4.0 Safety instructions

1. Never disconnect, remove, or adapt any of the safety devices and

safety covers.

2. Every MAREDO ST operator must be fully informed and understand

how to use the MAREDO machine safely. Reading and understanding the

manual before first use of the ST machine is mandatory.

3. Inspect the surface, where the MAREDO ST machine will be used.

Remove loose obstacles and avoid uneven areas.

4. Drive carefully during work and during transport.

5. Ensure that other people are standing at least 2 m./ 6 ft. away from

the MAREDO ST machine during work and transport.

6. The driver must wear appropriate clothing. Wear strong shoes with

steel enforced toe caps, long trousers, gloves, protection glasses and tie

up long hair.

7. Never overload the MAREDO ST. Overloading will be noticeable when a

MAREDO head starts vibrating or bouncing. The machine will become

unsafe and serious damage could occur.

8. Inspect the MAREDO ST at least once a week on loose bolts, loose

nuts, and damaged parts. Tighten or repair parts if needed.

9. A MAREDO ST may never be used without protection covers and

safety decals.

10. Only use original MAREDO ST spare parts to ensure a safe operation

of the machine.

11. Never use the MAREDO ST in darkness, in heavy rain, on frozen

grounds, in surfaces which holds rocks and stones and on slopes steeper

than 20 degrees.

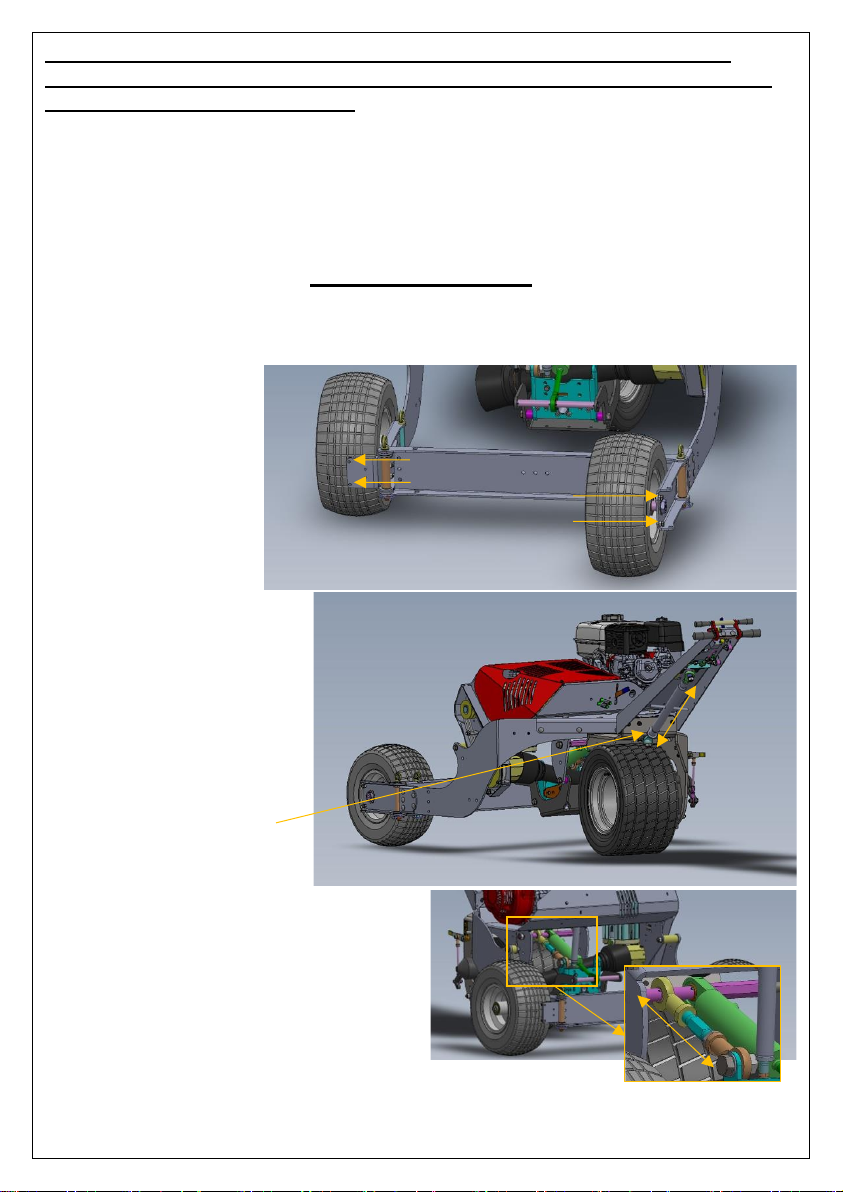

12. The rear wheels of the STrac 700 will always need to be placed beside the

machine when used in undulated areas.

13. The rear wheels of the STrac 700 can only be used behind the machine to

pass a gate or work close to a fence or wall. It is forbidden to use the

rear wheels behind the STrac 700 in undulated areas as the machine

could tip over.

14. Always apply the STrac 700’s handbrake when parking on slopes and

during transport on a trailer.

15. Make sure to always close the fuel valve on the engine, during transport

and long storage.

16. Maintain a logbook of all repairs on the MAREDO ST.

17. Be aware that changes made at the MAREDO ST, could release the

manufacturer from any safety regulations. The machine should be

homologated by the party who made the changes.

Always follow the safety instructions as described on the safety decal: