3- Close all building doors and windows and all doors be-

tween the space in which the appliances remaining

connected to the common venting system are located

and other spaces of the building.Turn on clothes dry-

ers and any appliances notconnected tothe common

venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they willop-

erate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

4 - Follow the lightinginstruction.Place the appliance be-

ing inspected in operation. Adjust thermostat so ap-

pliance will operate continuously.

5 - Test for spillageat the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a

match or candle, or smokefl'om a cigarette, or a cigar.

6- After you have determined that each appliance re-

maining connected to the common venting system

properly vents when tested as outlined above, return

doom, windows, exhaust fans, fireplace dampers and

any other gas-burning applianceto their previouscon-

dition of use.

7- If improper venting is observed during any of the

above tests, the commonventing system mustbe cor-

rected. The common venting system should be re-

sized to approach the minimum size as determined by

using the appropriate tables in appendix G in the cur-

rent standards of the National Fuel Gas Code ANSI

Z223-1 in the U.S.A., and the appropdate Category 1

Natural Gas and Propane appliances venting sizing

tables in the current standards of the CAN/

CGA-B149.1 and .2 in the Natural Gas and Propane

Installation Code in Canada.

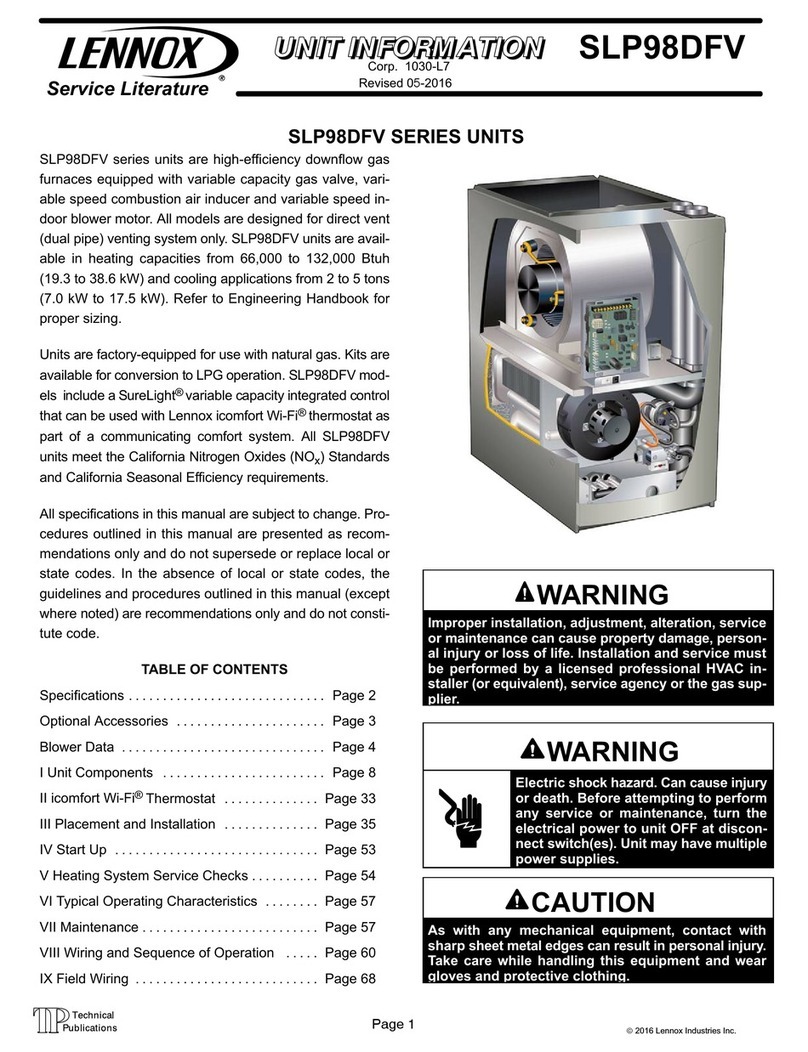

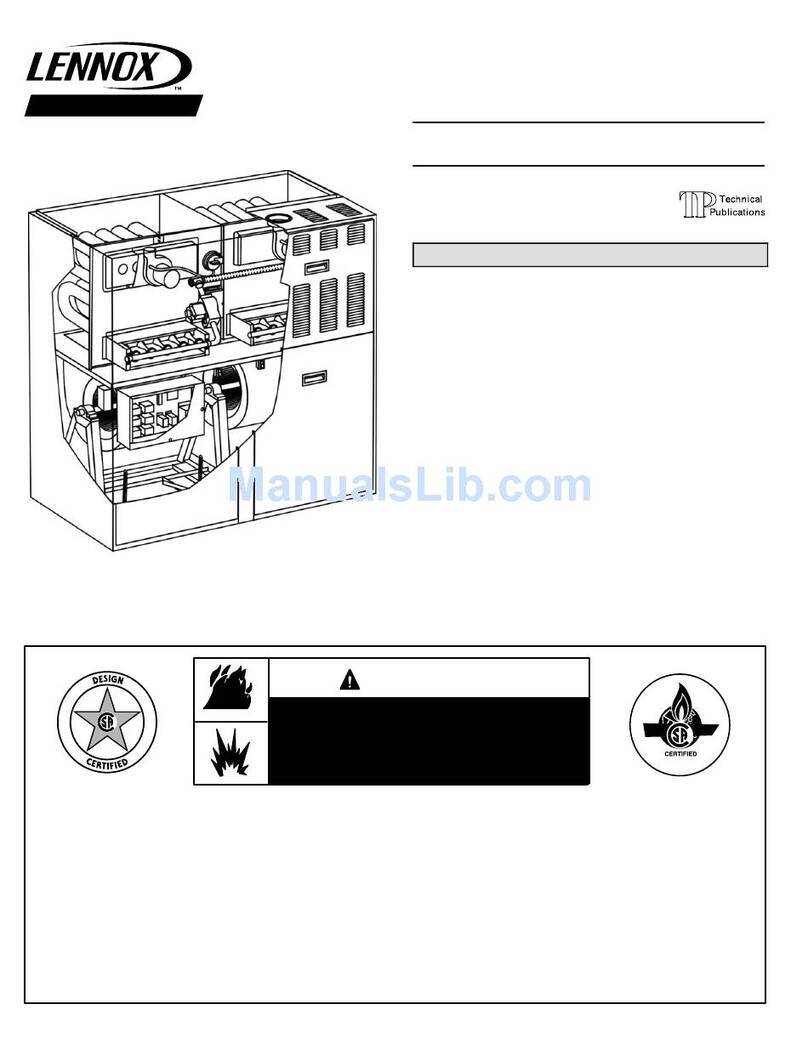

Intake and Exhaust Piping Terminations

Intake and exhaust pipes may be routed either horizontally

through an outside wall or vertically through the roof. In at-

tic or closet installations, vertical termination through the

roof is preferred. Figures 8 through 20 show typical ter-

minations.

1-Use recommended piping materials for both intake

and exhaust piping.

2 - Secure all joints, including drain leg, gas tight using

approved cement.

3-Piping diameters should be determined according to

length of pipe run. See table 4. Locate intake piping

upwind (prevailingwind) from exhaust piping.To avoid

re-circulation ofexhaust gas on roofterminations, end

of exhaust pipe must be higher than intake pipe.

Exhaust and intake exits must be in same pressure

zone. Do not exit one through the roofand one on the

side. Also, do not exit the intake on one side and the

exhaust on another side of the house or structure.

4-

5-

Intake and exhaust pipes should be placed as close

together as possible at termination end (refer to il-

lustrations). Maximum separation is 3 inches (76mm) ,-

on roof terminations and 6 inches (152mm) on side

wall terminations.

Exhaust piping must terminate straight out or up as

shown. In rooftop applications, a 2 inch X 1-1/2 inch re-

ducer for 2 inch venting, 3 inch x 2 inch reducer for 3

inch venting must be used on the exhaust piping at the

point where it exits the structure to improve the velocity

of exhaust away from the intake piping.

On roof terminations, the intake piping should termi-

nate straight down using two 90° elbows (See figure 8).

A IMPORTANT

NOTE -If winter design temperature is below 32°F (O°C),

exhaust piping must be insulated with 1/2 inch (13mm),

Armaflex or equivalent when run through unheated

apace. Do not leave any surface area of exhaust pipe

open to out-side air; exterior exhaust pipe must be insu-

lated with I/2 inch (13mm) Armaflex or equivalent. In ex-

treme cold climate areas, 3/4 inch (19mm) Armaflex or

equivalent is recommended. Insulation on outside runs oi

exhaust pipe must be painted or wrapped to protect in-

sulation from deterioration.

Inches(mm) 3(76 MAX.__ 3 x 2 (76 x 51) OR

_2 x 1-1/2 (51 x38)

/PVC REDUCER

8 (203I MIN 1/2 (13) FOAM

INSULATION IN

UNCONDITIONED

12 (305) ABOVE SPACE

AVE"*OESNOW

ACCUMULATION

3 (76) OR UNCONDITIONED

2 (51) PVC ATTIC SPACE

PROVIDE SUPPORT

FOR INTAKE AND

EXHAUST LINES

ROOF TERMINATION KIT

(15F75) LB-49107CC for 2 (51) Venting

(44J41) LB-65678A for 3 (76) Venting

FIGURE 8

NOTE -Dudng extremely cold temperatures, belov_

approximately 20°F (6.67°C), units with long runs of venl

pipe through unconditioned space, even when insulated,

may form ice in the exhaust termination that prevents the

Page 10