K244XX Programmable Ashing Furnace

Operation and Instruction Manual

K244XX-Manual -3-

2 Safety Information and Warnings

Safety Considerations. The use of this

equipment may involve hazardous materials and

operations. This manual does not purport to

address all of the safety problems associated with

the use of this equipment. It is the responsibility of

any user of this equipment to investigate,

research, and establish appropriate safety and

health practices and determine the applicability of

regulatory limitations prior to use.

Equipment Modifications and Replacement

Parts. Any modification or alteration of this

equipment from that of factory specifications is not

recommended voids the manufacturer warranty,

product safety, performance specifications, and/or

certifications whether specified or implied, and

may result in personal injury and/or property loss.

Replacement parts must be O.E.M. exact

replacement equipment.

Unit Design. This equipment is specifically

designed for use in accordance with the applicable

standard test methods listed in section 1.2 of this

manual. The use of this equipment in accordance

with any other test procedures, or for any other

purpose, is not recommended and may be

extremely hazardous.

Chemical Reagents Information. Chemicals and

reagents used in performing the test may exhibit

potential hazards. Any user must be familiarized

with the possible dangers before use. We also

recommend consulting the Material Data and

Safety Sheet (MSDS) on each chemical reagent

for additional information. MSDS information can

be easily located on the internet at

http://siri.uvm.edu or http://www.sigma-

aldrich.com.

Disposal. Upon delivery the furnace does not

contain any material which is to be classified as

hazardous waste. However, process residues

may collect in the insulation during operation.

These may be dangerous to health and/or

dangerous to the environment.

Therefore we recommend proceeding as follows:

•Remove electrical components and dispose of

as electrical waste.

•Remove insulation and dispose of as special/

hazardous waste (wear a protective mask P2,

protective gloves and a protective suit).

•Dispose of the housing as scrap metal

3 Getting Started

The instructions for preparing the equipment

assume that the user is aware of the contents of

this document, which lists the warranty conditions

and important precautions.

3.1 Unpacking

Carefully unpack and place the instrument and

accessories in a secure location. Ensure that all

parts listed on the packing list are present. Inspect

the unit and all accessories for damage. If any

damage is found, keep all packing materials and

immediately report the damage to the carrier. We

will assist you with your claim, if requested. When

submitting a claim for shipping damage, request

that the carrier inspect the shipping container and

equipment. Do not return goods to Koehler without

written authorization.

3.2 Setup

3.2.1 Installation Site

Place the furnace on a non-flammable support

(stone, metal or similar). Keep a safe distance

from flammable components, 0.5 m from the

furnace sides and 1 m from the top. The minimum

distance between the furnace sides and non-

flammable materials can be reduced to 0.2 m.

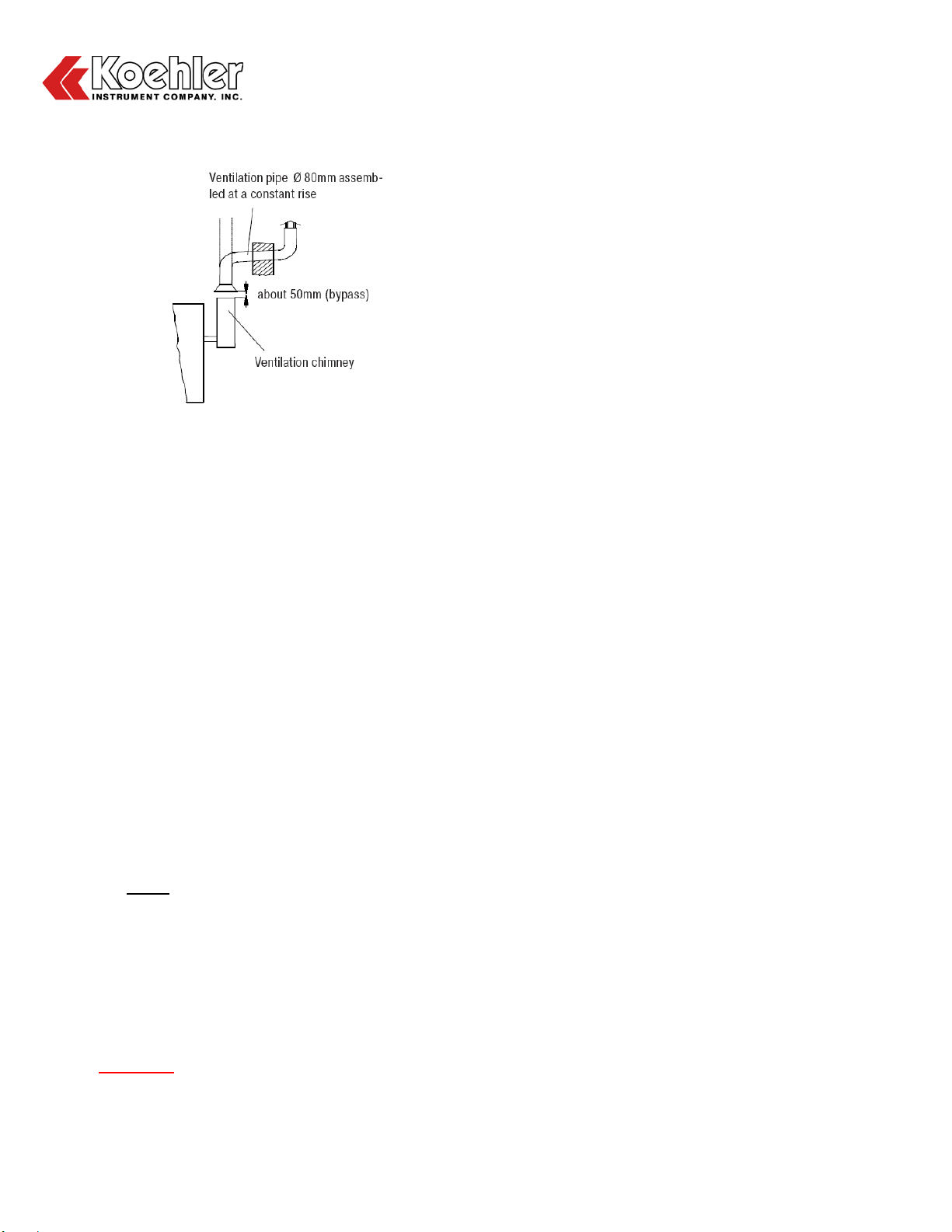

Ventilation. Provide sufficient room ventilation to

carry off exhaust heat and gases which develop

during the process. Non-observance can result in

a fire risk and danger to health.