Project name / Order No SC

Halifax House, High Wycombe, Buckinghamshire, HP12 3SE 3

5. Manufacturers Product Details & Operation:

Please see below for the specification sheets.

SPECIFICATION

COOL-PHASE® low energy cooling and ventilation system

COOL-PHASE® is a low energy cooling and ventilation system that reduces the running costs of

buildings and creates a fresh and healthy indoor environment. The system uses a thermal energy

store comprising of a phase change material (PCM) in combination with intelligently controlled

mechanical ventilation to actively cool and ventilate the building. The COOL-PHASE system has been

developed for use in the commercial, education and healthcare environments.

The COOL-PHASE system can maintain temperatures within the comfort zone, while radically

reducing energy consumption by up to 90%, compared to a conventional Air Conditioning system.

The reduction in energy usage combined with low servicing and maintenance costs and a long life

result in a strong financial case over traditional cooling approaches. Since no compressors or

hazardous coolants are used, the system also has a number of environmental benefits, while the lack

of external units means the COOL-PHASE system can be used where outside space or planning

permission is an issue.

Features:

Ceiling mounted COOL-PHASE low energy cooling and ventilation system, supplied

complete with:

Air Handling Unit:

Air Handling Unit (AHU) comprising of a low energy, variable speed elliptical curved fan.

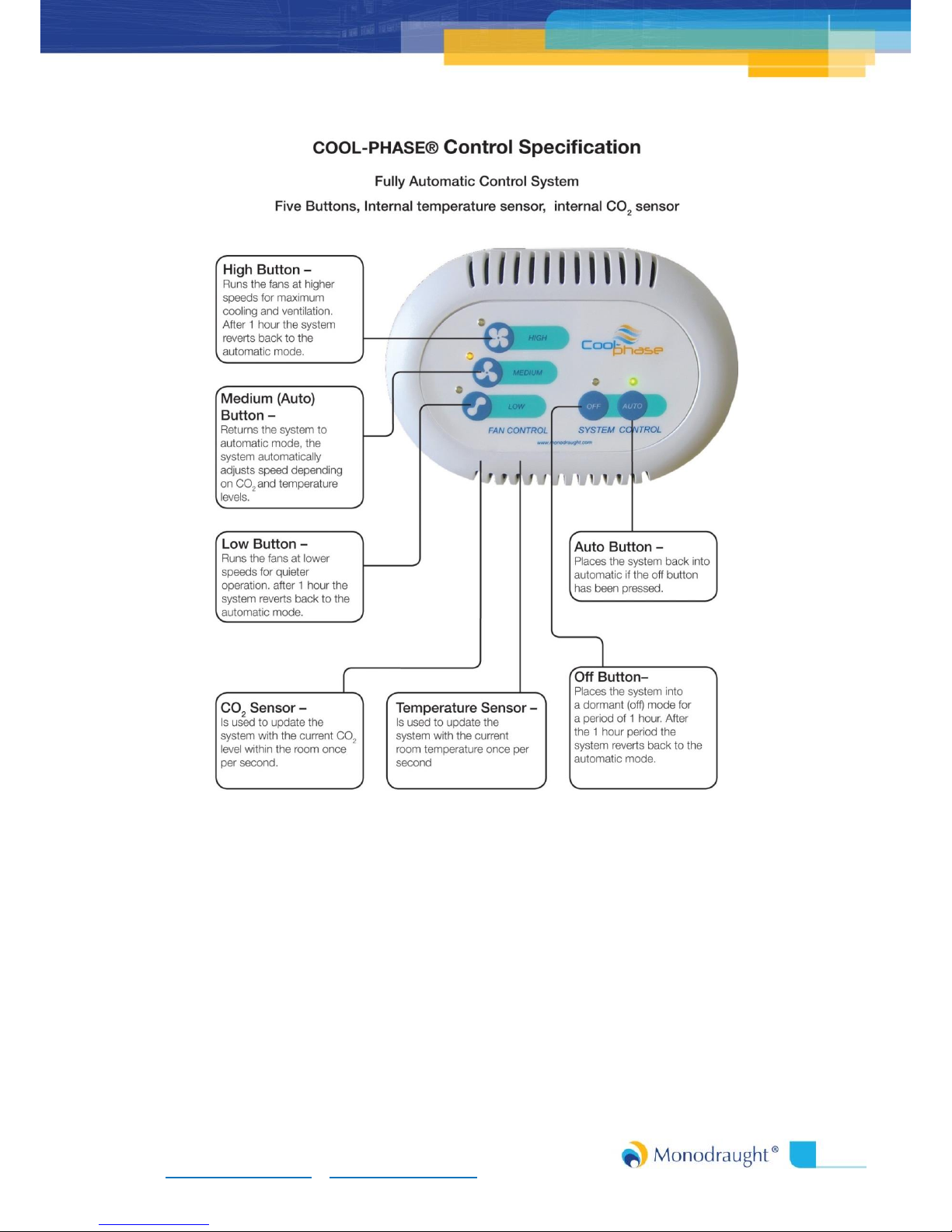

Intelligent control system with integrated data logger.

Rotational Air Director Drum.

Temperature sensors.

Thermal Batteries:

Thermal Battery modules including phase change panels.

Optional LED lighting to indicate battery charge.

Temperature Sensors.

Battery Options:

4 Thermal Battery Modules (6kWh).

6 Thermal Battery Modules (8kWh).

8 Thermal Battery Modules (10kWh).

Recirculation Module: