6.3 Group A2....................................................................................................................................................................35

6.4 Group A3....................................................................................................................................................................37

6.5 Group A4....................................................................................................................................................................39

6.6 Group A5....................................................................................................................................................................40

6.7 Group A6....................................................................................................................................................................42

6.8 Group A7....................................................................................................................................................................51

6.9 Group A8....................................................................................................................................................................52

6.10 Group b0.................................................................................................................................................................. 53

6.11 Group b1.................................................................................................................................................................. 55

6.12 Group b2.................................................................................................................................................................. 56

6.13 Group b3.................................................................................................................................................................. 58

6.14 Group b4.................................................................................................................................................................. 58

6.15 Group C0................................................................................................................................................................. 59

6.16 Group C1................................................................................................................................................................. 59

6.17 Group C2................................................................................................................................................................. 63

6.16 Group C3................................................................................................................................................................. 65

6.19 Group d0.................................................................................................................................................................. 67

6.20 Group d1.................................................................................................................................................................. 68

6.21 Group d2.................................................................................................................................................................. 69

Chapter 7 Troubleshooting................................................................................................................................................. 70

Chapter 8 Maintenance....................................................................................................................................................... 73

8.1Daily Maintenance..................................................................................................................................................... 73

8.2Periodical Maintenance.............................................................................................................................................73

8.3 Replacing Wearing Parts.........................................................................................................................................74

8.4 Storage....................................................................................................................................................................... 74

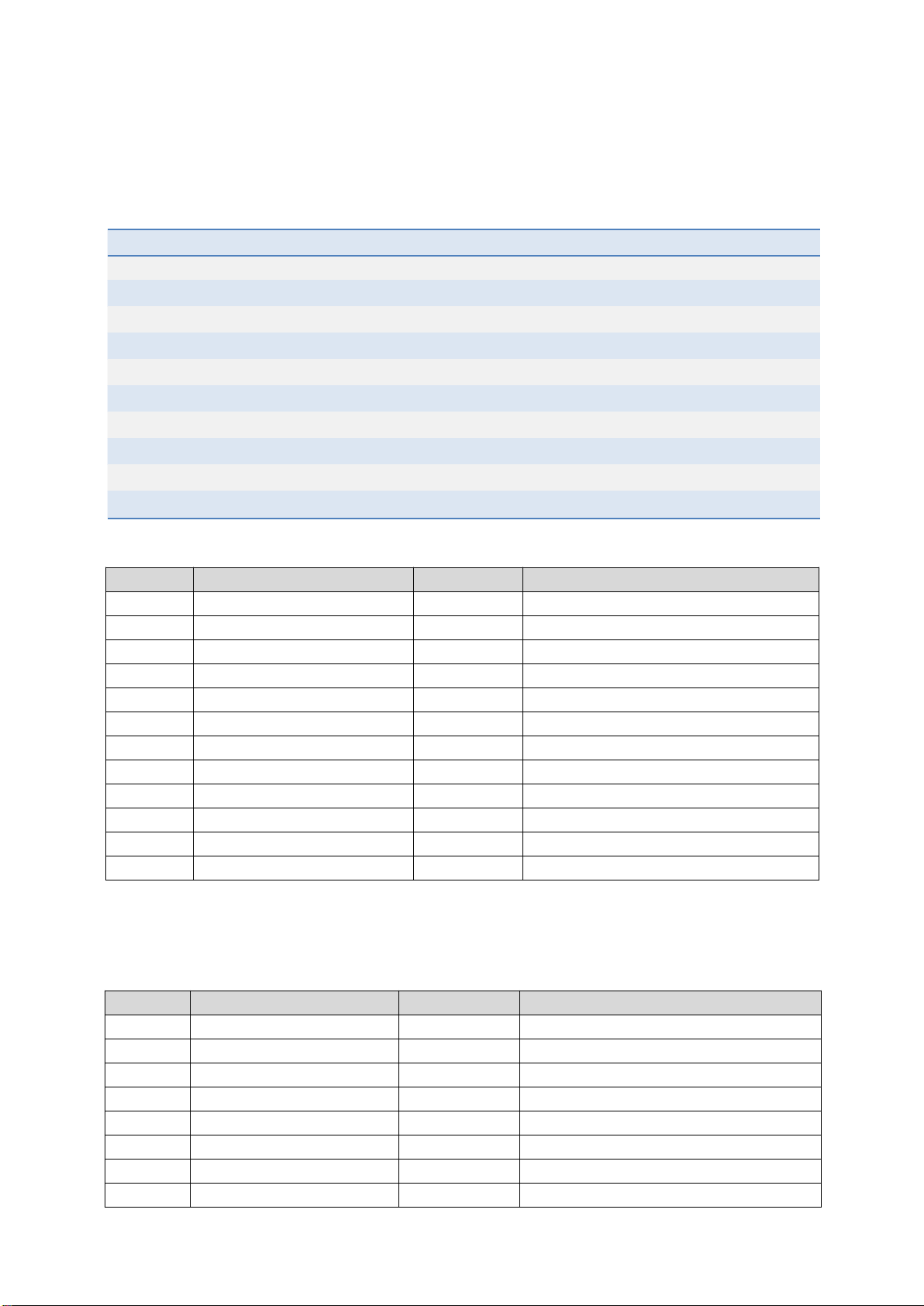

Chapter 9 List of Parameters..............................................................................................................................................75

Chapter 10 Communication Protocol.............................................................................................................................. 102

10.1 Networking Mode................................................................................................................................................. 102

10.2 Interfaces............................................................................................................................................................... 102

10.3 Communication Modes........................................................................................................................................102

10.4 Protocol Format.................................................................................................................................................... 102

1). RTU mode....................................................................................................................................................... 103

2). ASCII mode..................................................................................................................................................... 103

10.5 Protocol Function................................................................................................................................................. 104

10.6 Control parameters and status parameters of VFD........................................................................................104

10.7 Some instructions.................................................................................................................................................109

10.8 Application example.............................................................................................................................................110

Chapter 11 Basic adjustment guide................................................................................................................................ 112

11.1 Motor parameter self-tuning.............................................................................................................................112

11.2 Start by Terminal, Fr equency given by Analog.........................................................................................112

11.3 Multi-speed operation....................................................................................................................................... 113

11.4 Communication mode controls the inverter...................................................................................................114