0650329-56 / 506265-03Issue 1924Page 2 of 13

Installation

This EF electric furnace is designed for ease of installation

featuring horizontal, upow, and downow (counterow)

applications. The units are shipped from the factory

completely assembled. Accessories may also be ordered

as eld-installed items. All models are designed for indoor

installations only.

Read the entire instruction manual before starting the

installation. Several of the installation steps can be done

prior to setting the unit in place and doing this can save

time and simplify installation. Do not remove the cabinet

knockouts until it has been determined which knockouts

will need to be removed for the installation. Determining

which knockouts to remove will depend on application and

in some cases preference.

These instructions are intended to be a general guideline

and do not supersede any local or national codes.

Installation must conform with the local building codes and

with the latest editions of the National Electric Code or

Canadian Electric Code.

Improper installations not following these instructions

can result in unsatisfactory operation and/or dangerous

conditions and may void the unit warranty.

General Information

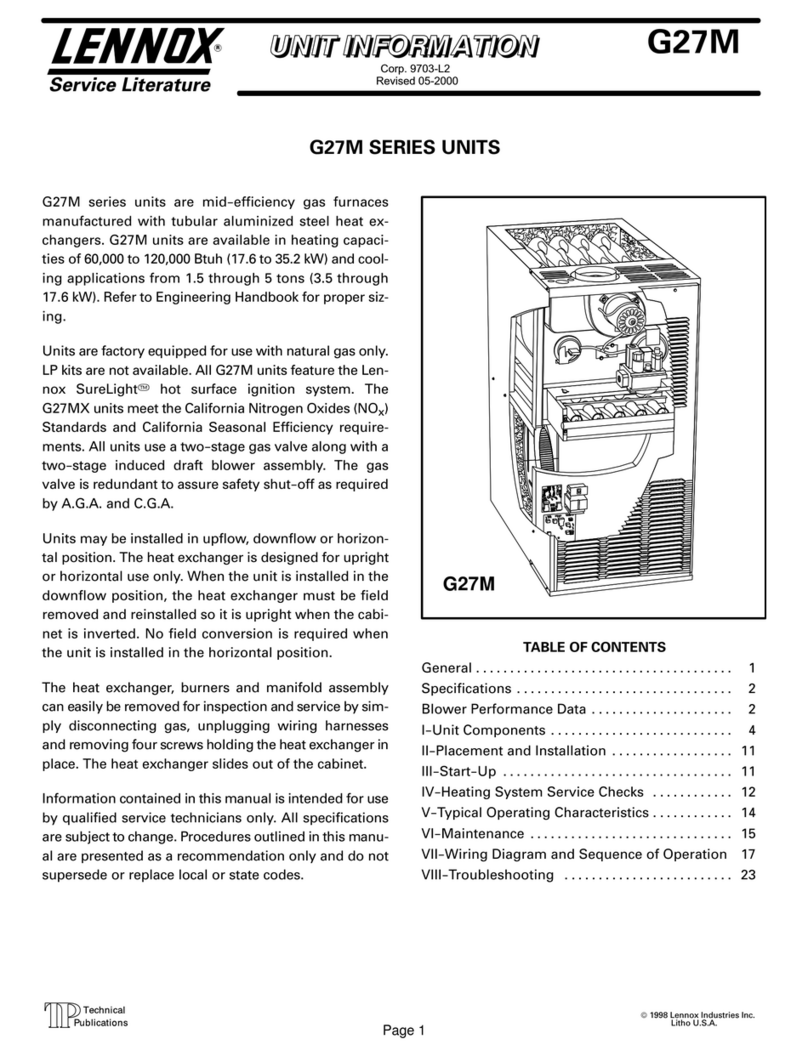

The EF electric furnace may be used with optional mating

furnace coil cabinets in upow, counterow, or horizontal

applications (see Figure 3 for acceptable system

congurations). Tie-plates and the necessary hardware

are packaged with the blower sections to connect the

furnace and coil section cabinets together.

To avoid drain pan overow of coil cabinets, the web must

be removed from inside any threaded drain pan hole to

which a drain line is to be connected. Use care when

removing the web so as to not damage the coil.

To avoid property damage caused by condensate drain

blockage, install a eld fabricated auxiliary drain pan with a

separate drain line to the outside under any indoor electric

furnace where condensate overow could occur. If local

building codes apply, install per those codes.

Select the best position which suits the installation site

conditions. Take into consideration required clearances,

space, routing requirements for refrigerant line, condensate

disposal, lters, ductwork, wiring, and accessibility for

service. Refer to the unit specications sheet and the unit

rating plate for specic information.

These electric furnaces are completely factory assembled

and all components are performance tested. Each unit

consists of a blower assembly, optional refrigerant coil,

and controls, in an insulated galvanized factory nished

enclosure, and may also include electric heat as specied.

Knockouts are provided for electrical power wiring

entrance.

When used on cooling applications, excessive sweating

may occur when unit is installed in a very humid space.

If installed in an unconditioned space, sealant should be

applied around the power wires, control wires, refrigerant

tubing, and condensate lines where they enter the cabinet.

Power wires should be sealed on the inside where they

exit the conduit opening. Sealant is required to prevent air

leakage into and condensate from forming inside the unit,

control box, and on electrical controls.

The unit must be installed in such a way as to allow

free access to the coil compartment and blower/control

compartment.

The unit must be installed in a level position to ensure

proper condensate drainage. Make sure unit is level in

both directions within 1/8”.

Units with circuit breakers installed in the vertical position

must have breaker switch position “ON” in the up position

and switch position “OFF” in the down position. This

is necessary to meet agency certication and National

Electric Codes requirements.

Conversion to Vertical Downow

The EF furnace may be converted for vertical downow

applications. The circuit breaker(s) must be rotated 180°.

To comply with certication and the National Electric Code,

units with circuit breakers installed in the vertical position

must have circuit breakers installed so that the breaker

switch “ON” position and marking is up, and “OFF” position

and marking is down.

All electric furnaces installed with a mating coil section must

follow the instructions listed below for proper condensate

drainage. It is recommended that the auxiliary drain be

connected to a drain line for all units. If the auxiliary drain

is not connected, it must be plugged with provided cap. For

counterow units, the auxiliary drain must be connected

and routed to a drain.

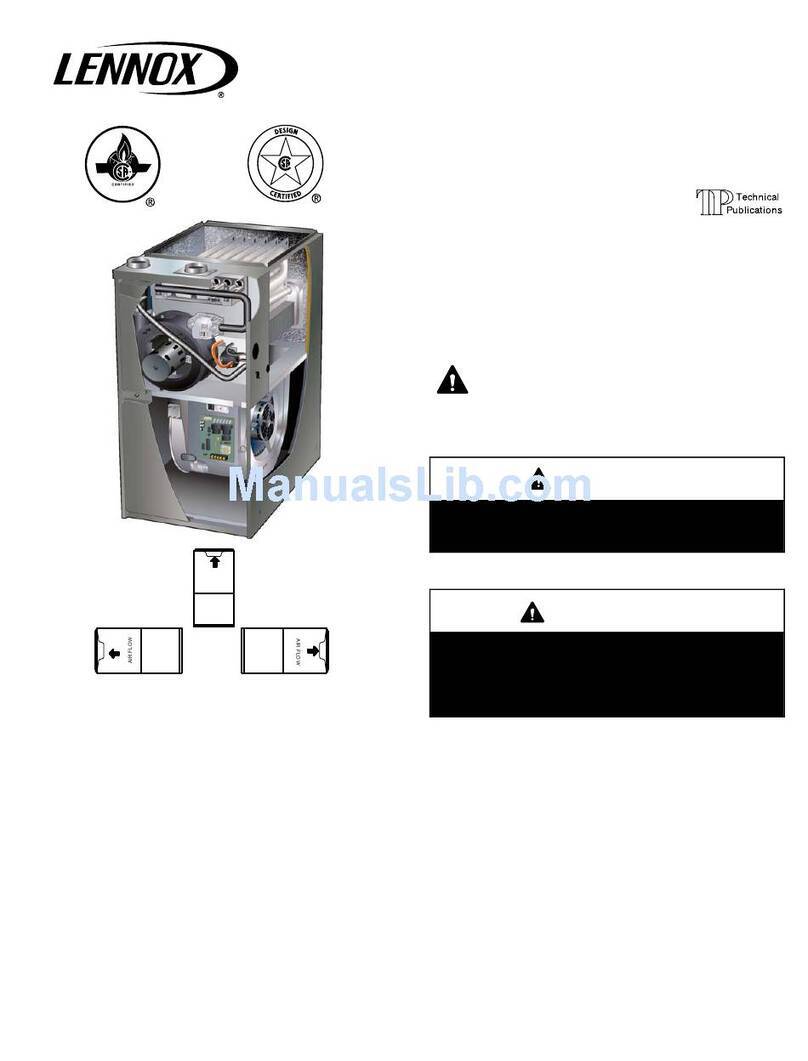

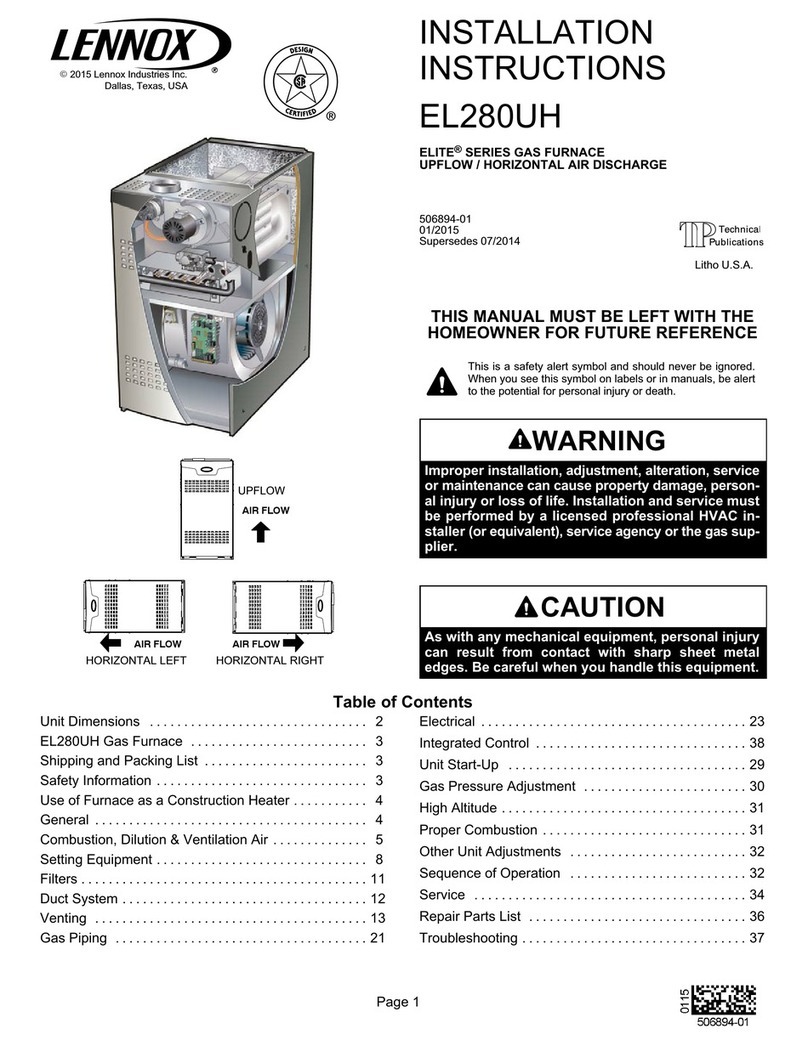

Horizontal Installations

Horizontal installations can be left or right hand. Adequate

support must be provided to insure cabinet integrity.

Ensure that there is adequate room to remove service

and access panels if installing in the horizontal position.

Refer to the airow congurations in Figure 3 for correct

horizontal coil installations.