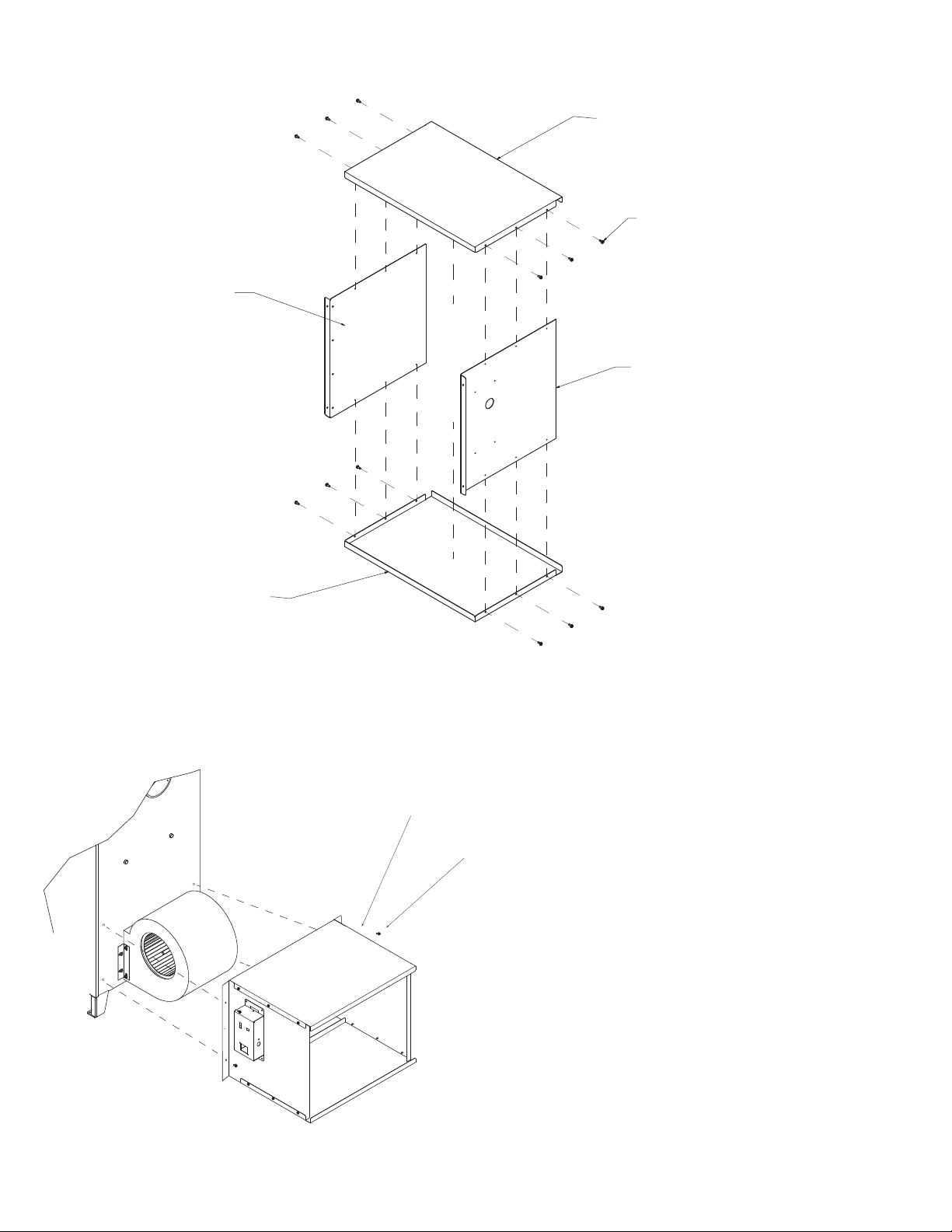

General Information

The Shelter 2020 EPA-Certied Furnace has been engineered to accommodate the heating requirements of the average sized

home, even during winter’s coldest months. It is constructed with high grade, heavy gauge steel and is continuously welded to

assure the highest structural strength. In addition, the rebox is lined with insulated stainless steel panels to ensure many years of

energy efcient service. The design of the secondary combustion chamber increases fuel efciency by creating a “secondary burn”

of smoke and wood gases before they are vented up the chimney. The cast iron doors are custom tted to provide an airtight seal,

greatly extending the burn time and ensuring maximum efciency in fuel consumption. The heavy-gage cast iron grate allows for

convenient ash removal and reduced maintenance.

For total comfort and convenience, a thermostatically-controlled Draft Blower and fan-limit-controlled Circulation Blower are

included. These fully automatic components provide heat disbursement throughout your home, minimizing recovery time when

the wall thermostat demands heat.

All of these features are standard, offering you the most efcient, durable, and affordable indoor wood burning furnace.

Efciency was determined using the higher heating value of the fuel per B415.1-10 testing requirements. Dry seasoned wood will

develop greater BTU output. A well-insulated dwelling will always lead to better results and overall improved fuel usage efciency.

Your Shelter Furnace is designed to be either a supplemental or central heating source for your home. This wood burning furnace

may be installed in parallel with a properly operating electric, gas or oil-red central furnace, listed or certied in accordance with a

nationally recognized safety standard, and within clearances specied on the nameplate. When in a parallel installation, the static

pressure of the central furnace plenum may not exceed 0.15 water column inches, and the maximum setting on the central furnace

limit switch is 182°F. With the Shelter Furnace in an “Interconnection Arrangement,” your furnace should be upstream of the central

furnace. The Shelter Furnace warm air supply should never be connected to return air for the central furnace. A qualied installer

should perform the installation.

Forced Hot Air Circulation:

The plenum size of your Shelter Furnace must not be reduced to less than 100 square inches, and must provide a minimum of 18

inches between the top of your Shelter Furnace and the main trunk connection. Do not modify the outer shell of the furnace at any

time. The plenum attached to the furnace must be constructed of metal. The warm air supply duct system should be constructed of

materials with a minimum temperature rating of 250°F.

Clearances:

Unit must be placed on a non-combustible oor. This oor must extend at least 16 inches in front of, and 8 inches on either side of,

the fuel loading and ash removal doors; underneath the chimney connector; and 2 inches on either side of the chimney connector.

The furnace must maintain the following clearances to combustibles:

• Heat plenum = 2 inches

• Chimney connector = 18 inches

• Front = 48 inches

• Rear = 12 inches

• Sides = 6 inches

• Main furnace = 12 inches

These are minimum clearances and should be strictly followed. In the case of a power outage, a dangerous level of heat

accumulation may develop. Do not store fuel or other combustible materials within installation clearances.

4

IMPORTANT: FOR TECHNICAL SUPPORT OR CUSTOMER SERVICE

ISSUES, DO NOT RETURN TO THE STORE OR TO THE DEALER.

CALL 1-800-875-4788.