV

mm in.

J4,445

L4,750

M5,207

N5,385

P5,512

R5,969

T6,426

V6,883

152

175

187

205

212

217

235

253

271

CODE

S

DESCRIPTION

A NEW LETTER

T WILL BE ALLOTTED

U AT EVERY MAJOR

... MODIFICATION

Z

CODE

1

ASSEMBLY PLANT

HINO MOTORS, LTD.

HINO PLANT IN JAPAN

3 Canada Plant

4 W.V Plant

MODEL

CODE

MAKE

NF HYDRAULIC

LINE & CAB/BODY TYPE

INCOMPLETE VEHICLE

Intended GVWR and Vehicle Class

and Class

BRAKE

SYSTEMS

NV

FULL AIR

FULL AIR

INCOMPLETE VEHICLE

INCOMPLETE VEHICLE

INCOMPLETE VEHICLE

INCOMPLETE VEHICLE

NJ 10434 kg. - 11793 kg or less

[23,001 - 26,000 (lbs.)] (CLASS 6)

13609 kg. - 14968 kg or less

[30,001 - 33,000 (lbs.)] (CLASS 7)

13609 kg. - 14968 kg or less

[30,001 - 33,000 (lbs.)] (CLASS 7)

14969 kg - 15875 kg or less

[33,001 - 35,000 (lbs.) ] (CLASS 8)

NE

HINO

HINO

NHHINO

HINO

HINO 8846 kg. - 11793 kg or less

[19,501 - 26,000 (lbs.)] (CLASS 6) HYDRAULIC

FULL AIR

SHTS00Z000200007

GENERAL INTRODUCTION (CHASSIS)GN02–10

2. VEHICLE NOISE EMISSION CONTROL INFORMATION

•The Vehicle Noise Emission Control Information is affixed to the side

of the left door. The name of manufacturer, production year and

month, and noise emission applicable to medium and heavy trucks in

conformity with U.S. EPA Regulations are displayed.

3. ENGINE SERIAL NUMBERS.

•Please quote these numbers when ordering spare parts or reporting

technical matter to receive prompt service attention.

The engine serial number is engraved on the engine cylinder block.

4. CHASSIS SERIAL NUMBER

•Chassis serial number is engraved on the left side frame near the

front wheel.

5. CLEAN IDLE CERTIFIED LABEL FOR U.S.

•Make sure that the following clean engine idling certified label is

affixed to the outside of the left door.

By the CARB below, the label must be affixed there to prove that the

new vehicle with diesel engine manufactured from Jan., 2008 con-

forms to this low.

VEHICLE NOISE EMISSION CONTROL INFORMATION

THIS VEHICLE CONFORMS TO U.S. EPA REGULATIONS FOR NOISE

EMISSION APPLICABLE TO MEDIUM AND HEAVY TRUCKS.

THE FOLLOWING ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE

PROHIBITED BY THE NOISE CONTROL ACT OF 1972.

(A)THE REMOVAL OR RENDERING INOPERATIVE. OTHER THAN FOR

PURPOSES OF MAINTENANCE, REPAIR, OR REPLACEMENT, OF ANY

NOISE CONTROL DEVICE OR ELEMENT OF DESIGN (LISTED IN THE

OWNER' S MANUAL) INCORPORATED INTO THIS VEHICLE IN

COMPLIANCE WITH THE NOISE CONTROL ACT.

(B)THE USE OF THIS VEHICLE AFTER SUCH DEVICE OR ELEMENT OF

DESIGN HAS BEEN REMOVED OR RENDERED INOPERATIVE.

MFD BY:HINO MOTORS, LTD. DATE OF MANUFACTURE 03/2009

For all models

SHTS00Z000200010

SHTS00Z000200011

SHTS00Z000200012

SHTS00Z000200013-C

CARB § 1956.8. Exhaust Emission Standard and Test Procedure

(a) (b) Heavy-Duty Diesel Engine Idling Requirements

GENERAL INTRODUCTION (CHASSIS) GN02–11

6. VEHICLE EMISSION CONTROL INFORMATION

•The Vehicle Emission Control Information is affixed to the side of the

left door. The name of manufacturer, production year and month, and

emission applicable to medium and heavy trucks in conformity with

U.S. EPA Regulations are displayed.

VIN

label

Vehicle emission

control information

GN02-13-1-0

For example

GN02-13-1-1

GENERAL INTRODUCTION (CHASSIS)GN02–12

HOW TO USE THIS WORKSHOP MANUAL

EN00Z00020200002

This workshop manual is designed as a guide for servicing the vehicle.

An INDEX is provided on the first page of each chapter.

TROUBLESHOOTING is dealt with in each chapter.

When beginning operations, refer to the TROUBLESHOOTING section for

a guide to appropriate diagnosis.

SPECIAL TOOL is dealt with in each chapter.

When ordering a special tool, confirm the part number with the applicable

parts catalog.

•RERAIR PROCEDURES

Repair procedures when self-explanatory, such as simple installation

and removal of parts, have been omitted. Illustrations, such as the

one below, have been provided to make such simple procedures

clear. Only essential procedures requiring specific directions have

been dealt with explicitly.

GENERAL INTRODUCTION (CHASSIS) GN02–13

MAIN CYLINDER

EXAMPLE:

Tightening torque Unit: Nm {kgfcm, lbfft}

In some cases, illustrations may be of parts which differ in some nonessen-

tial way from the parts found on your particular vehicle. In such cases, the

principle or procedure being illustrated applies regardless of such nones-

sential differences.

•DEFINITION OF TERMS

Definition of vehicle right and left.

Right and left refers to the left and right sides of the vehicle as seen

while looking down the center line from the rear towards the front.

SHTS00Z000200014

1 Clevis 8 Return spring

2 Lock nut 9 Body

3 Push rod 10 Hose joint

4 Boot 11 O-ring

5 Retainer ring 12 Soft washer

6 Thrust washer 13 Bolt

7Piston

A 2.5-4.4 {25-45, 1.8-3.2}

GENERAL INTRODUCTION (CHASSIS)GN02–14

SHTS00Z000200015C

Table of contents

Other Hino Automobile manuals