Maytag MDG30V User manual

Other Maytag Dryer manuals

Maytag

Maytag Bravos W10201177B User manual

Maytag

Maytag MED5900TW0 User manual

Maytag

Maytag Epic z W10112937A User manual

Maytag

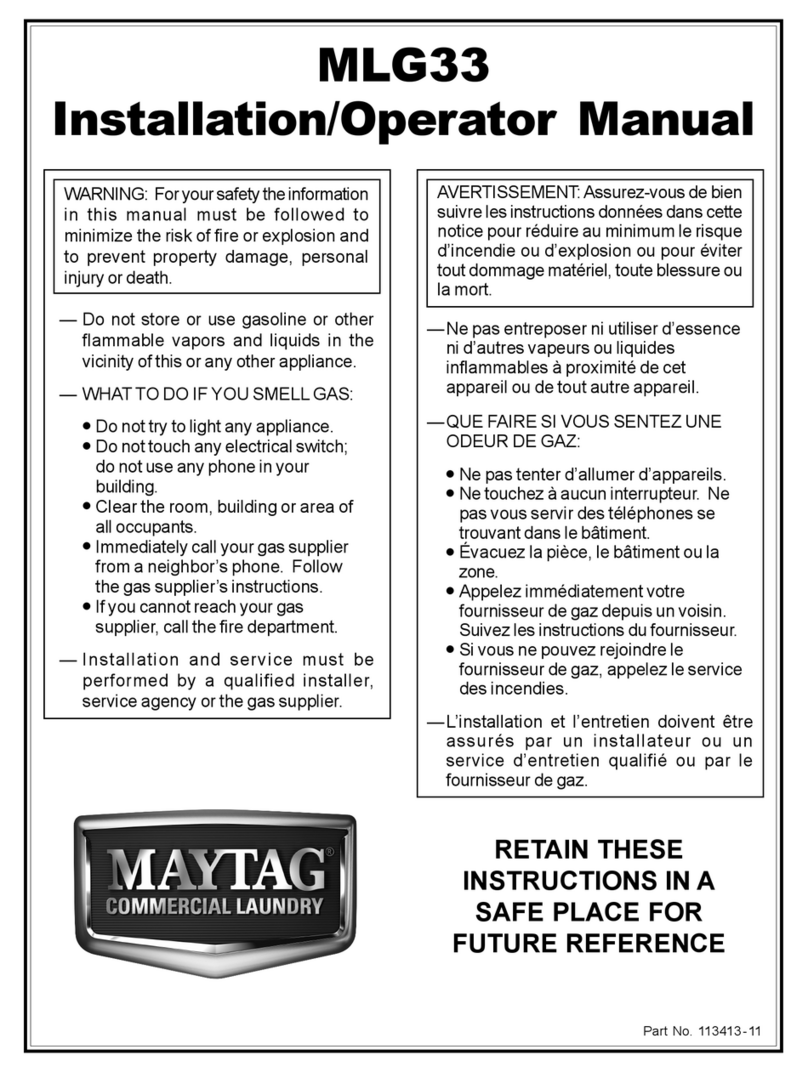

Maytag MLG33 Administrator Guide

Maytag

Maytag D-8 User manual

Maytag

Maytag MEDE201YW User manual

Maytag

Maytag MDE18PD User manual

Maytag

Maytag Neptune MDE9700AYM User manual

Maytag

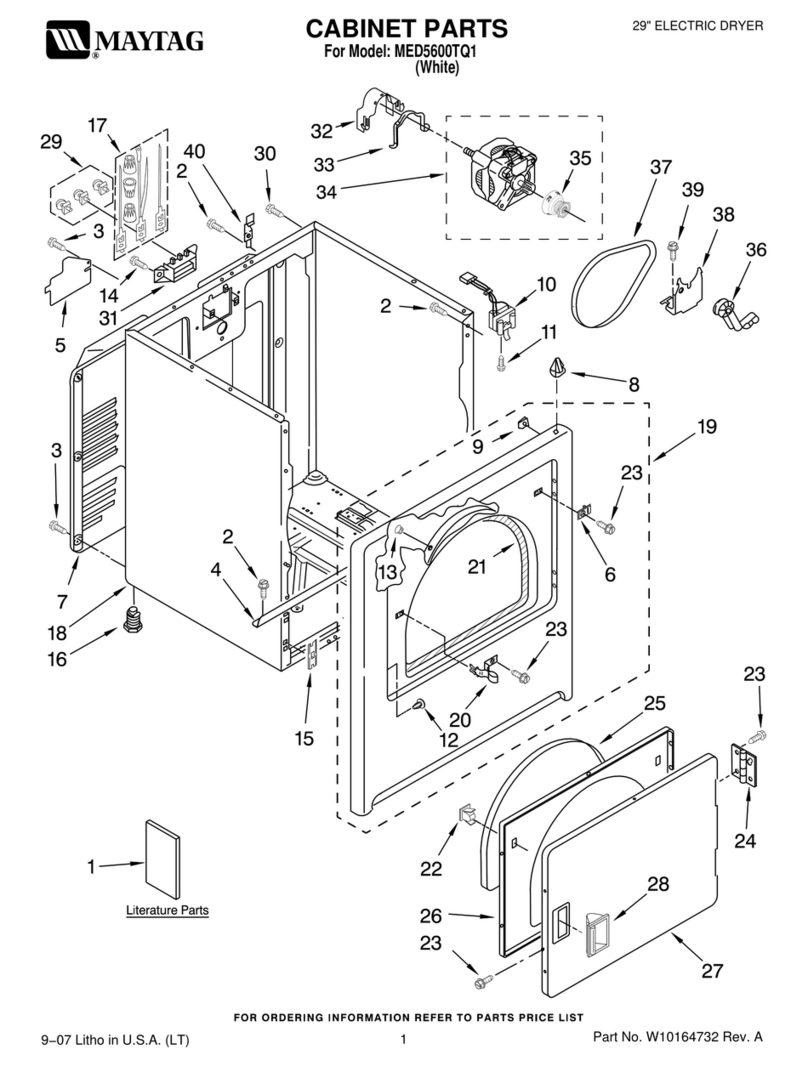

Maytag MED5600TQ1 User manual

Maytag

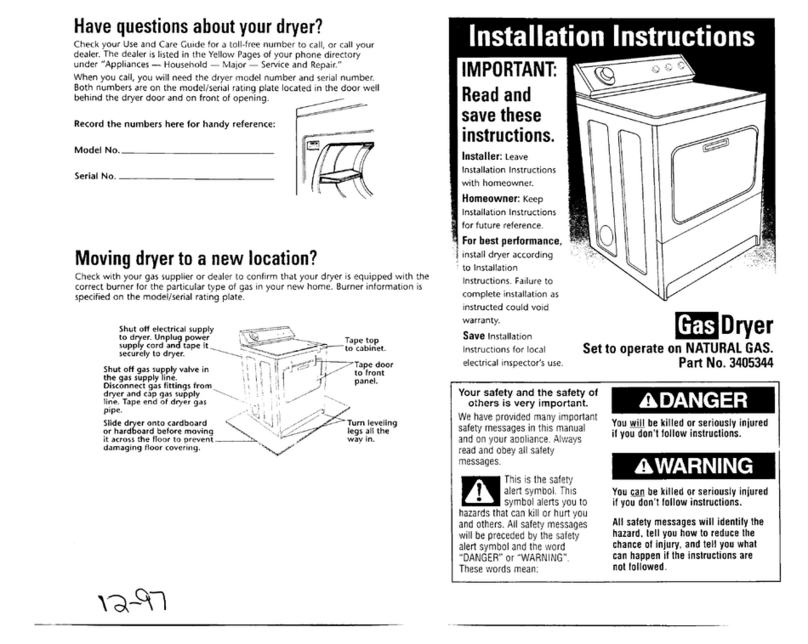

Maytag 3405344 User manual

Maytag

Maytag MDG8600 User manual

Maytag

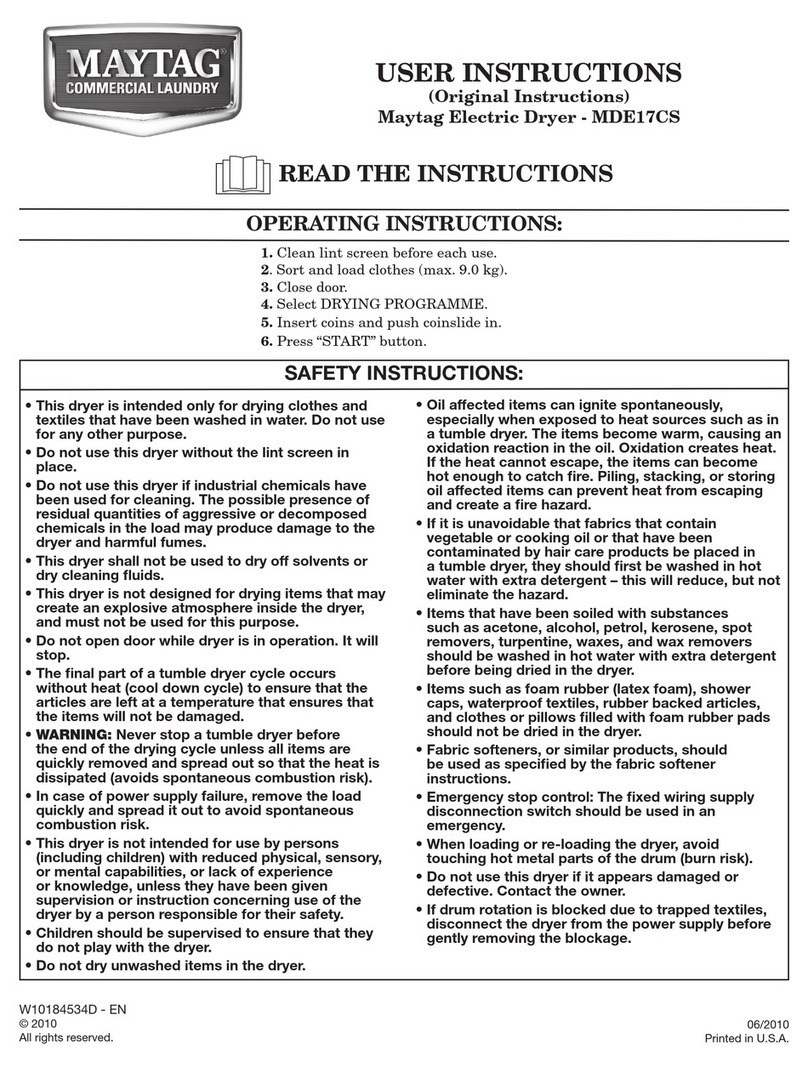

Maytag MDE17CSBGW User manual

Maytag

Maytag MEDC500VW - Centennial Series 29 Inch Electric... User manual

Maytag

Maytag W10312954A User manual

Maytag

Maytag W10239302B User manual

Maytag

Maytag BRAVOS W10201176C User manual

Maytag

Maytag MDE18CSAZW0 User manual

Maytag

Maytag MEDP475EW User manual

Maytag

Maytag MEDC215EW Installation instructions

Maytag

Maytag MGD6600TQ - R BravosR Steam Gas Dryer User manual

Popular Dryer manuals by other brands

Alliance Laundry Systems

Alliance Laundry Systems TMB795C Installation

Asko

Asko T793C operating instructions

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual