6

LESCO

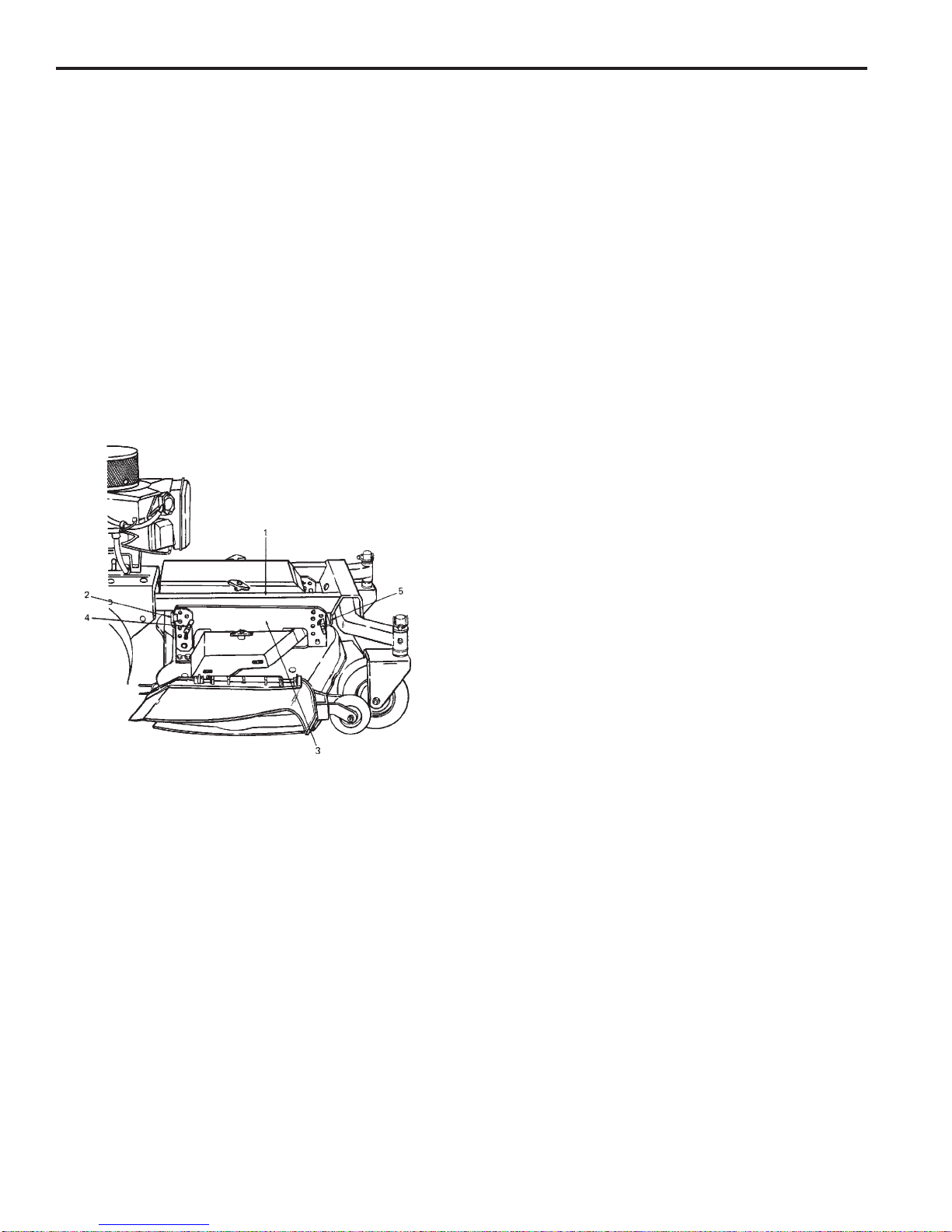

the turnbuckle at the top of the long control rod on

the side of the mower which seemed to creep must

be adjusted. Loosen the top and bottom nut on the

turnbuckle and adjust until the drive wheel stops

moving. Then retighten the top nuts.

7. Theshort traction/steeringcontrolrods whichrun

down from the traction/steering levers on each side

of the handle assembly should initially be adjusted

so that when the ground speed control levers are in

neutral and the traction/steering levers are in the

neutral lock position, the mower stands still with

the engine running. If the mower starts to creep

forward or to the rear in this situation, then the rod

end bearing at the bottom of the short control rod

on the side of the mower which seemed to creep

must be adjusted. Remove the hairpin holding the

long control rod in place in the rod end bearing,

remove the flat washer and pull the long control rod

from the rod end bearing. Loosen the lock nut and

adjust the rod end bearing ½ turn clockwise if the

creep was forward or ½ turn counter-clockwise if

the creep was to the rear. Tighten the lock nut,

replacethelong control rodinthe rod endbearing,

replace the flat washer and the hairpin.

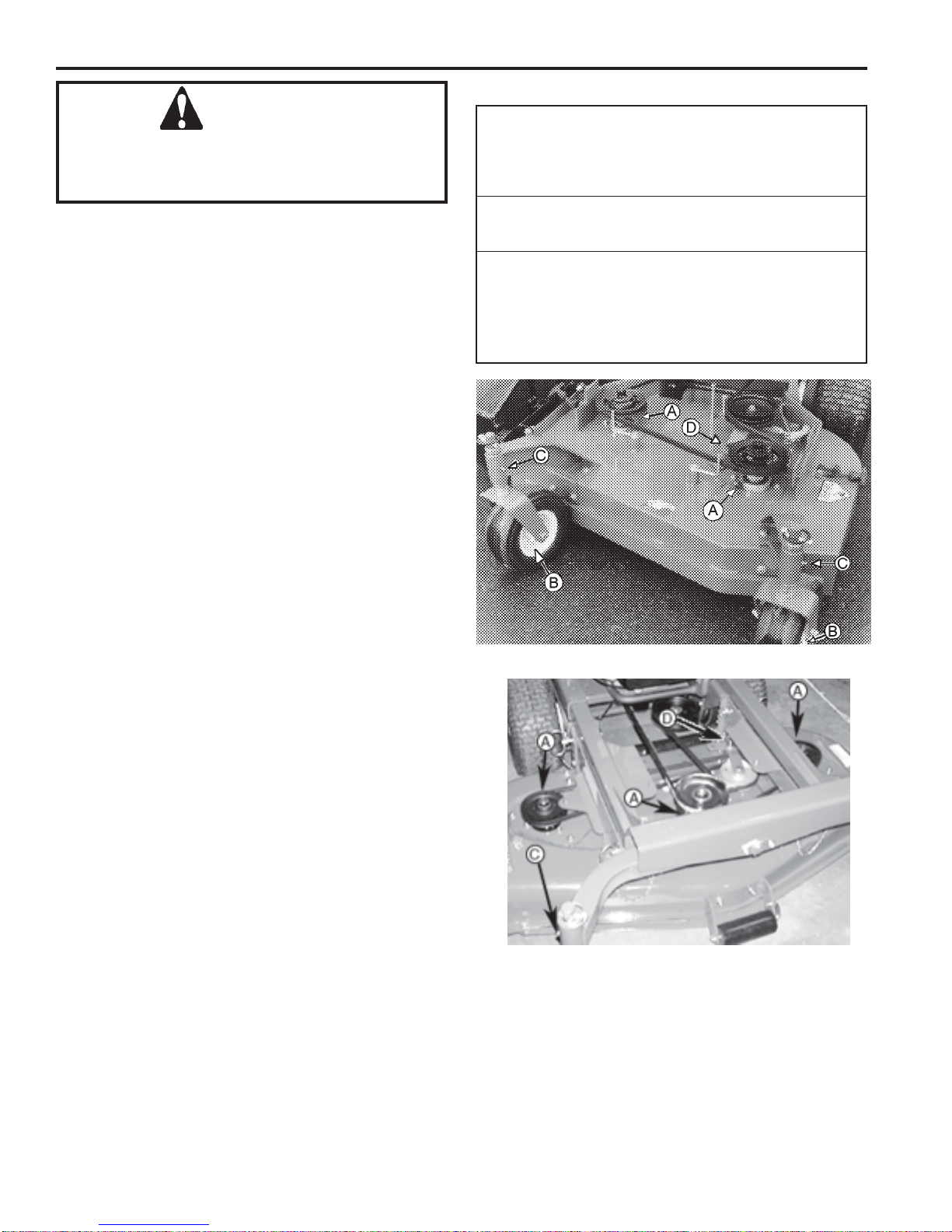

8. Adjusting the cutting height: The mower is shipped

with the cutting height set at 3 inches

±1/4 inch depending on the air pressure in the

tires. To change the cutting height, blade spacers

and/or caster spacers must be moved according to

the table on page 6.

9. Lubricate all fittings listed in the maintenance

section.

C.Break-lnandOperation.

1. Make certain you thoroughly understand all of the

safety precautions before you attempt to operate

this machine.

2. Check the engine oil level. Fill to the proper level

with10W40or10W30engineoilratedforserviceSEorSF.

3. Check the hydraulic oil level. Remove the fill cap

and make sure the oil level is up to the bottom of

the strainer screen. Leave this air space for

expansion. If the oil level is low, fill with a good

grade of SAE 20W50 engine oil.

3. Movethe mower outdoors.Checkthe engine

gasoline level. When filling the tank, stop when the

gasoline reaches one inch from the top. This space

must be left for expansion. Use fresh, clean,

unleaded,regulargasoline.

4. Move the mower to a “test area” where you can

operatethe mowerforabouthalfan hourwithout

beingdisturbed.

5. To start the engine:

a.Move the ground speed control levers back to

theneutralposition.

b.Disengagetheblade clutch.

c.Place the neutral latch levers in the neutral lock

position.

d.Connect the spark plug wire.

e.Open the fuel shutoff valve.

f. Move the throttle lever to the “Choke” position.

g.Put the key in the ignition switch and turn the

switch to “Start”. (Do not hold the key in the

start position for more than 10 seconds or you

maydamagethestarter.)

h.Set the throttle at 50% of full engine RPM and

allow the engine to warm up. Then, adjust the

throttle to 75% of full engine RPM.

6. After the engine has warmed up, shut off the

ignition and check the operation of the safety

switches. Make certain that the engine will not

start unless the ground speed control levers are in

neutral and the blade clutch is disengaged. If the

engine will start with either of the ground speed

control levers in any position other than neutral,

immediately shut off the engine and replace the

neutral safety switch operated by that lever under

the control panel. If the engine will start with the

blade clutch engaged, immediately shut off the

engine and adjust or replace, if necessary, the

blade safety switch mounted on the engine deck.

Starttheengine and holdtheleft operator presence

lever down against the left handle and move the

left ground speed control lever out of neutral. Now

takeyourhand off the operator presenceleverand

the engine should die. If it does not, immediately

shut off the engine and adjust or replace, if neces-

sary,theoperatorpresence switch under the

controlpanel. Repeatthis proceduremoving the

right ground speed control lever out of neutral. If

the engine does not die, immediately shut off the

engine and adjust or replace, if necessary, the

operatorpresenceswitchunderthecontrolpanel.

Movebothground speedcontrollevers into neutral,

restartthe engine, holdthe leftoperatorpresence

controldown againstthe lefthandleandengage

the blade clutch. Now take your hand off of the

operatorpresenceleverandtheengineshoulddie.

If it does not, immediately shut off the engine and

adjust or replace, if necessary, the operator

presenceswitch underthecontrolpanel.Disen-

gage the blade clutch.

7. Restarttheengine.

8. Push the blade clutch lever forward until it engages

and the cutter blades start rotating.

9. Movethe ground speed contol levers forwardto

about one third of full speed.

OPERATING INSTRUCTIONS

CAUTION

Set the ground speed control levers at no

more than one third full speed until you are

fully familiar with the operation of the mower.