Industrial Fiber Optics IF 511 User manual

Laser Audio Transmission

Project

Experiment & Product Guide

IF 511 and IF 512

INDUSTRIAL FIBER OPTICS

*

Copyright © 2010

Previous Printings 2000, 2003, 2006

by Industrial Fiber Optics, Inc.

Revision - C

Printed in the United States of America

* * *

All rights reserved. No part of this publication may be reproduced, stored in

a retrieval system, or transmitted in any form or by any means (electronic,

mechanical, photocopying, recording, or otherwise) without prior written

permission from Industrial Fiber Optics, Inc.

* * * * *

- i -

Introduction

This manual provides information about Industrial Fiber Optics' Laser Audio

Transmission Project. The project can be purchased with either a Helium Neon

(HeNe) laser, IF HN08M (P/N IF 511), or a Semiconductor Diode laser, IF RL08-635

(P/N IF 512), as the laser light transmission source. The manual contains all the

information you need for both lasers to complete this project safely and

knowledgeably, even if you are a novice to this technology. Please read the manual

carefully while completing activities.

As soon as you receive the Laser Audio Transmission Project, inspect it and the

shipping container for damage. If any damage is found, immediately refer to the

section of this manual entitled "Shipment Damage Claims". Then check the contents

against the appropriate kit listed in Table 1.

Industrial Fiber Optics makes every effort to incorporate state-of-the-art

technology, highest quality and dependability in its products. We constantly explore

new ideas and products to best serve the rapidly expanding needs of industry and

education. We encourage comments that you may have about our products, and we

welcome the opportunity to discuss new ideas that may better serve your needs. For

more information about our company and products refer to http//www.i-

fiberoptics.com on the Worldwide Web.

Thank you for selecting this Industrial Fiber Optics product. We hope it meets

your expectations and provides many hours of productive activity.

Sincerely,

The Staff at Industrial Fiber Optics

- ii -

- iii -

TABLE OF CONTENTS

Introduction

.................................................................................... i

LASER CLASSIFICATIONS ..................................................... iv

PROJECT KIT COMPONENTS ................................................ 1

LIGHT for COMMUNICATION.................................................. 2

ACTIVITIES

HeNe Procedure..................................................................... 3

Diode laser Procedure ............................................................ 5

Fiber Optic Procedure ............................................................. 7

TROUBLESHOOTING............................................................... 8

SERVICE AND MAINTENANCE ............................................. 9

WARRANTY .............................................................................. 10

SHIPMENT DAMAGE CLAIMS ................................................ 11

- iv -

LASER CLASSIFICATIONS

All manufacturers of lasers used in the United States must conform to regulations

administered by the Center for Devices and Radiological Health (CDRH), a branch of the U.S.

Department of Health and Human Services. CDRH categorizes lasers as follows:

Class

Description

I A laser or laser system which does not present a hazard to skin or eyes

for any wavelength or exposure time. Exposure varies with wavelength.

For ultraviolet, .2 to .4 !m exposure is less than from .8 nW to .8 !W.

Visible light exposure varies from .4 !W to 200 !W, and for near IR, the

exposure is < 200 !W. Consult CDRH regulations for specific

information.

II Any visible laser with an output less than 1 mW of power. Warning label

requirements — yellow caution label stating maximum output of 1 mW.

Generally used as classroom lab lasers, supermarket scanners and

laser pointers.

IIIa Any visible laser with an output over 1 mW of power with a maximum

output of 5 mW of power. Warning label requirements — red danger label

stating maximum output of 5 mW. Also used as classroom lab lasers, in

holography, laser pointers, leveling instruments, measuring devices and

alignment equipment.

IIIb Any laser with an output over 5 mW of power with a maximum output of

500 mW of power and all invisible lasers with an output up to 400 mW.

Warning label requirements — red danger label stating maximum output.

These lasers also require a key switch for operation and a 3.5-second

delay when the laser is turned on. Used in many of the same applications

as the Class IIIa when more power is required.

IV Any laser with an output over 500 mW of power. Warning label

requirements — red danger label stating maximum output. These lasers

are primarily used in industrial applications such as tooling, machining,

cutting and welding. Most medical laser applications also require these

high-powered lasers.

- 1 -

Project Kit Components

Table 1 lists all components included in both models of the Laser Audio

Transmission Kit. Before proceeding to activities, identify each component listed in the

table below for the appropriate kit number.

Table 1. P roje ct kits com ponen t lis t.

General Description P/N

IF 511

P/N

IF 512 Quantity

Laser Audio Receiver IF 513 IF 513 1

Helium Neon (HeNe)

Laser

IF HN08M 1

Diode Laser IF RL08-635 1

Microphone 57 0022 57 0022 1

Plastic Optical Fiber IF C E1000 IF C E1000 3 meters

After inspecting your kit for the correct contents you can proceed to set up a

voice transmission project. Go to page 3 if you have the helium neon laser project and

to page 5 if you have the semiconductor laser project.

T abl e 2. C o mm on ab bre vi ati on s us ed i n t his m an ua l.

Abbr. Long version Scientific Notation

mW milliwatts 1 x 10-3 watts

!W microwatts 1 x 10-6 watts

nW nanowatts 1 x 10-9 watts

mm millimeters 1 x 10-3 meters

!m micrometers 1 x 10-6 meters

nm nanometers 1 x 10-9 meters

- 2 -

Light as Communication

Light is usually thought of as a modern means of communication, be it line of

sight directly from source to receiver or through a medium such as a fiber optic cable.

However, light has been used to provide communications since ancient times.

One of the earliest recorded uses of light for communications comes from the

ancient city of Alexandria. One of the 7 wonders of the ancient world was the Pharos

Lighthouse constructed around 290 BC. This impressive structure towered over the

city and provided guidance for sailors at sea as far as 35 miles. It used a mirror to

reflect sunlight during the day and bonfires at night to guide ships to the harbor.

Moving forward historically, the advent of modern communications with light

can be said to have started with Alexander Graham Bell. In addition to the telephone

this prolific inventor created what he called the photophone. Utilizing sunlight

reflected from mirrors Mr. Bell generated the worlds first wireless telephone call on

June 3, 1880. He considered this an even greater invention than the telephone, and

the ever growing field of fiber optic communications pays tribute to his belief that light

was the communication method of the future.

- 3 -

HeNe Laser Procedure

Equipment Needed:

• HeNe Laser ; IFO part number IF HN08

• 120-VAC to 12-VDC powe adapters (2)

• Microphone; IFO part number 57 0022

• Laser Audio Receiver; IFO part number IF 513

Procedure:

1. Choose a flat, level surface about 60 x 120 cm (2 x 4 feet) in size.

2. Collect all the items listed in the “EQUIPMENT NEEDED” section above.

3. Review the Rules for Laser Safety listed on the back cover of this booklet.

4. For detailed information regarding the operation of the helium neon laser refer

to its operating manual.

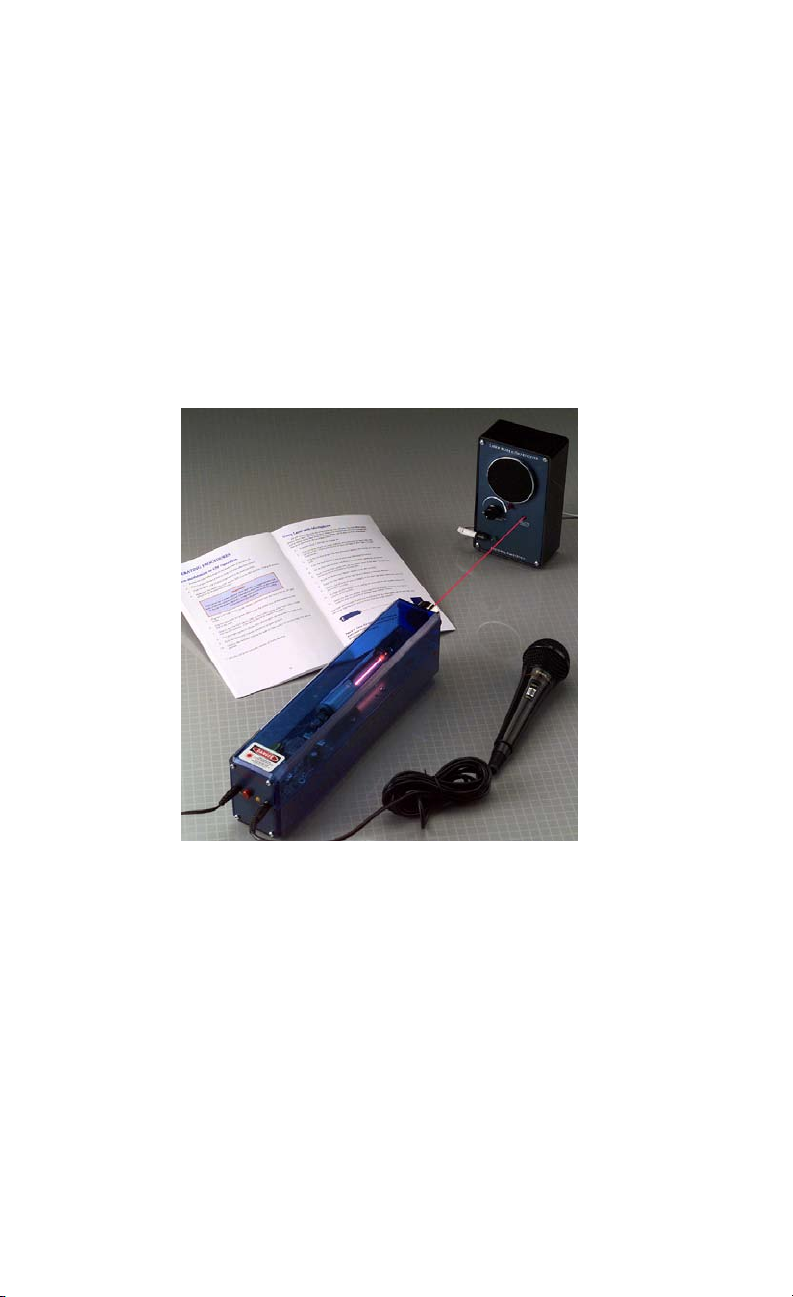

5. Position the laser and the receiver as shown in Figure 1.

6. Push the laser shutter’s handle downward to its closed position.

7. Make sure the laser's ON/OFF switch (SW) is in its OFF position. (The push

button should be in its extended position.)

audio

receiver

laser

Figure 1. Side vie w of th e lase r an d audio re ceiver.

8. Plug the VAC-to-DC laser power adapter into an AC electrical outlet.

9. Plug the cord from the power adapter into the power jack (PWR) located on

the rear of the laser.

10. Plug the VAC-to-DC audio receiver power adapter into an AC electrical outlet.

11. Plug the cord from the power adapter into the power jack located on the front

of the audio receiver.

12. Plug the microphone into the 3.5 mm audio jack on the back of the laser.

- 4 -

13. Depress the ON/OFF switch (SW) on the control panel of the laser until it

clicks into the ON position. (The switch should be slightly depressed.) The

pilot light (green LED) on the laser should now be lit, showing that it is on.

14. Open the laser shutter.

15. Dim the room lights to help you observe the laser

beam. Position the receiver in line with the laser

so the beam strikes the audio receiver close to

the photodetector access hole. Manually align

the beam with the optical input (photo diode) of

the audio receiver.

16. Turn on the microphone using the switch located

on the side.

17. Turn the ON/OFF volume knob on the audio

receiver to the 12 o’clock position. The pilot light

(yellow LED) on the audio receiver should now be lit, showing that it is on.

18. Speak into the microphone and listen for your voice to come out of the audio

receiver. If you do not hear your voice on the first attempt, continue to speak

into the microphone while turning up the volume control clockwise on the

audio receiver. If you reach maximum volume and still do not hear your voice,

realign the laser beam with the audio receiver while speaking into the

microphone.

19. When you have the audio receiver and the laser properly aligned you should

easily hear your voice from the receiver when you speak into the microphone.

20. If you continue to have problems at this point refer to the

“TROUBLESHOOTING” section in the back of the manual. If you have

successfully established an audio link using the laser continue with your

experiment.

21. Upon completing the experiment close the laser beam shutter. At this time

you can either continue to the Fiber Optic Transmission procedure on page 7

or switch off the laser and complete the remaining steps below.

22. Turn the volume knob on the audio receiver to the OFF position.

23. Turn off the microphone.

24. Unplug the power adapters from the electrical outlets, the laser and the audio

receiver.

25. Remove all equipment from the table and store in their proper locations.

Direct Laser Beam

through hole and

onto detector

1515.eps

Figu re 2. Clos e up

view of the

ali gn m en t la se r

beam to rece iver

ap ert u re.

- 5 -

Diode Laser Procedure

Equipment Needed:

• Diode Laser; IFO part number IF RL08-635

• 120 -VAC to 12-VDC power adapter (2)

• Microphone; IFO part number 57 0022

• Laser Audio Receiver; IFO part number IF 513

Procedure:

1. Choose a flat, level surface about 60 x 120 cm (2 x 4 feet) in size.

2. Collect all the items listed in the “EQUIPMENT NEEDED” section above.

3. Review the Rules for Laser Safety listed on the back cover of this booklet.

4. For detailed information regarding the operation of the semiconductor diode

laser refer to its operating manual.

5. Position the laser and the receiver as shown in Figure 3.

6. Push the laser shutter’s handle downward to its closed position.

7. Make sure the laser's ON/OFF switch (SW) is in its OFF position. (The push

button should be in its extended position.)

audio

receiver

laser

Figure 3. Side vie w of th e lase r an d audio re ceiver.

8. Plug the VAC-to-DC laser power adapter into an AC electrical outlet.

9. Plug the cord from the power adapter into the power jack (PWR) located on

the rear of the laser.

10. Plug the VAC-to-DC audio receiver power adapter into an AC electrical outlet.

11. Plug the cord from the power adapter into the power jack located on the front

of the audio receiver.

12. Plug the microphone into the 3.5 mm audio jack on the back of the laser.

Direct Laser Beam

through hole and

onto detector

1515.eps

Figu re 4. Clos e up

view of the

ali gn m en t la se r

beam to rece iver

ap ert u re.

- 6 -

13. Depress the ON/OFF switch (SW) on the control panel of the laser until it

clicks into the ON position. (The switch should be slightly depressed.) The

pilot light (green LED) on the laser should now be lit, showing that it is on.

14. Adjust the Gain Control knob on the laser to the fully counter-clockwise

position. (Gain = 1)

15. Open the laser shutter.

16. Dim the room lights to help you observe the laser beam. Position the receiver

in line with the laser so the beam strikes the audio receiver around the

photodetector access hole. Manually align the beam with the optical input

(photo diode) of the audio receiver.

17. Turn on the microphone using the switch located on the side.

18. Turn the ON/OFF volume knob on the audio receiver to the 12 o’clock

position. The pilot light (yellow LED) on the audio receiver should now be lit,

showing that it is on.

19. Speak into the microphone and listen for your voice to come out of the audio

receiver. If you do not hear your voice on the first attempt, continue to speak

into the microphone while turning up the volume control clockwise on the

audio receiver. If you reach maximum volume and still do not hear your voice,

realign the laser beam with the audio receiver while speaking into the

microphone.

20. When you have the audio receiver and the laser properly aligned you should

hear your voice from the receiver when you speak into the microphone. If you

do not slowly adjust the Gain Control knob clockwise while continuing to

speak into the microphone. (Maximum gain = 50 at the full clockwise

position)

21. If you continue to have problems at this point refer to the

“TROUBLESHOOTING” section in the back of the manual.

22. Upon completing the experiment close the laser beam shutter. At this time

you can either continue to the Fiber Optic Transmission procedure on next

page or switch off the laser and complete the remaining steps below.

23. Turn the volume knob on the audio receiver to the OFF position.

24. Turn the Gain Control knob fully counter-clockwise and turn off the

microphone.

25. Unplug the power adapters from the electrical outlets, the laser and the audio

receiver.

26. Remove all equipment from the table and store in their proper locations.

Fiber Optic Transmission Procedure

Additional Equipment Needed:

3 meters 1.0 mm core plastic optical fiber

- 7 -

Procedure:

The assumption is made that one of the proceeding laser procedures is still set up

and operational as an optical audio link, and you are now familiar with the safe

operation of the laser. It is recommended that 2 people be used for this procedure to

simplify the handling of the equipment and the fiber. If you need to do this

experiment by yourself it is recommended that the microphone be replaced as the

audio input source with a radio or other device to provide the modulation for the

laser. This will allow the use of both hands to handle the plastic optical fiber.

If you are starting this procedure as a new stand alone experiment please refer to

the initial set-up steps, up to the point of turning on the laser, for the project kit that

was purchased. The intent of this procedure is to show how optical fiber is used as a

waveguide for light so that a straight line of sight from the sending point to the

receiver is no longer required.

1. Move the audio receiver out of the laser path.

2. Grasp one end of the fiber optic cable between your thumb and forefinger.

Open the shutter of the laser and hold the fiber in the path of the laser beam

(input side). DO NOT LOOK AT THE OUTPUT END OF THE FIBER AT

THIS TIME.

3. Have a second person grasp the other end of the fiber optic cable (output side)

and hold it up to the optical input, (photo diode) of the audio receiver.

4. Speak into the microphone and listen to hear your voice coming from the

audio receiver. If your voice is not heard increase the volume slowly until

maximum volume is reached. If you still do not hear your voice check to see

that the fiber is aligned with the laser beam and is being transmitted through

the fiber to strike the optical input photo diode. DO NOT LOOK DIRECTLY

AT THE OUTPUT END OF THE FIBER. Hold the fiber end up to a white

sheet of paper to verify beam transmission.

5. If you continue to have problems at this point refer to the

“TROUBLESHOOTING” section in the back of the manual. If you have

successfully established an audio link using the plastic optical fiber continue

with your experiment.

6. Once the procedure is completed turn off all equipment and return the

equipment to its appropriate storage location.

- 8 -

TROUBLESHOOTING

NO PILOT LIGHT

• Is the laser’s ON/OFF switch in the ON position?

• Is the 110 (220) VAC-to-VDC power adapter plugged into the laser and an

appropriate wall outlet or extension cord?

• Is there power to the wall outlet?

NO LIGHT OUTPUT FROM LASER

• Check pilot light. If not on, go to the previous Troubleshooting step.

• Is the mechanical beam stop in its open position?

• Damaged or inadequate power adapter.

• Low voltage to the wall outlet.

NO SOUND FROM LASER AUDIO RECEIVER

• Is the 110 (220) VAC-to-VDC power adapter plugged into the laser audio

receiver and an appropriate wall outlet or extension cord?

• Is the receiver’s power indicator light on?

• Is the laser beam positioned properly so its beam hits the receiver detector?

• Are input signals to the laser of sufficient amplitude? (Speak louder into the

microphone.)

• For Diode Laser Only: Check to see if the Gain control knob is turned to the

12 o’clock position (refer to the Laser Diode instruction manual for the

operation of the Gain Control knob).

• Check for damaged or open electrical circuit in the microphone cord.

• Slowly turn down the volume control on the receiver while continuing to talk

into the microphone. (This will desensitize the receiver in case the receiver is

too sensitive [saturating] for this laser.)

• Check the troubleshooting section in your laser audio receiver manual.

Do not attempt to troubleshoot the laser or laser receiver beyond the steps listed

above. If all your connections are correct, and you are confident that power is being

supplied to the laser and any input devices, please return the laser for appropriate

inspection/servicing to Industrial Fiber Optics,as described in the section entitled

“SERVICE AND MAINTENANCE”.

- 9 -

SERVICE AND MAINTENANCE

Periodic operation, maintenance and service of this equipment is not required. The

warranty will be voided if entry has been made, and/or any screws have been removed.

In the unlikely event this equipment malfunctions and you wish to have it repaired,

please do the following:

• In writing, describe the problem, person to contact, phone number, and return

address.

• Carefully pack the item, its power adapter, manual, and written description in

a stout box with sufficient packing material to prevent damage in shipment.

• Ship the package to:

INDUSTRIAL FIBER OPTICS

1725 West 1st Street

Tempe, AZ 85281-7622

USA

- 10 -

WARRANTY

Industrial Fiber Optics products are warranted against defects in materials and

workmanship. The warranty for the product, excluding laser, is for one (1) year. The

warranty for the individual laser is dependent upon model. Refer to the manual which was

included with the laser for the proper warranty period. The warranty will be voided if

internal or external components have been damaged, mishandled, or altered by the buyer.

Warranty liability is limited to repair or replacement of any defective unit at the

company's facilities, and does not include attendant or consequential damages. Repair or

replacement can be made only after failure analysis at the factory. Authorized warranty

repairs are made at no charge, and are guaranteed for the balance of the original warranty.

Industrial Fiber Optics will pay the return freight and insurance charges for warranty

repair within the continental United States, by United Parcel Service or Parcel Post. Any

other delivery means must be paid for by the customer.

If an item is not under warranty, repairs will not be undertaken until the cost of such

repairs have been prepaid by the customer. Typical repair costs range from $25 - $75, and

completion times from two to three weeks.

When returning items for analysis and possible repair, please do the following:

• In a letter, describe the problem, person whom we should contact, phone number,

and return address.

• Pack the warranted item and your letter carefully in a strong box with adequate

packing material, to prevent damage in shipment.

• Ship the package to:

INDUSTRIAL FIBER OPTICS

1725 West 1st Street

Tempe, AZ 85281-7622

USA

- 11 -

SHIPMENT DAMAGE CLAIMS

If damage to an Industrial Fiber Optics product should occur during shipping, it is

imperative that it be reported immediately, both to the carrier and the distributor or

salesperson from whom the item was purchased. DO NOT CONTACT INDUSTRIAL FIBER

OPTICS.

Time is of the essence because damage claims submitted more than five days

after delivery may not be honored by the carrier. If damage has occurred during

shipment, please do the following:

• Make a note of the carrier company; the name of the carrier employee who

delivered the damaged product; the date; and the time of the delivery.

• Keep all packing material.

• In writing, describe the specific nature of damage to the product.

• In cases of severe damage, do not attempt to use the product, install batteries,

or connect any other power source.

• Notify the carrier immediately of any damaged product.

• Notify the distributor from whom the purchase was made.

------------------------------

- 12 -

Table 3. Me tric Prefi xes an d Their Meanings.

Prefix Symbol Multiple

tera T 1012 (trillion)

giga G 109 (billion)

mega M 106 (million)

kilo k 103 (thousand

hecto h 102 (hundred

deca da 101 (ten)

deci d 10-1 (tenth)

centi c 10-2 (hundredth)

milli m 10-3 (thousandth)

micro ! 10-6 (millionth)

nano n 10-9 (billionth)

pico p 10-12(trillionth)

femto f 10-15 (quadrillionth)

12 0130

Rules for Laser Safety

• Lasers produce a very intense beam of light. Treat them with respect. Most

educational lasers have an output of less than 3 milliwatts, and will not harm the skin.

•Never look into the laser aperture while the laser is turned on. PERMANENT EYE

DAMAGE COULD RESULT.

•Never stare into the oncoming beam. Never use magnifiers (such as binoculars or

telescopes) to look at the beam as it travels — or when it strikes a surface.

•Never point a laser at anyone's eyes or face, no matter how far away they are.

•When using a laser in the classroom or laboratory, always use a beam stop, or

project the beam to areas which people won't enter or pass through.

•Never leave a laser unattended while it is turned on — and always unplug it when it's

not actually being used.

•Remove all shiny objects from the area in which you will be working. This includes

rings, watches, metal bands, tools, and glass. Reflections from the beam can be nearly as

intense as the beam itself.

•Never disassemble or try to adjust the laser's internal components. Electric shock could

result.

This manual suits for next models

1

Table of contents

Other Industrial Fiber Optics Test Equipment manuals

Popular Test Equipment manuals by other brands

Proceq

Proceq Zonotip+ Service Manual & Repair Guide

ATEQ

ATEQ F600 manual

Allied Radio

Allied Radio Knight KG-640 Operator's manual

Sunrise telecom

Sunrise telecom CaLan N1776A user manual

Agilent Technologies

Agilent Technologies 54810A User's quick start guide

Agilent Technologies

Agilent Technologies E5022A Operation manual