15. DoNotOverreach

Keep proper footing and balance at all time.

16. Maintain Tools With Care

Keep tools sharp and clean for better and safer

performance.

Do not use dull or broken Rotabroach Cutters.

Follow instructions for lubricating and changing

accessories.

Inspect tool cords periodically and, if damaged,

have repaired by authorized service facility.

Inspect extension cords periodically and, if damaged,

have repaired by authorized service facility.

Keep handles dry, clean, and free from oil and

grease.

17. Disconnect Tools

Disconnect when not in use, before servicing, and when

changing Rotabroach Cutters or accessories.

18. Remove Adjusting Keys and Wrenches

Form a habit of checking to see that keys and

wrenches are removed from tool before turning it on.

19. Check Damaged Parts

Before further use of the drill, a part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A part

that is damaged should be properly repaired or replaced

by an authorized service center unless otherwise

indicated elsewhere in this operator manual. Do not

operate tool if switch does not turn it on and off.

20. Stay Alert

Watch what you are doing.

Use common sense.

Do not operate tool when you are tired.

Have defective switches replaced by authorized service

center.

21. Outdoor Use Extension Cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

22. AdditionalSafetyPrecautions

Spindle and cutter should never be used as a hand-

hold.

Keep hands and clothing away from all moving parts.

Do not use Rotabroach Cutters where ejected slug

might cause injury (slug ejected at end of cut).

Be sure that all safety devices are properly adjusted

and in use. Also, adhere to all operating instruc-

tions.

Do not drill through any surface that may contain live

electrical wiring. Drilling into a live wire could cause

exposed metal parts of the drill to be made live.

Remove chips wrapped around Rotabroach Cutter

and arbor after each hole. With motor off and

power disconnected, grasp chips with leather gloved

hand or pliers and pull while rotating counter-

clockwise.

Should the cutter become jammed in the work, stop

the unit immediately to prevent personal injury.

Disconnect the drill from the power supply and loosen

jammed cutter by turning the arbor counterclockwise.

Never attempt to free the jammed cutter by starting the

motor.

Service at authorized repair center only.

23. Non-Conforming Cutting Tools

Your Magnetic Drill is designed to use Hougen

Rotabroach Cutters. The use of drilling tools having

different shank styles is not recommended as they may

not tighten securely in the drill arbor with risk of acci-

dent or injury.

24. Operating Near Welding Equipment

When operating your Magnetic Drill near an arc welder,

it is important that they are connected to the same Earth

Ground. If they are not, severe damage to the unit,

particularly the power cord, could occur. This could

also result in personal injury to the operator.

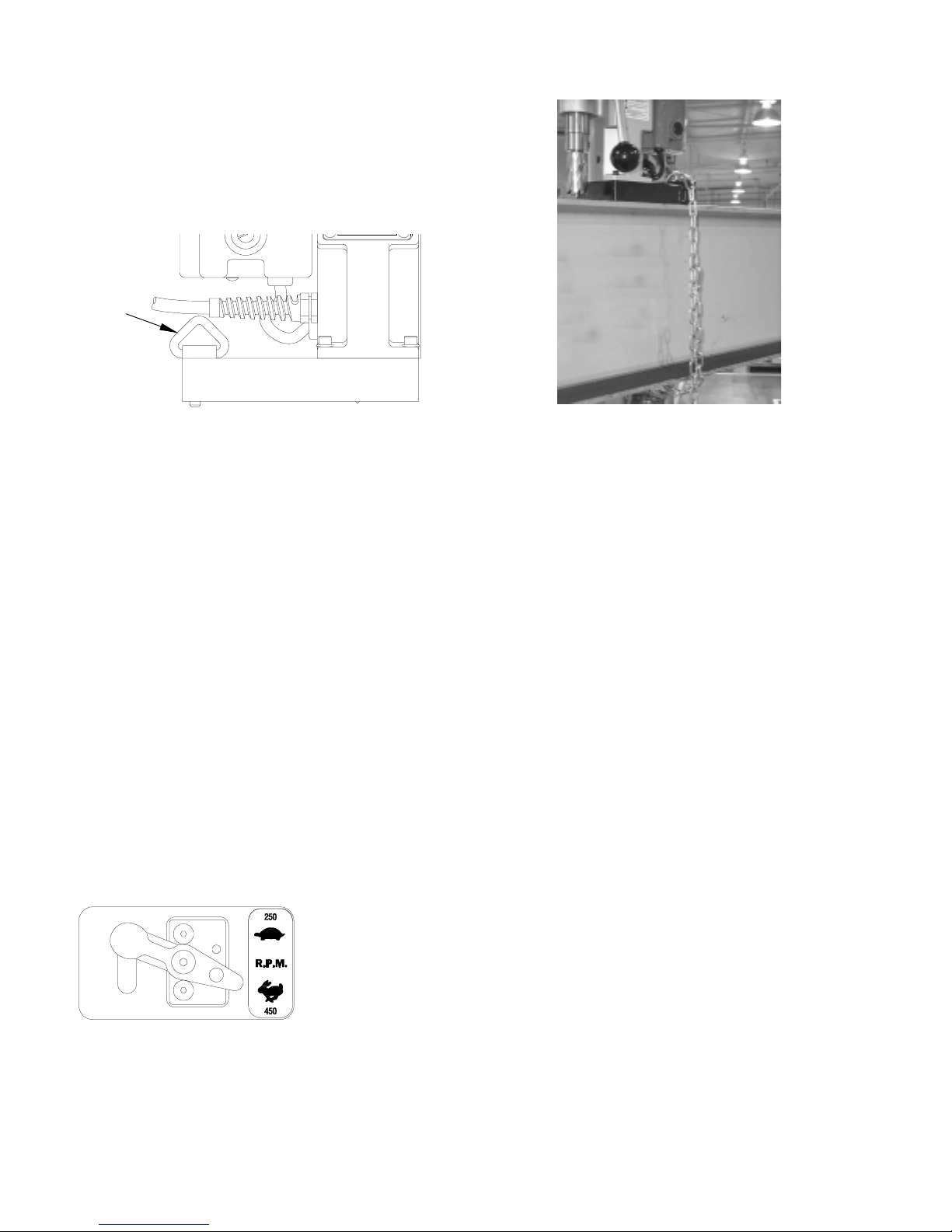

25. SafeElectricalConnection

Wet electrical connections are

shock hazards. To prevent the

cutting fluid from traveling along

the cord and contacting the plug

or power outlet, tie a drip loop as

shown at right. Also elevate

extension cords or gang box

connections.

26. Save These Instructions

IMPORTANTSAFETYINSTRUCTIONS