The Power Switch/Reversing Switch:

1. To turn on the drill, squeeze the power switch (69) which is located on the left rear

handle (68). To turn off the drill, release pressure on the power switch.

2. The reversing switch (69) is located below the power switch, and is used to remove

stuck drill bits from holes. IMPORTANT: Do not use the reversing switch when the drill

is moving in a forward (clockwise) rotation. Doing socan cause serious damage to the

internal gears of the drill. Wait until the drill is completely stopped, then use the

reversing switch.

Drilling A Workpiece:

1. CAUTION! Use clamps (not included) or other practical ways to secure and support a

smaller workpiece to a stable platform. Holding the work by hand or against your body is

unstable and may lead to loss of control.

2. WARNING! If drilling into a wall, floor surface, etc., make sure no hidden electrical

wiring, cables, the drill’s own power cord, or other obstructions are in the drilling path.

3. To prevent damage when drilling into thin woodstock or light gauge metal, place a block

of scrap wood behind the workpiece.

4. Install a drill bit in the chuck (43). Secure the drill bit in the chuck with the chuck key

(24). Then, make sure to remove the chuck key (24).

5. Plug the power plug (74) into the nearest 120 volt, grounded, electrical outlet.

6. When using the drill, always maintain a firm grip on the tool with both hands as torque

from the drill’s motor will cause the drill to twist.

7. Make sure the drill bit lightly touches the point on the workpiece where the hole is to be

drilled prior to squeezing the power switch (69) of the drill.

8. While the drill is running, apply light downward pressure on the drill. Do not attempt to

force the drill to cut faster than it was designed to cut.

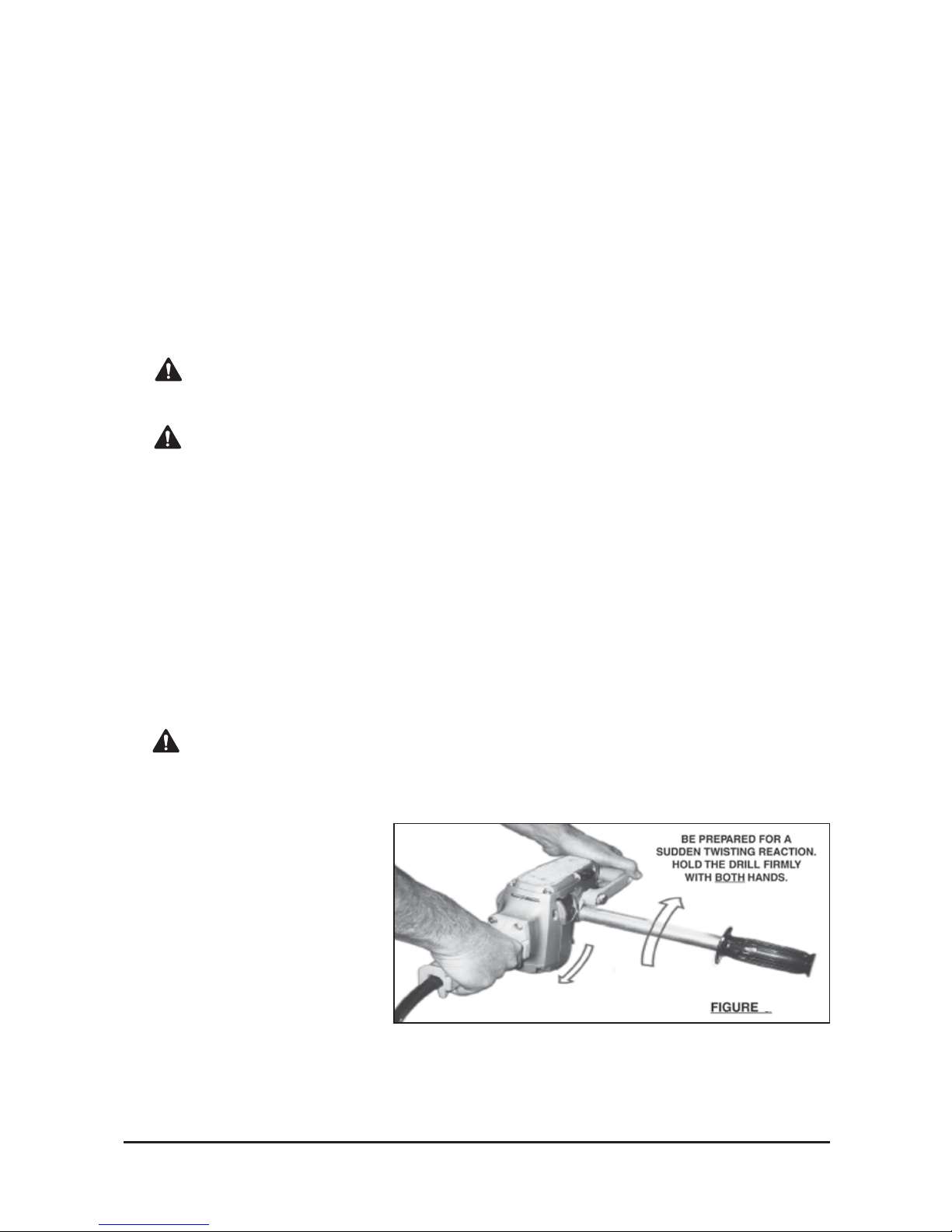

9. CAUTION! Always be prepared for a sudden twisting reaction of the drill. Never place

your hands, or other body parts, between the part of the drill being braced and the object

it is being braced against. Hands, or other body parts, that are in the direct path of a

twisting reaction can be pinched, crushed and broken. Minimize the chances of a sudden

twisting reaction by: using

the proper drill bit for the job,

using sharp drill bits, setting

the speed switch Lever (34) to

the proper speed for the size

of drill bit, avoiding knotty,

warped, or wet workpieces,

and avoiding hidden nails or

other objects in the workpiece.

(See Fig. F)

10. As soon as the drill bit cuts completely through the workpiece, remove the drill bit from

the hole while the drill is still running . This helps keep the drill bit from becoming

jammed in the hole.

11. Release pressure on the power switch (69) to stop the drill, and unplug the drill from its

electrical outlet. Remove the drill bit. Then store the drill in a clean, dry, safe location.

F