4.5Hydraulic attachments execution

NOTE: Material damages caused by permeable

connections!

Attachment duct lines install without connecting

on TK-ELG connections.

NOTE: Installation damage due to bad quality of

water! Heating installation can be damaged by

corrosion or scale depending on water

characteristics.

Comply with filling requests for water according

to VDI 2035 or project documentation and

catalogue.

Heating duct lines connect as follows:

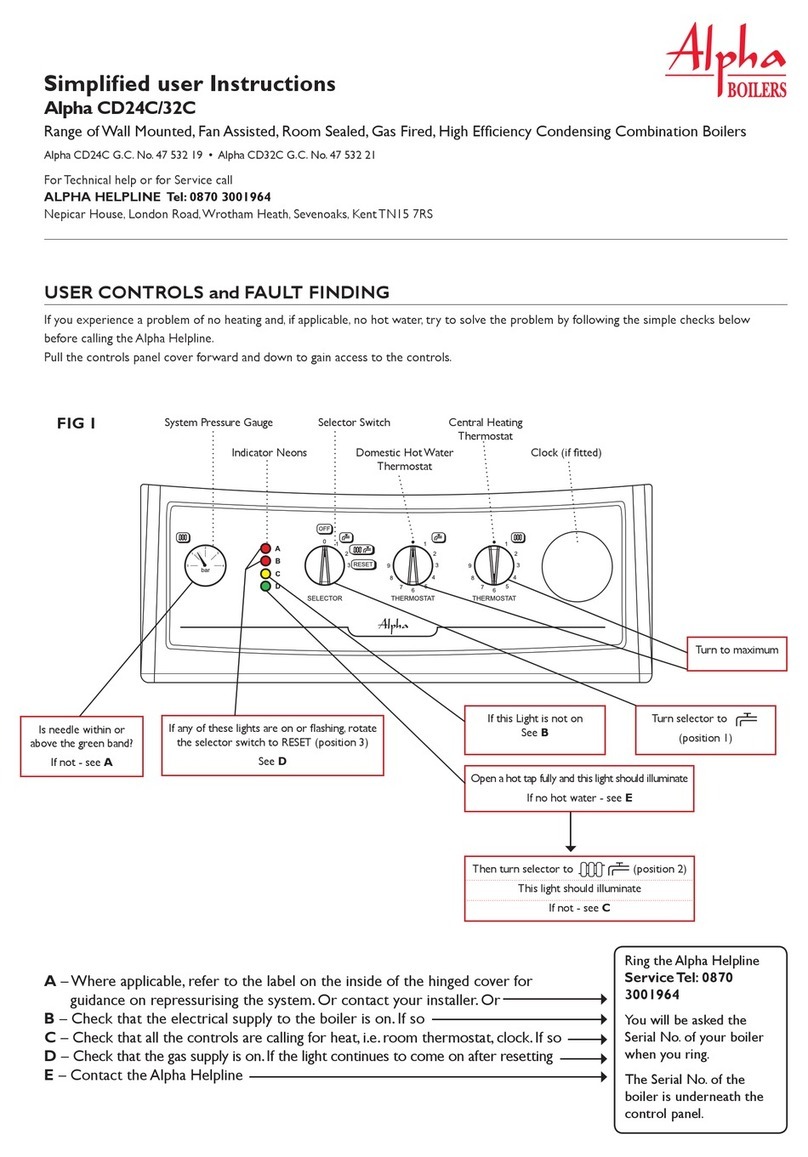

Connect return line on connection 1(image 2).

Connect start line on connection 4(image 2).

4.5.1 Filling the TK-eLG with heating

water and sealing test

Impermeability should be tested prior to put on the

boiler.

DANGER: Injuries and/or material damages can

occur with overpressure when testing watertight!

High pressure can damage regulatory and

safety devices and reservoir.

After filling with water set the TK-ELG on

pressure that is equal to the opening pressure

of safety valve.

Comply with maximum pressure of installed

components.

After testing sealing, open again closing

valves.

Make sure that all pressures, regulatory and

safety parts work correctly

DANGER: Health threat due to mix of drinking

water!

It is demanding to respect state norms and

regulations on avoiding mix drinking water

(with water from heating installations).

Comply with EN 1717.

NOTE: Material damage due to temperature

tension.

If you fill the TK-ELG in hot condition,

temperature tension can cause cracks due to

tensions. TK-ELG will start to leak

Fill the TK-ELG only in cold condition

(temperature of empty duct can be max 40°C)

Fill the TK-ELG only through quick valve on

pipe installation (return line) of the TK-ELG

Connect the filling hose to the water supply network

and slowly fill it with water so that all the air comes out of it

and the water starts to flow continuously.

Close the tap on the water supply network and

connect the free end of the hose to the tap for filling and

emptying the heating installation. Secure the hose with a

clamp.

Open the installation filling and draining tap and

slowly charge the TK-ELG. Monitor the pressure rise and

close the tap when the operating pressure is reached.

Bleed the installation via the valve on the radiator.

If the operating pressure drops by venting, the water

must be topped up.

Test for leaks according to local regulations.

After you have tested the tightness, open all the

elements that you closed due to filling.

Check that all safety elements are working properly.

If the TK-ELG is tested for leaks and no leakage is

observed, set the required operating pressure, according to

the pre-pressure of the expansion vessel.

Remove the hose from the filling and emptying tap.

Enter the operating pressure and water quality

values in the operating instructions.

4.5.2 Heating pump air emission and de-

blocking

This device does not have a circulation pump in it.

When the external pump is blocked, do the following:

Unscrew the center screw in the middle of the "head"

of the pump

Carefully try to unlock the pump shaft with a suitable

screwdriver.

4.5.3 TK-ELG venting and installation

This device does not have a built-in vent, because

the construction of the TK-ELG vessel is such that air

cannot remain trapped in the boiler but exits the TK-ELG

through the pressure pipe.

Ventilation must be installed on the installation, so as

to ensure venting of the air that can come out of the

pressure pipe, as well as venting of the entire installation.