Please read all instructions carefully prior to operate the Radial Machine.

1. Operators should wear safety glasses, hat, shoes, etc.

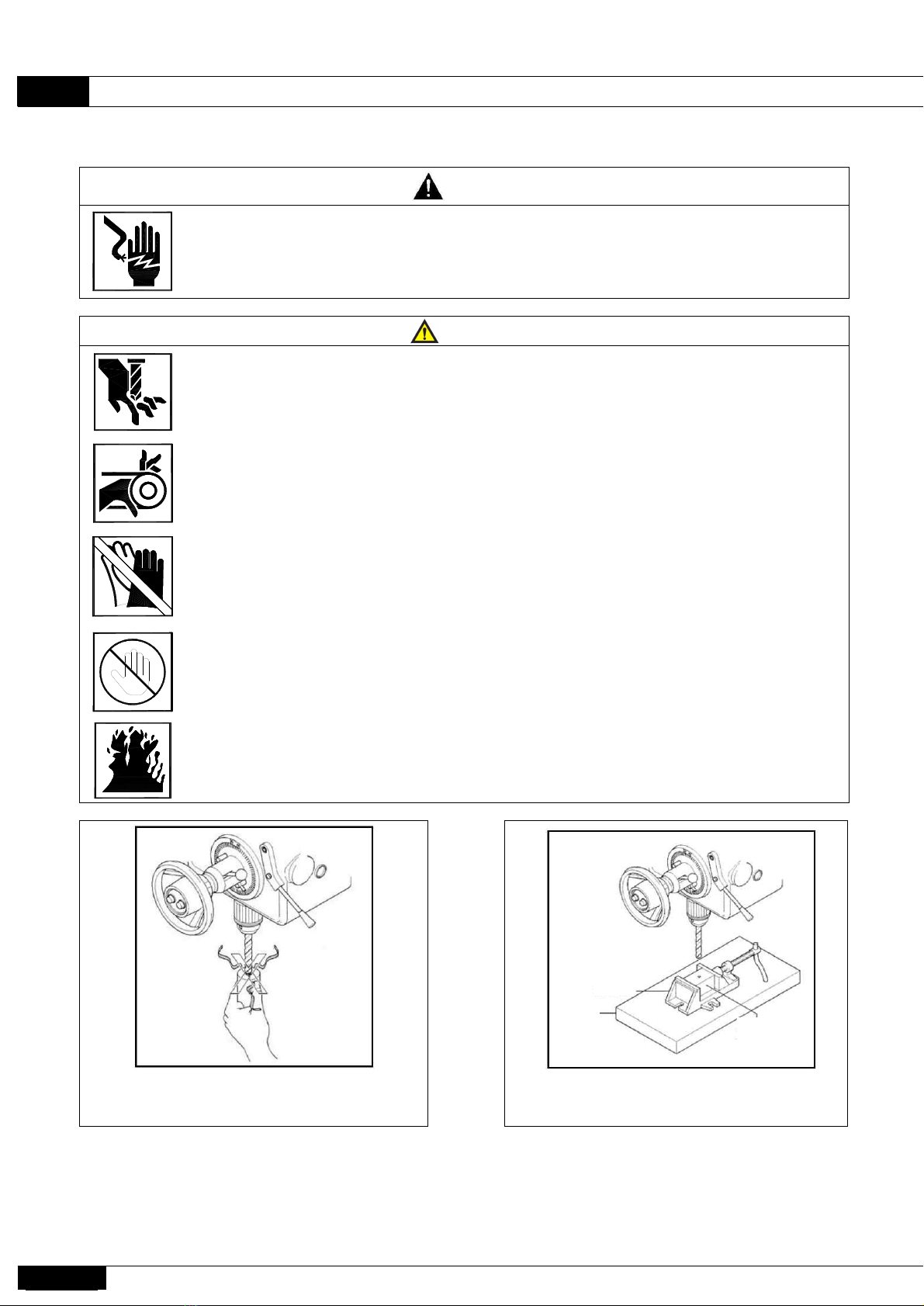

Wearing gloves are dangerous.

2. Machine should be checked before use as fuel, cutting condition, tools equipped, clamps, etc.

3. 'Power up' should start with the order of the drive switch of power console panel and 'Power down' should

start with the reverse order

4. Please be aware of the location of the emergency stop switch

5. Do not touch spinning objects when it's spinning. Hands or fingers could get stocked or caught in the

machine.

6. Do not clean chips with bare hands. Use a brush or proper cleaner when the machine is completely stop.

7. Do not use the machine for other uses.

8. All label and pictogram should be kept clean and please contact the customer service when damaged for

new one.

9. Do not remove any protective devices.

Without protective devices, serious disaster could happen

10. For further safety details, please contact us.