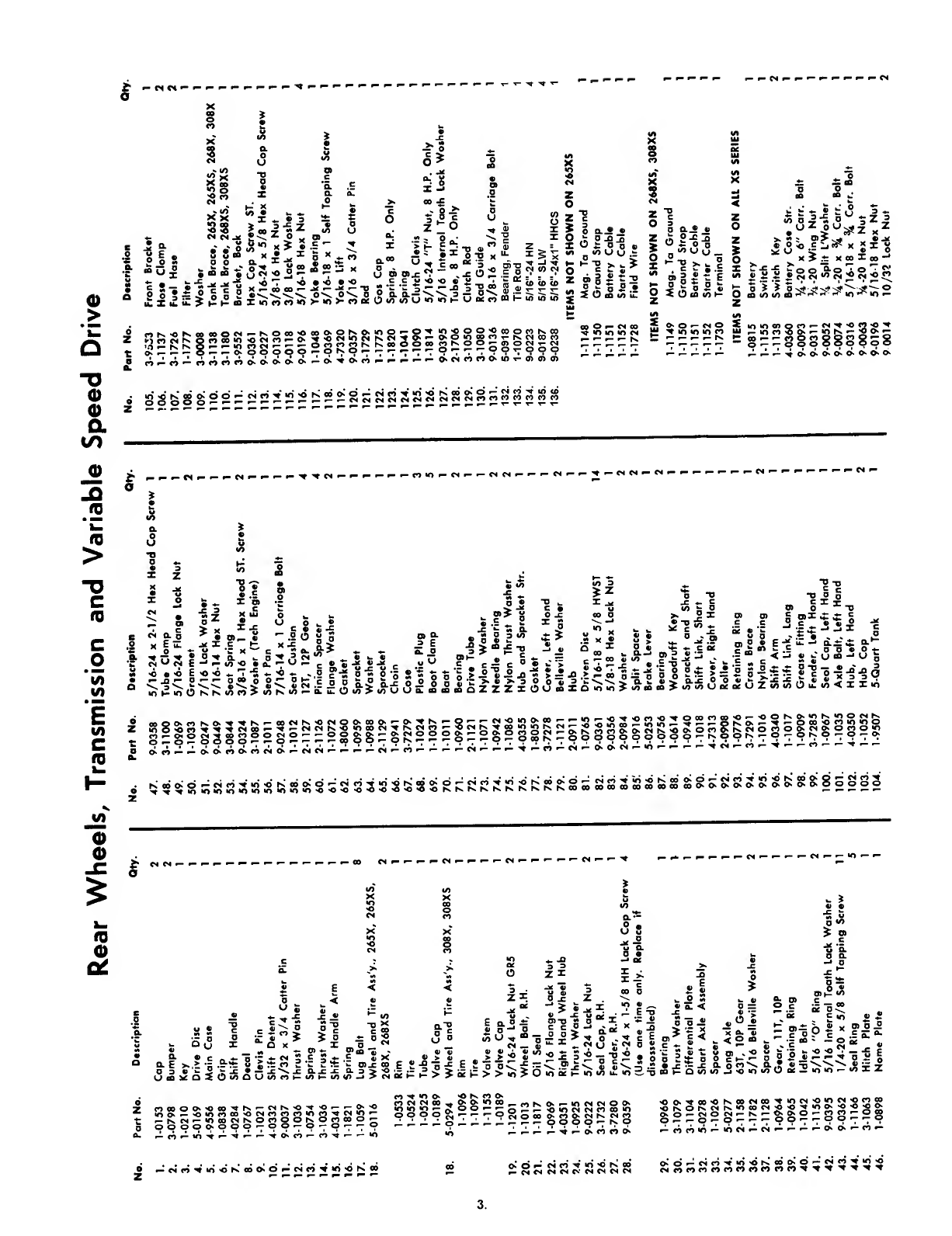

Rear

Wheels,

Transmission

and

Variable

Speed

Drive

t

—

«

«H

o

.8

S

£

I

■

£

Si

'

•c

“

u

J

-

o

c

c

o

:

>

o

o

±

.

•

>

K

H

*0

.

i

ZlO

,5

J

J

“••

.s

J

o^

O

,

;

o.«

n^l==|:s”^

'

«~~"2l2*“-ooora*‘<o‘<>“>*

I

u

tS

iS'^u

OT^iS

u«rifflP3iB5>

J

O

O-i

«

z

(5

2-gS

5

-

«/>

U

u

—

*

°-0

»

w

g

^

o

S

?;

o

i;

Q

^

O

iS

*'>

o

^

“S

o

u

Z

0

Os

«>

_

>

«

>•

J

2

5

0

>>

•

0

«

.E

J

:

X

^

.t:

X

e

«||

iS8«8;

1.^

iHB^isiiisiiiiiippliiiiiiiiiiii

jj^^^j^pi^^c^eooKOKO^OKCx^CK^OKo*-*-*-

—

—

d.w«o<nOKio-»-<AOT<A

^

^

o

(N

o

S

JJJ

X>

*0

*0

CO

JJJ

•O'oetjQo^ex'^'Ocj^^

.-lOeoNO^

—

xjhs^jgo-j-

g::::

8

§

8

8

8

S

8

5

8

•

«o

*0

rs.

I

2

S

S

3

!

:::«”

2

:

22

S

:

228

s

a

S

5

S

S

f

5

S

?

i

8

s

S

8

S

SS

c*

-“

£

=

S

5

sz

«

Q.§

^

S

X

E

u.

^

X

o

^

SoS

E

°2,

•

<0

E

'C

<0

^

jQ

•-

0^»-

lo

h-

«o

O

rs

hs

I

UJ

o

w

^

c

8

8

'“.2

0

*5

.

»

o

0

0

t*

.

^

^

•

«x

.

f

>

vj

rs

v>

•-^

I

655

«

=

15

15

==i5

.

0

)>V

o_c

ooo

>.

•

iSx;;

•

-cts'Sa

i

>o

^

^

it

»5g2«

Sx«

S;

“i

»

"

•

aX

c

—

oo**/)^

.

"

o*^

o

rt*5

*

•«

S'^S'x'a

o

oT

3‘C'^*>'a2

8>

jZZZlOo«XOioio>»n«o«o>

'•

■

to

..

»

u.

Q.

*:.;

.

o

o

I

V

k.

u

CO

'

2

•

o

^

«

2

c

p

-=

•

«.8

i

•

!j;?8ig;sSjS5!iS5iSS;S:5S53SS5gSS^KR;jRSP:f;S:g53SS2

2fe£S§5:SS5gSB:SS8oSSS

o

•

"c

A

s

O

Q

u

X

W

3

^

^

.Z

^

u

flo

^

o

<

O

«/)

I

_

d»

u

.o

^

^

£

•

>

Ox

D

%/)

5

“O

><

*=

2

X

oS

o>

a

t;

'

c

5

X

w

Q>J=

CO

:

a

D

>

X)

7

V>

^

>

CN

o>

®

<

o)

.s

—

,

.E

S

0'

ij

o

t/)

o

Q

j

_•

CN

_

a>

V

^

e

2-§-5^

.1

2*0

‘

=

5'

c

i

0

8

3

3

)

IX

2

x>

8

.^

^

X

z

OOOOO.X)OO^K^C.|^*C^-

0

^

;

-

5

;'0

S?£?S"srgg

3

3

5

i

2

r

::Sj;

5

qgj':jgg

•o<>‘*-x>«o<noo«ocs<

2

J

’J

5

S

^

2

3

SS

^

oooog'-'-'

7

o

g

o

o

o

5

«

0

'wrsCNco

—

fscx

—

•o»cHhs

0

2

2

®

C

5

®

S

2

*

®°rt

■

oooooHOOO^oo^o-

70^'70

^^^,-0

—

.-.-.-^^

.

vvvv.^.

’OC>K'X'oo'ON.oocxoo'^x>cc'

0

«

oeN^c

2

o

p

^Ko”csrsioooex«'

02

'

00

j;

0

'

0

'

00

^

0

'

0

'

-cxocNt-rN.»-^^o^

2

5

2'"®2

o^-*-

0

'

-o^'

7

^

o

o

^

'

700

'

7'70

*-‘c«ir>^‘

0

'

OKooO‘

0

^

<

xr>^>o>©rseo

o»o^cx<^'^‘n'ON.«

#»<x<xcxcxr>cx<x<x<N

o^O'—cxfoV*o<>rs.

5

5

^

o

^

2

522!03

cscortocoo<*)co<^oco^^^^^^^

3