2

Safety Overview

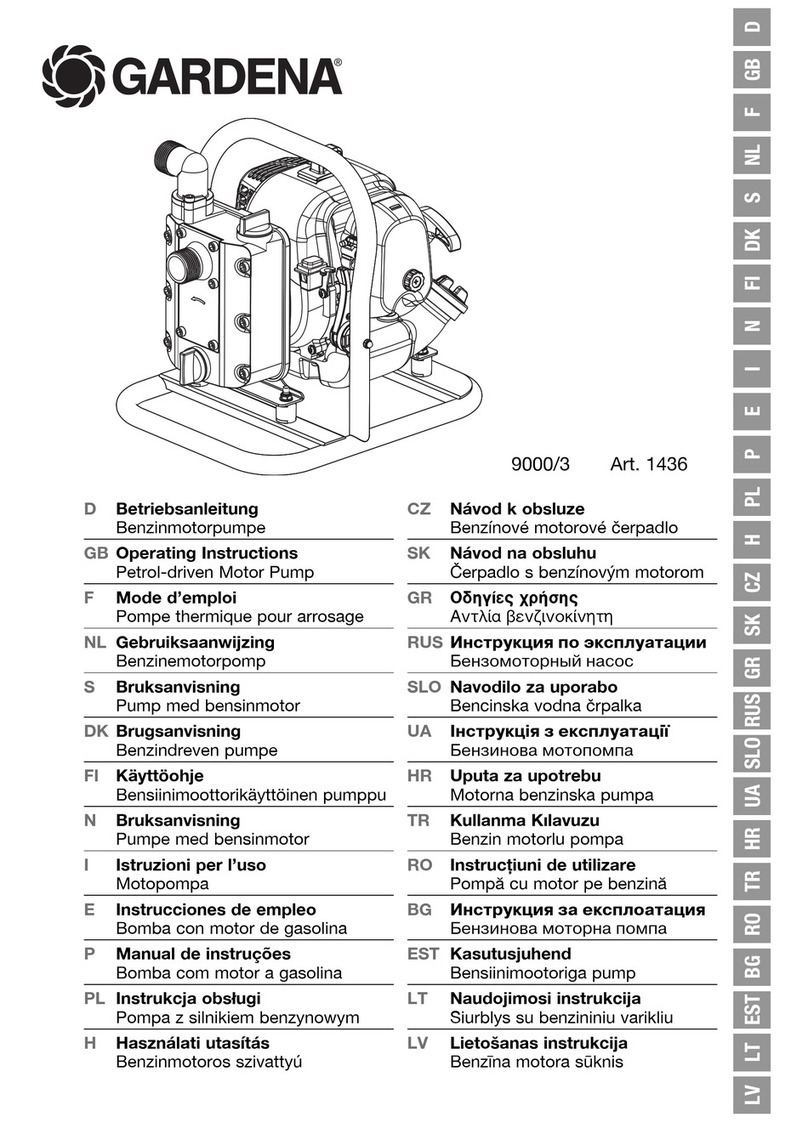

This unit was designed for specific applications. It

should not be modified or used for any application

other than that for which it was designed.

The Owner's Manual constitutes an essential part

of the water pump and should be kept in a safe

place for future reference. If you sell the water

pump, all manuals should be provided to the new

owner. Read this manual carefully before using

the product – know your equipment.

Save these instructions. The Owner's Manual

should remain with unit at all times.

Important Safety Precautions

6. Do not run the engine in an enclosed area.

Exhaust fumes contain carbon monoxide

which is an odourless, poisonous gas;

exposure can cause loss of consciousness

and may lead to death.

7. If the pump is located in an enclosed area,

use an exhaust line to the outside and

regularly check for exhaust leaks. Be sure

the area is well ventilated.

8. To prevent fire hazards and to provide

adequate ventilation, keep the pump at

least 1 metre (3 feet) away from building

walls and other flammable substances

as well as other equipment during

operation.

9. Do not place flammable objects close to

the pump.

10. For safety, never pump flammable or

corrosive liquids such as gasoline or acid.

11. Wear safety glasses at all times when

working with hazardous chemicals.

12. Check the wind direction before pumping

hazardous chemicals to ensure that spray

or mist does not come into contact with

people or animals.

13. To avoid pump corrosion, never pump sea

water, chemical solutions, or caustic liquids

such as used oil, wine, or milk.

14. Know how to stop the pump quickly, and

understand the operation of all controls.

Never permit anyone to operate the pump

without proper instruction.

15. Keep the work area clean, uncluttered and

properly lighted. Keep visitors at a safe

distance from the work area. Children and

pets must be kept away from the area of

operation due to a possibility of burns from

the hot engine components.

16. Periodically inspect pump and system

components. Perform routine maintenance

as required. (Refer to the Honda Engine

Owner's Manual.)

17. Carefully read the Operating Manual

supplied by the engine manufacturer before

attempting to assemble, operate or service

the engine.

18. Release all pressure and drain all fluids

from the pump before attempting to service

any component.

Safety Precautions

The following safety precautions are essential

for the safe operation of your pump. Make sure

anyone who may be using this gas-powered

pump is familiar with these important safety

safety and equipment precautions.

If safety precautions are overlooked or ignored,

personal injury or property damage may occur.

Always heed these precautions, as they are

essential when using any mechanical equipment.

1. Always make a pre-operation inspection

before you start the engine. You may

prevent a serious accident or equipment

damage.

2. Regularly check engine oil and fuel levels

before start-up. (Please refer to the Honda

Engine Owner's Manual for details.)

3. Secure and inspect all hoses before

start-up, making certain that all connections

are secure. Be sure to provide a means of

pressure relief for the pump if the discharge

line could be shut off or obstructed.

4. If the pump is located in an area subject to

freezing temperatures the pump should

be drained when not in operation.

5. Place the pump on a firm, level surface.

If the pump is tilted or overturned fuel

spillage may result.

IMPORTANT: The muffler becomes very hot

during operation and remains hot for a while

after stopping the engine. Be careful not to

touch the muffler while it is hot. Allow the

engine to cool before storing the pump

indoors.