INDUSTRIAL MAID AZTech T3500 User manual

1

Owners Manual

AZTech Model T3500/T4500

INDUSTRIAL AIR CLEANER

Contents

Safety/Inspection ...................................................... 2

Specications............................................................ 3

Installation................................................................. 4

Replacement Parts ................................................... 6

Electrical ................................................................... 7

Troubleshooting/Notes.............................................. 13

Warranty ................................................................... 18

2

SAFETY

PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING YOUR AIR CLEANER.

Follow all building and safety codes when installing this equipment. Pertaining but not limited to,

the Occupational Safety and Health Act (OSHA), National Electric Code (NEC), Uniform Building

Code (UBC), National Fire Prevention Act (NFPA) & all state and local codes.

A qualied electrician should perform all electrical connections.

Keep Flammable Objects away from the air cleaner and under no condition should a burning

object be allowed into the air cleaning system.

Take proper caution in placing units in buildings with radiant heaters installed. Follow the radiant

heater manufacturer’s guidelines for clearance to combustibles.

Do not mix materials collected in your Air Cleaner. The captured materials could create a

hazardous environment or a condition of operation for which the equipment is not intended. The

Manufacturer is relieved of any liability if the unit is not operated according to this manual.

Do not use the Air Cleaner for an application other than for which it was intended. Consult your

distributor, Applicable Codes, or call Industrial Maid for application assistance.

A re suppression system is not included. Please consult your local re protection specialist for

any required extinguishing equipment.

Consult with your insurance underwriter about any other protection from re damages.

The Manufacturer reserves the right to make design changes, which may improve the air cleaner.

This unit is intended for use to collect ambient smoke, airborne pollutants, and fumes in industrial

and manufacturing facilities. Do not use for the collection of ammable or explosive metals, dust,

fumes, or other potentially hazardous materials.

INSPECTION

Upon receiving your Industrial Maid air cleaner, please inspect for any damage incurred during

shipment. Inspect carefully; some damage may not be noticeable until the unit is installed. Notify

your shipper of any damage immediately. Claims must be led with the shipper within 15 days.

Freight damage claims are the responsibility of the purchaser.

3

Cabinet 14 ga powder coated steel frame. 3/16 polyethylene panels(14 ga steel

panels, optional)

Size 25”H x 72”L x 25”D (single cabinet)

Weight T3500 - 192 lbs.

T4500 - 199 lbs.

Power T3500 208-230/460/3/60 6.0/3.0amps

T4500 208-230/460/3/60 7.6/3.8 amps

Air Volume T3500 - 3,500 CFM

T4500 - 4,500 CFM

Motor T3500 - 2 HP 208-230/460/3/60 TEFC

T4500 - 3 HP 208-230/460/3/60 TEFC

Blower 10 x 10 Belt Drive Forward Curve

Exhaust Four Way adjustable louver

Filters Prelter - (2) 4” Pleats

Main Filter – (2) 24 x 24 x 21, 95%, 10 Pocket Fiberglass Bags

Warranty 3 year limited warranty

SPECIFICATIONS

4

INSTALLATION

The system’s weight must be taken into account when choosing the proper installation method

(see specication). Follow all applicable building and electrical codes.

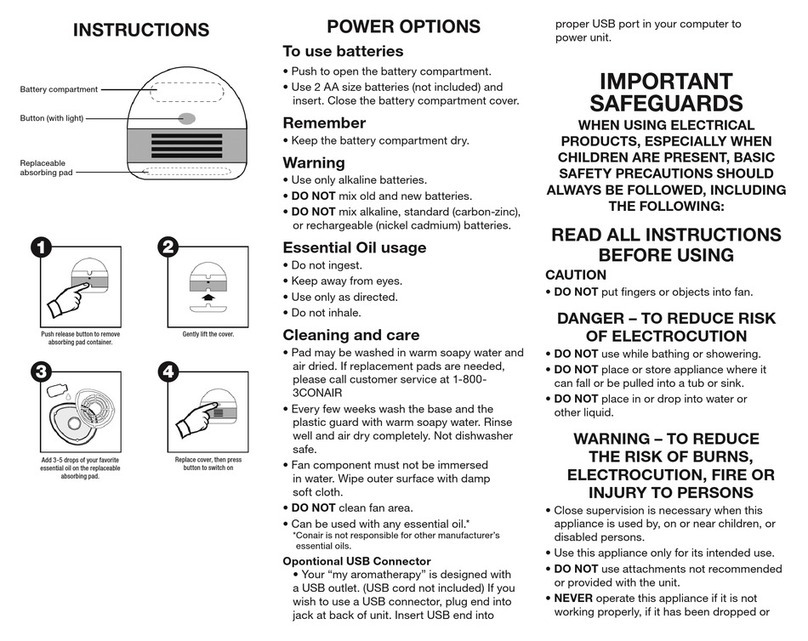

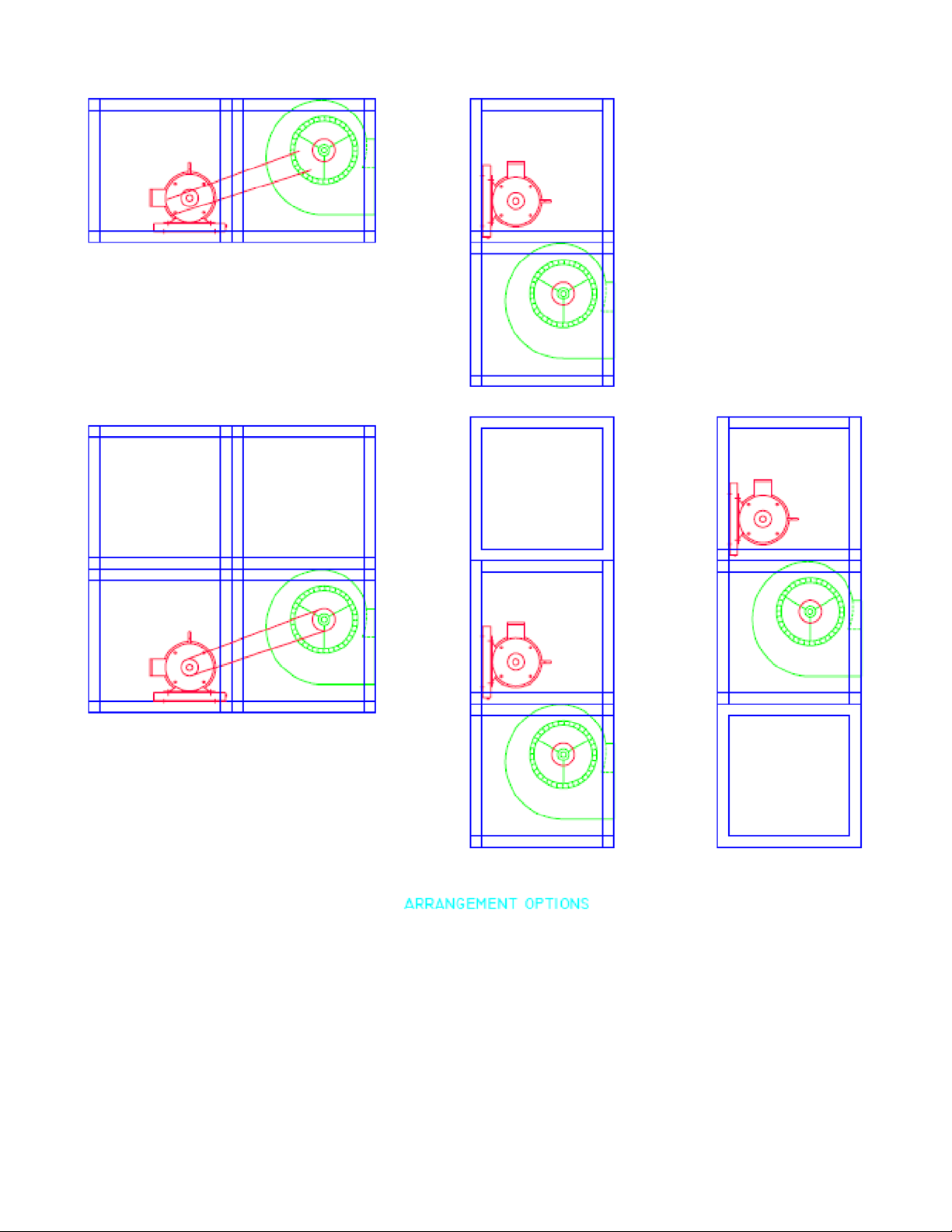

There are three main ways of installing your Model 3500 air cleaner, Chain Hanging (eye bolts

factory installed as option), rod & cradle , or angle braces. Figure 2 illustrates these methods.

Do not chain mount double cabinet units, use (4) 5/8” threaded rod and cradle the collector

(lower right, gure 2).

Figure 1.

5

Mounting materials must be able to support the weight of the air cleaner plus the additional

weight of the material collected. Consult your local building code for proper installation methods

and materials. Failure to use the proper materials could result in injury or damage equipment

and will void the warranty.

Figure 2.

6

REPLACEMENT PARTS

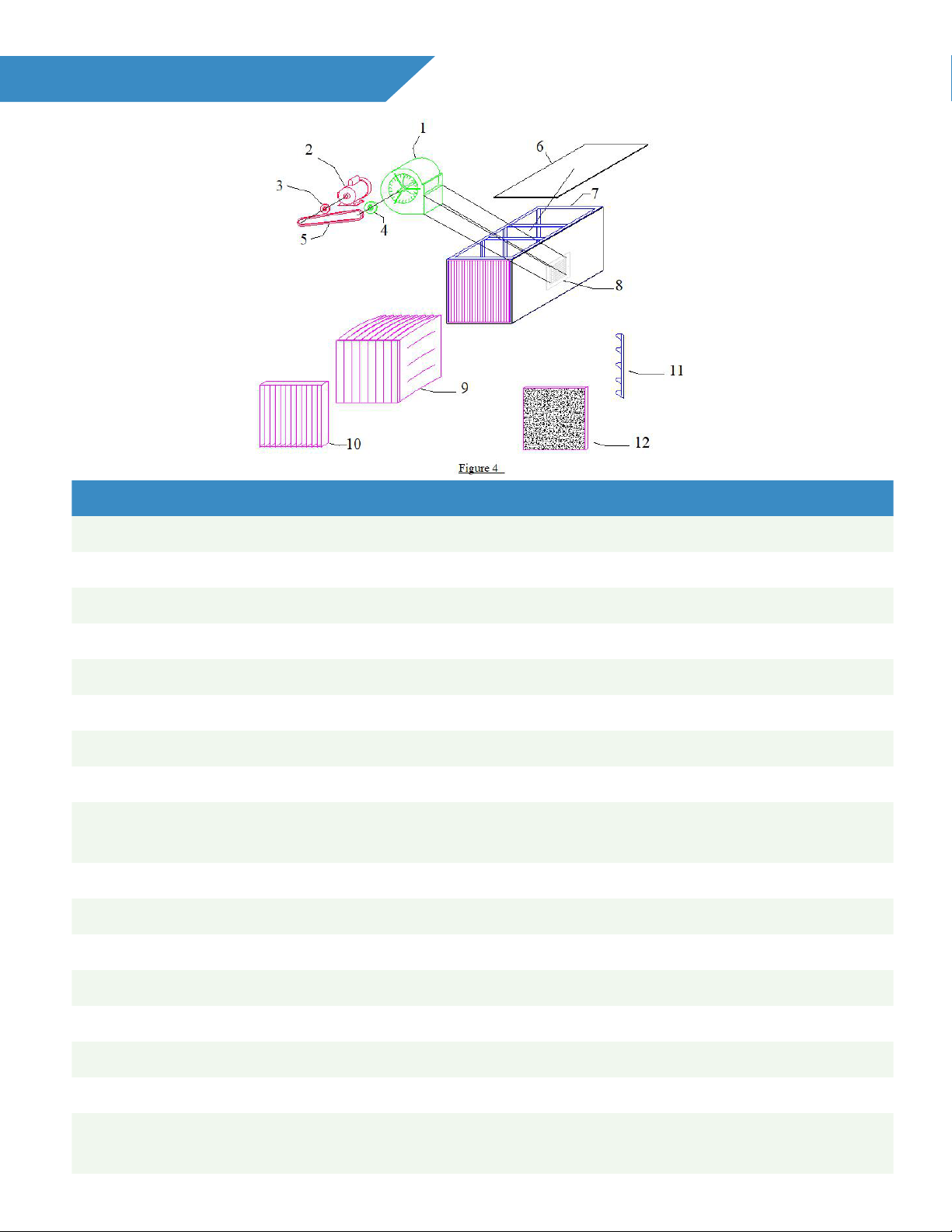

ITEM PART NUMBER QTY DESCRIPTION

1 BW10-AA10 1 2 & 3 HP BLOWER ASSEMBLY

2A MT02-2431-SG 1 T3500, 2 HP 230/460/3/60 TEFC MOTOR

2B MT03-2433-SG 1 T4500, 3 HP 230/460/3/60 TEFC MOTOR

3 PT78-0035 1 2 & 3 HP DRIVE PULLEY

4A PT34-0005 1 2 HP BLOWER PULLEY, 5” FIXED

4B PT34-0010 1 3 HP BLOWER PULLEY, 10” FIXED

5A PT0A-0040 1 2 HP - A40 DRIVE BELT

5B PT0A-0049 1 3 HP - A49 DRIVE BELT

6A 003500-11PE 3,5 or 7 3/16 POLYETHYLENE PANELS, TOP, BOTTOM,

& BACK

6B 003500-10PE 1 3/16 POLYETHYLENE PANEL, EXHAUST

7 FR35-ASSY 1 14 GA FRAME ASSEMBLY

8 GR07-0013 1 4-WAY ADJUSTABLE EXHAUST GRILLE

9A FB91-2424 2,4,6 or 8 95 % FIBERGLASS BAG FILTER

9B FB61-2424 2,4,6 or 8 65 % FIBERGLASS BAG FILTER

10 FP44-2424 2,4,6 or 8 4” PLEATED PREFILTER

11 FD02-2727 2 2” POLY PAD PREFILTER - OPTIONAL

12 253560-PFHK 2 POLY PAD PREFILTER MOUNTING HOOK -

OPTIONAL

7

ELECTRICAL WIRING

Unit comes wired to a junction box Additional wiring will be required to get power to unit, which is

not supplied with this product.

Motor Starters, disconnect, wiring, overloads, and thermal protection are NOT provided by the

Manufacturer

All Field wiring should be performed by a qualied electrician and must meet all local, NFPA and

NEC codes. Failure to install the proper electrical wiring, thermal protection, and controls will

void the warranty.

After completion of the eld wiring, turn the unit on to check for proper rotation. Rotation is

marked on the side of the blower housing. Backward rotation will result in a much lower air ow,

louder noise, and will over amp the motor. Check the motor nameplate before switching wires

and reversing rotation, to ensure the unit is operating at or below rated amp draw.

8

9

Motor 25 to 50 Feet 100 Feet 150 to 200 Feet

HP 200V 230V 460V 200V 230V 460V 200V 230V 460V

1/3 14 14(16)* 14(18)* 12 12 14(18)* 8 10 14(18)*

1/2 14 14(16)* 14(18)* 12 12 14(18)* 8 10 14(18)*

3/4 14 14(16)* 14(18)* 12 12 14(18)* 8 10 14(18)*

1 14 14(16)* 14(18)* 12 12 14(18)* 8 10 14(16)*

1 1/2 12 14 14(18)* 10 10 14(16)* 6 8 14

2 12 12 14(18)* 8 10 14(16)* 6 6 12

3 10 12 14(18)* 6 8 14 4 6 12

5 8 10 14(16)* 4 6 12 2 4 10

7 1/2 6 8 14 4 4 10 1 2 8

10 6 6 12 3 4 10 1/0 1 6

15 4 4 10 1 2 8 3/0 2/0 4

20 3 4 10 1/0 1 6 4/0 3/0 4

25 2 3 8 2/0 1/0 6 250kcmil 4/0 3

30 1 3 8 3/0 1/0 6 300kcmil 4/0 3

40 1/0 1 8 4/0 3/0 4 400kcmil 300kcmil 1

50 2/0 1 6 250kcmil 3/0 3 500kcmil 350kcmil 1

60 3/0 1/0 6 300kcmil 4/0 3 600kcmil 400kcmil 1/0

75 4/0 2/0 4 350kcmil 250kcmil 2 700kcmil 500kcmil 2/0

100 250kcmil 3/0 4 500kcmil 350kcmil 1 900kcmil 700kcmil 3/0

125 300kcmil 4/0 3 600kcmil 400kcmil 1/0 1250kcmil 800kcmil 4/0

150 350kcmil 250kcmil 2 700kcmil 500kcmil 2/0 1500kcmil 900kcmil 250kcmil

200 500kcmil 350kcmil 1/0 1250kcmil 800kcmil 4/0 1750kcmil 1250kcmil 350kcmil

250 600kcmil 400kcmil 2/0 1500kcmil 900kcmil 250kcmil 2000kcmil 1500kcmil 400kcmil

MOTOR MOUNTING

Motor must be securely fastened to a rigid, at surface to prevent vibration and minimize noise.

For secure mounting use high-quality bolts of the largest possible diameter.

Belt-drive sheaves must be in-line. Use a straight edge to check. Do not over-tighten belts.

Direct coupled installations require a careful check of shaft and coupling alignment, shaft offset

and/or angular misalignment should be less than .002”. Shim motor base as necessary. Do not

depend on a exible coupling to compensate for misalignment.

Table A - Minimum Wire Sizes for 3- Phase Motors

NOTE: kcmil denotes thousand circular mils. AWG sizes formerly given in MCM.

(*) Type S, SO, SJ, SJO, etc. exible cable wire sizes. See NEC article 400 for ampacity.

10

CONNECTING POWER TO MOTOR

To connect motor for proper voltage and rotation, refer to the connection diagram on the

nameplate or inside the terminal/conduit box.

Motor 25 Feet 50 Feet 100 Feet 150 Feet 200 Feet

HP 115V 230V 115V 230V 115V 230V 115V 230V 115V 230V

1 10 14(16)* 6 12 4 10 2 8 1 6

1 1/2 8 14 6 12 3 8 1 6 1/0 6

2 8 14 4 10 2 8 1/0 6 2/0 4

3 6 12 3 8 1/0 6 2/0 4 4/0 3

5 - 10 - 6 - 4 - 2 - 1

7 1/2 - 8 - 6 - 3 - 1 - 1/0

10 - 8 - 4 - 2 - 1/0 - 2/0

Table B - Minimum Wire Sizes for Single Phase Motors

* Type S, SO, SJ, SJO, etc. Flexible cable wire sizes. See NEC Article 400 for ampacity.

NOTE: NEC Article 310-5 --- Minimum conductor size for general wiring at 115-440VAC is

No. 14AWG.Above wire sizes based on approximate 5% voltage drop during starting; copper

conductors; and 75° C type THHW, THW, THWN, RH, RHW insulation, etc. For aluminum

wire, increase two wire size steps minimum. See NEC Article 310 for ampacities of aluminum

conductors.

11

RECOMMENDED MAINTENANCE

WARNING

All aspects of the installation must conform to the requirements of

the NEC, including Article 430 (Motor circuits and Controllers), and all

local codes.

Wherever possible, each motor should be powered from a separate circuit of adequate capacity

to keep voltage drop to a minimum during starting and running. Increase wire size where motor is

located a distance from the power source. Wire size must be adequate to minimize voltage drop

during starting and running. Refer to Tables A and B for suggested wire sizes. Distances shown

are one-way between source and motor. Portable cords, if used, should be as short as possible

to minimize voltage drop. Long or inadequately sized cords, especially on hard starting loads, can

cause motor failure. All electrical connections in system must be secure to prevent voltage drop

and localized heating.

• Determine direction of rotation before connecting driven equipment to prevent damage.

• To prevent bearing damage, do not strike shafts with hammer or other tool.

• If the motor has been damp or wet, then have motor serviced by a qualied motor repair

shop before operating.

Recommended Maintenance

Remove dirt accumulations in and around vent openings, by vacuuming. Dirt accumulations

can cause motor overheating and a re hazard. Enclosed motors can be cleaned with an air

jet; wear eye protection.

Periodically inspect the installation. Check for dirt accumulations; unusual noises or vibration;

overheating; worn or loose couplings, sheaves and belts; high motor current; poor wiring or

overheated connections; loose mounting bolts or guards; and worn motor starter contacts.

Dayton ball-bearing motors without lubrication provision do not require periodic relubrication.

Where motor has provision for bearing lubrication, lubricate as follows:

1. After stopping motor and disconnection power, thoroughly wipe the housing around both of

the motor bearings, ller and drain plugs (on TEFC) ratings, remove fan cover for access

to plugs).

2. Remove ller and drain plugs and install a 1/8” pipe thread lube tting in ller hole.

3. Using a low pressure grease gun, pump new grease into motor until it appears at the drain

hole.

4. Run motor for several minutes to discharge excess grease. Shut motor OFF, replace ller

and drain plugs, and reinstall fan cover.

See Table C for suggested regreasing intervals.

12

MOTOR HP AT 1800 RPM MAX

TYPE OF SERVICE UNDER 50 50 TO 100 OVER 100

Infrequent operation or light duty in clean atmosphere 2 Years 2 Years 1 Year

8 to 16 hours per day in clean, relatively dry atmosphere 2 Years 1 ½ Years 1 Year

12 to 24 hours per day heavy duty use, or if moisture is

present

1 Year 1 Year 6 months

Heavy duty use in dirty, dusty locations; high ambients;

moisture laden atmosphere; constant vibration

4 Months 4 Months 3 Months

NOTE 1: Motors operating faster than 1800 RPM should be relubricated on a more frequent

maintenance schedule. Use a reputablebrand lithium or synthetic-base grease intended for electric

motor ball bearings. Recommended greases include: Standard Oil of California (Chevron) SRI#2,

and Exxon Corp. PolyRex-EM. Keep grease container clean and covered.

Table C – Suggested Regreasing Intervals

13

MOTOR TROUBLESHOOTING

This chart suggests common answers to electric motor problems. The information is not

all-inclusive and does not necessarily apply in all cases. When unusual operating conditions,

repetitive failures, or other problems occur, consult an electric motor service rm.

Symptom Possible Cause(s) Corrective Action

Motor fails to start 1. Blown fuses 1. Replace with time-delay fuses.

Check for grounded winding

2. Voltage too low at motor

terminals due to line drop

2. Consult local power company.

Increase wire size (refer to

Tables A & B). Check for poor

connections

3. Overload in motor starter tripped 3. Check and reset overload

relay in starter. Check heater

rating against motor nameplate

current rating

4. Overload (internal thermal

protector) tripped

4. Check motor load. If motor

has an automatic or manual

reset thermal protector, check

if tripped

5. Improper line connections 5. Check connections against

diagram supplied with motor

6. Motor may be overloaded 6. Reduce load or increase motor

size

Motor does not come up to

speed or takes too long to

accelerate

1. Not applied properly 1. Consult motor service rm for

proper type. Use larger motor

2. Voltage too low at motor

terminals

2. Increase wire size (refer to

Tables A & B). Check for poor

connections. Check for voltage

unbalance (3-Phase)

3. Starting load to high 3. Check load motor is carrying at

the start

4. Excess loading; tight belts 4. Reduce load; increase motor

size. Adjust belts

14

Symptom Possible Cause(s) Corrective Action

5. Defective motor. 5. Replace or repair

6. Inadequate starting torque. High

inertia load

6. Replace with a larger motor

Motor stalls during

operation

1. Overloaded motor 1. Reduce load or increase the

motor size

2. Low motor voltage 2. Verify that nameplate voltage is

maintained

Motor vibrates or is

excessively noisy

1. Motor shaft is misaligned 1. Realign

2. 3-phase motor running on single

phase

2. Check for open circuit, blown

fuses or unbalanced voltages

3. High or unbalanced voltages 3. Check wiring connections.

Consult local power company

4. Worn, damaged, dirty or

overloaded bearings

4. Replace bearings; check

loading and alignment

5. Defective winding. Bent or

bowed shaft

5. Repair or replace

6. Loose sheave or misaligned

coupling

6. Tighten set screw(s); realign

coupling

Motor overheats while

running under load

1. Overloaded 1. Reduce load; increase motor

size; belts may be too tight

2. Dirt blocking ventilation openings 2. Clean motor

3. If 3-Phase, one phase may be

open

3. Check lines for open phase.

Check voltage with motor

disconnected, one fuse may be

blown.

4. Unbalanced supply voltage 4. Check for faulty connections.

Voltage on all three lines

should be balanced within 1%.

Balance single phase loads.

5. Faulty connection 5. Clean, tighten, or replace

6. High or low voltage 6. Check voltage at motor, should

not be more than 10% above or

below rated

7. Defective motor 7. Repair or replace

15

BLOWER OPERATION

After electrical connections are completed, start motor briey to determine the direction of wheel

rotation. If necessary to reverse the rotation, follow instructions given on the motor nameplate or

terminal box cover.

With air system in full operation, and with all ducts attached and inspection door(s) closed, measure

the current input to the motor and compare with nameplate rating to determine if the motor is

operating under safe load conditions.

Blower Maintenance

1. After electrical connections are completed, start motor briey to determine the direction of

wheel rotation. If necessary to reverse. The rotation, follow instructions given on the motor

nameplate or terminal box cover.

2. Follow motor manufacturer’s instructions for motor lubrication. Remove excess lubricant.

3. Follow Replacement Parts Manual for blower bearing lubrication.

4. Check wiring to make sure it is secure and well insulated

BLOWER TROUBLESHOOTING CHART

Symptom Possible Cause(s) Corrective Action

Excessive noise and/or

vibration

1. Foreign object 1. Remove

2. Wheel rubbing on housing 2. Center the wheel

3. Loose wheel or sheave on

shaft

3. Tighten all set screws

4. Motor or blower not secure 4. Tighten Mounting

5. Belt(s) too loose/too tight 5. Adjust Tension

6. Worn belt(s) 6. Replace

7. Mismatched belt(s) 7. Replace

8. Loose or worn bearings 8. Replace

9. Bearing or drive alignment 9. Realign

10. Accumulation of material on

wheel

10. Clean

11. Motor out of balance 11. Replace

12. Wheel out of balance 12. Replace or Re-balance

13. Sheaves eccentric or out of

balance

13. Replace

16

Symptom Possible Cause(s) Corrective Action

Insufcient air ow 1. Blower speed too low 1. Check for correct drives

2. Dampers or registers closed 2. Open

3. Dirty or clogged lters 3. Clean or replace

4. Leaks in duct work 4. Repair

5. Elbows, cabinet walls, or other

obstructions

5. Correct

6. Belt slippage 6. Adjust or replace

Too much air ow 1. Blower speed too high 1. Check for correct drives

2. Filter(s) not in place 2. Install lter(s)

Unit fails to operate 1. Blown fuse or open circuit

breaker

1. Replace fuse or reset circuit

breaker

2. Broken fan belt 2. Replace

3. Defective motor and/or

capacitor

3. Replace

Motor overloads or overheats 1. Blower speed too high or motor

horsepower too low

1. See Speccations for correct

drives and HP

2. System static pressure too low 2. Check static pressure and

correct syst

3. Shorted windings in motor 3. Replace

17

SERVICE RECORD

Date Description Serviced By Location Comments

351 S. 12th Rd.

Cortland, NE 68331

Ph. (402) 798-7116

Fx. (402) 798-7117

www.industrial-maid.com

START UP DATA: (write down for future reference)

MODEL NUMBER____________________________ SERIAL NUMBER_______________________

HP________________________ VOLTAGE____________________MFG. DATE__________________

VOLTAGE - L1_______________________L2________________________L3____________________

AMP DRAW - L1______________________L2________________________L3____________________

OTHER NOTES: ______________________________________________________________________

_____________________________________________________________________________________

PRESSURE GAUGE READING(AT START UP)____________________________________________

18

WARRANTY

1. Limited Product Warranty. Industrial Maid, LLC, 351 S. 12th Rd., Cortland, NE, 68331, hereby

warrants to any owner who has purchased the equipment other than for purposes of resale, as

follows:

A. All components of air cleaners and air ltration equipment manufactured (collectively

“Components”) by Industrial Maid, as well as motors and drives installed on Industrial Maid

units (collectively “Components”) will be manufactured in conformity with stated materials,

dimensions, and tolerances;

B. Components manufactured by Industrial Maid, as well as motors and drives installed in

Industrial Maid units, will, in normal use and service, be free from defects in material and

workmanship for a period of thirty-six (36) months;

C. Components not manufactured by Industrial Maid (other than motors and drives) are not

included within the thirty-six (36) month Warranty. These excluded items include HMI

Control Panels, motor starters, disconnects, lters, duct work, and installation not supplied by

Industrial Maid. The Limited Product Warranty on these items, when sold by Industrial Maid

as part of the unit, is twelve (12) months and parts only.

D. Upon delivery, Industrial Maid will convey good and marketable title to the Components

to Owner free and clear of all liens and encumbrances other than those arising in favor of

Industrial Maid, including the purchase money security interest.

2. Duration of Warranty/Notice Requirements. The warranties set forth in Section1 above shall

apply to covered defects in Components that are discovered by Owner within the respective

thirty-six (36) months or twelve (12) months following the Invoice Date (the “Warranty Period”)

and are reported to Industrial Maid in writing within thirty (30) calendar days following their

discovery (the “Notice Period”).

3. Exceptions and Exclusions. Notwithstanding anything herein to the contrary, the warranties set

forth in Section 1 above do not cover any of the following, each of which are hereby expressly

excluded therefrom:

A. Defects that are not discovered during the Warranty Period;

B. Defects that are not reported to Industrial Maid in writing within the Notice Period;

C. Usual and customary deterioration or wear resulting from normal use, service and exposure;

D. Consumable items such as lters, belts, and lter hammer are not warranted;

E. Any Components that are installed outside of the United States, Canada, or Mexico, United

Kingdom and European Union;

F. Any xtures, equipment, materials, supplies, accessories, parts, or Components that have

been manufactured and/or furnished by any third party;

G. Any shortages in or damage to any Industrial Maid Components at delivery, all of which shall

be exclusively governed by the invoice or Purchase Agreement;

H. The durability and/or variation in the appearance or color of Components;

I. Any Components which have been removed from the Industrial Maid unit on which they were

originally installed;

J. The effect or inuence any Industrial Maid Components may have on any pre-existing or

other structures, including without limitation, any damage associated with loads imposed by

the Industrial Maid Components on such structures;

19

K. Any defect and/or any loss, damage, cost or expense incurred by Owner or any third party to

the extent the same arise out of, relate to or result, in whole or in part, from any one or more

of the following:

i. Damage in transit or in handling;

ii. Theft, vandalism, accident, war, insurrection, re or other casualty;

iii. Incorrect installation, servicing or operation;

iv. Defects or damage caused by Owner or any third party, including misuse, neglect or

accident;

v. Exposure to marine environments, including frequent or sustained salt or fresh water

spray;

vi. Operation beyond factory rated capacity;

vii. Exposure to corrosive, chemical, ash, smoke, fumes, or the like generated or released

either within or outside of the structure on which the Components are installed from

sources such as chemical plants, plating operations, foundries, kilns, fertilizer plants or

paper plants regardless of whether or not such facilities are owned or operated by Owner

or an unrelated third party;

viii.Any Industrial Maid Components that have been altered, modied or repaired by Owner

or any third party without Industrial Maid’s prior written consent;

ix. The placement or attachment of any xtures, equipment, accessories, materials, parts

or Components not furnished by Industrial Maid on or to any of the Industrial Maid

Components without the prior written approval of Industrial Maid;

x. Exposure to or contact with animals, animal waste and/or decomposition;

xi. The failure of Owner and/or any third party to:

a. properly handle, transport and/or store any Industrial Maid Components;

b. properly select and prepare a location that is adequate for where the Industrial Maid

Components will be installed;

c. properly erect and install the Industrial Maid Components, including, without limitation,

installing an improper material or material containing defects that are detectable

by visual inspection, or the failure to erect the Components in conformity with the

Industrial Maid’s Manuals;

d. properly design, construct and install all required heating, ventilation, air conditioning,

and mechanical systems;

e. properly design, construct and install all required insulation systems; and/or

f. properly maintain, operate, and use, if applicable, any Industrial Maid Components

either before or after installation.

4. Resolution of Warranty Claims. In the event Industrial Maid is notied of a warranty claim

within the notice Period, in conformity with the notice requirements set forth in Section 2 above,

Industrial Maid shall, with the full cooperation of Owner, immediately undertake an investigation

of such claim. To the extent Industrial Maid shall determine, in its reasonable discretion, that

the warranty claim is covered by the foregoing Limited Product Warranty, Industrial Maid will, as

Owner’s sole remedy provide:

A. Parts only replacement: Ship replacement Components to the Owner as soon as is

reasonably possible and at Industrial Maid’s sole cost and expense. Industrial Maid shall

not be responsible to Owner for the cost of dismantling any defective Components or

installing replacement Components, all of which shall be and for all purposes remain the sole

20

responsibility of Owner.

5. Warranty Not Transferable. This Warranty applies to original Owner and is not transferable.

As such, this Warranty does not cover any Industrial Maid’s Components that are sold or

otherwise transferred to third parties or any subsequent purchaser of the structure on which the

Components are originally installed.

6. Limitation on Warranties, Liabilities, and Damages. Owner expressly agrees that the

allocation of the risk, liability, loss, damage, cost, and expense arising from defects in the

Components as set forth above are fair and reasonable and acknowledge that such allocation of

risk was negotiated by the parties and was reected in the Purchase Price of the Components.

Accordingly, the Owner expressly agrees as follows:

A. Disclaimer of Implied Warranties. EXCEPT AS IS OTHERWISE EXPRESSLY SET FORTH

HEREIN, INDUSTRIAL MAID MAKES NO OTHER REPRESENTATIONS OR WARRANTIES

OF ANY KIND, WHETHER EXPRESS OR IMPLIED, BY OPERATION OF LAW OR

OTHERWISE WITH RESPECT TO ANY GOODS OR SERVICES THAT INDUSTRIAL

MAID SELLS OR PROVIDES TO OWNER INCLUDING WITHOUT LIMITATION ANY

REPRESENTATION OR WARRANTY WITH RESPECT TO MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE OR USE, SUCH WARRANTIES ARE

EXPRESSLY DISCLAIMED.

B. Limitation on Liability. EXCEPT AS IS OTHERWISE EXPRESSLY SET FORTH IN

SECTION 4 ABOVE, INDUSTRIAL MAID’S LIABILITY TO OWNER FOR ANY GOODS OR

SERVICES WHICH DO NOT CONFORM TO THE WARRANTIES SET FORTH ABOVE

SHALL NOT, IN ANY EVENT, EXCEED THE ACTUAL ORIGINAL COST PAID BY OWNER

AS TO SUCH NON-CONFORMING COST OF SUCH NON-CONFORMING GOODS OR

SERVICES.

C. Limitation on the Nature of Damages. EXCEPT AS EXPRESSLY PROVIDED IN SECTION

4 ABOVE, INDUSTRIAL MAID SHALL NOT, UNDER ANY CIRCUMSTANCES, BE LIABLE

TO OWNER OR ANY THIRD PARTY FOR ANY SPECIAL, INDIRECT, INCIDENTAL,

CONSEQUENTIAL, LIQUIDATED OR PUNITIVE DAMAGES OF ANY NAME, NATURE OR

DESCRIPTION. INDUSTRIAL MAID IS NOT RESPONSIBLE FOR LOSS OF USE, LOSS

OF TIME, INCONVENIENCE FOR ANY REASON.

7. Applicable Law. This Standard Limited Warranty shall be governed by, and construed in

accordance with, the internal laws of the State of Nebraska, USA. Any legal action or proceeding

arising under or with respect to this Agreement shall be brought only in the district courts of

Nebraska, or the United States District Court for the District of Nebraska. Industrial Maid and

Owner each hereby accepts for itself and in respect of its property, generally and unconditionally,

the jurisdiction of the aforesaid courts and each hereby irrevocably waives any objection thereto,

including, without limitation, personal jurisdiction or forum non conveniens.

This Limited Product Warranty gives you specic legal rights. No agent, employee, or representative

of Industrial Maid, nor any dealer, installer, fabricator, or other person is authorized to modify

this Warranty in any respect. The invalidity of all or a part of any of the provisions of this Limited

Product Warranty shall not affect or invalidate any other provision of this Limited Product Warranty.

Questions about this Limited Product Warranty may be directed to Industrial Maid, email: sales@

industrial-maid.com, phone: 1-877-624-3247 or visit our website at industrial-maid.com.

This manual suits for next models

1

Table of contents

Other INDUSTRIAL MAID Air Cleaner manuals